At its core, a portable CNG tank is simply energy on demand. It’s a way to get compressed natural gas exactly where you need it, without being tied to a permanent pipeline. Think of it like a giant, mobile power bank, but for natural gas—perfect for any situation where you have a temporary or remote energy need.

How Portable CNG Delivers Energy Anywhere

Let's get practical. Imagine you’re running a large construction site miles from the nearest utility hookup. Or maybe you manage a fleet of vehicles that need refueling far from an established station. What about keeping a factory running when the main gas line is shut down for maintenance?

These are tough spots to be in. Building permanent gas lines is incredibly slow and expensive, especially for a short-term need. This creates an energy gap that can bring operations to a grinding halt.

This is exactly the problem portable CNG tanks were built to solve. They function as a "virtual pipeline," giving you a flexible and immediate source of cleaner-burning fuel. By trucking compressed natural gas directly to your site, you can completely sidestep the limitations of the traditional gas grid.

Bridging the Infrastructure Gap

The real magic of a portable CNG solution is the energy independence it provides. Instead of waiting months—or even years—for a utility to run a new line, a mobile unit can be on-site and operational in a matter of hours.

This rapid deployment is a game-changer for a few key scenarios:

- Construction Projects: You can power heaters and other crucial equipment to keep the project on track, which is often a key step for getting a certificate of occupancy.

- Industrial Operations: It's the perfect backup plan. A portable tank ensures you can continue production during planned maintenance or unexpected interruptions to your main gas supply.

- Fleet Fueling: Need to set up a temporary refueling depot for your trucks or buses in an area without public CNG stations? This is how you do it.

- Emergency Power: When the grid goes down, these tanks can supply fuel to backup generators at critical facilities like hospitals and data centers.

This technology provides a bridge to cleaner fuel without the immense cost and time commitment of permanent infrastructure. It’s about delivering the right amount of energy, right where you need it, right when you need it.

It's no surprise that this mobile energy solution is catching on fast. In 2024, the global market for CNG tanks hit a value of around USD 2.72 billion, and portable systems are a huge driver of that growth. This trend underscores just how much demand there is for flexible energy options across all kinds of industries.

You can dive deeper into the numbers by checking out the global CNG tanks market forecast on ResearchAndMarkets.com.

Breaking Down the Portable CNG Tank System

At first glance, a portable CNG tank system might look pretty complicated, but the idea behind it is actually quite simple. The best way to think of it is as a giant, mobile power bank, but for natural gas instead of electricity. It’s designed to be safely moved around and set up fast.

It’s more than just a big tank, though. It's a complete, self-contained energy delivery unit.

The heart of the whole system is the high-pressure vessel. This is where we see the real power of compression. A huge amount of natural gas—sometimes enough to power a large building for days—is squeezed down to pressures often hitting over 3,600 PSI. This lets you store a massive amount of energy in a footprint that’s surprisingly small.

This is what really separates CNG (Compressed Natural Gas) from LNG (Liquefied Natural Gas). LNG has to be cryogenically frozen to turn it into a liquid. CNG, on the other hand, stays in its gaseous state; it's just stored under immense pressure at normal temperatures. That makes a portable CNG tank a much simpler and often more practical choice for temporary energy needs.

Core Components of a Mobile System

So, how do these units actually work? Let's peel back the layers and look at the essential parts. Every component has a specific job, working together to make sure the gas is stored safely and delivered exactly as needed.

- High-Pressure Vessels: These are usually a bundle of cylinders made from either high-strength steel or, in some newer models, advanced composite materials to save weight. Every single one is tested to handle incredible internal pressure.

- Valve and Regulator System: This is the brains of the whole operation. It’s a sophisticated setup of valves, gauges, and regulators that carefully controls the flow and pressure of the gas as it comes out, ensuring it matches what the equipment on the other end needs.

- Protective Skid or Frame: The entire assembly is mounted on a heavy-duty steel frame, often called a "skid." This structure does more than just hold everything together; it protects the tanks and valves from getting banged up during transport and provides a solid, stable base when it's on-site.

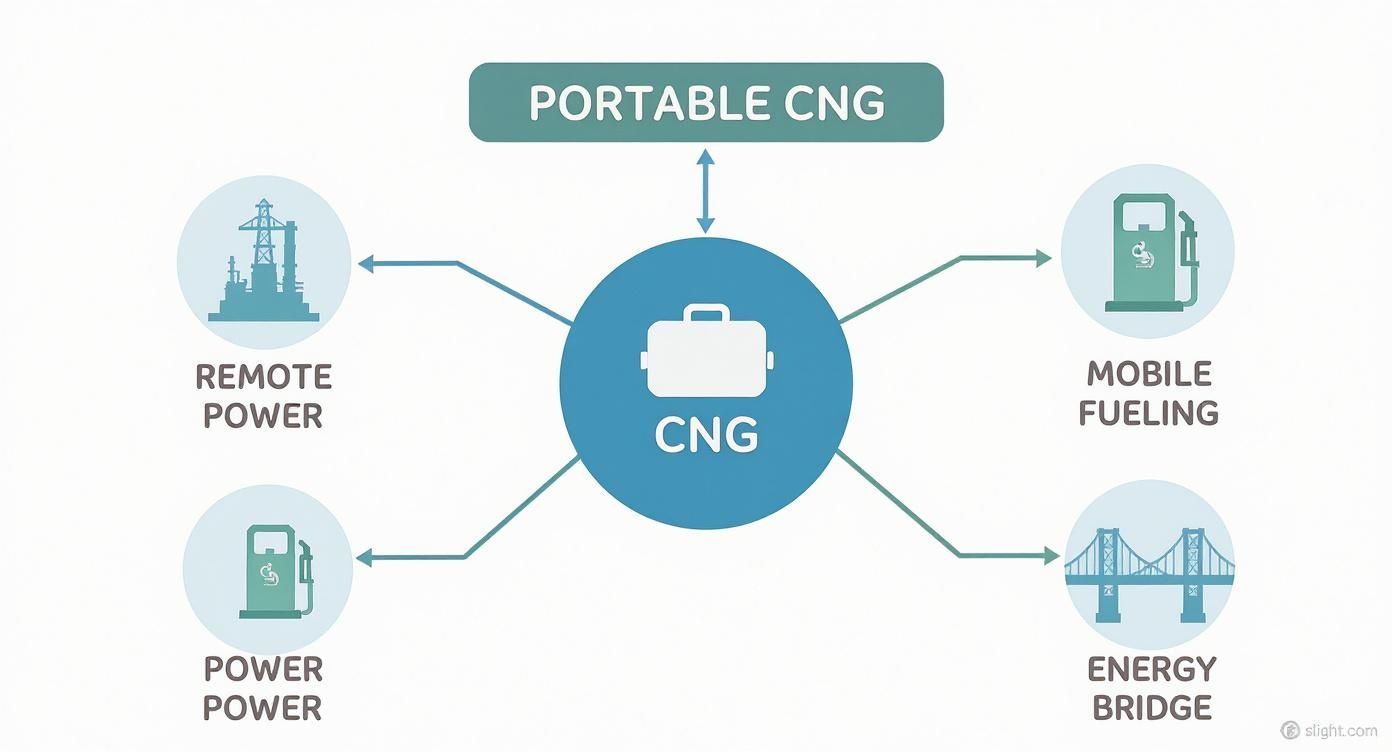

The infographic below gives you a great visual of how one of these systems can become a central energy hub for all sorts of applications.

As you can see, a single portable CNG tank can act as a critical energy bridge, doing everything from running remote power generators to fueling a fleet of vehicles.

Portable CNG Tank vs Stationary CNG Storage

To really grasp the value of these mobile units, it helps to compare them directly with traditional, fixed CNG storage. The table below breaks down the key differences.

| Feature | Portable CNG Tank | Stationary CNG Storage |

|---|---|---|

| Mobility | Fully mobile; can be trucked to any location. | Fixed in one place; cannot be moved. |

| Installation | "Drop-and-go" setup with minimal site prep. | Requires significant construction and permitting. |

| Infrastructure | No permanent infrastructure or pipeline needed. | Tethered directly to a natural gas pipeline. |

| Cost | Lower upfront cost; rental model is common. | High capital investment for construction. |

| Best Use Case | Temporary projects, emergencies, remote sites. | Permanent, high-volume fueling or energy supply. |

| Flexibility | Extremely high; easily swapped when empty. | Inflexible; capacity and location are permanent. |

Ultimately, the choice comes down to permanence versus flexibility. While stationary storage is a fantastic solution for a permanent, high-demand facility, it locks you into one location. Portable tanks offer a level of adaptability that fixed infrastructure simply can't match.

Flexibility Over Fixed Infrastructure

The biggest win for a portable CNG tank is its incredible flexibility, which is a world away from stationary storage. A permanent CNG cascade is bolted to the ground, hooked up to a pipeline, and requires a ton of construction and cash to build.

On the other hand, a portable system is all about mobility. You can truck it to just about anywhere, hook it up, and when it’s empty, just swap it out for a full one. This "drop-and-go" approach means you don't need to pour a single yard of concrete.

This is precisely why portable CNG is the perfect answer for temporary projects, emergency power outages, or job sites miles from the nearest gas main. It gives you all the benefits of clean-burning natural gas without the long-term commitment and eye-watering upfront costs of building something permanent. It completely changes the game for how businesses can get the energy they need, when and where they need it.

Why Mobile CNG is a Smart Strategic Move

More and more, industries are seeing portable CNG not just as a quick fix, but as a fundamental part of their energy planning. It's a shift that comes down to three game-changing advantages that hit the operations and the bottom line hard: incredible flexibility, real cost savings, and a genuine commitment to cleaner energy.

The first thing you’ll notice is the flexibility. A portable CNG tank is, quite simply, energy that goes wherever you need it. Picture a construction crew on a remote site trying to cure concrete in the dead of winter. Instead of watching deadlines slip away, a mobile tank can be on-site and running heaters in a matter of hours. The fuel shows up exactly when and where it's needed.

That same adaptability becomes a lifeline in an emergency. If a pipeline gets knocked out by a storm or equipment failure, a portable unit can be rolled in to keep essential places like hospitals or data centers up and running. No drama, just continuous power.

A Smarter Way to Manage Costs

Beyond just being handy, portable CNG offers a much more intelligent financial approach. Let’s be honest, building a permanent gas pipeline is a colossal investment. We're talking millions of dollars and months of headaches with planning and construction. For a temporary project, that kind of spending is a non-starter.

Mobile CNG completely changes the conversation. By renting a unit or using a service-based model, companies sidestep those massive upfront costs entirely. This opens up some serious financial perks:

- Zero Capital Expenditure: You get all the energy you need without sinking capital into infrastructure you might not need next year.

- Pay-As-You-Go Supply: Need more gas this month? No problem. Need less next month? You can scale your supply up or down on the fly, so you're only paying for what you actually use.

- Slash Downtime Costs: Keeping your operations running during planned pipeline maintenance can save you far more money than the rental itself costs.

A portable CNG tank lets you treat natural gas as a simple operational expense (OpEx) instead of a massive capital expense (CapEx). This makes your entire energy strategy more nimble and financially sound.

Making a Real Environmental Impact

Finally, making the switch to CNG is a concrete move toward sustainability. When you stack it up against traditional fuels like diesel or heating oil, natural gas is a much cleaner-burning option. That transition delivers immediate and positive results for the environment.

Using CNG cuts down on harmful pollutants like nitrogen oxides and particulate matter, which directly improves local air quality. It also shrinks an operation's carbon footprint. While propane produces fewer pollutants, natural gas emits less carbon dioxide, making both a significant step up from oil. This helps companies stay ahead of tough environmental regulations and hit their own green targets. In fact, portable CNG tanks are now a key piece of the puzzle in the global push for cleaner transportation, especially where permanent CNG stations are scarce. You can dig deeper into how mobile solutions are fueling this trend by checking out the latest innovations in the CNG tank market on StellarMR.com.

Portable CNG Tanks in Action

It’s one thing to talk about the theory, but let's look at how portable CNG is solving tough energy problems on the ground right now. This is where the technology truly shines—in demanding, real-world situations where a reliable energy source is make-or-break. Think of it less as a simple backup plan and more as a strategic tool for keeping the lights on and the machines running.

Take a manufacturing plant, for instance, that's set up miles from the nearest natural gas pipeline. Without a steady fuel source, production grinds to a halt. This is where the idea of a "Virtual Pipeline" becomes a reality. By rotating a supply of portable CNG tanks, the plant gets a constant, uninterrupted flow of fuel. It’s almost as if it were hooked directly into the grid.

Fueling Operations Anywhere

The uses for mobile CNG go far beyond factories and industrial sites. We're seeing a lot of smart applications in the logistics and transportation sectors, too.

Imagine a large logistics company running a whole fleet of CNG-powered trucks. Instead of losing time and money sending each truck to a public station, they can bring the fuel to the fleet. They use a massive portable CNG unit—often called a "mother station"—to refuel every vehicle overnight, right in their own yard. The efficiency gains are enormous.

Here are a few other powerful examples of this in action:

- Critical Healthcare Support: A hospital’s backup generators are its lifeline during a major power outage. A portable CNG tank can be dispatched quickly to keep those generators supplied with clean fuel, ensuring that life-saving medical equipment never stops running.

- Remote Mining Operations: Think about the heavy machinery needed at a remote mining site. Mobile CNG offers a cleaner and often cheaper alternative to diesel, delivered directly to the location to power everything from excavators to processing equipment.

These scenarios reveal the true value of portable CNG. It’s not just a container for gas; it's a flexible, dynamic solution that closes critical energy gaps, allowing operations to continue without a hitch, no matter how remote or challenging the circumstances.

Of course, getting these high-pressure units to a site is a crucial piece of the puzzle. Understanding the logistics of specialized tank shipping services is essential for putting these tanks to work effectively and safely.

Powering a Growing Market

The sheer versatility of this technology is fueling some serious market growth. The global CNG market was valued at an impressive USD 147.6 billion in 2024, and experts project it will climb to USD 210.9 billion by 2031. Portable CNG tanks are a massive part of that expansion, especially in areas where permanent infrastructure is still being built out.

These examples really show how a portable CNG tank can be a targeted solution for specific operational headaches. Whether you’re trying to keep a factory running, a fleet moving, or a hospital powered, mobile CNG delivers energy precisely where it's needed most.

Safety Standards and Handling Best practices

Let’s be honest: when you're talking about gas stored at over 3,600 PSI, safety is the only thing that matters. It’s not just a bullet point on a sales sheet; it's the entire bedrock of portable CNG technology. These tanks are engineered from the ground up to be incredibly tough, built to handle the immense internal pressures and the demanding conditions of being moved and used on active job sites.

The first line of defense is the tank itself. We’re not talking about a simple metal container. These are sophisticated pressure vessels, often built from high-strength steel for maximum durability or from advanced, lightweight composite materials to make transportation easier without sacrificing an ounce of integrity.

Before any portable CNG system makes its way to a customer, it endures a gauntlet of rigorous tests. These aren't just suggestions—they are mandatory certifications required by regulatory bodies like the U.S. Department of Transportation (DOT) and the International Organization for Standardization (ISO). This exhaustive process guarantees that every unit is more than capable of handling its high-pressure contents safely.

Built-In Safeguards and Protections

Beyond sheer material strength, every portable CNG system is layered with built-in safety features. Think of them as automatic fail-safes, constantly working in the background to manage pressure and stop potential problems before they ever begin.

A critical piece of this puzzle is the pressure relief device (PRD). It’s essentially a smart safety valve. If for any reason the pressure inside the tank climbs beyond a predetermined safe limit, the PRD automatically opens and vents the excess gas in a controlled way, protecting the vessel's integrity.

From the thick walls of the tank to the final valve on the hose, the entire system is designed with redundancy. This layered approach to safety ensures that even in an unlikely event, the system is built to fail safely.

On-Site Handling and Best Practices

Once a portable CNG unit arrives at your location, sticking to clear handling procedures is key to a smooth, safe operation. Any good supplier will take care of this for you, but knowing the process helps you understand just how secure the technology really is.

Here’s a quick look at the standard on-site protocols:

- Site Preparation: The ground where the unit will sit needs to be level, stable, and well away from any potential ignition sources. A clear safety perimeter is always established around the equipment.

- Proper Connection: High-pressure hoses should only ever be connected or disconnected by trained technicians. They follow a strict, step-by-step procedure to create a secure, leak-free connection to your equipment.

- Routine Inspections: Throughout the job, technicians conduct regular visual checks on all the gauges, valves, and connections. This constant monitoring ensures everything is operating exactly as it should.

When you combine this intensely tested equipment with disciplined, professional handling, portable CNG stands out as a mature, reliable, and exceptionally safe energy solution for any remote or temporary need.

How to Get Your Hands on a Portable CNG Solution

So, you need a portable CNG tank for your project. The good news is, getting one is surprisingly straightforward. Unlike permanent natural gas infrastructure that can cost a fortune upfront, these mobile CNG solutions are almost always handled through rentals or service agreements. This keeps things flexible and frees up your cash for other parts of the job.

It all starts with a simple conversation about your needs. Any provider worth their salt will sit down with you to figure out two critical numbers: the total gas volume you'll need and the required flow rate. Getting the volume right ensures the tank is big enough for your daily or weekly burn, while nailing the flow rate guarantees it can keep up with the demands of your equipment, whether it's a massive industrial heater or a backup generator.

Choosing the Right Partner

Once you know what you need, it's time to find a supplier. This isn't just about finding the cheapest option—you're looking for a genuine partner who knows their stuff and won't let you down. The right company will have a solid reputation, years of real-world experience, and a non-negotiable commitment to safety.

When you're vetting potential suppliers, here’s what to zero in on:

- Safety Record: Don't be shy about asking for their safety procedures. How are their technicians trained? What does their equipment maintenance schedule look like? Safety should be their #1 priority, period.

- Service and Support: What happens if something goes wrong at 2 a.m.? You need a partner who offers 24/7 support to get you back up and running fast and minimize any operational headaches.

- Logistical Muscle: Can they actually get the tanks to your site? Ask them about their process for tank swaps or on-site refilling. You need a seamless, uninterrupted supply.

A good provider will make the quoting process totally transparent. You should get a clear, itemized quote that breaks down every single cost—delivery, setup, the gas itself—with absolutely no hidden fees.

Finally, think about the money side of things. Even though it's typically a rental, understanding the difference between equipment financing vs. leasing can help you frame the financial side of the agreement. By taking the time to map out your needs and properly vet your partners, you can source a portable CNG solution that keeps your project powered, safe, and right on schedule.

Your Top Questions About Portable CNG

When you're looking into a new energy source, the practical questions are always the first to pop up. Let's dig into the details of portable CNG systems to see what they can really do and how they stack up against other options.

One of the first things people ask is about capacity. So, how much gas can one of these skids actually hold? We measure this in Gasoline Gallon Equivalents (GGE), which makes it simple to compare with fuels you're already familiar with. A standard portable CNG unit holds between 450 to over 1,000 GGE, giving you a serious amount of on-site energy.

Getting It There and What Makes It Different

Logistics and safety are, of course, huge considerations. Moving high-pressure gas around isn't something you take lightly, and it's covered by strict rules for good reason. Every portable CNG tank has to meet Department of Transportation (DOT) regulations. These rules dictate everything from how the tank is built and tested to the way it's secured on a truck, ensuring every delivery is as safe as possible.

It's also really important to understand the difference between CNG and its cousin, LNG (Liquefied Natural Gas). They often get talked about in the same breath, but they're fundamentally different animals.

- CNG (Compressed Natural Gas): This is natural gas that stays in its gaseous state, just squeezed under very high pressure (around 3,600 PSI) at a normal, ambient temperature.

- LNG (Liquefied Natural Gas): This is natural gas that's been chilled to a frosty -260°F (-162°C) until it turns into a liquid. It's stored at a much lower pressure.

The real takeaway here is pressure versus temperature. For most temporary needs, a portable CNG tank is the simpler, more direct choice, letting you skip the complex equipment needed to handle super-cooled liquids.

This distinction is crucial. Because CNG is stored at normal temperatures, it's a much more straightforward "drop-and-go" solution for things like powering generators or providing temporary heat. LNG is more energy-dense, but it needs special equipment to turn it back into a gas, making it a better fit for huge, long-term operations. Knowing this helps you pick the right tool for the job.

Need a reliable, on-demand natural gas supply for your project? Blue Gas Express delivers portable CNG and LNG solutions directly to your site. Visit us online to learn more and keep your operations powered without interruption.