If you've started looking for natural gas trucks for sale, you're on the same path as many fleet managers who are making a strategic shift to cut both emissions and fuel costs. This isn't just about buying a new vehicle; it's an investment in a cleaner, more sustainable future for your entire operation. The first big decision you'll face is choosing between the two main fuel types: Compressed Natural Gas (CNG) and Liquefied Natural Gas (LNG).

Why Fleets Are Switching to Natural Gas

Thinking about moving your fleet from diesel to natural gas is a bit like upgrading your company’s core software. The upfront cost can feel significant, but the long-term payoff in efficiency, compliance, and operational muscle often makes it a smart bet. It's a strategic move, usually prompted by a mix of regulatory heat, corporate sustainability goals, and the very real possibility of long-term fuel savings.

The market reflects this shift. The global natural gas powered truck market is on track for some serious growth, with forecasts showing a compound annual growth rate (CAGR) of about 7.5% from 2025 to 2033. That growth is expected to push the market value to around USD 15 billion by 2033, largely because of tighter emission rules and a worldwide demand for cleaner transport. You can dig deeper into these numbers with data from Strategic Revenue Insights on the natural gas powered truck market.

Navigating Environmental Regulations

Let's be honest: stricter emissions standards are a huge reason operators are searching for natural gas trucks for sale. Government agencies at all levels are cracking down on nitrogen oxides (NOx) and particulate matter—the kind of pollutants diesel engines are known for. Natural gas vehicles, on the other hand, produce far less of these harmful emissions.

This means switching to natural gas isn't just a "green" initiative; it's a practical way to future-proof your fleet. By getting ahead of the curve, companies can stay compliant and sidestep the fines or operational headaches that come with outdated equipment.

The real advantage here is the cleaner burn. Compared to a diesel engine, a natural gas engine can slash NOx emissions by up to 90% and practically eliminate particulate matter. That’s a game-changer for meeting clean air standards.

Achieving Corporate Sustainability Goals

Beyond just staying compliant, many companies are setting their own tough environmental, social, and governance (ESG) goals. Running a cleaner fleet is one of the most visible ways to show you're serious about sustainability, which does wonders for public perception and brand reputation.

For businesses hauling goods for major corporations, a low-emissions fleet is fast becoming a major competitive edge. In some cases, it's even a non-negotiable for landing contracts with clients who demand a green supply chain. The main drivers here are:

- Smaller Carbon Footprint: Natural gas has a lower carbon content than diesel, which means fewer greenhouse gas emissions.

- Quieter Operation: Natural gas engines are noticeably quieter than their diesel counterparts. This is a big deal for reducing noise pollution, especially on routes through urban or residential areas.

- Customer and Investor Appeal: A clear commitment to cleaner energy can help attract customers and investors who care about where their money goes.

Choosing Your Fuel Type: CNG vs. LNG

When you start looking at natural gas trucks, you'll immediately see two main options: Compressed Natural Gas (CNG) and Liquefied Natural Gas (LNG). They're both natural gas, of course, but how they’re stored and used onboard a truck makes all the difference. Getting this right from the start is the key to a successful switch from diesel.

Think of it like this: CNG is like the air in a scuba tank. It’s natural gas in its normal, gaseous state, just squeezed under very high pressure—around 3,600 psi—into tough, thick-walled tanks. On the other hand, LNG is more like the liquid in a thermos. To create it, natural gas is chilled to a bone-chilling -260°F (-162°C), which turns it into a dense, clear liquid.

This fundamental difference in storage drives everything else—the truck's range, its design, the refueling process, and ultimately, what kind of job it's best for. It’s not about which one is better, but which one is the right fit for your fleet’s daily grind.

CNG vs. LNG Trucks at a Glance

To make sense of the key differences, it helps to see them side-by-side. This table breaks down what you need to know when comparing CNG and LNG systems for your fleet.

| Feature | CNG (Compressed Natural Gas) Trucks | LNG (Liquefied Natural Gas) Trucks |

|---|---|---|

| Storage Method | Stored as a gas at high pressure (3,600 psi) in durable, heavy cylinders. | Stored as a cryogenic liquid at low pressure (-260°F) in vacuum-insulated tanks. |

| Energy Density | Lower. Requires more tank volume for the same amount of energy as diesel or LNG. | Higher. Stores roughly 600 times more energy in the same space as its gaseous form. |

| Typical Range | 400 to 750 miles. Ideal for regional routes and daily returns to a home base. | 800 to 1,500+ miles. Built for long-haul and cross-country freight. |

| Best For | "Return-to-base" fleets: waste management, local delivery, public transit. | Over-the-road trucking, long-distance logistics, and high-mileage routes. |

| Refueling Time | Slower. "Time-fill" (overnight) is common; "fast-fill" is faster but more complex. | Faster. Similar to diesel refueling, taking about 10-15 minutes. |

| Infrastructure | More widespread public stations and established private station technology. | Less common but growing, especially along major freight corridors. |

Ultimately, your choice will hinge on your routes. Are your trucks coming home every night, or are they crossing state lines? The answer will almost always point you toward either CNG or LNG.

CNG Trucks: The Regional and Return-to-Base Champion

Because it’s stored as a gas, CNG takes up a lot of room. To get the same energy as a tank of diesel, you need much larger and heavier tanks. This simple fact makes CNG the clear winner for fleets that run predictable routes and come back to a central depot every night.

These "return-to-base" operations are the perfect scenario for a CNG truck. With a typical range of 400 to 750 miles, a Class 8 truck has plenty of juice for most regional and local jobs. We see them everywhere in:

- Waste Management: Garbage trucks run the same routes daily and can refuel overnight at the yard.

- Local Delivery: Think beverage distributors, parcel services, and food suppliers operating within a city or metro area.

- Public Transit: City buses are one of the most common and successful applications for CNG.

The refueling infrastructure for CNG is also more mature. There's a decent network of public stations, and the technology for building a private, on-site station for your fleet is well-understood and readily available.

LNG Trucks: The Long-Haul Powerhouse

LNG’s biggest advantage is its energy density. By turning natural gas into an ultra-cold liquid, you can pack about 600 times more energy into the same amount of space. This is what finally makes natural gas a real contender for long-haul trucking.

An LNG-powered Class 8 rig can cover 800 to over 1,500 miles on a single tank, making it a viable workhorse for the over-the-road freight industry. We've seen LNG adoption really take off in places with tough emissions standards. For instance, in China, the LNG truck fleet ballooned to over 450,000 vehicles by 2022 after new emissions rules kicked in. These trucks produce about 15% less CO2 than diesel over their lifecycle, a major plus for any company serious about sustainability. You can find more details on this trend in a global natural gas demand report from GECF.org.

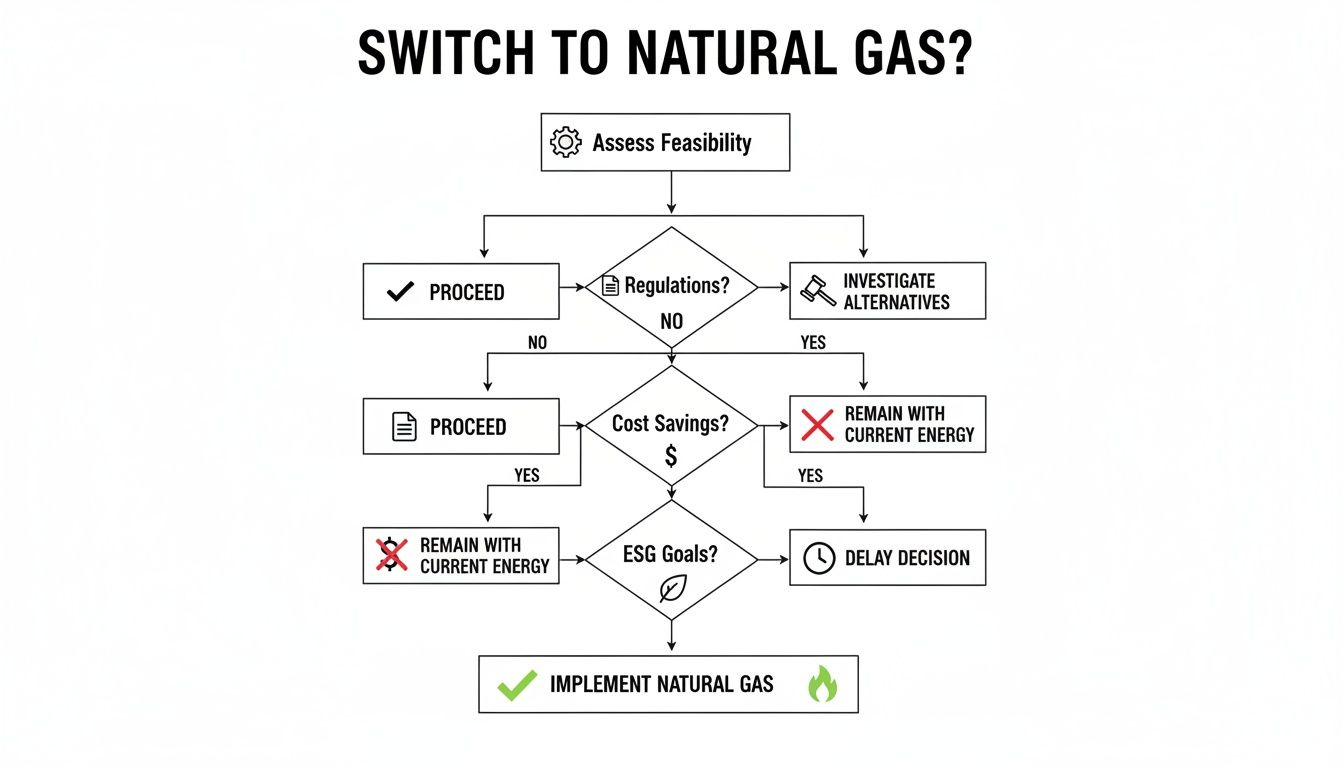

This decision tree gives you a good visual of how fleet managers weigh their options. The move to natural gas is almost always driven by a combination of regulations, cost savings, and ESG goals.

As you can see, the path usually starts with one of those three big motivators. From there, it's about drilling down into the operational details to pick the right fuel and the right truck.

How to Evaluate Technical Specifications

Staring at a spec sheet for a natural gas truck can feel a bit overwhelming at first. You'll see familiar numbers for horsepower and torque, but a whole new set of terms pops up that are critical to your daily operations and, ultimately, your bottom line. Getting a handle on these details is the key to comparing different natural gas trucks for sale and choosing the right one for your fleet.

Let's cut through the jargon and focus on the numbers that really matter for performance, range, and profitability. We’ll go beyond the basics and dig into the specs that are unique to CNG and LNG vehicles.

Decoding Fuel Capacity and Range

The first thing you’ll probably look for is fuel capacity, but it’s not as simple as checking the gallon size. With natural gas, you’ll run into terms like DGE and LGE.

DGE (Diesel Gallon Equivalent): This is your best friend when comparing trucks. It's a straightforward measure that tells you how much natural gas provides the same energy as one gallon of diesel. DGE lets you make a direct, apples-to-apples comparison between a natural gas truck and the diesel rigs you're used to.

LGE (LNG Gallon Equivalent): This is specific to LNG trucks and measures the fuel's energy content relative to one gallon of liquefied natural gas.

To figure out a truck's real-world range, just multiply its DGE capacity by the miles per gallon you expect to get. This simple calculation will tell you if a truck can actually handle your routes without needing constant pit stops.

Understanding Pressure and Tank Systems

With a CNG truck, the fuel system's pressure rating is a big deal, affecting both how quickly you can refuel and overall safety. The industry standard for these tanks is 3,600 psi (pounds per square inch). That high pressure is what allows enough compressed gas to be stored onboard to give you a decent driving range.

When you're looking at a CNG truck—especially a used one—it's crucial to check the tank’s certification and expiration date. These tanks are built like fortresses, but they don't last forever. They have a limited service life, typically 15-20 years, which you absolutely need to factor into your decision.

For LNG trucks, you’re looking at something different. Forget pressure; the spec to watch is the cryogenic tank hold time.

Think of an LNG tank as a giant, high-tech thermos built to keep fuel at a frosty -260°F. The "hold time" is simply how long the tank can keep the fuel that cold before it starts to warm up and vent off as gas. If your trucks might sit idle for a few days, a longer hold time is a must-have.

Calculating Your True Payload Capacity

Here's a detail that trips a lot of people up: the weight of the fuel system itself. Natural gas fuel systems, especially the heavy-duty cylinders needed for CNG, weigh a lot more than a simple diesel tank.

That extra weight eats directly into your payload. For instance, a common CNG fuel system can add 1,500 to 2,000 pounds to a truck's empty weight. You have to subtract that number from the truck’s Gross Vehicle Weight Rating (GVWR) to figure out how much you can actually haul. Overlook this, and you could be facing steep fines for running overweight and messing up your efficiency calculations. Always confirm the real-world empty weight of any truck you're seriously considering.

Understanding the Total Cost of Ownership

When you’re looking at natural gas trucks for sale, that initial sticker price is just the first chapter of a much bigger story. To make a truly smart business decision, you need to look at the Total Cost of Ownership (TCO). Think of it as the complete financial picture of what a truck will cost your company from the day you buy it to the day you retire it.

This means you have to look past the upfront cost and factor in everything else: fuel, maintenance, available incentives, and refueling infrastructure. It’s the critical difference between knowing the price of a truck and understanding its true cost over its entire working life.

Running the numbers on TCO gives you the clarity you need to build a solid business case for transitioning your fleet. Most importantly, it ensures there are no expensive surprises waiting for you down the road.

Breaking Down the Purchase Price and Incentives

Let's get the big one out of the way first. Natural gas trucks do have a higher upfront cost than their diesel counterparts, typically by $30,000 to $50,000. That premium pays for the specialized, high-pressure fuel tanks, reinforced fuel lines, and advanced engine components needed to run safely on CNG or LNG.

However, that initial sticker shock can be dramatically reduced by a wide range of government incentives. These programs exist to encourage fleets like yours to adopt cleaner technologies, and they can make a huge difference in your return on investment.

Be sure to look for incentives like:

- Federal Tax Credits: These are a big deal, as they can directly lower your company's tax bill for the year you put the truck into service.

- State-Level Grants and Rebates: Many states have their own programs that might offer cash back, vouchers, or other funds to help offset the initial purchase price.

- Alternative Fuel Infrastructure Credits: If you’re thinking about building an on-site refueling station, there are often separate credits designed specifically to help cover those construction costs.

Keep in mind that these programs can and do change, so doing your homework on the current incentives available in your specific state and region is a must before you sign any paperwork.

Analyzing Fuel Costs Diesel vs Natural Gas

Fuel is almost always one of the biggest line items in a fleet’s operating budget. This is exactly where natural gas trucks really start to shine, delivering significant long-term savings. On a diesel gallon equivalent (DGE) basis, natural gas has historically been consistently cheaper than diesel.

While diesel prices are notoriously volatile and tied to the whims of the global oil market, natural gas prices tend to be more stable and are sourced domestically. This stability makes your fuel budget far more predictable and shields your operation from sudden, painful price spikes at the pump.

This cost advantage is a major reason why the market for these vehicles is growing so quickly. The global medium and heavy-duty truck segment powered by natural gas generated revenues of around USD 52.7 billion and is projected to more than double to roughly USD 107.4 billion by 2030. You can dig deeper into the data on this expansion by checking out the market analysis from Grand View Research.

Factoring in Maintenance and Infrastructure Expenses

So, what about keeping these trucks on the road? Maintenance costs for natural gas engines are generally in the same ballpark as diesel, but there are some important differences. For starters, you can say goodbye to the diesel particulate filter (DPF) and diesel exhaust fluid (DEF), which eliminates two of the most common and expensive maintenance headaches for modern diesel owners.

On the other hand, natural gas engines have their own maintenance needs, like regular spark plug changes and the use of specialized engine oils. When all is said and done, most fleet managers find that the total maintenance spend over the truck's life is very similar to—or even slightly less than—a comparable diesel truck.

The final piece of your TCO puzzle is the refueling infrastructure. Here, you have two main paths you can take:

- Rely on Public Stations: This is the most straightforward approach. The key is to make sure there's a reliable network of CNG or LNG stations conveniently located along all your regular routes.

- Build a Private On-Site Station: This requires a serious capital investment upfront, but it pays off with maximum convenience and the potential for lower fuel costs by buying in bulk. For return-to-base fleets, a private station is often the most logical long-term solution.

By carefully weighing each of these components—the initial price, incentives, fuel savings, maintenance, and infrastructure—you can build a truly accurate TCO model. This data-driven approach will give you the real story of the financial impact and potential benefits of adding natural gas trucks to your fleet.

Planning for Maintenance and Resale Value

A truck isn't just a piece of equipment; it's a long-term investment. When you're looking at natural gas trucks for sale, thinking about the vehicle’s entire life—from its first oil change to the day you sell it—is just as critical as its price tag or horsepower. The day-to-day reality of owning a natural gas truck involves different service routines and specialized skills compared to a diesel-only fleet.

Getting a handle on these differences from the start is the key to maximizing uptime, keeping costs in check, and getting the best possible return on your investment when it's time to upgrade. Let's dig into what it takes to keep these trucks on the road and what the resale market really looks like.

Comparing Maintenance Needs

While natural gas and diesel engines share a lot of the same DNA, the unique fuel systems in natural gas trucks change the maintenance game. One of the biggest wins is that you get to say goodbye to the notoriously fussy diesel particulate filter (DPF) and diesel exhaust fluid (DEF) systems. That alone eliminates a major source of downtime and expense.

But natural gas engines do have their own checklist:

- Spark Plug Replacements: Natural gas engines ignite fuel with spark plugs, unlike diesels which use compression. These plugs need to be replaced on a regular schedule.

- Different Oil Change Intervals: Natural gas burns cleaner, but the engine oil has to be a specific formula designed to handle the higher combustion temperatures. This can affect how often you change it.

- Specialized Fuel Filters: The filters for CNG and LNG are built for either high-pressure gas or super-cooled liquids, meaning they have their own unique replacement procedures and schedules.

The big picture? Maintenance isn't necessarily more expensive, but it is different. Getting your team trained and your service schedule dialed in is crucial for keeping your trucks reliable for the long haul.

Technician Training and Safety

Your maintenance crew is your first line of defense against downtime. Working safely with high-pressure CNG tanks (around 3,600 psi) or cryogenic LNG (a frosty -260°F) requires specialized training that goes way beyond a standard diesel mechanic’s skillset. Your techs need to be experts on the properties of natural gas, know the right way to depressurize a system, and understand how to handle cryogenic fluids.

Beyond the shop, knowing the essential pre-trip inspection procedures for these fuel systems is vital for drivers to operate safely and catch small issues before they become big problems. Investing in certified training programs ensures your shop can handle these advanced systems safely and efficiently, protecting your people and your assets.

A Realistic Look at Resale Value

The resale market for used natural gas trucks is definitely growing up. In the past, the limited refueling network and a smaller pool of buyers meant their resale value often lagged behind their diesel counterparts. But that picture is changing fast.

Several key trends are boosting the long-term value of these trucks:

- Expanding Infrastructure: With more public CNG and LNG stations popping up along major highways, used natural gas trucks are becoming a much more practical option for a wider range of buyers.

- Tighter Emissions Rules: As environmental regulations continue to get stricter, more fleets will turn to the used market for a budget-friendly way to clean up their operations.

- Proven Reliability: These trucks have been on the road long enough to prove their staying power. As more of them hit high mileage milestones, their reputation for durability gives second-hand buyers a lot more confidence.

So, while a diesel truck might still have a slight edge on resale value today, that gap is closing. Investing in a natural gas fleet is a forward-thinking move, putting you in an asset class that's clearly on the rise.

Your Top Questions About Natural Gas Trucks, Answered

Switching your fleet to a new fuel source is a big decision, and it’s only natural to have a lot of questions. When fleet managers first start looking at natural gas trucks for sale, I've found they usually circle back to the same key concerns: performance, range, and safety. Getting solid, no-nonsense answers to these is the first step toward making a smart investment.

So, let's dive into the questions I hear most often and clear things up.

Are Natural Gas Trucks as Powerful as Diesel Trucks?

This is usually the first question out of anyone's mouth, especially from operators who depend on diesel's legendary pulling power. And it's a fair question. The great news is that modern natural gas engines have come a long, long way. The performance gap has essentially closed.

Today's leading manufacturers are building 12-liter and 15-liter natural gas engines that go toe-to-toe with their diesel cousins. It's not uncommon to see models pushing out over 400 horsepower and 1,850 lb-ft of torque. Those are serious numbers, making these trucks more than capable of handling heavy-duty loads for both regional and long-haul routes.

Ultimately, just like with diesel, it's all about spec'ing the right engine for the job. Most drivers I've spoken to say the performance is right where they need it to be, and they almost always mention how much quieter and smoother the ride is—a welcome bonus.

What Is the Real-World Driving Range of a Natural Gas Truck?

How far you can go on a full tank really comes down to which type of natural gas you’re using—CNG or LNG—and the size of the tanks on the truck. This is probably the most important factor in deciding which fuel is the right fit for your operation.

CNG Trucks: A typical Class 8 truck running on Compressed Natural Gas can usually cover 400 to 750 miles. This makes it a perfect fit for return-to-base fleets and regional routes where you can refuel at a central depot overnight.

LNG Trucks: This is where the game changes for long-haul. Because Liquefied Natural Gas is so much denser, it packs more energy into the same space. An LNG-equipped tractor can travel anywhere from 800 to over 1,500 miles on a single fill, making it a true diesel replacement for over-the-road freight.

Here's a pro tip: when you're looking at specs, pay attention to the fuel capacity listed in Diesel Gallon Equivalents (DGE). This number gives you an apples-to-apples way to compare a natural gas truck's range directly with your current diesel rigs.

How Safe Are the Fuel Systems on Natural Gas Trucks?

Safety is always priority one, and you can rest assured these fuel systems are built like tanks—literally. Both CNG and LNG systems are engineered with multiple layers of safety and have to pass incredibly strict federal standards.

The fuel systems on natural gas trucks are incredibly robust. CNG tanks, for example, are often constructed from high-strength steel or carbon fiber and must pass rigorous crash, fire, and even ballistics tests. In many cases, they are more durable than a standard diesel tank.

LNG tanks are basically industrial-strength thermoses, featuring double walls and a vacuum seal to keep the fuel stable at its super-cold temperature. On top of that, both systems come loaded with safety features like pressure relief devices and automatic shut-off valves that kick in if there's an accident.

Natural gas itself also has a key safety advantage over diesel. It's lighter than air, so if a leak were to happen, the gas rises and dissipates quickly. This dramatically lowers the risk of a pool fire on the ground, which is a real hazard with liquid fuels.

If you're facing delays with permanent gas line installations or need a reliable temporary fuel source, Blue Gas Express offers mobile CNG and LNG delivery to keep your projects on schedule. Learn more about our rapid deployment services.