When it comes down to choosing a fuel, the real question between propane and CNG is simple: do you need portability, or do you have infrastructure? Let’s cut to the chase. Propane is a highly portable liquid fuel, perfect for remote job sites or temporary setups that are nowhere near a pipeline. CNG, on the other hand, is a compressed gas that makes more sense for high-volume, fixed operations that can tap into existing infrastructure.

Choosing The Right Fuel: Propane vs. CNG

Picking between propane and compressed natural gas (CNG) is one of those foundational decisions that will shape your project's logistics, operating costs, and even its long-term viability. While both are a huge step up from diesel or gasoline in terms of emissions, their physical properties create completely different playbooks for storage and delivery. The propane vs. cng debate isn't about finding a single "best" fuel; it's about matching the right fuel to the right job.

Propane, also known as liquefied petroleum gas (LPG), has a major advantage: it’s stored as a liquid under relatively low pressure. This makes it incredibly easy to transport in tanks of all sizes, from small cylinders to massive bulk tanks. It’s the go-to choice when you need flexibility and a quick setup.

CNG is a different beast entirely. It stays in a gaseous state, just under extremely high pressure. This means it either needs a direct connection to a natural gas pipeline or requires specialized, high-pressure tube trailers for any kind of off-grid application.

At a Glance: Propane vs. CNG Differentiators

For those who need a quick reference, this table cuts through the noise and highlights the most critical differences between propane and CNG. It's designed to help you make a fast, high-level assessment.

| Attribute | Propane (LPG) | Compressed Natural Gas (CNG) |

|---|---|---|

| Primary State | Stored as a liquid under moderate pressure (~150 psi) | Stored as a gas under high pressure (~3,600 psi) |

| Delivery Method | Highly portable; delivered by truck in tanks | Delivered via pipeline or specialized mobile units |

| Energy Density | Higher energy content per unit of volume | Lower energy content per unit of volume |

| Infrastructure Needs | Minimal; requires only a storage tank and regulator | Significant; often needs a pipeline or compressor station |

| Ideal Use Case | Remote sites, temporary projects, mobile applications | High-volume, stationary operations with pipeline access |

This table really boils the decision down to its core elements, helping you quickly see which fuel aligns with your operational realities.

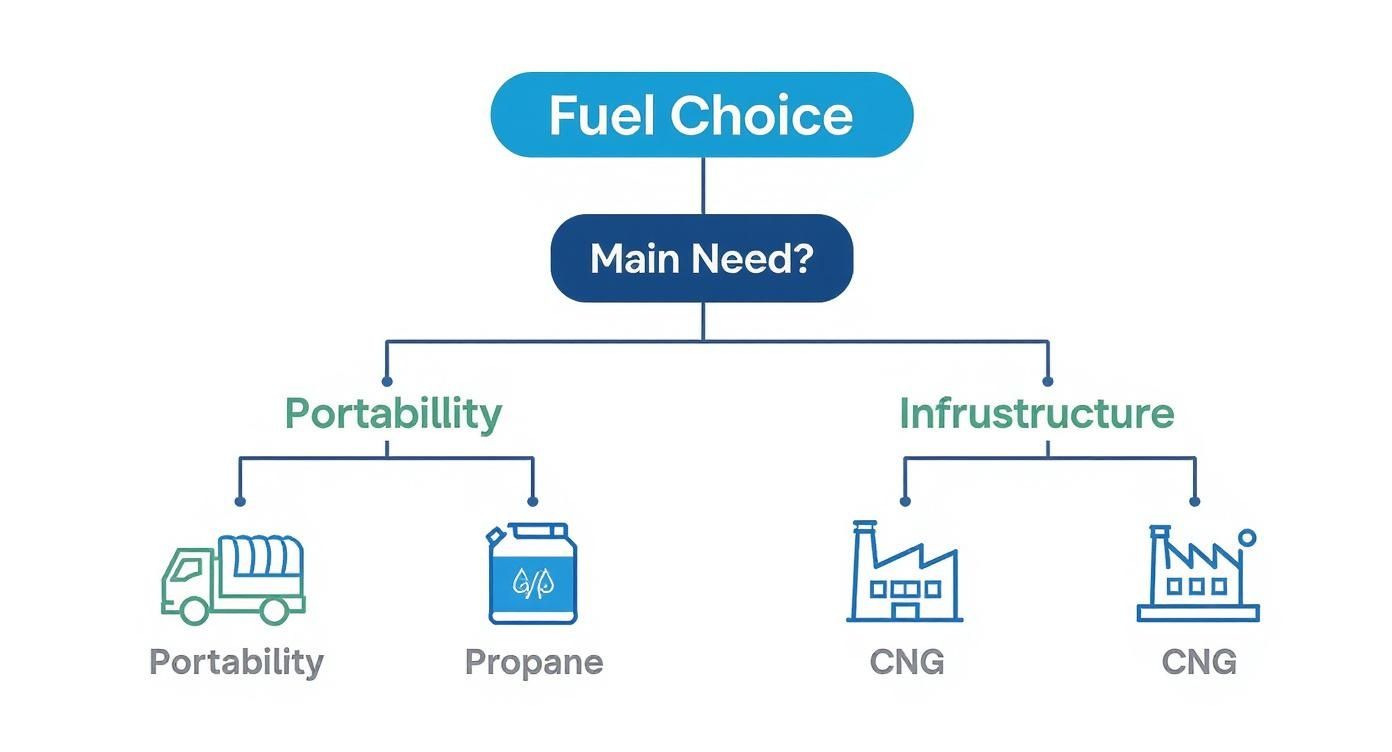

Ultimately, this decision tree visualizes the fundamental choice you're facing. You can either prioritize the unmatched portability of propane or capitalize on the cost efficiencies of CNG if you have the infrastructure.

As the graphic shows, your project's specific needs—especially its location and access to existing utilities—are the biggest factors in the propane vs. cng decision. For a more granular look at how these fuels perform in a specific application, this detailed breakdown of natural gas vs propane for commercial griddles offers some great real-world insights. With this initial framework in mind, we can dive deeper into the specifics.

Comparing Fuel Properties and Energy Output

When you get down to the brass tacks of the propane versus CNG debate, it all starts with their fundamental chemical properties. The way each fuel stores and releases energy is what dictates everything from the size of your on-site storage to how well your equipment performs. Getting these technical details right is the first step in solid project planning.

The most important distinction is how they’re stored. Propane is kept as a liquid under relatively low pressure—usually around 150 psi. This is its secret weapon. By turning into a liquid, propane packs a massive amount of energy into a compact, easy-to-handle volume.

On the other hand, Compressed Natural Gas (CNG) is exactly what its name implies: a gas, always. To make it practical, it's squeezed under incredible pressure, often hitting 3,600 psi. That kind of pressure requires heavy-duty, thick-walled cylinders and a much more complex infrastructure to manage it all safely.

Energy Density and Fuel Efficiency

For any fuel, energy density is the stat that matters most. It's a simple measure of how much punch you get from a certain amount of fuel. This is where the trade-offs between propane and CNG really start to show.

Propane has a much higher energy density by volume. A single gallon of liquid propane delivers about 91,500 BTUs (British Thermal Units) of energy. Because it's stored as a dense liquid, it’s incredibly effective for jobs that need a lot of power without taking up a lot of space.

CNG, being a gas, is naturally less dense. To make a fair comparison, the industry often measures it in Gasoline Gallon Equivalents (GGE). While one GGE of CNG packs more energy at roughly 126,670 BTUs, it takes up far more physical space than a gallon of liquid propane. This is a critical point: you need a lot more room to store the same amount of energy with CNG, which can be a deal-breaker for mobile operations or tight job sites.

To put it simply, one gallon of liquid propane contains about 2.5 times the energy of the same volume of natural gas at normal atmospheric pressure. Compressing the gas helps close that gap, but propane's liquid state gives it a clear advantage for efficient energy storage.

This difference has a real-world impact on logistics. For a project needing a certain amount of energy, you might get by with a single 1,000-gallon propane tank. To get the same energy from CNG, you’d likely need a large cascade system of multiple cylinders, which means a bigger footprint and more complex setup.

How Physical State Impacts On-Site Operations

The basic difference between liquid and gas creates a ripple effect that touches every part of your operation, from storage and delivery to the equipment itself. These aren't just minor technicalities—they shape the day-to-day reality of managing your fuel supply.

- Tank Design and Weight: Propane tanks are fairly simple and lightweight since they only need to handle moderate pressure. CNG cylinders, however, are built like tanks—literally. They have to be incredibly heavy and thick-walled to contain that high pressure, making them a challenge to move and install.

- Refueling and Delivery: Getting propane is straightforward. A bobtail truck pulls up and transfers liquid fuel into your on-site tank. CNG is more complicated. It either needs a direct pipeline connection or a "virtual pipeline" delivery using special tube trailers, which involves a more involved depressurization process.

- Equipment Operation: Propane becomes a gas right before it's burned, a simple process handled by a standard regulator. CNG is already a gas, but it starts at such high pressure that it has to be stepped down through multiple regulators before an engine or heater can use it. This just adds another layer of complexity to your fuel system.

Understanding these core properties is essential for accurately calculating your fuel consumption, planning your equipment needs, and forecasting how your operations will run.

When you're choosing between propane and CNG, the technical specs are just one part of the story. To make a smart long-term decision, you have to look at the market forces shaping each fuel. How stable is the supply chain? What does future growth look like? These factors will directly hit your wallet and your project's reliability down the road.

In the propane vs cng debate, we're really looking at two completely different market personalities. One is mature and steady, the other is in a phase of rapid, industry-fueled expansion.

Propane is the definition of a well-established market. Since it's a byproduct of natural gas processing and crude oil refining, the supply is consistent and comes from all over the world. This maturity gives it a rock-solid distribution network that can get fuel just about anywhere—from a high-rise in the city to a construction site in the middle of nowhere. For industries that can't afford downtime, that kind of dependability is gold.

CNG, on the other hand, is the energetic newcomer. Its growth is being driven hard by environmental regulations and its appeal to big, energy-hungry industries. While that growth is exciting, the market itself is a bit more fragmented because it all hinges on having a natural gas pipeline nearby. This is a huge advantage in areas with good pipeline access, but it becomes a major logistical hurdle where they're sparse or nonexistent.

Propane's Bedrock Stability

Think of the propane industry as a cornerstone of the energy world. It’s known for steady demand and predictable growth. You don't see wild, volatile swings here. Instead, it just keeps chugging along, growing consistently because it’s so essential for everything from home heating to farming and countless commercial uses. For a project manager trying to forecast costs and lock in a reliable supply, that predictability is a huge asset.

The numbers back this up. The global propane market was valued at 187.5 million tons in 2024 and is expected to climb to 252.8 million tons by 2033. That’s a compound annual growth rate (CAGR) of 3.4%—a clear signal of its lasting importance. You can dig deeper into these propane market trends to see what they mean for long-term supply.

The key takeaway for propane is predictability. Its established supply chains and steady growth mean less risk of supply disruption, making it a safe bet for projects where fuel reliability is non-negotiable.

This mature market also means you have a fiercely competitive and resilient distribution network. With so many suppliers, from massive national companies to local outfits, businesses have plenty of options and can shop around for good pricing. If your operations move from one site to another, this widespread availability makes logistics a whole lot simpler.

CNG's Rapid Ascent

The CNG market is a different beast entirely. It’s all about fast growth, kicked into high gear by the push for cleaner energy in transportation and heavy industry. As companies get squeezed by emissions regulations, many are looking at CNG as a more affordable, lower-emission alternative to diesel. This shift is creating a ton of momentum and attracting serious investment in new infrastructure.

What’s feeding this fire?

- Tighter Regulations: Strict emissions standards are forcing heavy-duty fleets and industrial plants to switch to cleaner fuels, and CNG fits the bill.

- Lower Costs: For high-volume users who can tap into a pipeline, CNG often delivers a lower cost per unit of energy than petroleum fuels, which can add up to massive savings over time.

- Government Support: Tax credits and grants for vehicle conversions and infrastructure projects are helping to lower the upfront costs for businesses wanting to make the switch.

This explosive growth is changing the energy game in regions with a lot of natural gas. But it's not happening everywhere at once. The success of a CNG project is still fundamentally tied to how close you are to a pipeline. While clever solutions like mobile "virtual pipelines" are popping up to serve off-grid sites, they introduce logistics and costs that simply don't exist with propane.

Ultimately, the propane vs cng decision often comes down to this very point: are you willing to navigate a developing infrastructure to get CNG’s benefits, or do you need the proven, plug-and-play reliability of propane?

How Do CNG and Propane Growth Rates Stack Up?

When you’re looking at the long-term viability of a fuel, its market growth tells a compelling story. It gives you real insight into industry confidence, where the investment dollars are flowing, and what future availability might look like. In the great propane vs cng debate, the two fuels have very different growth narratives. One is a story of steady, reliable expansion, while the other is all about a rapid, sector-driven surge.

Propane's growth is best described as stable and mature. It’s been a cornerstone of the energy landscape for decades, with deep roots in homes, businesses, and farms. Its market expansion is consistent and predictable, driven by its incredible flexibility for off-grid applications. For project managers who need supply chain resilience above all else, this steady trajectory is a huge asset.

Compressed natural gas (CNG), on the other hand, is on a much more aggressive growth path. This boom is almost entirely fueled by the transportation and heavy industrial sectors, which are scrambling for cheaper, cleaner alternatives to diesel. This momentum signals strong market confidence and serious investment in new infrastructure and technology.

The Forces Behind CNG’s Rapid Expansion

CNG’s impressive growth isn’t just happening by chance; it’s a direct response to powerful economic and regulatory pressures. For operations that burn through a lot of fuel, the potential cost savings from switching to CNG can be massive, especially for vehicle fleets or industrial plants with access to natural gas pipelines.

A few key factors are really pushing CNG forward:

- Environmental Regulations: As emissions standards get tighter, heavy-duty vehicle fleets and industrial sites are being pushed to adopt cleaner-burning fuels. CNG is a natural fit.

- Cost Incentives: For high-volume users, CNG often has a lower cost per unit of energy than petroleum fuels. Over the long haul, that adds up to major operational savings.

- Infrastructure Investment: A mix of government grants and private investment is actively expanding the network of CNG fueling stations and pipeline access, which makes it easier for new users to get on board.

This trifecta creates a powerful incentive for industries to make the switch, which is exactly why CNG is penetrating the market so quickly.

The real difference comes down to their growth drivers. Propane’s growth is steady and spread across many sectors. CNG's is explosive and concentrated in high-demand industries like transportation and power generation.

This is a critical distinction for long-term planning. You might choose propane for its proven, widespread availability and predictable market. Or, you might bet on CNG to ride the wave of a rapidly growing infrastructure and cash in on its cost advantages in high-volume applications.

A Tale of Two Growth Rates

The numbers paint a clear picture of these two different paths. While propane continues to see healthy, consistent growth, CNG's expansion is much faster, marking it as a disruptive force in the alternative fuel market.

Globally, compressed natural gas is one of the fastest-expanding alternative fuel sectors. In the U.S. alone, the compressed natural gas market brought in USD 13,434.2 million in 2024. It’s projected to hit USD 26,616.7 million by 2030, which is an impressive compound annual growth rate (CAGR) of 12.3% from 2025 to 2030. You can dig into the details in this U.S. compressed natural gas market outlook to see what's driving the trend.

That high CAGR isn’t just a number on a spreadsheet. It’s a loud and clear signal of where investment and technology are headed. If you’re making a long-term commitment to a fuel, aligning with a market growing that fast can give you a strategic edge, from better access to new tech to more competitive pricing as the infrastructure scales up.

Ultimately, this comparison highlights a fundamental choice in the propane vs cng decision. Do you go with the stability and proven reliability of a mature market like propane? Or do you align with the rapid expansion and emerging opportunities of the dynamic CNG sector? The right answer really depends on your project’s risk tolerance, long-term goals, and whether you need to rely on existing or developing infrastructure.

Evaluating the Total Cost of Ownership

It’s a classic mistake to just look at the price per gallon when choosing between propane and CNG. That kind of thinking can lead to some serious budget blowouts down the road. To get a real financial picture, you have to dig into the Total Cost of Ownership (TCO), which covers everything from the initial equipment purchase to the long-term operational headaches. This is the only way to accurately calculate your return on investment and make a decision that actually helps your bottom line.

Of course, the fuel price is the obvious starting point. A quick look at the numbers shows some clear differences in how propane and CNG are positioned in the market. Based on recent data, propane is running about $3.37 per gallon, while CNG is closer to $3.08 per gasoline gallon equivalent (GGE). On paper, that makes CNG look a bit cheaper per unit of energy. You can always check the latest alternative fuel prices to see how these numbers are trending.

But that per-gallon price? It's just the tip of the iceberg. The real story—and the real cost—is hidden in the massive differences in infrastructure and equipment.

Breaking Down Upfront Capital Investments

The initial cash you need to get a fuel system up and running is often the biggest factor separating propane and CNG. Propane infrastructure is famously simple and relatively cheap to set up. For most jobs, all you need is an on-site storage tank and a basic regulator system. The parts are easy to get, and installation is usually quick and painless.

CNG is a completely different animal. It demands a much heavier capital investment, especially if you’re not sitting right on top of a natural gas pipeline.

- Compressor Stations: If you have pipeline access but need to fuel equipment, you'll need a compressor station to crank the gas pressure up to a whopping 3,600 psi. These are complex, expensive machines, and you’re easily looking at a six-figure investment.

- High-Pressure Storage: Storing CNG requires a cascade of heavy-walled steel cylinders. They're far pricier and take up a much larger footprint than a propane tank holding the same amount of energy.

- Virtual Pipeline Logistics: For any site without a direct pipeline connection, you're forced into a "virtual pipeline" model using mobile tube trailers. This immediately adds a layer of transportation and logistical costs you just don't have with standard propane delivery.

The core financial trade-off is this: Propane has a low upfront cost but may carry a slightly higher per-unit fuel price over time. CNG often offers a lower fuel price, but it comes with a steep, non-negotiable price tag for specialized, high-pressure infrastructure.

This huge initial cost is exactly why CNG is almost exclusively used by high-volume operations like city bus fleets or massive industrial plants. They are the only ones who burn enough fuel to eventually see a return on that massive upfront investment.

Ongoing Maintenance and Operational Expenses

The costs don't stop after installation. Day-to-day maintenance and operational expenses also look very different for the two fuels. Propane systems are low-pressure and mechanically simple, which means they generally need very little attention. A few routine inspections and the occasional regulator check are usually enough to keep things running smoothly for years.

CNG systems are far more demanding. Those high-pressure compressors are sophisticated pieces of equipment that need regular service for filters, oil, and valves, just like any complex engine. On top of that, the high-pressure storage cylinders must undergo periodic hydrostatic testing and recertification to ensure they're safe. It's another recurring expense you have to bake into your budget.

When you look beyond the fuel price, the total cost picture becomes much clearer. Here's a breakdown of the key factors that contribute to the total cost of ownership for both fuels.

Comparing Total Cost of Ownership Factors

| Cost Factor | Propane | Compressed Natural Gas (CNG) |

|---|---|---|

| Initial Infrastructure | Low (storage tank, regulator) | High (compressor, high-pressure storage, pipeline tap) |

| Equipment Conversion | Moderate costs for conversion kits | High costs due to complex high-pressure systems |

| Ongoing Maintenance | Minimal (simple, low-pressure system) | Significant (compressor servicing, cylinder inspections) |

| Regulatory Compliance | Standardized and well-established | More stringent due to extremely high pressures |

Looking at the full TCO, you can see that the initial sticker price of the fuel is only a small part of the equation.

For smaller operations, temporary projects, or anyone who can't stomach a massive capital investment, propane's low barrier to entry and simple maintenance often make it the obvious financial winner. But for large-scale, long-term operations with predictable, heavy fuel demands, the high upfront cost of CNG can sometimes be justified by lower fuel prices over the long haul—but only if you run the numbers very, very carefully first.

Navigating Infrastructure and On-Site Logistics

How you get fuel to your site—and where you put it once it’s there—is a make-or-break detail for any project. When you’re weighing propane vs cng, the logistical differences are night and day. These differences will directly influence your project’s timeline, physical layout, and day-to-day operations. The right choice really comes down to your site's location, the project duration, and how much fuel you'll burn through.

Propane's biggest strength is its incredible portability. Because it’s stored as a liquid under relatively low pressure, it travels easily by truck and can be pumped directly into tanks on-site. This simple, time-tested delivery system makes it the go-to fuel for temporary or remote jobs far from any utility hookups.

This built-in flexibility means you can get your operation fueled and running almost instantly. There's no waiting around for complex installations or utility crews. The on-site setup is refreshingly minimal, usually just a storage tank and a regulator.

Comparing Delivery Models

The way fuel shows up at your doorstep defines your operational rhythm. Propane and CNG couldn't be more different here, each with unique requirements and advantages.

Propane's Drop-and-Go Approach: It’s as straightforward as it gets. A bobtail truck rolls up, fills your on-site tank, and leaves. The whole process is fast, doesn't require a specialized crew on your end, and can be scheduled as needed. This is ideal for dynamic sites, like construction projects, where fuel demand can swing wildly from one week to the next.

CNG's Infrastructure-Heavy Models: With CNG, you have two paths. The first is tapping directly into a natural gas pipeline, but that's really only practical for permanent industrial facilities with massive, steady demand. The second option is the "virtual pipeline," a clever mobile solution that gets CNG to sites off the grid.

A virtual pipeline is essentially a convoy of high-pressure tube trailers that deliver CNG. While it makes off-grid use possible, it brings a whole new level of logistical complexity. You need specialized equipment to depressurize the gas, and the setup itself takes up a much larger footprint than a simple propane tank.

This is a critical distinction. Propane offers a low-touch, hassle-free solution. CNG, especially for temporary use, demands far more planning and on-site management.

On-Site Footprint and Equipment

The amount of real estate your fuel system occupies is a huge deal, especially on a cramped job site. Propane systems are famously compact. All you really need is a level pad for the tank.

A mobile CNG setup, on the other hand, is a space hog. You have to make room for the large tube trailer, the pressure reduction skids, and the required safety perimeters. This can quickly eat into valuable space needed for material staging or other operations.

On top of that, CNG systems often require vaporizers to get the gas to the right temperature and pressure before use. That’s just one more piece of equipment to install, power, and maintain.

When it comes right down to it, propane’s logistical simplicity is a massive advantage for any project that values speed, flexibility, and a small on-site footprint. CNG only starts to make sense when your fuel consumption is consistently high enough to justify the significant infrastructure and planning it requires.

Your Questions Answered: Propane vs. CNG

When you're on the verge of a decision, a few practical questions always pop up. It's one thing to compare spec sheets, but it's another to understand how these fuels perform in the real world when it comes to safety, environmental impact, and equipment. Let's tackle some of the most common questions we hear.

Getting straight answers here can clear up any lingering doubts and help you finalize your project plans with confidence.

Which Fuel is Safer, Propane or CNG?

Both fuels have excellent safety records when handled properly, but their physical differences create distinct safety considerations. Propane is heavier than air. If a leak occurs, the vapor can settle and pool in low-lying areas, which could create an ignition risk without good ventilation.

CNG, on the other hand, is lighter than air. In a leak, it dissipates upward and away into the atmosphere very quickly—a clear safety advantage. The trade-off? CNG is stored under immense pressure, around 3,600 psi, while propane sits at a much lower 150 psi. This means CNG tanks have to be incredibly robust and are subject to stringent regulations to ensure they can safely handle that high pressure.

What Are the Main Environmental Differences?

Both propane and CNG burn much cleaner than diesel or gasoline, which is a major reason they're so popular. On paper, CNG produces slightly fewer carbon dioxide (CO2) emissions for the energy it delivers.

The big "but" here is methane. CNG is almost entirely methane, a powerful greenhouse gas. If any unburned methane escapes during production, transportation, or use—a problem known as "methane slip"—it can chip away at its environmental edge. Propane creates a little more CO2 at the point of use but doesn't have a methane slip problem, making its total emissions impact much more straightforward and predictable.

The core environmental question becomes: does CNG's lower CO2 output make up for the risk of methane slip? For projects where total emissions containment is a top priority, propane's reliable profile is a major plus.

Can I Convert My Equipment From Propane to CNG?

Technically, yes, but it's rarely a good idea. Converting equipment from one fuel to the other is a complicated and usually very expensive undertaking. It's not just a simple swap.

The process requires a certified technician to completely rework the fuel system with a specialized kit—we're talking new regulators, different injectors, and sometimes even new engine components to handle the huge difference in pressure and fuel characteristics. Honestly, it's almost always smarter and cheaper to buy equipment built specifically for your fuel of choice right from the start. That way, you know you're getting the best performance, full safety compliance, and keeping your warranty intact.

For reliable, on-demand fuel solutions when you need them most, trust Blue Gas Express. We specialize in providing temporary mobile CNG and LNG to keep your projects running without interruption. Learn more about our rapid deployment services.