Imagine having a way to bottle sunshine or capture the wind, storing it for a rainy day. That's the core idea behind Power-to-Gas technology. It's a practical way to build energy resilience by taking extra electricity from renewable sources and turning it into hydrogen or synthetic natural gas that you can store.

Think of it as a huge, green energy reservoir. This technology effectively decouples your operations from the whims of the grid, giving you a reliable source of on-demand power exactly when you need it.

Your Guide to Uninterrupted Energy

We all know the feeling. An unexpected power outage halts a critical project, delays an occupancy permit, or brings an entire industrial plant to a standstill. For construction managers and facility operators, relying on an aging or sometimes non-existent grid is a massive financial and logistical gamble.

Every hour of downtime adds up, translating directly into lost productivity and ballooning costs. This is a huge pain point for any business that depends on a steady stream of energy for heating, running heavy equipment, or powering essential processes.

The intermittency of renewable energy only complicates things. Solar and wind are fantastic resources when they're active, but what happens when the sun sets or the wind dies down? That inconsistency has always been the biggest hurdle to relying on them for the 24/7 power modern industry demands.

Bridging the Energy Gap

This is precisely the problem Power-to-Gas (P2G) was designed to solve. It acts as a bridge, converting excess renewable energy—which would otherwise go to waste—into a tangible, storable asset. It’s a game-changer for long-duration energy storage, accomplishing something that traditional batteries can’t easily do at a massive scale.

By converting electricity into a chemical energy carrier like hydrogen or synthetic natural gas, P2G creates a buffer against supply fluctuations. This ensures that clean energy is available for days, weeks, or even months after it was generated.

This stored gas becomes a completely dependable fuel source, ready to power your site regardless of what the grid is doing or what the weather looks like. It’s more than just a backup plan; it’s a permanent, resilient energy strategy.

A Growing Market for Energy Independence

The industry is clearly taking notice. P2G is fundamentally changing the energy storage game by smoothing out the unpredictable nature of renewables, a critical function for industries across North America and Europe.

The numbers tell the story. The global power-to-gas market, valued at USD 38.34 million in 2025, is expected to surge to USD 96.68 million by 2034. That’s a strong compound annual growth rate of 10.44%. You can explore additional market growth projections to see just how quickly this space is evolving.

This rapid expansion points to a clear trend: businesses are actively seeking greater energy independence and operational stability, and they're turning to innovative solutions like P2G to get there.

How Power To Gas Turns Sunshine And Wind Into Fuel

At its core, power to gas (P2G) is a bit like energy alchemy. It takes something we often have too much of at the wrong times—excess electricity from solar and wind—and converts it into a stable, storable fuel we can use whenever we need it. Think of it as an energy savings account; you make deposits when the sun is shining and the wind is blowing, and you can make a withdrawal anytime, day or night.

Let's picture a sunny, windy weekend. Solar farms and wind turbines are cranking out more power than the grid needs. Normally, that potential is wasted—turbines are shut down, and solar inverters are curtailed. But a P2G system steps in and captures every last drop of that clean, surplus electricity. This is where the magic begins.

Of course, to get the most out of any P2G system, you need to maximize your input. For solar-powered setups, this means maintaining peak performance of your solar panels to ensure every available kilowatt-hour is ready for conversion.

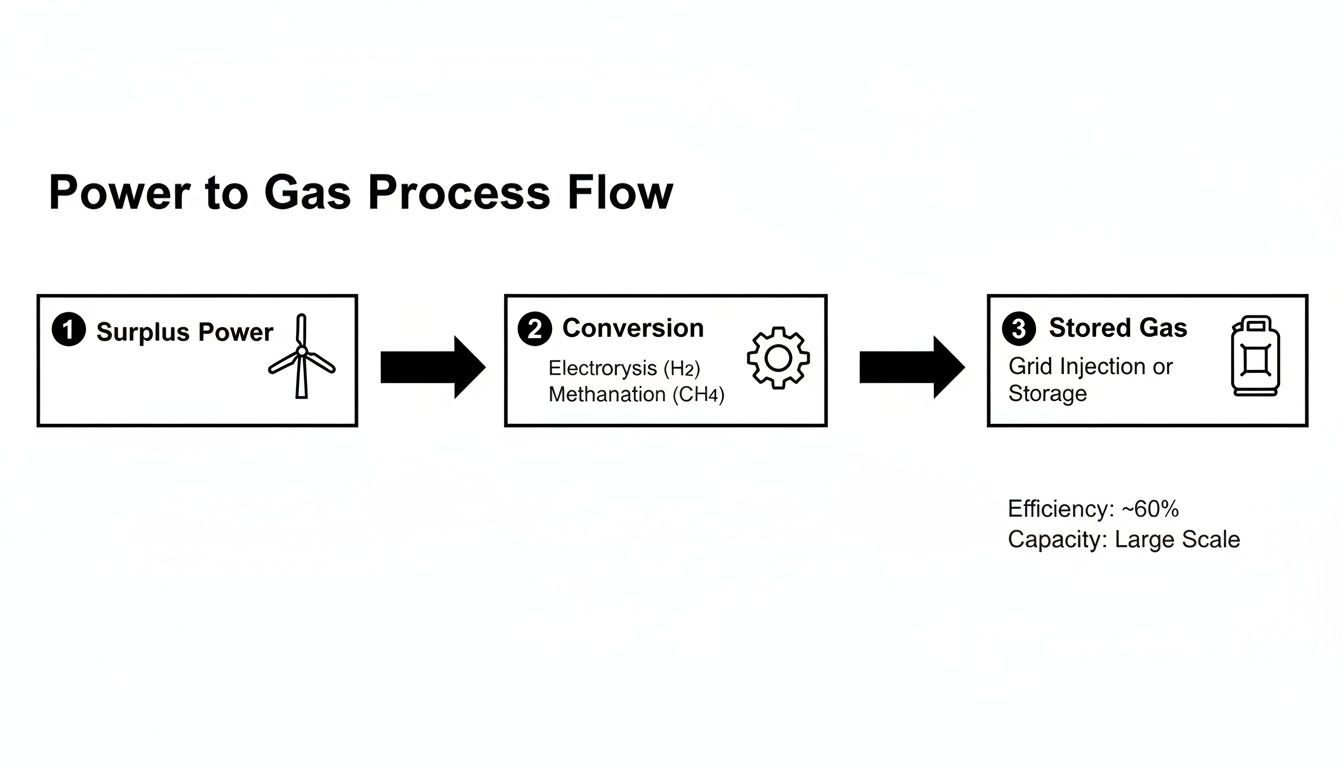

This diagram shows you the journey from surplus power to stored gas.

As you can see, the process starts with renewable electricity, moves through a conversion process, and ends with a versatile gas fuel, ready for storage or immediate use.

The First Step: Electrolysis Creates Green Hydrogen

The first critical step is electrolysis. It's a straightforward but powerful process: we use the captured electricity to split water (H₂O) into its basic elements. Inside a device called an electrolyzer, that power zaps water molecules, separating them into hydrogen (H₂) and oxygen (O₂).

The oxygen is simply released, but the hydrogen is the real prize. Because it was made using clean, renewable power, we call it “green hydrogen”—a powerful, zero-carbon fuel. This hydrogen is the first major product of the P2G system, and it can be stored and used as-is.

Once that green hydrogen is created, the system offers two distinct pathways. The choice depends entirely on what you need to power. Let's look at the comparison.

Two Pathways Of Power To Gas Technology

This table compares the two main outputs of the P2G process, green hydrogen and synthetic natural gas, highlighting their characteristics and primary uses for industrial and commercial applications.

| Feature | Green Hydrogen (H₂) | Synthetic Natural Gas (SNG/e-methane) |

|---|---|---|

| Production Process | Electrolysis of water | Electrolysis + Methanation |

| Chemical Composition | Pure hydrogen (H₂) | Methane (CH₄), identical to fossil natural gas |

| Infrastructure | Requires dedicated storage tanks & pipelines | Compatible with existing natural gas infrastructure |

| Common Uses | Fuel cells, industrial feedstock, specialized transport | Power generation, heating, transportation (CNG/LNG) |

| Key Advantage | Completely carbon-free at point of use | "Drop-in" replacement for fossil natural gas |

Each path provides a different tool for the job. Hydrogen is a pure, clean fuel, while SNG offers unparalleled flexibility by tapping into the infrastructure we already have.

The Methanation Option: Upgrading to Synthetic Natural Gas

The second route involves an extra step called methanation. Here, the green hydrogen is reacted with captured carbon dioxide (CO₂), transforming it into methane (CH₄)—the main component of natural gas.

This new product is called Synthetic Natural Gas (SNG) or e-methane. Its superpower is that it's chemically identical to the natural gas we pull from the ground. It’s a true “drop-in” fuel.

This is a game-changer. It means you can use SNG in your existing pipelines, generators, boilers, and vehicle fleets without a single modification. It’s a practical way to decarbonize operations without the massive expense and disruption of replacing proven, reliable equipment.

Why Power To Gas Is A Game Changer For Your Operations

It’s one thing to understand the science behind power to gas technology, but it’s another thing entirely to see how it can fundamentally change your day-to-day operations. This isn't just an interesting concept; it's a strategic tool that redefines how you manage energy, hit your sustainability targets, and keep your business running no matter what.

The most immediate benefit? A huge leap in energy security. By creating and storing your own fuel right on-site, you build a powerful shield against disruptions. Think about what happens during a major storm or a surprise grid failure. While competitors might be shutting down, your facility can keep humming along, powered by gas you made yourself. This simple capability protects you from crippling downtime and keeps critical projects on track.

Achieving True Energy Independence

This on-site production gives you something incredibly valuable: resilience. You’re no longer entirely at the mercy of grid stability or volatile fuel prices from suppliers hundreds of miles away. You gain real control, ensuring you have the power you need, when you need it.

For companies serious about decarbonization, P2G provides a practical, direct path forward. You can blend green hydrogen or synthetic natural gas (SNG) into your existing energy mix, immediately lowering your carbon footprint without needing to rip out and replace all your current equipment. This makes it far simpler to meet environmental regulations and answer the growing demand for corporate sustainability.

Power to gas isn't just about storing energy. It’s about turning a potential liability—like wasted renewable electricity—into a high-value asset: a storable, reliable fuel. It creates certainty in a very uncertain world.

The rapid growth of the P2G market shows just how vital it is for cleaning up tough industries like steel, chemicals, and heavy transport. Europe, which grabbed over 44.46% of the global market revenue in 2023, is relying on P2G to handle the massive influx of new renewables. With 510 GW of solar and wind added worldwide in 2024, the grid needs a way to absorb it all. Pilot projects are already blending hydrogen up to 20% in some natural gas networks. To get a better sense of this global shift, you can review key market dynamics and growth factors.

Long-Duration Storage: The Key Differentiator

Perhaps the most powerful advantage of P2G is its capacity for long-duration storage. Batteries are fantastic for short-term needs, like storing solar power for a few hours to use overnight. But P2G systems can store enormous amounts of energy for weeks, months, or even across entire seasons.

Here’s a simple way to think about it: a battery is a sprinter, delivering a fast, powerful burst of energy. P2G is a marathon runner, providing steady, sustained energy over a much longer haul. This is crucial for managing seasonal demand shifts or bracing for a prolonged grid outage.

They each have a distinct role:

- Battery Storage: Perfect for balancing the grid second-by-second, smoothing out solar production during the day, or providing a few hours of backup.

- Power to Gas: Ideal for capturing massive amounts of surplus energy from windy springs or sunny summers and saving it for the calm, dark winter months.

This long-term storage doesn't just provide security; it opens up new financial strategies. By storing energy when electricity is cheap and plentiful, you can use it later to avoid paying high prices during peak demand. In some markets, you can even sell that stored energy back to the grid when prices spike, turning your energy system from a cost center into a source of revenue.

Putting Power To Gas To Work In Your Industry

The real power of this technology shines when we move past the theory and look at how it solves nagging, real-world problems. Power to gas isn't some far-off concept; it's a practical tool you can put to work today to keep projects moving, guarantee uptime, and hit decarbonization targets. Whether you're on a remote construction site or running a massive factory, P2G delivers clean, on-demand fuel right where you need it.

This is about bridging the gap between clean energy potential and the realities of getting the job done.

Construction And Development

Picture this: a large-scale housing development or a new commercial park, miles from the nearest natural gas pipeline. Waiting for the utility company to extend service can mean months of delays. Everything from temporary heat to final inspections for occupancy permits gets put on hold. It’s a common, expensive bottleneck.

This is exactly where a P2G system can be a game-changer. By setting up an on-site system, you can produce a steady supply of synthetic natural gas (SNG) to power heaters, ground-thawing equipment, and generators. Suddenly, your project schedule is no longer hostage to the utility's timeline. It's also a much cleaner alternative to noisy, fume-belching diesel generators, helping you meet tightening environmental regulations.

Here’s how it helps:

- Temporary Heating: Keep crews working and materials protected in the cold without depending on trucked-in propane or diesel.

- Equipment Fueling: Power heavy machinery that’s been converted to run on natural gas, cutting both local emissions and fuel expenses.

- Bridging Utility Gaps: Provide the gas needed to commission and test a building's HVAC and plumbing systems long before the permanent pipeline is live.

By making your own fuel on-site, a construction project gains a massive degree of self-sufficiency. What was once a logistical nightmare becomes a serious competitive advantage.

Industrial And Manufacturing Facilities

For any industrial operation, a steady energy supply isn't a luxury—it's the absolute lifeblood of production. If you're in metal fabrication, glass manufacturing, or chemical production, you know that high-heat processes need a huge, uninterrupted flow of fuel. Even a short disruption can mean ruined batches and hours of costly downtime.

Power to gas offers a powerful dose of energy resilience. By producing and storing SNG or green hydrogen on-site, a plant can give its most critical systems a reliable backup fuel that plugs right into its existing infrastructure.

Think of a P2G system as an industrial-scale insurance policy. It guarantees your blast furnaces, kilns, or backup generators keep running, even if your primary gas supply is cut off.

This stored green fuel can also be blended with the facility's normal natural gas feed. It’s a straightforward way to start chipping away at your carbon footprint and meeting ESG goals without having to rip out and replace your core equipment.

Gas Utilities And Grid Management

Gas utilities are juggling two big challenges: keeping their distribution networks reliable while also figuring out how to navigate the shift to a lower-carbon world. Power to gas is a key piece of that puzzle. Utilities can deploy P2G facilities to solve the problem of grid congestion when renewable energy production is high.

Instead of being forced to shut down wind turbines on a blustery day, that excess electricity gets converted into SNG and injected directly into the existing pipeline network. This move cleverly solves several problems at once:

- Grid Stabilization: It gives surplus renewable power a productive place to go, helping to balance the electric grid.

- Decarbonization: It introduces a green, carbon-neutral gas into the supply, lowering the carbon intensity of the fuel being delivered to homes and businesses.

- Long-Term Storage: It essentially uses the immense capacity of the natural gas pipeline system as a massive battery for renewable energy.

This strategy allows utilities to use the infrastructure they already have as a huge energy storage asset, building a more flexible and sustainable energy system for everyone.

The Dollars And Sense Behind Power-To-Gas

While the technical side of Power-to-Gas is impressive, any real business decision comes down to the numbers. The great news is that the financial case for P2G is getting stronger by the day, thanks to falling technology costs and some serious financial incentives. Think of it as an investment in making your operations resilient, and the math is finally starting to look very attractive.

What's driving this shift? First and foremost, the cost of renewable energy has plummeted. Solar and wind are now the cheapest sources of new electricity in many places, giving a P2G system the affordable energy it needs to run. At the same time, the price tag on electrolyzers—the heart of the system that makes green hydrogen—is dropping as manufacturers ramp up production.

A Look At The Costs: Upfront And Ongoing

When you're planning a P2G project, you have to look at both the initial investment and the day-to-day running costs. Getting a handle on both is crucial for building a business case that holds water.

Capital Expenditures (CapEx): This is what you'll spend to get the system built and commissioned. The big-ticket items are:

- The Electrolyzer: This is usually the largest single expense, as it’s the machine doing the heavy lifting of creating hydrogen.

- The Methanation Unit: You'll only need this if your goal is to convert the hydrogen into synthetic natural gas (SNG).

- Gas Storage and Compression: This includes the tanks and hardware required to safely store the fuel you're producing on-site.

- Control Systems and Integration: The brains of the operation—all the software and hardware that automates and manages the whole process.

Operational Expenditures (OpEx): These are the costs to keep the system running smoothly.

- Electricity: Your main input cost, but the whole point is to use cheap, off-peak, or even free surplus renewable power to keep this low.

- Maintenance: Just like any industrial equipment, electrolyzers, compressors, and pumps need regular servicing to stay in top shape.

- Water Supply: You'll need a steady source of purified water for the electrolysis process.

The initial price can seem high, but you have to weigh it against the long-term gains: lower fuel bills, no more disruptions from supply chain issues, and the sheer value of being in control of your own energy supply.

Tapping Into The Incentive Landscape

This is where the financial picture gets really interesting. Governments are rolling out the red carpet for clean hydrogen and P2G technologies with a growing number of incentives. These programs are specifically designed to take the sting out of the initial investment and help companies make the switch to green fuels faster.

The key thing to remember is that you don't have to fund this alone. By strategically using federal and state incentives, you can slash the net cost of a P2G project and hit profitability much sooner than you might think.

One of the biggest game-changers is the U.S. Inflation Reduction Act (IRA). It introduced a massive tax credit for producing clean hydrogen, offering up to $3 per kilogram. That can dramatically cut the effective cost of the fuel you produce, making it competitive right out of the gate.

This isn't just a local trend; it's a global movement. The P2G market was valued at USD 36.35 million in 2023 and is expected to surge to USD 122.56 million by 2030—that's a compound annual growth rate of 19.2%. This explosive growth is being driven by major policies like the EU's REPowerEU plan and the IRA, which has already kicked off more than 50 P2G projects across North America. For a deeper dive, check out the market analysis from Fortune Business Insights to see the global momentum.

On top of federal help, many states have their own programs—from direct grants and tax credits to renewable energy mandates that can open up new ways for P2G operators to make money. By layering these incentives, a savvy company can build a financial model that not only pays for the project but also sets it up for long-term, sustainable success.

Building a Future-Proof Energy Strategy

The real trick to a smart energy plan is connecting what you need right now with where you want to be in the long run. We've talked about power to gas as the bedrock for a permanent, sustainable energy supply. Now, let’s tie it all together into a practical, two-part strategy that ensures you're never held hostage by energy supply problems again.

Think of it like this: a permanent P2G installation is your own personal water reservoir—a massive, reliable supply you can count on for decades. But what if there’s a sudden drought before the reservoir is built? You'd call in a water truck to get you through.

The Hybrid Approach to Energy Resilience

This is exactly why a hybrid strategy is so effective. It pairs the immediate, flexible support of mobile gas services with the long-term security of an on-site P2G system. It’s a realistic approach that acknowledges you have problems to solve today while you build for a more resilient tomorrow.

Mobile natural gas, delivered as CNG or LNG, is the perfect bridge for those gaps. It’s your energy rapid-response team, ideal for situations like:

- Powering up a new construction project months before the utility pipeline is connected.

- Keeping your plant running during a planned gas line maintenance shutdown.

- Quickly commissioning equipment or securing a temporary certificate of occupancy to get a new building open.

This solves your urgent challenges right away, keeping projects on schedule and revenue flowing without forcing a long-term commitment. It’s the tactical fix that buys you the time to put the permanent solution in place.

P2G as Your Permanent Solution

While mobile gas handles the "now," a power to gas system is your final destination for true energy independence. This is the strategic, long-term play that permanently shields your business from grid failures, volatile pricing, and supply chain headaches. When you produce your own clean fuel on-site, you’re not just buying energy—you’re building a future-proof energy asset.

This dual strategy isn't an either/or choice. It's about creating a complete energy partnership—using mobile gas for immediate flexibility while you build toward the permanent resilience of P2G.

This method gives your business a complete toolkit. You get a fast, reliable partner for urgent needs and a clear roadmap to sustainable, self-sufficient operations. The goal is to make sure energy is never again a bottleneck. Instead, it becomes a strategic advantage that keeps you ahead of the curve.

For broader perspectives on emerging energy strategies and technologies, you can explore more energy insights. This hybrid model offers a clear, actionable path to get there, starting with a simple conversation about what you need today and where you want to be tomorrow.

Common Questions About Power-to-Gas

When leaders start looking into how Power-to-Gas (P2G) can fit into their operations, a few questions always seem to pop up. We've gathered the most common ones here to give you straightforward answers, covering everything from equipment compatibility to project timelines.

Can I Use the SNG From a P2G System With My Current Equipment?

Yes, and that’s one of the biggest selling points. The synthetic natural gas (SNG) created through the methanation process is chemically identical to the natural gas you're already using. Think of it as a true "drop-in" fuel.

This means you can feed it directly into your existing infrastructure without any costly or disruptive modifications. Your boilers, furnaces, commercial heaters, and natural gas generators won't know the difference. No new pipes, no special burners, no engine retrofits needed. It just works, which makes the switch much easier.

How Does P2G Stack Up Against Battery Storage?

This isn't an either/or situation. P2G and battery storage are both great, but they're built for different jobs. Trying to pick a "winner" misses the point—they actually work very well together in a complete energy strategy. The main difference boils down to how much energy you need to store and for how long.

Batteries are sprinters, perfect for short-term, rapid-response power. Power-to-Gas is a marathon runner, designed for massive, long-duration storage that can last for months.

Here’s a simple way to think about their roles:

- Battery Storage: Ideal for short-term grid balancing that happens over minutes or hours. It's fantastic for soaking up midday solar power to use in the evening or providing a few hours of instant backup during a power outage.

- Power-to-Gas Storage: Shines when you need to shift huge amounts of energy from one season to another. It can capture surplus renewable energy from windy spring months and store it as gas for use during the high-demand winter season, ensuring you have power for weeks or months at a time.

What's a Realistic Timeline for a P2G Project?

Putting a full-scale Power-to-Gas system in place is a serious industrial project. The exact timeline will depend on the project’s size, location, and the local permitting process, but it generally follows a clear, phased approach. This helps everyone involved know what to expect.

A typical project breaks down into these stages:

- Feasibility and Site Assessment: First, we run the numbers. This involves a deep dive into your energy needs, checking the availability of renewable power and water, and building a solid business case.

- Permitting and Engineering: Next comes the paperwork and planning. This phase is all about securing the necessary permits and finalizing the detailed engineering designs for the P2G facility.

- Construction and Installation: This is where things get built. We'll be on-site installing the electrolyzer, methanation reactor, gas storage, and all the control systems.

- Commissioning and Operation: In the final stretch, we test everything to make sure it runs perfectly, bring the plant online, and officially start producing green hydrogen or SNG.

If you need an immediate energy solution while your permanent P2G system is being developed, Blue Gas Express can bridge the gap. We deliver temporary CNG and LNG to keep your projects moving without a hitch. Learn how our mobile natural gas solutions can support your operations.