If you're running a fleet in construction, logistics, or utilities, you're always looking for an edge—a way to trim fuel costs and hit those sustainability targets. That's where natural gas vehicles (NGVs) come into the picture, and with them, a new kind of fueling station.

NGV gas stations are purpose-built facilities for refueling vehicles with either Compressed Natural Gas (CNG) or Liquefied Natural Gas (LNG). Getting a handle on how they work is a huge strategic advantage.

Decoding the World of NGV Fueling Infrastructure

Switching to natural gas isn't just about swapping out diesel for something cleaner; it's about rethinking your entire fueling strategy. Natural gas needs to be handled, stored, and pumped very differently than traditional fuels, so an NGV station is a far cry from the corner gas station we all know. For any fleet manager, understanding the nuts and bolts of this infrastructure is the first real step toward a smart, profitable transition.

Why make the change? Two big reasons: money and emissions. Natural gas is typically cheaper and its price is far more stable than diesel, which means you can actually predict your fuel budget. It also burns much cleaner, helping you stay ahead of tightening emissions regulations and meet your own green goals.

Why Fleet Managers Must Understand NGV Stations

When you know the ins and outs of NGV fueling, you can make decisions that perfectly match your fleet's daily grind. The right setup for a local delivery fleet that returns to a depot every night is completely different from what a long-haul trucking operation needs.

It all starts with one fundamental choice between the two forms of natural gas:

- Compressed Natural Gas (CNG): This is the go-to for vehicles that stick to a local or regional route. Think delivery vans, waste-hauling trucks, or city buses that can head back to a central yard to refuel overnight.

- Liquefied Natural Gas (LNG): Best for the big rigs. LNG offers the energy density and long range that heavy-duty, long-haul trucks need to compete with diesel.

The choice between CNG and LNG is the cornerstone of your entire NGV strategy. It dictates everything from station design and vehicle choice to the overall cost of the project.

Once you’ve settled on the type of gas, you can explore different station setups. Are you building a permanent station for a large, established fleet? That’s a major long-term investment. Or do you need flexibility for a temporary project, like a remote construction site or to provide fuel during a pipeline outage? That’s where mobile fueling solutions shine.

This guide will walk you through all these options, giving you the clarity to pick the right path for your fleet.

Decoding CNG and LNG Fueling Stations

When you start looking into natural gas for your fleet, you’ll quickly run into two acronyms: CNG and LNG. While they both come from the same raw material, how they're processed and stored makes them completely different fuels. Getting this distinction right is the first, most critical step in choosing the right kind of fueling station for your operation.

The two main players are Compressed Natural Gas (CNG) and Liquefied Natural Gas (LNG). The one you choose will have a massive impact on your station's design, its cost, and how you'll manage your daily fueling.

Compressed Natural Gas: The High-Pressure Workhorse

Think of CNG like the air in a scuba tank. We take natural gas straight from a pipeline, clean it up, and then compress it to an incredibly high pressure—usually between 3,000 and 3,600 pounds per square inch (psi). Critically, it stays a gas the entire time, just squeezed into a much smaller space. It’s then stored in super-strong, durable cylinders on the vehicle.

Because it remains a gas, CNG naturally takes up more physical space than a liquid fuel with the same amount of energy. This isn't a problem for vehicles that stick to predictable, shorter routes and head back to a central yard every night to refuel.

You'll see CNG fleets everywhere in these kinds of jobs:

- Municipal Buses: Running the same routes day in and day out, always returning to the depot.

- Waste Management Trucks: Perfect for consistent, neighborhood-based collection routes.

- Local Delivery Vans: Ideal for last-mile logistics where trucks stay within a defined city or region.

Liquefied Natural Gas: The Dense Long-Haul Solution

LNG is a completely different beast. Instead of compressing the gas, we do the opposite of boiling water: we chill it down to a frosty -260°F (-162°C). At that ridiculously cold temperature, the natural gas condenses and turns into a clear, non-toxic liquid.

The best way to picture it is turning an entire room full of steam back into a single cup of water. This process makes LNG incredibly dense, packing about 600 times more energy into the same amount of space compared to its gaseous form. That energy density is LNG's superpower, giving heavy-duty trucks a range that can truly compete with diesel.

For long-haul trucking and other heavy-duty jobs where range is everything, LNG is almost always the better fit. Its density means you can store far more fuel on board, wiping out the range anxiety that comes with cross-country trips.

This is why you see LNG as the go-to for Class 8 trucks that have to cover hundreds of miles between stops. The fueling process is also much quicker, feeling a lot more like a typical diesel fill-up.

CNG vs LNG Fueling Stations At a Glance

So, how do these differences play out at the pump? This table breaks down the key characteristics of CNG and LNG stations to help you zero in on the right technology for your fleet's unique demands.

| Feature | CNG Stations | LNG Stations |

|---|---|---|

| Fuel State | Gaseous (compressed to 3,000-3,600 psi) | Liquid (super-cooled to -260°F) |

| Energy Density | Lower—requires larger, heavier tanks for the same range. | High—packs 600x more energy by volume, enabling diesel-like range. |

| Ideal Use Case | Return-to-base fleets: transit buses, refuse trucks, local delivery. | Long-haul trucking, marine, and other high-horsepower applications needing maximum range. |

| Station Cost | Generally lower upfront cost, especially for time-fill configurations. | Higher initial investment due to cryogenic storage tanks and specialized dispensing equipment. |

| Fueling Time | Varies. 5-10 minutes for fast-fill; several hours for overnight time-fill. | Fast. Typically comparable to diesel fueling times, around 8-12 minutes. |

| Infrastructure | Requires access to a natural gas pipeline and powerful compressors. | Doesn't need a pipeline; fuel is delivered by cryogenic tanker trucks. |

| On-Vehicle Tank | Heavy, high-pressure cylinders. | Lighter, insulated cryogenic tanks (thermos-like). |

Ultimately, the choice isn't about which fuel is "better," but which fuel system is better for you. CNG is a workhorse for predictable routes, while LNG is the undisputed champion for long-distance hauling.

Different Fueling Station Types

The physical differences between CNG and LNG naturally lead to a few different types of fueling stations, each built for a specific operational rhythm.

Fast-Fill Stations (Primarily CNG)

A fast-fill station is exactly what it sounds like—it’s the NGV world’s version of a standard gas station. It uses a large "cascade" of storage tanks to blast high-pressure CNG into a vehicle in just 5 to 10 minutes. This is the setup you'd want for a public station or for a private fleet that can't afford to have vehicles sitting idle for hours.

Time-Fill Stations (CNG)

Time-fill stations are the opposite. They’re designed for fleets that have the luxury of refueling overnight. Vehicles park and connect to simple fueling posts, and the tanks are filled slowly over several hours at a lower, more consistent pressure. This approach is much more energy-efficient and easier on the equipment, making it a fantastic, cost-effective choice for fleets like school buses or utility trucks.

Mobile and Temporary Stations (CNG & LNG)

What if your project is temporary or in a location with no pipeline? That’s where mobile fueling comes in. These self-contained units, like the ones provided by Blue Gas Express, act as an on-demand NGV gas station. We can deploy them rapidly to remote construction sites, disaster response zones, or anywhere a permanent fuel supply is impossible or delayed. It’s all about bringing the fuel directly to you, so your operation never misses a beat.

Getting Your Station Sited and Permitted

Putting in permanent NGV gas stations is a lot more involved than just pouring a concrete slab and setting up some dispensers. It's a challenging process that really comes down to three key things: picking the right spot, wrestling with a mountain of permits, and building safety into every single part of the design. If you get these right from day one, you're set for a smooth launch. If not, you're looking at a project mired in expensive delays and regulatory nightmares.

Think of it like building a house. If you don't plan carefully and stick to the blueprints, the whole thing could come crashing down. For an NGV station, that foundation is built on smart site selection, persistent permitting work, and an absolute commitment to safety.

Choosing the Right Site

You know the old saying in real estate—location, location, location. Well, it’s doubly true for NGV fueling infrastructure. A poorly chosen site can absolutely hamstring your operations, no matter how great the station itself is. The trick is finding a location that perfectly balances your logistical needs with what the regulators will actually allow.

Here's what you need to be thinking about:

- Fleet Accessibility: Your trucks have to get in and out easily and safely. That means you need to consider turn radiuses, local traffic flow, and how close the site is to the main highways your fleet travels every day.

- Pipeline Proximity (for CNG): If you're building a CNG station, being right next to a high-pressure natural gas pipeline is a huge win. It drastically cuts down on the cost and headache of getting your fuel supply connected.

- Zoning and Land Use: Not all land is created equal. You’ve got to dive into the local architectural zoning regulations, which control what you can build and where. A parcel zoned for industrial use is a much easier sell than one earmarked for retail or, worse, residential.

Get in touch with the local planning department as early as you can. They’re the ones with the maps and information you need to find a good spot before you sink too much time and money into it.

Demystifying the Permitting Maze

Once you’ve zeroed in on a potential site, the real paperwork begins. The permitting process is almost always the longest part of developing NGV gas stations. It requires an incredible amount of detail and constant back-and-forth with different agencies. Trying to rush this step is a classic mistake.

The main group you'll be dealing with is the local Authority Having Jurisdiction (AHJ). This could be anyone from the city fire marshal to a county building inspector. The AHJ’s job is to make sure every part of your station plan meets all the required codes and standards.

The rulebook for NGV stations in the U.S. is NFPA 52, the Vehicular Gaseous Fuel Systems Code. This is the definitive guide for everything—from where you can place equipment and how to wire it, to ventilation requirements and emergency shutdown systems.

Talking to your AHJ early and often is the single best thing you can do. Don’t see them as a roadblock; treat them like a partner. When you walk in with a solid plan that shows you've done your homework and are following NFPA 52, you build trust and make the whole approval process go a lot faster.

Putting Operational Safety First

Safety isn't just about checking a box for the regulators. It's the absolute bedrock of a well-run NGV fueling station. You’re dealing with the high pressures of CNG and the extreme cold of LNG, so tough safety measures are simply not optional. This goes way beyond the construction phase and into the nitty-gritty of daily work.

A truly solid safety plan has multiple layers of protection:

- Engineered Safeguards: This starts with the physical station design. Things like methane detectors, thermal relief devices, breakaway hoses, and big red Emergency Shut-Down (ESD) buttons are your first line of defense.

- Procedural Protocols: You need clear, written instructions for everything—routine fueling, maintenance checks, and what to do when things go wrong. Every person on site should know their role inside and out, whether it’s for a tiny leak or a major emergency.

- Personnel Training: All the best equipment and procedures in the world don’t mean a thing if your people aren't trained properly. Everyone needs thorough training on the properties of natural gas, how the station works, and all your emergency plans. And it’s not a one-and-done deal; this training needs to be documented and refreshed regularly to keep everyone sharp.

The Global Boom in NGV Fueling Stations

Let's face it: switching a fleet to natural gas vehicles can feel like a leap of faith. The number one question I hear from fleet managers is, "Is the fueling infrastructure really there?" It's a fair question, but the answer is a resounding yes. The network of NGV gas stations isn't some niche experiment; it's a mature, established, and rapidly growing global reality.

Looking at what's happening internationally gives you a real sense of where things are headed. Countries all over the world have already built out massive NGV fueling networks, proving the model is not just possible, but scalable and incredibly effective. This growth isn't happening on a whim—it's a direct response to the powerful economic and environmental pull of natural gas, especially for heavy-duty commercial fleets. The infrastructure is racing to keep up with demand, creating a stable and reliable ecosystem for operators.

China: A Real-World Blueprint for NGV Scale

If you want to see the true potential of NGV infrastructure, look no further than China. They are, without a doubt, the world leader in NGV gas stations, with the highest density of both CNG and LNG fueling points on the planet. This wasn't an accident. It was a deliberate strategy to power their massive fleets of natural gas trucks and buses, slashing urban pollution and cutting their dependence on diesel.

In the last few years alone, sales of LNG trucks in China have exploded, kicking off a parallel boom in refueling stations along major freight routes. While the exact numbers are always shifting, China’s network is estimated in the tens of thousands. To put that in perspective, Europe currently has around 750 LNG stations for 30,000 trucks, while the U.S. has just 50 stations serving 25,000 trucks. You can dive deeper into this global NGV landscape and its growth drivers.

China's success provides a clear blueprint. It shows that with targeted investment and supportive policy, it's entirely possible to build a comprehensive network that makes running an NGV fleet just as practical as a diesel one.

Building Smart: The Rise of Fueling Corridors

While no one is matching China's sheer scale just yet, North America and Europe are smartly tackling range anxiety for long-haul trucking by developing strategic "fueling corridors." The concept is simple and incredibly effective: instead of trying to put a station on every corner, developers are focusing on placing NGV gas stations at predictable intervals along major highways and transport routes.

Think of it like a string of pearls laid across a highway map. Each station is a pearl, spaced just right so a long-haul truck can travel coast-to-coast without ever sweating about its next fill-up.

This strategic placement means fleets can map out cross-country journeys with the same confidence they have with diesel. Major logistics players are investing heavily in these corridors, not just for their own trucks but as public fueling hubs, which in turn strengthens the entire network for everyone.

What This Global Growth Means for Your Fleet

This worldwide expansion of NGV fueling isn't just an interesting trend; it has real, on-the-ground implications for any fleet manager weighing the switch.

- Your Investment is Secure: A growing global infrastructure proves you're not betting on a fad. You’re adopting a mature energy solution with long-term viability.

- Range Anxiety is Fading: As fueling corridors get built out, the old operational limits of NGVs are vanishing. This makes them a rock-solid choice for regional and even long-haul routes.

- The Technology is Proven: The success stories from around the world mean there’s a ton of data and best practices to draw from. New NGV gas stations are being built with time-tested, reliable technology.

At the end of the day, the global growth in NGV infrastructure sends a clear message: this is a dependable, cost-effective, and cleaner fuel solution that's here for the long haul. It’s a solid foundation you can build the future of your fleet on.

Permanent Stations Versus Mobile Fueling Solutions

Choosing how to fuel your NGV fleet feels like a major fork in the road. Do you build a permanent, fixed station, or go with a flexible, mobile fueling solution? There's no single right answer here—the best choice really comes down to your fleet's specific mission, timeline, and the day-to-day rhythm of your operations.

Ultimately, this decision is a classic trade-off: long-term stability versus short-term agility. Let's break down the practical scenarios where each one shines to help you figure out which path makes the most sense for your business.

Permanent NGV Gas Stations: The Long-Term Workhorse

A permanent NGV gas station is a serious capital investment built for the long haul. Think of it like building a custom home designed specifically for your fleet’s energy needs. It’s the perfect solution for large, centralized fleets that run on predictable schedules and return to a home base every single day.

This model is a fantastic fit for operations like:

- Municipal Bus Depots: Where dozens, or even hundreds, of buses follow the same routes and come back to the same yard for overnight refueling.

- Waste Management Fleets: Whose collection trucks serve a defined territory and can easily use a time-fill system overnight.

- Large Logistics Hubs: Where a company's private fleet of regional delivery trucks can refuel efficiently at an on-site station.

Building a permanent station means you get total control over your fuel supply, often at the lowest possible cost per gallon equivalent over the long run. The catch? This path requires a long lead time for siting, permitting, and construction, often taking many months or even years to get up and running.

Mobile Fueling Solutions: The On-Demand Specialist

Mobile fueling solutions, like the ones we provide at Blue Gas Express, are the special forces of the NGV world. They bring unmatched flexibility, speed, and precision, delivering fuel exactly where it’s needed, right when it's needed. Instead of building a house, you’re bringing in a high-tech, fully equipped mobile command center.

This "fuel-on-demand" approach is the clear winner for situations that are temporary, urgent, or in geographically tough spots.

Mobile fueling bridges the gap when permanent infrastructure is impractical, impossible, or just too slow. It keeps you operational by deploying a complete NGV gas station in a matter of hours, not months.

Think about these real-world scenarios where mobile fueling is the only practical choice:

- Temporary Construction Sites: Perfect for powering heavy equipment or vehicles on a project that will only last a few months.

- Disaster Recovery Operations: When natural disasters knock out utility pipelines, mobile units can provide essential gas service to critical facilities like hospitals and shelters.

- Pipeline Integrity Projects: Gas utilities use mobile solutions to keep customers online during planned maintenance, preventing service interruptions.

- Commissioning New Equipment: Before permanent gas lines are live, mobile units can fuel generators or industrial equipment for critical testing.

This kind of agility is a game-changer for projects where speed is everything and a permanent station just doesn't make financial or logistical sense. The global market for NGV gas stations is booming, with projections showing a jump from USD 5 billion to USD 9 billion by 2033. Much of this growth is fueled by innovations like mobile units that erase range anxiety and make NGV fleets viable for more operators. You can read more about the expanding NGV fueling station market for a deeper dive.

Head-to-Head Comparison: Which Is Right for You?

Making the right call means taking a clear-eyed look at the trade-offs. You have to weigh the initial investment against your need for scalability and speed.

| Factor | Permanent NGV Station | Mobile Fueling Solution |

|---|---|---|

| Capital Investment | High. Requires a significant upfront spend on land, equipment, and construction. | Low. Operates as a service-based expense, so you avoid the major capital hit. |

| Deployment Speed | Slow. The entire process can take 6 months to 2+ years with permitting and construction. | Fast. Can be on-site and fully operational within hours or days, not months. |

| Flexibility | Low. It's a fixed asset, permanently tied to one location. | High. You can move it from site to site as your projects and needs change. |

| Best For | Stable, long-term, high-volume operations with predictable routes and schedules. | Temporary projects, emergency response, and bridging gaps in infrastructure. |

How to Plan a Temporary NGV Fueling Project

When your project runs on natural gas but the nearest pipeline is miles away—or months from completion—a temporary fueling setup is your lifeline. Pulling off a successful deployment isn't about crossing your fingers; it's about having a solid, step-by-step game plan. This playbook walks you through the critical stages to get your temporary NGV fueling online safely and keep your operation humming.

The real work starts long before a truck ever shows up on site. It all begins with a deep dive into what you actually need, which is the single best way to avoid the costly mistake of ordering too much or too little fuel.

Step 1: Define Your Fueling Requirements

The first, and most critical, question is simple: what does your operation really need? You have to get more specific than just "we need natural gas." Getting the details right from the start is what allows a provider to engineer a solution that truly fits your project.

Be ready to answer these key questions:

- Fuel Volume: How many standard cubic feet (SCF) or gasoline gallon equivalents (GGEs) do you burn through in a day? A single shift? Get as precise as you can.

- Pressure Requirements: What delivery pressure, in pounds per square inch (psi), does your equipment demand to run efficiently?

- Flow Rate: How fast does the gas need to move? This little detail dictates the size of the hoses, regulators, and other critical hardware.

- Project Duration: Are we talking days, weeks, or months? The timeline shapes everything from logistics to the terms of your agreement.

Step 2: Select Your Provider and Analyze the Site

Once you have your numbers dialed in, it’s time to find a reliable mobile fueling partner. You want to look for a company with a proven track record, especially in your industry and region—like Blue Gas Express—and one that puts safety above all else. After you've chosen a provider, a joint site safety analysis isn't just a good idea; it's non-negotiable.

This involves walking the proposed location together to pinpoint a safe, level, and accessible spot for the mobile fueling unit. You'll map out truck routes, establish a secure perimeter, and identify any potential hazards like overhead power lines or buried utilities.

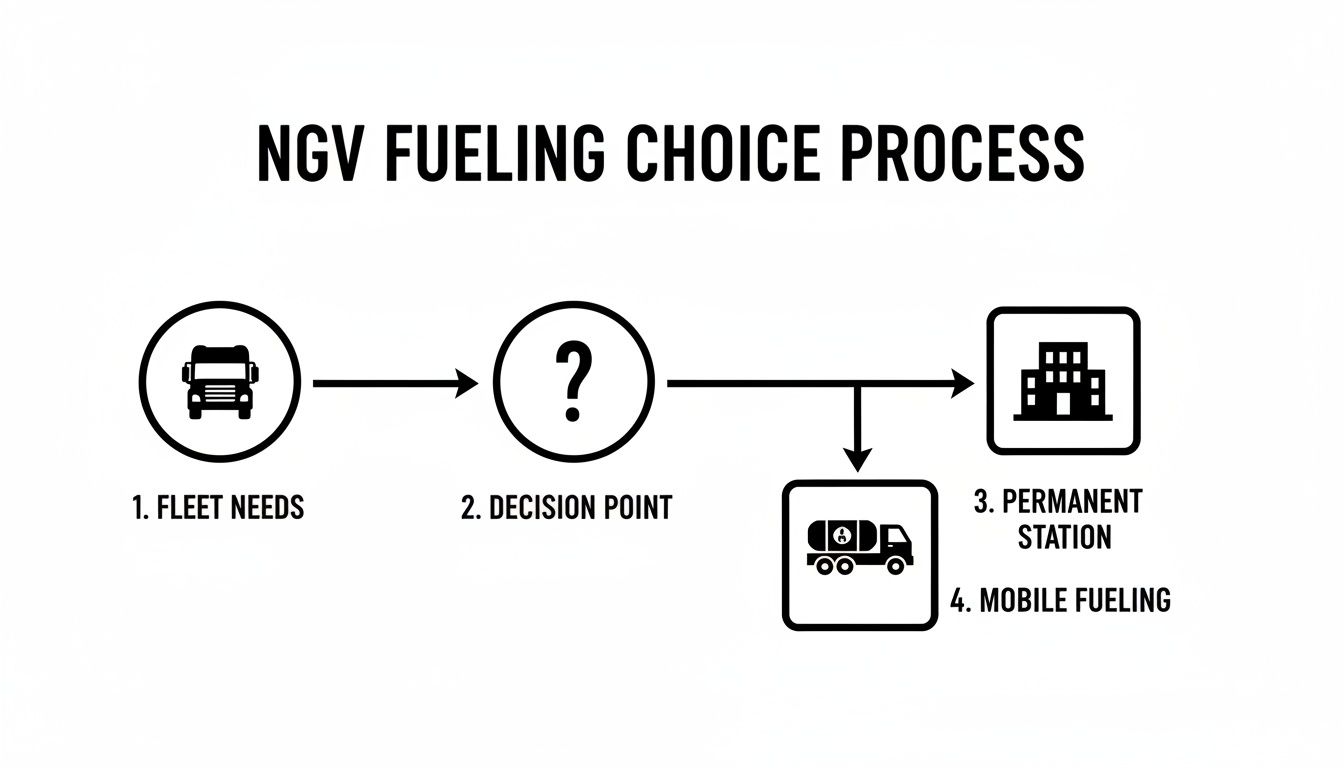

This flowchart illustrates the decision-making process, from identifying fleet needs to choosing between a permanent or mobile solution.

As the chart shows, when you need fuel now or require flexibility, mobile solutions provide a direct path to keeping the work going without interruption.

Step 3: Coordinate Logistics and Permitting

The final piece of the puzzle is all about execution. While your provider will manage the heavy lifting of delivering and setting up the equipment, clear and constant communication is what makes it all work. You’ll need to coordinate delivery windows, confirm the site is prepped and ready, and schedule your team for the final hookup and commissioning.

Communication is the glue that holds a temporary fueling project together. Maintaining an open line between your project manager, the fuel supplier, and local officials prevents delays and ensures everyone is aligned on safety protocols.

At the same time, either you or your provider will be working with the local Authority Having Jurisdiction (AHJ) to lock down any temporary permits. This usually means submitting a site plan and showing you meet all safety codes. A proactive approach here can shave significant time off the approval process.

This kind of careful planning is becoming more common as the NGV market is projected to grow from USD 15.02 billion to USD 23.78 billion by 2032. As more commercial fleets make the switch to natural gas, smart, flexible fueling solutions are more critical than ever. You can explore more analysis on the growth of the NGV market to see where the industry is headed.

Common Questions About NGV Gas Stations

When you're thinking about switching your fleet to natural gas, the questions that come up are usually practical ones that hit the bottom line. You need straightforward answers that make sense for your day-to-day operations. Let's tackle some of the most common questions we hear from folks in construction, utilities, and commercial hauling.

Is Natural Gas Safe for Vehicle Fueling?

Absolutely. When you're using the right equipment and following standard procedures, natural gas is a very safe vehicle fuel. Both CNG and LNG systems are built with safety layered in from the ground up.

CNG, for example, is lighter than air. That means in the unlikely event of a leak, it doesn't pool on the ground like gasoline; it just vents up and away into the atmosphere. LNG, on the other hand, isn't even flammable in its liquid state.

And the vehicle tanks themselves? They're built like vaults.

- CNG Tanks: These are incredibly tough cylinders made of steel or advanced composites. They're far more resistant to puncture than the gas tank in your pickup truck.

- LNG Tanks: Think of these as a high-tech thermos. They're double-walled, vacuum-insulated containers designed to withstand serious impacts.

The entire system, from the station nozzle to the truck's fuel tank, is regulated by strict safety codes like NFPA 52 here in the States. These rules demand features like automatic shut-offs and pressure relief devices, all backed by rigorous testing. It’s all about creating a safe environment for your crew.

How Long Does It Take to Refuel an NGV?

This really comes down to the station type and the fuel you're using. There's no single answer, but the good news is that it's often right in line with what you'd expect from diesel.

A fast-fill CNG station is designed to get you back on the road quickly—we're talking 5-10 minutes to refuel, just like a regular gas station. On the flip side, a time-fill CNG station is built for fleets that return to base every night. You just plug them in, and they'll refuel over several hours while everyone's home for the night.

LNG fueling is a different beast altogether and it's consistently fast. You can fill the cryogenic tank on a Class 8 truck in about 8-12 minutes. For long-haul operations where every minute of downtime costs money, that kind of speed is a game-changer.

Can Natural Gas Fuel Be Tampered With?

Here's a benefit you might not have thought about: it's incredibly difficult to mess with natural gas fuel. Unlike diesel or gasoline, where you hear stories about water or solvents being mixed in to stretch a buck, tampering with natural gas just isn't practical.

With CNG, the fuel is piped directly from a utility line into a closed-loop system for compression and dispensing. For LNG, the extremely cold temperatures and specialized equipment make it nearly impossible to alter the fuel's makeup without some serious, expensive machinery. This built-in purity means you get consistent, high-quality fuel every time, which protects your engine and your investment.

When you need a reliable, on-demand natural gas supply without the delays of permanent infrastructure, Blue Gas Express delivers. We provide temporary CNG and LNG fueling solutions directly to your site, keeping your projects on schedule. Learn how our mobile units can bridge your energy gap by visiting us at https://bluegasexpress.com.