Pipeline corrosion protection is all about stopping metal pipes from breaking down. It’s a constant battle against nature, where the metal tries to revert to its original state through chemical reactions with its surroundings. We fight back with specialized coatings, clever electrical techniques like cathodic protection, and sometimes chemical inhibitors. The goal is simple: keep the pipeline safe, operational, and in the ground for as long as possible. Get it wrong, and you’re looking at catastrophic leaks, environmental messes, and massive service disruptions.

Why Pipeline Corrosion Is a Critical Threat

Don't think of pipeline corrosion as just another item on a maintenance checklist. It's a silent, relentless force chipping away at your assets' structural integrity, operational uptime, and safety record. At its heart, corrosion is just metal trying to return to its natural ore state—think of it as iron wanting to become rust again. This process is always happening, and it shows up in a few particularly nasty ways.

For anyone managing a project or building infrastructure, knowing the enemy is half the battle. You have to recognize the specific threats your pipeline is up against.

- Galvanic Corrosion: This is what happens when you have two different metals touching each other in a corrosive environment, like wet soil. One metal sacrifices itself (the anode) to protect the other (the cathode). A classic mistake is connecting a brass valve directly to a steel pipe without proper isolation; you’ve just created a battery that will chew through the steel.

- Pitting Corrosion: This one is especially insidious. It creates tiny, deep holes—or "pits"—in the metal. It can punch through a pipe wall surprisingly fast, even when the rest of the surface looks perfectly fine. That makes it incredibly difficult to spot before you have a leak.

- Crevice Corrosion: This menace thrives in tight, oxygen-starved spaces, like right under a gasket or where metal plates overlap. The stagnant environment creates an aggressive, localized corrosion cell that attacks the metal from within the crevice.

The Real-World Impact of Unchecked Corrosion

Letting corrosion run wild has consequences that ripple far beyond just the pipe itself. Picture a new housing development where crews are laying natural gas lines. A single, tiny scratch in the pipe's coating from being mishandled can become ground zero for corrosion. Within months, that "minor" flaw could turn into a pinhole leak, jeopardizing occupancy permits and throwing the entire project schedule into chaos.

This isn't just a problem for permanent infrastructure. Think about a temporary gas delivery system, like the mobile solutions from Blue Gas Express used to keep a construction site running through the winter. Even though those pipes are temporary, they're still exposed to moisture and temperature swings.

Corrosion doesn’t wait for a project to become permanent. Even short-term infrastructure requires a robust protection strategy to prevent leaks that could halt work, pose safety hazards, or damage expensive equipment.

Core Pillars of a Strong Defense

This is why a proactive strategy is non-negotiable. For anyone responsible for pipeline assets, a solid defense is built on two pillars that work in tandem:

- Protective Coatings: This is your first line of defense. A good coating acts as a physical barrier, isolating the pipe's metal surface from the corrosive soil or water around it.

- Cathodic Protection (CP): This is the backup. It's an electrochemical technique that essentially turns the entire pipeline into the protected side of a corrosion cell. If there's a nick or flaw in the coating, the CP system steps in to stop corrosion before it can start.

Treating these methods as essential investments—not just costs—is the right mindset. They are your insurance policy for reliability, safety, and operational continuity. Whether you're laying permanent pipelines or deploying temporary gas lines for a critical job, a well-designed pipelines corrosion protection system is the only way to guard against predictable and preventable failures.

Designing Your Protection and Prevention Strategy

Building a truly effective defense against corrosion isn’t about picking a product off a shelf; it’s about crafting a smart, layered strategy from the ground up. The plan for your pipelines corrosion protection has to be built around the real-world environment your asset will live in, day in and day out. This isn't just for massive, permanent infrastructure—the same logic applies to temporary gas delivery systems, too.

It all starts with a hands-on environmental risk assessment. You have to get granular. What’s the soil like? Are we talking high electrical resistivity, which is relatively benign, or is this pipeline going into a damp, low-resistivity swamp that will actively try to chew through steel? The answers you find here will drive every subsequent decision, from the materials you choose to the specific protection methods you deploy.

Choosing Your Primary Defense: Coatings

The first line of defense—and arguably the most important—is the external coating. Think of it as the pipeline's armor. It's the primary barrier standing between your steel and a corrosive environment. For this reason, locking in a partnership with reliable industrial coating suppliers is one of the most critical moves you'll make. The quality of your materials can make or break the entire project.

While there are many options out there, a couple of high-performance coatings have become the workhorses of the industry for a good reason.

- Fusion-Bonded Epoxy (FBE): This is a tough-as-nails thermosetting powder that’s applied to a heated pipe. It melts and fuses directly to the steel, creating a hard, incredibly durable, and corrosion-resistant layer. FBE is known for its phenomenal adhesion and its ability to shrug off chemical attacks.

- 3-Layer Polyethylene (3LPE): This system is the best of both worlds. It starts with an FBE primer for that tenacious bond to the steel, adds a copolymer adhesive in the middle, and finishes with a rugged outer layer of polyethylene for serious mechanical protection.

So, which one do you choose? It really boils down to the specific demands of your project. FBE often gets the nod for its fantastic performance at higher operating temperatures. On the other hand, 3LPE offers unmatched mechanical strength, making it the go-to for projects where the pipe might get knocked around during handling or buried in rocky terrain.

Comparing Primary Pipeline Coating Systems

To really wrap your head around the options, it helps to see them side-by-side. Each coating has a distinct personality, making it a better fit for certain jobs. This table breaks down the essentials to guide your selection process.

| Coating Type | Key Features | Best For | Main Advantage |

|---|---|---|---|

| Fusion-Bonded Epoxy (FBE) | Hard, thermoset polymer coating with excellent adhesion and chemical resistance. Applied as a single layer. | High-temperature applications and environments where chemical exposure is a concern. | Superior bonding to steel and high-temperature tolerance. |

| 3-Layer Polyethylene (3LPE) | Multi-layer system with FBE, adhesive, and a tough polyethylene topcoat. | Pipelines requiring high mechanical strength to resist damage during transport and installation. | Excellent mechanical durability and impact resistance. |

Getting this choice right from the start is fundamental to ensuring your pipeline's longevity.

Integrating Cathodic Protection as a Secondary Shield

Here’s a hard truth: no coating is perfect. Even with the most careful application, tiny defects, scratches, or "holidays" are almost inevitable during transport and installation. That’s where your second line of defense, cathodic protection (CP), comes into play. CP is a clever electrochemical technique that essentially turns the entire pipeline into the cathode of a battery, which stops the corrosion process cold wherever metal is exposed.

It’s a common mistake to think a great coating is enough. The reality is that coatings and cathodic protection are designed as a system. The coating does 99% of the heavy lifting, and the CP system stands guard over that last 1%.

This one-two punch is the industry standard for buried pipelines for a simple reason—it works. The coating drastically cuts down on the amount of electrical current the CP system has to deliver, making the whole strategy efficient and affordable over the pipeline's entire life.

The global reliance on these advanced coatings is massive. Consider that the Middle East and Africa represent a dominant 34.7% of the worldwide oil and gas corrosion protection market. Within this market, advanced coatings make up a 48.3% share. Digging deeper, fusion bonded epoxy coatings alone account for 39.6% of the pipe coatings market, valued for their proven ability to provide up to 25 years of corrosion resistance. This data, which you can explore further on market.us, really highlights how critical these choices are, especially in demanding offshore projects that drive 67.7% of all applications.

By meticulously assessing the environment, choosing the right high-performance coating, and integrating a complementary cathodic protection system, you build a powerful, multi-layered defense. This is how you ensure your pipeline—whether it's a permanent fixture or a temporary mobile gas unit—is ready to stand up to its environment for decades.

Implementing Cathodic Protection Systems

Once your pipeline has a solid coating, you might think the job is done. But that coating is just the first line of defense—a crucial one, but still just the primary shield. For true, long-term pipelines corrosion protection, you need an active defense system. This is where cathodic protection (CP) comes into play.

At its core, CP is a clever electrochemical trick. It manipulates the natural corrosion process by turning your entire pipeline into the protected side (the cathode) of an electrical circuit. This effectively stops rust in its tracks, especially at those tiny, inevitable flaws or "holidays" in the coating. It's not an optional add-on; it's a fundamental part of modern pipeline integrity management.

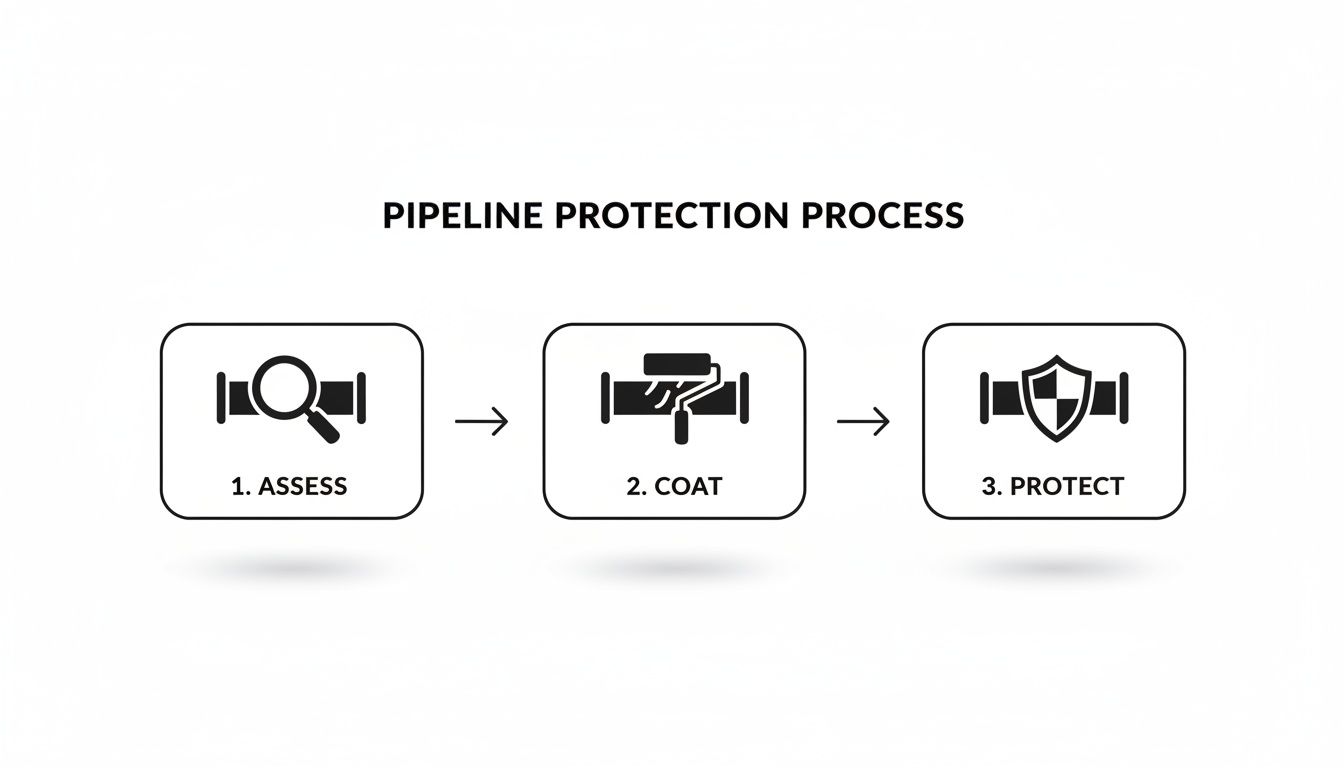

The process boils down to a few key stages: assessing the risk, applying the right coating, and then energizing the whole system with cathodic protection.

This simple flow shows how CP is the final, critical step that makes the whole protective strategy work, safeguarding the initial investments you made in assessment and coating.

Sacrificial Anode Systems for Targeted Protection

For smaller, shorter, or electrically isolated pipelines, a sacrificial anode cathodic protection (SACP) system is often the most practical and cost-effective solution. The concept is beautifully simple: you bury blocks of a more reactive metal—usually zinc or magnesium—and connect them directly to your steel pipeline.

Because these "anodes" have a more negative electrochemical potential than steel, they corrode first, "sacrificing" themselves to protect the pipeline. Think of it as a bodyguard taking a bullet for the asset it's protecting.

- Anode Placement: The trick is putting them in the right spots. Anodes are typically buried in clusters or "beds" at carefully calculated intervals. The exact spacing depends on factors like soil resistivity, coating quality, and the pipe’s diameter.

- Calculating Requirements: Engineers do the math to figure out the number and size of anodes needed based on the pipeline's total surface area and how corrosive the local soil is. The goal is to provide enough protective current to last for the intended design life, which is often 20 years or more.

A classic real-world scenario is protecting a short section of new pipe under a road crossing. In a case like that, a few strategically placed magnesium anodes can provide decades of reliable protection with almost no maintenance. It's an ideal "set it and forget it" solution.

Impressed Current Systems for Large Networks

When you're dealing with vast, complex pipeline networks, sacrificial anodes just can't pack enough punch. There's a limit to how much protective current they can naturally generate. This is where an impressed current cathodic protection (ICCP) system comes in.

Instead of relying on the natural voltage difference between two metals, an ICCP system uses an external power source—like a rectifier—to "impress" a direct current onto the pipeline. This current flows from a bed of long-lasting anodes (made from robust materials like high-silicon cast iron or mixed metal oxide) through the soil and onto the pipeline surface. The result is a powerful, controllable, and far-reaching protective shield.

This technology is the backbone of modern infrastructure. With North America's pipeline network stretching over 2.6 million miles, it's a leader in the global cathodic protection market. When designed and maintained correctly, these systems can prevent up to 95% of corrosion failures and extend a pipeline's life by 20-30 years.

Verification Through Test Stations

So, how do you know if your expensive CP system is actually working? You can't just bury it and cross your fingers. That's why test stations are an absolutely critical part of any cathodic protection design.

These are simple, accessible points installed along the pipeline route that allow technicians to take vital electrical measurements. By connecting a voltmeter to the leads in the test station, an engineer can measure the pipe-to-soil potential. This reading is the ultimate proof of whether the pipeline is receiving enough current to halt corrosion.

Regular monitoring at these stations isn't just a good idea—it's a non-negotiable part of maintaining the system and meeting regulatory compliance. Without them, you're just flying blind, and your multi-million dollar asset is completely at risk.

A Look Inside: Using Corrosion Inhibitors for Internal Protection

So far, we've been talking about protecting pipelines from the outside. But what about corrosion that starts from within? External coatings and cathodic protection are powerless against the corrosive elements that can be present in the product stream itself. That's where a different strategy comes into play: corrosion inhibitors.

These are highly specialized chemicals that we inject directly into the gas or liquid flowing through the pipe. They work by creating an incredibly thin, protective film on the internal steel surface. It’s like a liquid-applied coating that constantly replenishes itself, creating a durable barrier between the pipe wall and corrosive agents like water, carbon dioxide (CO2), or hydrogen sulfide (H2S). This is your frontline defense for maintaining the pipe's integrity from the inside out.

Choosing the Right Inhibitor for the Job

You can't just pick any inhibitor off the shelf. They're formulated to combat specific threats, and choosing the right one is critical. The chemical composition of the product being transported, especially in natural gas pipelines, is the deciding factor.

You'll most commonly run into two main types:

- Film-Forming Inhibitors: These are the real workhorses of internal protection. Their molecules have a natural attraction to the steel surface, where they line up to form a tight, non-reactive film. This thin layer physically blocks corrosive elements in the gas stream from ever touching the metal.

- Oxygen Scavengers: Just like the name implies, these chemicals are designed to hunt down and neutralize any dissolved oxygen in the product. Oxygen is a major corrosion accelerant, so even trace amounts can lead to serious pitting. Scavengers chemically bond with the oxygen molecules before they get a chance to attack the pipe wall.

The selection process always starts with a detailed analysis of the product stream. For instance, a pipeline carrying gas with a high concentration of wet CO2 would almost certainly require a heavy-duty film-former. On the other hand, if you're dealing with a system prone to oxygen getting in, an oxygen scavenger becomes the priority.

A classic mistake I've seen is assuming a pipeline carrying "dry" natural gas is safe from internal corrosion. Big pressure and temperature drops along the line can easily cause water to condense from the gas, creating a localized, highly corrosive environment right where you least expect it.

Don't Let Corrosion Start in the Pipe Yard

Corrosion doesn’t politely wait for a pipeline to go into service. A brand-new pipe segment sitting in a storage yard or at a construction site is a sitting duck for atmospheric corrosion. A little rain, morning dew, or high humidity is all it takes to start the rusting process.

This is the perfect application for vapor corrosion inhibitors (VCIs). These compounds are fantastic for temporary protection. You can apply them as an internal spray, or even just place VCI-emitting pouches inside the pipe and cap the ends. They work by releasing a vapor that completely fills the pipe's interior and forms a protective molecular layer on every exposed steel surface.

Taking this simple step is a crucial part of a pipeline’s lifecycle management. It guarantees the asset you’re putting in the ground is in perfect condition, without any pre-existing surface rust that could undermine your long-term protection systems later on.

Protection for Mobile and Temporary Gas Systems

The need for internal corrosion control isn't just for massive, cross-country pipelines. It's just as important for temporary systems, like the mobile CNG and LNG units provided by companies like Blue Gas Express for utility outages or large construction projects.

These mobile systems have their own unique corrosion challenges. They're constantly being filled, moved, and depressurized, which creates opportunities for moist air to get inside.

Inhibitors are a key tool for managing these risks:

- Protecting Stored Equipment: When a mobile unit is between jobs, VCIs are perfect for protecting the internals of tanks, pipes, and regulators from just sitting and rusting.

- Managing Operational Risks: If a temporary gas source is known to have a higher-than-usual moisture content, the right inhibitor can be added during operation to keep the system's components safe and reliable.

This kind of proactive thinking is what ensures temporary gas delivery systems operate dependably. It prevents the kind of equipment breakdown that could lead to dangerous leaks or service interruptions. Whether it's a permanent pipeline or a temporary mobile rig, protecting it from the inside out is just good, fundamental asset management.

Monitoring and Long-Term Maintenance Planning

Putting coatings and cathodic protection in place is a huge milestone, but it's really just the beginning. The costliest mistake any asset manager can make is adopting a "set it and forget it" mindset. Truly effective pipelines corrosion protection is a living process, one that requires constant vigilance through a well-structured monitoring and maintenance program.

This isn’t just about ticking boxes. It’s about making sure your initial investment keeps paying dividends by catching small, fixable issues before they snowball into catastrophic failures. A good plan keeps your pipeline’s integrity intact, ensures you stay on the right side of regulations, and drastically cuts the risk of an unexpected shutdown.

The industry is catching on. As infrastructure ages globally, the market for cathodic protection is on track to hit USD 9.48 billion by 2033. This isn't surprising when you consider that solid corrosion management can slash pipeline maintenance costs by up to 40%. The numbers don't lie—unprotected pipelines simply fail three to five times more often. You can discover more about these market trends from Precedence Research.

Modern Inspection Tools and Techniques

The days of relying only on a quick visual check are long gone. Today, we have an impressive arsenal of inspection technologies that give us a clear picture of what’s happening both inside and outside the pipe.

One of the workhorses of the industry is the In-Line Inspection (ILI) tool, better known as a "smart pig." This piece of sophisticated tech travels right through the pipeline, pushed along by the product flow. As it moves, it uses sensors like magnetic flux leakage (MFL) or ultrasonic testers to find and measure metal loss, cracks, and other problems with incredible accuracy.

We also lean heavily on direct assessment methods, which give us critical data without having to run a tool inside the pipe. A great example is a Close Interval Survey (CIS), where a technician literally walks the pipeline route, taking pipe-to-soil potential readings every few feet. This gives you a detailed, granular profile of how well your cathodic protection system is performing.

By layering the data from smart pigs with insights from direct assessments, engineers create a comprehensive health record for the pipeline. This data-first approach lets you pinpoint trouble spots with surgical precision, long before they become a real threat.

The Shift to Proactive and Predictive Maintenance

The real game-changer lately has been the explosion of remote monitoring technology. Getting data in real-time is fundamentally reshaping how we approach pipeline maintenance.

We can now install IoT sensors and Remote Monitoring Units (RMUs) at key locations, like rectifiers and test stations. These devices constantly stream performance data—current output, pipe-to-soil potentials—back to a central dashboard. Instead of waiting for a field tech to do a quarterly check, you have a 24/7 view of your system's health.

This constant flow of information is what allows us to graduate from reactive or even proactive maintenance to a truly predictive model.

- Reactive Maintenance: "Something broke, go fix it." This is the most expensive and dangerous way to operate, almost always involving emergency repairs after a failure.

- Proactive Maintenance: "We inspect the system every six months and make scheduled repairs." A huge improvement, as regular check-ups prevent a lot of failures.

- Predictive Maintenance: "The data shows a downward trend in CP current in sector 7B, predicting a potential issue within the next 90 days. Let's schedule a non-emergency inspection." This is the goal. This is where you want to be.

Building a Sustainable Long-Term Plan

A sustainable maintenance plan is all about turning this firehose of data into a clear, actionable roadmap. It starts with pulling information from all your sources—ILI runs, direct assessments, remote sensors—into a unified asset management system.

This integrated view helps you prioritize maintenance based on actual risk. A tiny coating flaw on a low-pressure line in the middle of nowhere is a much lower priority than a similar flaw on a high-pressure gas main running through a suburb. This risk-based inspection (RBI) approach ensures you focus your time, budget, and people where they’ll have the biggest impact on safety and reliability.

By establishing this data-driven cycle of inspection, analysis, and targeted maintenance, you build a powerful framework for long-term pipeline integrity. This is how you guarantee your pipelines corrosion protection strategy works for the entire life of the asset, protecting your investment, the public, and the environment.

Common Questions About Pipeline Corrosion Protection

Even with a solid plan in place, a few questions always pop up when you're in the thick of designing or maintaining a pipeline corrosion protection program. I’ve seen project managers, engineers, and facility operators all run into the same real-world hurdles. Here are some straightforward answers to the questions I hear most often out in the field.

What’s the Most Effective Method for Pipeline Corrosion Protection?

There’s no magic bullet. The best approach is almost always a combination of different strategies working together. When we're talking about buried steel pipelines, the gold standard is a dual system that gives you two solid layers of defense.

It all starts with a high-performance external coating, like a Fusion-Bonded Epoxy (FBE). Think of this as the pipeline's primary shield, doing the heavy lifting to keep corrosive elements away from the steel. But no coating is perfect. That's why we always back it up with a cathodic protection (CP) system. The CP system actively protects any small spots where the coating might have gotten nicked or damaged, stopping corrosion cold before it can even get a foothold.

For what's happening on the inside, especially if you're moving product with corrosive stuff like water or H2S, corrosion inhibitors are your go-to. The right mix of these methods really boils down to your pipeline’s material, the soil and environment it’s in, and what you’re sending through it.

How Often Should We Be Inspecting Our Pipelines for Corrosion?

This isn't something you can just set on a generic calendar. How often you inspect is driven by a mix of government regulations, how old the pipeline is, what your risk assessment told you, and its operating environment. Naturally, lines in high-consequence areas—think near towns or sensitive wetlands—demand much more frequent and thorough inspections.

A typical schedule often looks something like this:

- Annual cathodic protection surveys to make sure the system is still pushing out enough protective current.

- In-line inspections (ILI) using "smart pigs" roughly every 7-10 years to get a detailed look at the internal pipe wall.

But the industry is moving towards a smarter, data-driven approach called risk-based inspection (RBI). This lets you focus your time, money, and resources on the specific pipeline segments that pose the highest risk. It’s about optimizing for both safety and cost.

Sticking to a rigid, calendar-based schedule is an old-school way of thinking. A risk-based program means you’re looking in the right places at the right times, guided by hard data, not just the flip of a calendar page.

Can New Technologies Actually Improve Corrosion Monitoring?

Absolutely, and it's a game-changer. Technology is making our monitoring far more precise and proactive than ever before. IoT sensors and Remote Monitoring Units (RMUs) are a huge leap forward, letting us track the performance of a cathodic protection system in real-time, from anywhere.

These systems can send an instant alert if the protective current drops, which often means you don't have to send a technician on a long drive to a remote site just for a routine check. All that constant data can then be fed into analytics platforms that predict problems before they happen. By analyzing trends from sensors and past inspections, these models can flag which parts of your pipeline are most likely to corrode, so you can get ahead of it with proactive maintenance.

What Happens If a Pipeline Coating Is Damaged During Installation?

Let’s be realistic—minor coating damage during handling and installation is going to happen. It's practically unavoidable, and that’s precisely why cathodic protection is so critical. Before any pipe goes into the ground, technicians will run a "holiday detection" test. This involves using a special electronic device that can find even pinhole-sized flaws in the coating.

Any dings or scrapes found during this check are carefully repaired right there on-site with approved patch kits. After the pipeline is backfilled, the cathodic protection system takes over. It sends a protective current that zeroes in on these tiny, unavoidable flaws, preventing the electrochemical process of corrosion from ever kicking off on the exposed steel.

At Blue Gas Express, we understand just how crucial it is to maintain asset integrity, even for temporary systems. Our mobile natural gas solutions are built with safety and reliability as the top priority, ensuring your projects keep moving without a hitch. If you're dealing with delays or outages, take a look at our temporary gas delivery services.