Hot tapping is a specialized technique for connecting to a live, pressurized gas pipeline without ever shutting it down. Think of it as performing surgery on a pipeline while it's still pumping. This method allows you to add branch connections, install new sensors, or make other critical modifications without causing costly and disruptive shutdowns. It’s a highly controlled and safe way to intervene while keeping the gas flowing.

Why Hot Tapping Is Essential for Live Gas Lines

Let’s say a new housing development needs to be connected to the main natural gas line running through the area. In the old days, this would have meant shutting off the gas for the entire neighborhood. That’s a massive inconvenience for residents and a logistical nightmare for the utility provider. This is exactly where hot tapping a gas line proves its worth.

Instead of bringing everything to a standstill, hot tapping lets technicians add a new connection point while the pipeline remains active and under its normal pressure. This completely sidesteps the need to drain the line, purge dangerous gases, and then go through the whole process of refilling the system. Every one of those steps adds risk, cost, and a lot of downtime.

The Unmatched Operational Advantages

The benefits here go way beyond simple convenience. For a big industrial plant, a pipeline shutdown could mean millions of dollars in lost production. For a utility company, it avoids service interruptions that can impact thousands of homes and businesses.

Here’s why it’s the go-to method:

- Zero Service Interruption: The biggest win is obvious—work gets done without shutting down the system. Service to all downstream customers continues without a single hiccup.

- Enhanced Safety: By not having to purge and vent huge volumes of natural gas, hot tapping is better for the environment and drastically cuts the risks of handling flammable vapors.

- Cost Efficiency: The savings are massive. Shutting down a major pipeline isn't just about lost product; it’s about the extensive labor costs for depressurizing, purging, and bringing the system back online.

Hot tapping isn't just a maintenance procedure; it's a strategic tool. It turns a potentially massive, high-cost project into a routine, controlled task, protecting revenue and keeping the public safe.

Significant Economic Impact

The financial argument for hot tapping is undeniable. It's a method that directly prevents the kind of production stoppages that bleed money. A 2016 economic analysis by the US Environmental Protection Agency showed that performing hot taps on 320 new natural gas connections delivered some serious returns.

With natural gas valued at $10 per thousand cubic feet (Mcf), the gas saved alone was worth $244,400. The entire investment paid for itself in just three months.

When you look at the broader operational impacts of industrial equipment downtime, you see how valuable continuous service truly is. Whether it’s a gas pipeline or any other critical machinery, avoiding shutdowns is the name of the game. This makes hot tapping a gas line an essential practice for modern infrastructure, allowing for growth and maintenance without ever stopping the flow of energy.

Critical Pre-Tap Planning and Site Assessment

Let me be blunt: the success of a hot tap is almost entirely decided before a single tool ever touches the pipe. The initial planning and site assessment phase is where the job is won or lost. If you rush this part, you're not just risking a botched job; you're creating a recipe for disaster. A methodical, almost obsessive, approach here ensures every variable is accounted for, creating a controlled and safe work environment.

This isn't just about shuffling paperwork. It's about getting your boots on the ground and developing a deep, hands-on understanding of the pipeline's real-world condition. Every decision you make now directly impacts your crew's safety and the long-term integrity of the gas line.

The Engineering Review and Material Verification

First things first, a thorough engineering review is absolutely non-negotiable. This is a deep dive into the pipeline's technical specs to confirm the tap is even feasible, let alone safe. You need to verify the pipe's material composition right away. Are you working with standard carbon steel, or is it a more exotic alloy?

This detail is critical because it dictates your choice of fitting, the specific welding procedure you'll use, and the type of cutter on your machine. Trying to weld a fitting to a high-strength alloy using a procedure meant for carbon steel could create a brittle weak point—a catastrophic failure waiting to happen under pressure.

At the same time, you have to lock down the line's exact operating pressure and temperature. These aren't just numbers on a page; they determine the pressure rating required for your hot tapping machine, the valve, and the fitting itself. Mismatching these components is a rookie mistake with serious consequences.

You also have to calculate the minimum wall thickness needed to safely perform the tap. You need enough "meat" on the pipe to support the new connection without compromising its structural integrity. This is where engineering precision completely replaces guesswork.

Non-Negotiable Integrity Checks

You can't see what's happening inside an active pipeline. Years of service can lead to internal corrosion, pitting, or other defects that are totally invisible from the outside. That's why non-destructive testing (NDT) isn't just a good idea—it's an essential part of the assessment.

Ultrasonic thickness gauging is the go-to NDT method here. This tool sends sound waves through the pipe wall, giving you a precise measurement of its thickness at multiple points all around your proposed tap location.

A hot tap should never be performed on a pipe with known defects, significant corrosion, or a wall thickness below the calculated minimum. NDT is the critical safety gate that prevents you from drilling into a compromised, unsafe section of the pipe.

Confirming the pipe's health ensures it can handle the stress of welding and drilling. It’s a simple step that stops a potentially dangerous situation before it even starts.

Building a Comprehensive Work Plan

With all your technical data locked in, it's time to translate it into a clear, actionable work plan. Think of this document as the playbook for the entire operation. It should leave zero room for ambiguity or improvisation on the day of the job.

Your work plan absolutely must detail the following:

- Step-by-Step Procedures: A crystal-clear sequence of events, from initial site prep all the way to the final integrity checks.

- Equipment List: The exact hot tapping machine, valve, fitting, and all support equipment needed. No generic descriptions.

- Personnel and Roles: Who is doing what? Clearly defined responsibilities are crucial for a smooth operation.

- Contingency Plans: What’s the plan if the equipment malfunctions? What if you see an unexpected pressure change? Thinking through these "what-ifs" beforehand is vital.

A key part of this planning is ensuring you have the right team. This might mean bringing in specialists, like a PG&E OQ certified gas line trenching company, for complex site prep. Don't forget to secure all necessary permits from local authorities and the pipeline operator well in advance.

Before breaking ground, a final pre-operation check is crucial. Running through a detailed checklist ensures that all engineering reviews, material verifications, and safety protocols have been addressed and signed off on by the responsible parties.

Hot Tapping Pre-Operation Safety Checklist

| Verification Item | Status (Verified/Not Verified) | Notes/Responsible Person |

|---|---|---|

| Engineering Review Complete | Verified | M. Jones, Lead Engineer |

| Pipe Material & Specs Confirmed | Verified | Material Certs attached. |

| Operating Pressure/Temp Verified | Verified | Control Room confirmed 720 PSI. |

| NDT (Ultrasonic) Results Approved | Verified | All readings exceed min. thickness. |

| Work Plan & JSA Finalized | Verified | Signed by all crew members. |

| Required Permits Secured | Verified | Copies on-site. |

| Equipment Inspected & Certified | Verified | S. Davis, Equip. Tech |

| Emergency Response Plan Reviewed | Verified | All crew briefed on muster points. |

This checklist acts as a final gate, preventing the operation from starting until every critical prerequisite is met.

The Job Safety Analysis and Site Preparation

The last step before you get to work is a Job Safety Analysis (JSA), conducted on-site with the entire crew. This isn't a lecture; it's a collaborative huddle where every team member walks through the plan, points out potential hazards, and confirms the control measures. It gets everyone on the same page.

From there, site prep begins:

- Isolate the Work Area: Use physical barriers and clear signage to keep anyone not involved with the job far away.

- Establish Ventilation: Proper airflow is key, especially in a trench or confined space, to prevent any accumulation of hazardous gases.

- Confirm PPE: Do a final gear check. Every single person must have and be correctly using their required personal protective equipment—fire-retardant clothing, safety glasses, and any needed respiratory protection.

Only after every single one of these steps is completed and double-checked can you begin the physical work. This disciplined, front-loaded approach is what separates a professional, safe hot tap from a high-risk gamble.

Choosing and Assembling Your Hot Tapping Rig

The hot tapping machine and its components are the heart of the whole operation. This isn't just a pile of parts; it's a precision-engineered system built to contain immense pressure while making a delicate, live cut. Picking the right gear and putting it together with meticulous care is the absolute backbone of a safe and successful hot tap.

I like to think of the rig as three systems working in perfect sync: the tapping machine itself, the fitting that marries up to the pipe, and the valve that isolates the whole setup. Every single piece must be perfectly matched to the job's specs—from the pipe material and wall thickness to the operating pressure. There’s zero room for “close enough” when you're working on a live gas line.

The demand for this specialized equipment is growing, too. The global hot tapping machines market, valued at around USD 1.2 billion in 2024, is expected to more than double to USD 2.5 billion by 2033. That growth is all about maintaining and expanding critical infrastructure, which tells you just how vital this machinery is to keeping our lights on and homes warm. You can get more insights on the hot tapping market's growth and see what it means for the industry.

Anatomy of the Hot Tapping Machine

This machine is what does the actual cutting, and it’s a whole lot more than just a fancy drill press. It’s a completely sealed, pressure-rated piece of engineering.

Here are the key parts you're dealing with:

- Pressure Housing: The main body of the machine. It's built like a tank to contain the full line pressure of the gas pipe.

- Boring Bar: This is the long shaft that extends and retracts through the housing. The cutter attaches to the end, and this is what drives the cut.

- Cutter and Pilot Drill: The pilot drill sits right in the middle of the cutter. It hits the pipe first to keep the cut stable and helps snag the piece of pipe you cut out—what we call the "coupon."

Before you even think about putting it together, every square inch of this machine needs a good, hard look. I'm talking about checking for any signs of metal fatigue, worn-out seals, or damaged threads. Even a tiny nick on a critical sealing surface can become a dangerous leak path under pressure.

Selecting the Right Fitting

The fitting is the bridge between your hot tap machine and the live gas line. We weld or bolt it directly onto the pipe, creating the permanent branch connection you need. The choice here is dictated entirely by the pipeline and the job itself.

You'll run into two main types:

- Welded Fittings: By far the most common for high-pressure steel pipelines. A full-encirclement split tee fitting wraps completely around the pipe, giving you maximum reinforcement. This is the gold standard for hot tapping a gas line.

- Bolted Saddles: These are what you'll see on lower-pressure lines or on pipe materials you can't safely weld, like some plastics or cast iron. They simply clamp onto the pipe and use gaskets to get a seal.

Whatever you choose, it must match the pipe's metallurgy, diameter, and pressure rating. Slapping a fitting rated for 300 PSI on a line running at 700 PSI is just asking for a catastrophic failure. Always, always cross-reference the fitting's material test report (MTR) with the pipeline's specs.

A dry-run assembly is a non-negotiable step in my process. Before anything gets near the live pipe, I assemble the entire rig—fitting, valve, and machine—on the ground. This confirms every component fits perfectly and that all bolts and flanges line up without issue.

The Critical Role of the Isolation Valve

The isolation valve is your main safety control—your lifeline, really. It gets bolted to the fitting before the hot tapping machine is even mounted. Once your cut is done and you've pulled the cutter back, you close this valve. That traps the line pressure, letting you remove the machine safely.

You’re generally choosing between two types of valves:

- Gate Valves: These give you a full, unobstructed path when they're open. This is perfect because it lets the cutter and the coupon pass through without getting snagged on anything.

- Ball Valves: They can also offer a full bore, but some designs have slight internal contours. They're often quicker to open and close, but you absolutely have to verify that the cutter's dimensions are compatible.

Just like the fitting, the valve's pressure rating has to exceed the max operating pressure of the gas line. It's another critical pressure-containing component. Taking this much care in choosing and assembling your rig is what turns a high-risk job into a controlled, predictable procedure.

Executing a Safe and Precise Hot Tap

All the planning is done, the site is prepped, and the gear is assembled. Now comes the moment where all that preparation pays off. This is where precision, control, and a relentless focus on safety come together. From the first spark of the weld to the final turn of the boring bar, every single action is a calculated part of a high-stakes operation.

It all starts with getting the hot tapping fitting onto the live gas line. On high-pressure steel lines, this almost always means welding on a full-encirclement split tee. This isn't your average welding job; it requires a certified pressure welder who follows a very specific, approved procedure. The last thing you want is to compromise the pipe's integrity while it's under pressure.

Once the weld cools, it’s immediately subjected to rigorous non-destructive testing (NDT). Think of it as a final quality inspection. We typically use ultrasonic or magnetic particle testing to hunt for any potential defects. The weld has to be perfect—no exceptions—before we can safely move on.

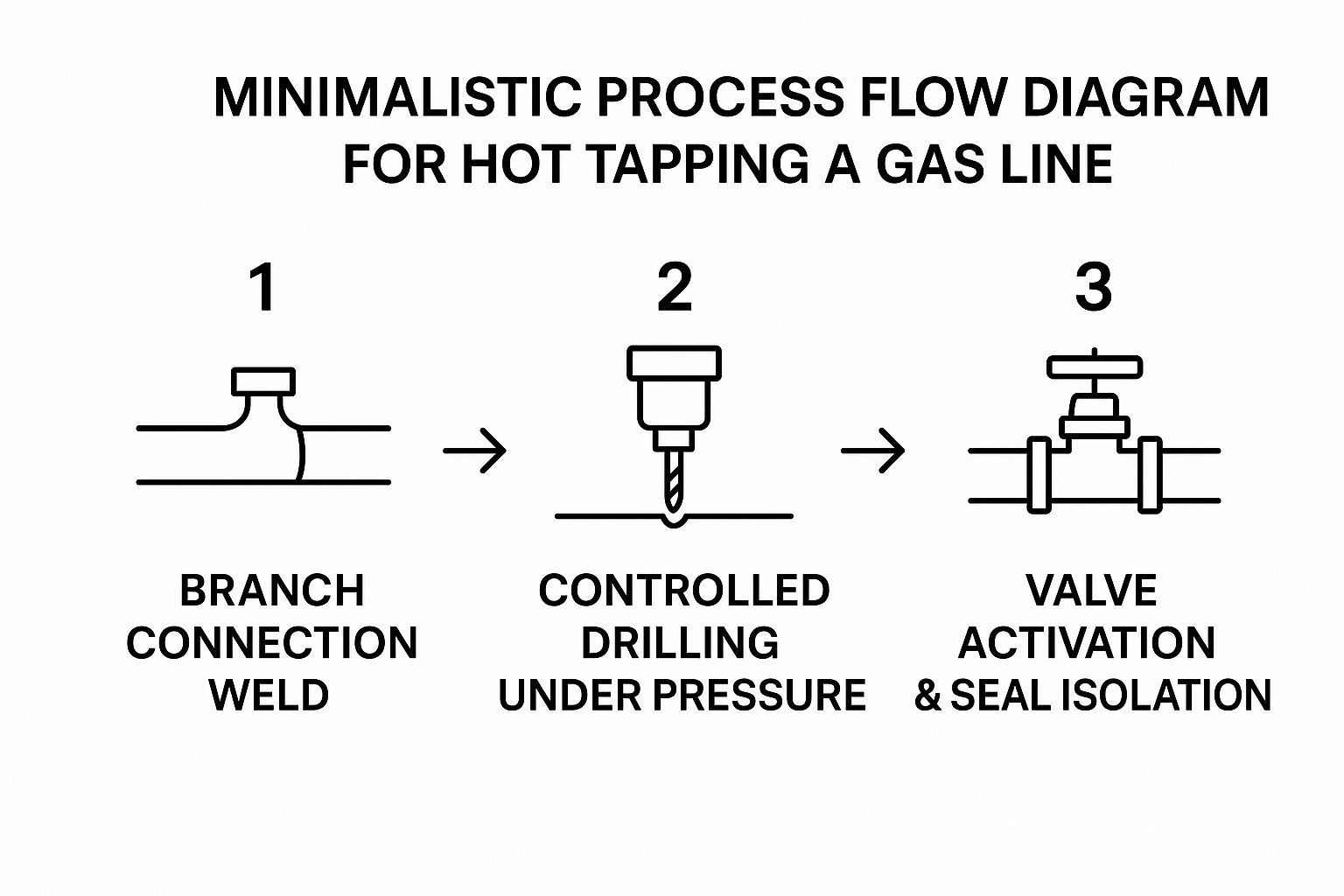

This visual breaks down the core sequence of a hot tapping operation, from welding the branch connection to isolating the new tie-in.

As you can see, each stage logically builds on the last, maintaining a completely controlled and pressurized environment from start to finish.

Mounting and Pressure Testing the Assembly

With the fitting solidly welded in place, the next move is to bolt the full-port isolation valve onto its flange. This valve is your most critical safety barrier, the component that will eventually let you remove the hot tapping machine safely. After the valve is torqued down, the hot tapping machine itself is mounted onto the valve’s outlet flange.

Now, before a single chip of metal is cut, the entire rig—fitting, valve, and machine—has to be pressure tested. This is a non-negotiable step to hunt down any potential leaks in gaskets or seals. We'll fill the enclosed space with a test medium like nitrogen and jack the pressure up to 1.5 times the pipeline’s normal operating pressure.

A successful pressure test is your green light. It confirms that the entire assembly is a single, sealed unit that can handle the full force of the gas line. Finding a leak now is an inconvenience; finding one during the cut is a five-alarm emergency.

This test is your proof that every gasket and connection is gas-tight before you breach the main pipe.

The Mechanics of a Controlled Cut

The moment of truth. The operator opens the isolation valve, giving the cutter a clear shot at the pipe. The machine’s boring bar, armed with the cutter and pilot drill, is then slowly advanced, either by hand or with hydraulic assistance.

An experienced operator relies heavily on feel here. You can literally sense the exact moment the pilot drill makes contact with the pipe wall. That pilot drill is key; it prevents the cutter from "walking" across the pipe and, more importantly, it’s designed to catch the piece of pipe that gets cut out.

Once the pilot is through, the main cutter blades engage. The feed rate—how fast you advance the cutter—is a delicate balance. Go too fast, and you risk stalling the machine or breaking teeth. Go too slow, and you can build up excessive heat. It's a nuanced skill that only comes with time on the machine.

Confirming the Coupon and Completing the Tap

As the cutter finishes its journey through the pipe wall, the operator will feel a distinct drop in resistance. That’s the sign the cut is complete. But we're not done yet. The most important confirmation is retrieving the "coupon," which is the round piece of pipe that was just cut free.

The pilot drill has a small retaining wire that snags the coupon, making sure it comes back out with the cutter. Pulling the boring bar back without the coupon is a massive problem. A loose piece of steel flying down a high-velocity gas pipeline can cause catastrophic damage to valves and equipment downstream.

Here’s the final sequence to wrap it all up:

- Fully Retract the Cutter: The boring bar is carefully drawn back until it is completely clear of the isolation valve’s gate.

- Close the Isolation Valve: The valve is shut securely, trapping the line pressure and safely isolating the hot tapping machine.

- Depressurize and Remove: The small amount of gas caught in the machine's housing is safely vented off. Only then is it safe to unbolt the machine and remove it.

With the machine gone, you’re left with a brand-new, flanged branch connection on a fully operational gas line, ready for the final tie-in. All of this is accomplished without ever shutting down service, turning a major engineering challenge into a controlled, routine procedure.

Finalizing the Connection and Post-Tap Integrity Checks

You've successfully removed the hot tapping machine, but don't pack up your tools just yet. The job isn't finished. A successful tap is more than just making a cut; it's about making sure that new connection is locked down, protected, and properly documented for the entire life of the pipeline. This is where we shift from the precision of the cut to the discipline of long-term asset management.

These finishing touches are what separate a good hot tap from a great one. They ensure the new branch connection stays leak-free, stands up to the elements, and meets every single regulatory standard. Rushing this part can undo all the careful work you've just put in.

Securing the Isolation Valve

Now that the tapping machine is out of the way, you're left with a brand-new isolation valve sitting on the fitting. That valve is your gateway to a live, high-pressure gas line, so making it secure against any accidental or unauthorized use is priority number one.

You’ve got two main ways to button this up:

- Completion Plugs: This is the gold standard in the industry. You’ll insert a specialized plug through the valve and screw it directly into the threads inside the hot tap fitting. This creates a solid, secondary metal-to-metal seal that’s completely separate from the valve’s own mechanism.

- Blind Flanges: If you're not using a completion plug, you absolutely must bolt a blind flange onto the valve's outlet. It provides a strong physical barrier, but just remember, it relies entirely on the valve's integrity to contain the line pressure.

No matter which method you use, the valve's handwheel needs to come off. Lock and tag the stem according to your company's procedures. This is the only way to be sure nobody accidentally opens a direct path to the atmosphere.

Corrosion Protection for Longevity

That new fitting and all your beautiful welds are now a permanent fixture on the pipeline. And just like every other inch of that line, they're vulnerable to corrosion from the second they're exposed to the air and soil. Applying a proper coating isn't just a good idea—it's essential for the long-term health of the connection.

Over time, corrosion will eat away at the fitting or the welds, creating a weak point that could fail years from now. The process starts with a meticulous cleaning. You have to get the entire surface spotless, removing any scale, slag, or contaminants left over from welding.

Think of corrosion protection as the final layer of armor for your new connection. A 90% reduction in pipeline corrosion-related incidents is often attributed to effective coating and wrapping systems. This step ensures your hard work today doesn't become a weak point tomorrow.

Once it's clean, you'll apply a multi-layer system. This usually involves a primer, a tough corrosion-inhibiting coating, and a durable outer wrap to fend off moisture and physical damage. It's crucial that this new system is fully compatible with the existing pipeline coating to create a seamless, uninterrupted shield.

The Critical Role of Documentation

The last, and arguably most important, step in this whole process is paperwork. In this business, if it isn’t documented, it didn’t happen. A complete and accurate record of the hot tap is vital for future integrity management, a breeze-through on regulatory audits, and for anyone who has to work on this section of the line down the road.

Good documentation creates a clear, auditable trail that proves the job was done safely and to spec. Your final report should be a comprehensive package that tells the whole story of the operation.

Make sure your documentation file always includes:

- Tap Details: Log the exact location (GPS coordinates are best), date, pipe diameter, wall thickness, and the line's operating pressure at the time of the tap.

- NDT Results: File the complete, signed-off reports from the non-destructive testing on the welds. Include the technician's certifications and all their findings.

- Pressure Test Records: Keep the chart or digital log from the pre-tap pressure test, clearly showing the test pressure, how long it was held, and the successful sign-off.

- Material Certifications: Have copies of the Material Test Reports (MTRs) for the fitting and valve. This is your proof that the components met the required engineering specifications.

This level of detailed record-keeping is what marks the true completion of a professional job. It creates a permanent history of the modification, safeguarding the pipeline's integrity for decades.

Got Questions About Hot Tapping Gas Lines? We've Got Answers.

Even after years in the field, hot tapping a live gas line is a procedure that commands respect. It’s natural to have questions, and honestly, asking them is a sign of a pro. Getting clear on the details is what keeps everyone safe on the job site.

Let's dive into some of the most common questions we hear from crews in the field, and I'll give you straight-up answers based on real-world experience.

What’s the Real Max Pressure for a Hot Tap?

This is a big one, and the answer isn't a simple number. Your maximum safe operating pressure isn't a single value; it's determined by the weakest link in your entire setup. Think of it as a chain—it's only as strong as its weakest component.

You have to look at three critical pieces of equipment:

- The Hot Tapping Fitting: This is the piece you're welding or bolting onto the main. Its pressure rating must be higher than the pipe's maximum allowable operating pressure (MAOP). No exceptions.

- The Isolation Valve: The valve you mount to the fitting has to be rated for the pressure, too. It's your primary barrier, so it needs to be up to the task.

- The Hot Tapping Machine: Every machine has its own operational limits set by the manufacturer. You can't push it beyond that, period.

The lowest pressure rating among these three is your project's ceiling. So, if your fitting and valve are good for 1,480 PSI, but the tapping machine is only rated for 1,000 PSI, then 1,000 PSI is your absolute maximum. It's that simple.

What Do You Do if Equipment Fails Mid-Cut?

Okay, this is the scenario that keeps people up at night. You've started the cut, and suddenly the machine jams or a hydraulic line blows. The first rule is: don't panic. This is where your pre-job safety meeting and contingency plan pay off.

Your immediate job is to make the situation safe.

- Don't Force It: Whatever you do, don't try to muscle a stalled cutter through. You're far more likely to snap the cutter or pilot drill, which turns a problem into a potential disaster.

- Hold Your Position: Keep the boring bar right where it is. Don't retract it unless that’s the specific, rehearsed emergency procedure for that exact situation.

- Isolate and Assess: Now, you follow the plan. That might mean closing the valve if the cutter is clear of the valve gates, or securing the machine in place while someone troubleshoots the power unit.

The best way to deal with an equipment failure is to prevent it from ever happening. A thorough, hands-on inspection of every single component before you even bring it to the pipe—from the teeth on the cutter to the fittings on the hoses—is the best insurance you have.

How Different Is Tapping Steel vs. Polyethylene Pipe?

It’s like night and day. While the goal is the same—create a new connection on a live line—the materials and methods couldn't be more different. The biggest factor? You can't weld on polyethylene (PE) pipe, which changes everything.

Let's break it down.

| Feature | Tapping Steel Pipe | Tapping Polyethylene (PE) Pipe |

|---|---|---|

| Connection Method | You use a full-encirclement fitting that's welded right onto the pipe. It becomes a permanent, fused part of the line. | You use a mechanical saddle or an electrofusion fitting. These clamp on and use gaskets to create a seal. |

| Cutter Type | You're using hardened steel cutters designed to machine through metal cleanly. | The cutters are totally different, designed to slice PE without melting it or leaving behind jagged plastic shavings. |

| Static Control | Static is always a concern with natural gas, but with PE, it's a major hazard. Grounding procedures are absolutely non-negotiable. | Specific protocols must be followed to prevent a static spark, which could easily ignite the gas. |

| Pressure Limits | You'll see this on high-pressure transmission and distribution lines all the time. | This is almost always done on lower-pressure distribution systems, as mechanical seals have their limits. |

At the end of the day, while the concept is similar, the equipment, fittings, and safety protocols for steel and PE are completely separate disciplines. Each requires its own specialized training and qualifications. Knowing these differences is absolutely fundamental to performing a safe and successful hot tapping a gas line job, no matter what kind of pipe you’re working on.

Are you facing delays in your natural gas line installation or dealing with a planned maintenance outage? Don't let your project grind to a halt. Blue Gas Express provides mobile, temporary CNG and LNG solutions to keep your operations running seamlessly. We offer rapid deployment of mobile gas units across the Carolinas, Tennessee, and Virginia, ensuring you get the gas you need, right when you need it. Learn more about our reliable temporary natural gas services.