Imagine trying to add a new faucet to your home's plumbing. The standard approach? You'd have to shut off the main water valve, draining the pipes and leaving the whole house without water until the job is done. Now, scale that up to a massive industrial pipeline carrying natural gas to an entire city. A shutdown isn't just an inconvenience; it's a logistical and financial nightmare.

This is where hot tapping comes in. It's a highly specialized technique that allows technicians to create a new connection to a live, pressurized pipeline without ever interrupting service. It’s like performing surgery on a utility line while it's still pumping, preventing catastrophic downtime.

Unlocking Pipeline Potential Without a Shutdown

Think about a city’s main water line or a critical natural gas artery that fuels thousands of homes and businesses. In the past, any modification—whether adding a new connection or performing maintenance—meant a full-blown system shutdown. This involved the costly and disruptive process of draining the pipeline, venting its contents, and bringing all operations to a grinding halt.

Hot tapping completely flips that script. It offers a safe, efficient way to tie into an active pipeline, making it an essential tool for any industry where continuous flow is everything.

The Core Concept: How It Works

So, what is hot tapping at its most basic level? It’s the process of drilling or cutting into a functioning pipeline to add a new branch or access point. This isn't done with a standard drill, of course. A specialized hot tapping machine is mounted directly onto the pipe, creating a sealed, pressurized environment. This allows the cut to be made with surgical precision, ensuring not a single drop of product escapes and the system’s pressure never falters.

The entire point of hot tapping is to avoid a shutdown. By keeping operations running, companies can prevent millions in lost revenue, sidestep service interruption penalties, and maintain critical infrastructure without affecting a single customer.

This method is a game-changer for several common scenarios:

- System Expansions: Seamlessly connecting new residential subdivisions or industrial parks to existing utility grids.

- Maintenance and Repairs: Creating temporary bypass lines to isolate and repair a damaged section, all without shutting down the entire network.

- Adding Instrumentation: Installing new sensors, gauges, or sampling points to better monitor the pipeline's health and performance.

A Growing Market Driven by Necessity

The rising demand for this technique really underscores its value in modern infrastructure management. The global hot tapping machines market was recently valued at around USD 1.2 billion and is expected to more than double, potentially hitting USD 2.5 billion by 2033.

This explosive growth is primarily driven by the oil and gas sector, where an uninterrupted flow is the bedrock of profitability and supply chain stability. You can dig into the market projections to see just how critical this technology is becoming.

To wrap it up, let's look at the key advantages in a simple format.

Core Benefits of Hot Tapping at a Glance

The table below breaks down the primary advantages hot tapping offers compared to the old-school method of shutting everything down.

| Benefit | Impact on Operations |

|---|---|

| No Shutdowns | Operations continue without interruption, eliminating downtime and associated revenue loss. |

| Cost Savings | Avoids the massive expenses of draining, venting, and refilling the pipeline. |

| Enhanced Safety | Contains the pipeline's contents, reducing the risk of hazardous material release. |

| Minimal Disruption | Customers and dependent industries experience no interruption in service. |

| Increased Flexibility | Allows for system modifications, repairs, and expansions on a live, active pipeline. |

Ultimately, hot tapping is a powerful blend of meticulous engineering, advanced equipment, and uncompromising safety protocols. It’s what allows critical infrastructure to evolve and expand without missing a beat, saving an incredible amount of time, money, and headaches on any given project.

The Hot Tapping Process Step by Step

To really get a feel for what hot tapping is, think of it less like a construction job and more like a carefully planned surgical procedure for a pipeline. It’s far from just drilling a hole. Instead, it's a sequence of precise, calculated steps designed to create a new, permanent connection without a single leak or second of downtime.

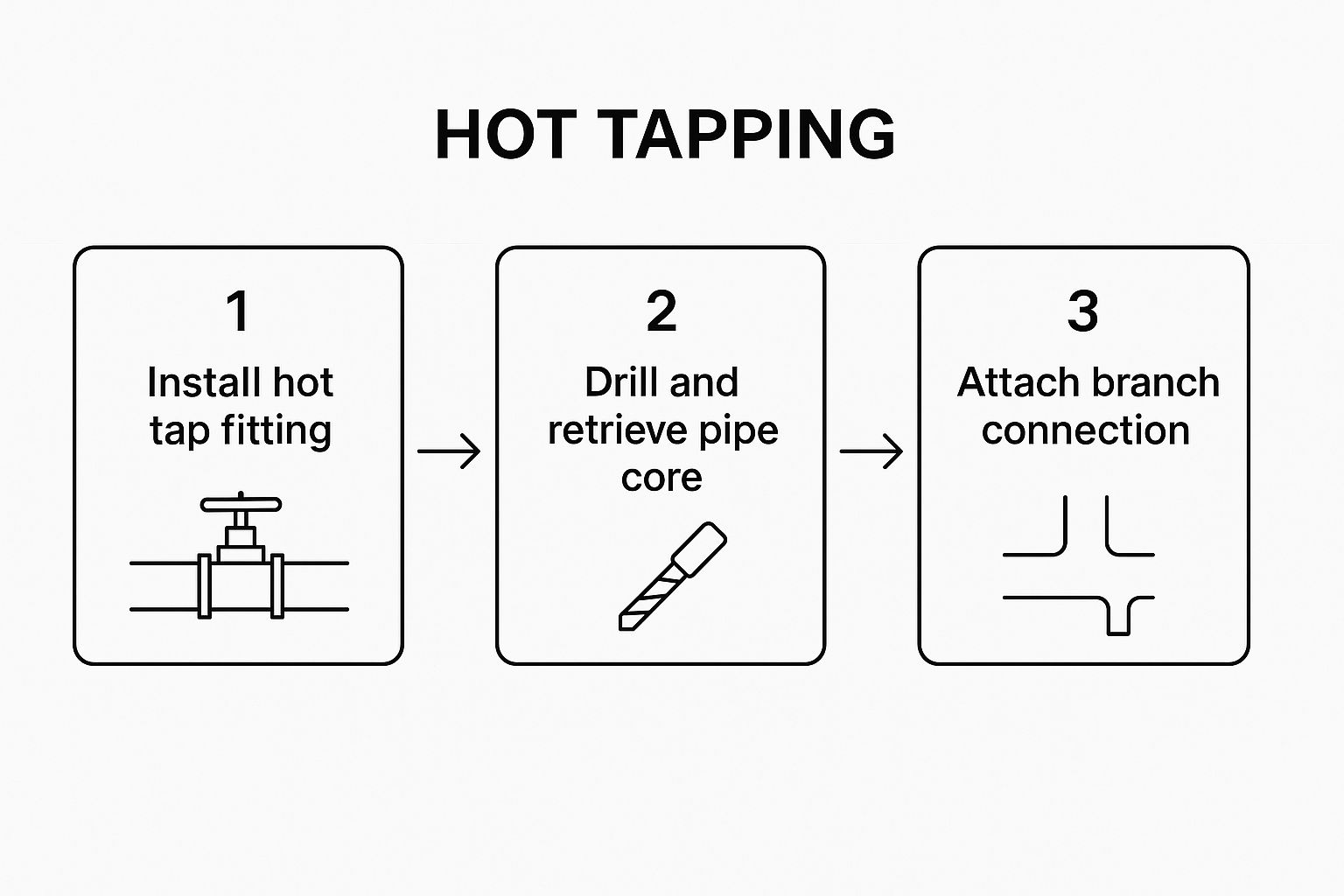

The image below gives you a great visual overview of the core steps involved, from the initial setup to the final, live connection.

As you can see, the whole operation breaks down into three main phases. It’s all about getting a secure fitting attached, making a perfect cut, and seamlessly integrating a new branch onto a live pipe.

Step 1: Installing the Fitting and Valve

First things first, we have to attach a specialized fitting to the outside of the existing, live pipe. This is often a split-tee fitting, which acts like a heavy-duty clamp that wraps completely around the pipe. This fitting also has a flanged outlet that will serve as the base for the new connection.

This isn't just bolted on; it's meticulously welded directly to the host pipe. The goal is to create a permanent, pressure-tight seal that’s just as strong as the original pipe. Once the fitting is perfectly welded, a permanent valve gets bolted onto its flanged outlet. This valve is the gatekeeper for the entire operation, first allowing the cutting equipment to pass through and later controlling the flow into the new line. Before we even think about cutting, everything is rigorously pressure-tested to make sure every weld and seal is perfect.

Step 2: Mounting the Machine and Making the Cut

With the fitting and valve locked down and tested, it's time to bring in the star of the show: the specialized hot tapping machine. This impressive piece of equipment is mounted directly onto the valve. It contains a boring bar with a pilot drill and a custom cutter, all housed inside a sealed, pressurized chamber.

The pilot drill is a clever bit of engineering—it centers the main cut and, more importantly, secures the piece of pipe that's about to be removed.

Once the machine is mounted, the valve is opened. The boring bar extends through the valve until the cutter meets the pipe wall. Then, the machine whirs to life, slowly and precisely cutting through the pipe. All the while, natural gas, water, or whatever is inside the pipe just keeps flowing under its normal operating pressure. The machine’s sealed design is what makes this possible, keeping the high-pressure contents safely contained.

The piece of pipe that gets removed is called the "coupon." The machine's pilot drill is specifically designed to catch this coupon, pulling it back out with the cutter. This is critical—it prevents a chunk of metal from falling into the pipeline and causing a major blockage or damage downstream.

Step 3: Retrieving the Coupon and Completing the Connection

Once the cut is through, the boring bar, now holding the coupon, is retracted back through the valve. As soon as it's clear, the valve is closed, once again sealing off the live pipeline. Only then can the hot tapping machine be safely unbolted and removed, leaving the new valve ready for action on the permanent fitting.

And just like that, the main goal is accomplished. We’ve added a new, flanged access point to a live pipeline without ever having to depressurize it or interrupt service. The new branch line can now be connected to the valve. When it's opened, product starts flowing into the new extension, and the project is complete. It’s an incredibly efficient and safe way to expand a system’s capacity.

How to Ensure Safety in Hot Tapping Operations

Let’s be direct: when you're cutting into a live, pressurized pipeline, there is zero room for error. A successful hot tap isn’t just about making a new connection. It's about pulling off a complex procedure with absolute precision and a relentless focus on safety. This isn't improvisation; it's a carefully choreographed operation where meticulous planning underpins every single move.

The real work of a hot tap starts long before a drill ever touches the pipe. The most important part of the entire job is the comprehensive pre-job analysis. Think of it as the mission blueprint—it’s an exhaustive investigation into the pipeline’s condition and the environment we’ll be working in.

The Critical Pre-Job Analysis

Before a single spark flies, our technicians need to be 100% certain about the integrity of the host pipe. We use a series of non-destructive tests to make sure the pipe can handle the heat from welding and the mechanical stress of the entire procedure.

This analysis involves a few key steps:

- Metallurgical Testing: We need to know exactly what the pipe is made of and if it's structurally sound. Experts look for hidden corrosion, weaknesses, or any defects that could turn into a serious problem under pressure.

- Wall Thickness Verification: Using ultrasonic tools, we measure the pipe wall to confirm it's thick enough at the exact point we plan to tap. If a pipe is too thin, the job is a no-go. It’s that simple.

- Pressure and Flow Calculations: Engineers run the numbers to understand exactly what’s happening inside the pipe. This ensures the equipment we bring to the site is perfectly rated for the system’s pressure and flow.

This level of detail means we’re working with a known quantity. We aren’t guessing about the pipe's condition; we're operating based on hard data.

Sticking to Standards and Managing Risk

With the analysis complete, the focus shifts to execution. Every step from here on out is strictly governed by established industry standards from organizations like the American Petroleum Institute (API). Following these proven, battle-tested procedures isn't optional—it's the core of how we keep everyone safe.

A safe hot tap is a planned hot tap. We have to identify every potential risk—from an equipment glitch to a sudden pressure spike—and have a clear plan to deal with it before the work ever starts.

This proactive approach means building in multiple layers of safety. We always establish a secure exclusion zone around the work area, allowing only certified personnel to enter. The technicians on-site are highly trained specialists who know the procedure inside and out, and they're also drilled on emergency response protocols. If something unexpected happens, they can react instantly and correctly.

Every job has a detailed, site-specific emergency plan that lays out the exact steps for any scenario you can imagine. From start to finish, safety isn't just a priority; it's the entire framework for the operation.

Where Hot Tapping Is Used in the Real World

The real power of hot tapping isn't just in the engineering—it's in what it prevents. This technique is the unsung hero that keeps our essential services flowing during major upgrades, expansions, and even emergency repairs across dozens of industries.

From bustling city centers to remote industrial sites, hot tapping is solving logistical headaches every single day.

Imagine a new hospital is being built in a fast-growing suburb. It needs to be connected to the city's main water line, but you can't just turn off the water for thousands of homes and businesses nearby. That's simply not an option. This is exactly the kind of problem hot tapping was made to solve.

Municipal and Utility Services

For any public utility, uninterrupted service is everything. Hot tapping gives them the power to expand and maintain their infrastructure without shutting down daily life for the communities they serve.

You’ll see it used for things like:

- New Service Connections: Tying in a new fire hydrant or adding branch lines for a new shopping center, all without causing a drop in water pressure for existing customers.

- System Upgrades: Installing modern valves and meters onto live water or natural gas lines to get better control and monitoring of the system.

- Infrastructure Relocation: Rerouting a major pipeline to make way for a new highway, all while the service stays completely active.

For a gas utility, hot tapping is fundamental. When a business needs temporary natural gas during construction for heating, a provider like Blue Gas Express can be brought in. Hot tapping creates the connection point for this temporary supply without ever taking the main gas grid offline.

Oil and Gas Sector

In the high-stakes world of oil and gas, shutting down a pipeline means immediate and massive financial losses. Hot tapping is an absolutely essential tool for keeping the vast network of pipelines that fuel our economy running.

It allows operators to add new lines from wells or create new connections to refineries and storage facilities without stopping the flow of millions of barrels of product. This kind of continuous operation is critical for a stable supply chain.

Industrial and Manufacturing Plants

Think about a large chemical plant or a massive manufacturing facility. They depend on a complex web of pipes carrying everything from steam and chilled water to specialized process chemicals.

A shutdown in one small part of that system can trigger a domino effect, bringing the entire plant to a standstill. Hot tapping lets these facilities modify their piping, add new equipment, or make repairs without suffering from incredibly expensive production delays.

The Economic and Environmental Case for Hot Tapping

Beyond the impressive engineering, the real power of hot tapping is how it directly impacts a company's bottom line and environmental footprint. It's a method that turns operational efficiency into real financial returns by making system shutdowns completely unnecessary.

At the same time, it’s a far cleaner approach to pipeline modification, helping to prevent the release of potent greenhouse gases. This is where smart engineering meets responsible business.

Driving Down Operational Costs

The financial case for hot tapping is crystal clear. When you shut down a pipeline the traditional way, you're not just pausing operations—you're kicking off a whole chain of costly events. Think about what’s involved: draining the entire line, purging what's left, and then going through the whole process of refilling and repressurizing it.

Those direct costs add up fast, but the real damage often comes from lost productivity. For a large manufacturing plant or a refinery, a single day of downtime can mean millions of dollars in lost production. Throw in the potential for penalties from customers whose service was interrupted, and the financial hit becomes enormous.

Hot tapping effectively reduces the cost of a pipeline modification to zero in terms of lost revenue. By keeping the product flowing, it eliminates the single most expensive aspect of traditional maintenance and expansion projects, protecting a company’s bottom line.

This simple fact makes it an essential tool for any industry where every minute of operation counts. It turns what could be a financial disaster into a routine, manageable task.

A Cleaner Approach to Pipeline Maintenance

The environmental benefits are just as compelling, especially when we’re talking about natural gas. The old-school way of working on a gas line involves isolating a section and doing what’s called a “blow down.” This means the natural gas trapped inside is just vented straight into the atmosphere.

That vented gas is mostly methane, a greenhouse gas that’s significantly more potent than carbon dioxide.

Hot tapping completely eliminates the need for this. Since the system stays live and under pressure, there’s no reason to vent huge volumes of methane into the air. The U.S. Environmental Protection Agency (EPA) even points to hot tapping as a key practice for cutting down on methane emissions. This is a big deal for companies working to meet environmental regulations and, frankly, for the health of our planet. You can read more about these environmental benefits from the EPA.

By keeping these gases in the pipe where they belong, hot tapping provides a much more sustainable way to manage our infrastructure. It’s a perfect example of how the right industrial process can be a win for both business and the environment.

Choosing the Right Hot Tapping Equipment

Just as a surgeon wouldn't use the same scalpel for every procedure, a hot tapping technician can't rely on a single machine for every job. The conditions on the ground—pipe size, what it's made of, the pressure inside, and even the surrounding environment—all dictate the kind of equipment needed. Picking the right machine isn't about convenience; it's a fundamental safety decision.

The choice really boils down to the power source driving the machine's cutter. Each type has its own strengths and is built for different scenarios, from massive industrial pipelines to smaller, more accessible utility lines. Getting a handle on these differences is the first step in planning a hot tapping operation that’s both safe and successful.

Comparing Power Sources: Hydraulic, Pneumatic, and Electric

The three main flavors of hot tapping machines are categorized by what makes them go: hydraulic, pneumatic, and electric. You can think of them like different engine types in a vehicle. A high-torque diesel is what you want for hauling a heavy load up a steep hill, while a quiet, nimble electric motor is perfect for zipping around a city.

While the core mission is always the same—to cut into a live, pressurized pipe without a single drop or wisp escaping—the technology has evolved to handle different challenges. Hydraulic systems give you raw power and incredible control, pneumatic units are valued for their safety and portability, and electric models offer reliability and ease of use. You can find more details on these equipment advancements and market trends in recent industry reports.

Let's look at the most common types you'll see in the field.

- Hydraulic Machines: These are the heavyweights. Powered by hydraulic fluid, they generate enormous torque, making them the only real choice for large-diameter, thick-walled pipes operating under extreme pressure.

- Pneumatic Machines: Running on compressed air, these machines are lighter and more mobile than their hydraulic cousins. Their biggest selling point is safety—they’re inherently spark-free, which is non-negotiable in potentially explosive atmospheres.

- Electric Machines: Offering a consistent source of power and straightforward controls, electric machines are workhorses for a huge range of standard jobs. They are often easier to set up and run, making them a reliable go-to for many common applications.

The single most important factor in equipment selection is matching the machine's capabilities to the pipeline's operational parameters. Trying to use an underpowered machine on a high-pressure line is a recipe for disaster and a serious safety risk.

Matching the Machine to the Mission

So, how do you make the final call? It really comes down to asking a few key questions about the job site and the pipe itself. A side-by-side comparison makes it clear where each machine type truly excels, helping technicians grab the right tool for the task at hand.

This table gives a clear, at-a-glance breakdown of which machine to use and when. It’s a great starting point for any project plan.

Comparison of Hot Tapping Machine Types

| Machine Type | Power Source | Primary Advantage | Best-Fit Application |

|---|---|---|---|

| Hydraulic | Hydraulic Fluid | Maximum Torque & Power | Large-diameter, high-pressure oil and gas transmission lines. |

| Pneumatic | Compressed Air | Spark-Free Operation | Volatile or explosive environments, such as natural gas facilities. |

| Electric | Electricity | Control & Consistency | Standard municipal water lines and general industrial piping. |

In the end, choosing the right hot tapping equipment is the cornerstone of a flawless operation. It demands a real-world understanding of each machine’s strengths and limitations, paired with a careful analysis of the pipeline's specific characteristics. This level of planning ensures every cut is made with the right power, the right precision, and an unwavering focus on safety.

Got Questions About Hot Tapping? We've Got Answers.

Let's clear up a few things. When project managers and facility owners first hear about hot tapping, the same questions usually come up. Here are some quick, straightforward answers to help you get a better handle on this incredibly useful technique.

Can You Hot Tap Just Any Pipe?

That’s a definite no. Not every pipe is a good candidate, and figuring that out is the crucial first step. Before any work begins, a thorough analysis of the host pipe is non-negotiable. We have to look at its material, measure the wall thickness, and check its overall condition.

Pipes that are badly corroded, have internal layers separating (lamination), or are made of brittle materials like cast iron are off-limits. The process puts a lot of stress on the pipe, so it needs to be strong enough to handle the welding and cutting without failing.

What's the Difference Between Hot Tapping and Line Stopping?

This one trips people up all the time. They're often used together, but they do completely different jobs.

Here’s a simple way to think about it: hot tapping creates a new doorway into a pipe, while line stopping temporarily closes that doorway (or another one) to block the flow.

- Hot Tapping: The whole point is to add a permanent new connection or branch to a pipeline while it's still running.

- Line Stopping: This is a temporary measure. We use a hot-tapped fitting to insert a stopper, which isolates a section of the pipe so you can make repairs without shutting everything down.

So, you often have to perform a hot tap first just to create the opening needed to insert a line stopper.

Hot tapping is about adding to a system—expanding it or tying in new equipment. Line stopping is about isolating part of that system so you can work on it safely.

Is Hot Tapping Safe for Any Kind of Product?

Hot tapping is incredibly versatile and is safely used all the time on pipelines carrying everything from natural gas and crude oil to gasoline, water, and steam. The critical factor is making sure the product inside the pipe won't have a dangerous reaction to the process.

That said, there are some hard-and-fast rules. It is strictly forbidden on lines with highly volatile or hazardous materials. You would never hot tap a line carrying pure oxygen, chlorine, or certain aggressive acids. The heat from welding could easily trigger a violent chemical reaction, and that's a risk no one is willing to take. Safety always comes first.

When your construction or industrial project needs a reliable temporary natural gas supply without disrupting the main grid, Blue Gas Express is the solution. We specialize in providing mobile CNG and LNG to keep your operations running smoothly. Learn more about our seamless temporary gas services.