When you need to get things done, a quick and accurate natural gas calculator conversion isn't just a tool—it's the key to your project's success. It turns confusing metrics like SCF, Therms, and MMBtu into real-world numbers you can actually use. This ensures you can order the right amount of temporary fuel, like mobile CNG or LNG, and avoid expensive delays on the job site.

Why Accurate Natural Gas Conversion Is Critical

Let's paint a picture. You’re in the final stretch of a major construction project. The building is almost finished, but the permanent natural gas line isn't live yet. This is a huge problem. Without gas, you can't fire up the HVAC system to pass inspections, which could push back your Certificate of Occupancy by weeks and rack up thousands in penalties.

This is exactly where understanding natural gas conversions becomes a total game-changer.

Bridging the Utility Gap

When the pipeline isn’t ready, temporary energy solutions, like those from Blue Gas Express, become an absolute lifeline. But you can't just call up and order "a tank of gas." You have to know precisely how much energy your equipment needs for critical tasks, such as:

- Commissioning a generator: Making sure the backup power system is ready to go before the facility opens.

- Securing occupancy permits: Running heating systems long enough to satisfy picky municipal inspectors.

- Preventing freeze-ups: Pumping in essential heat during a winter utility outage to keep pipes from bursting.

A reliable natural gas calculator conversion helps you translate an appliance's energy demand (usually listed in BTU/hr) into the exact volume of mobile CNG or LNG required to get the job done.

Think of it as the universal translator between your equipment's needs and the fuel supplier's delivery units. Getting it right means your operations continue seamlessly, on time and on budget.

The Growing Demand for Precise Energy Management

The need to get these calculations right has never been more pressing. U.S. natural gas consumption is hitting all-time highs, peaking at 126.8 billion cubic feet per day (Bcf/d) last January. This massive demand, fueled by extreme weather and the fact that 45% of American homes depend on natural gas for heat, puts a serious strain on our energy grid.

It also shines a spotlight on just how vital reliable temporary solutions have become. You can dig into the numbers behind this record consumption over at the EIA's website.

This guide is here to take the mystery out of the formulas and units behind natural gas conversion. We'll break down everything from basic volume (like SCF) to energy content (like Therms and MMBtu), giving you the confidence to manage any temporary fuel requirement with total precision.

Getting to Grips with Natural Gas Units

Before you can nail any natural gas conversion, you've got to speak the language. The industry has its own shorthand, full of acronyms and units that can look like alphabet soup at first glance. But once you know what they stand for, the whole process clicks into place.

Think of it like buying firewood. You can measure a pile of wood by its volume—how many cords you have. But what you really care about is the heat it will give off. Natural gas is the same; we measure it by both its volume and its energy content, and you need to understand both.

Volume: How Much Space the Gas Takes Up

The most basic way to measure natural gas is by its volume. This is simply the amount of physical space the gas occupies. You'll run into volume measurements all the time when you're talking about pipeline capacity, storage tanks, or reading a flow rate from a meter.

The foundational unit here is the Cubic Foot (CF). Picture a box that's one foot long, one foot wide, and one foot high. The amount of gas that can fit inside is one cubic foot. Simple enough, right? This basic unit is the building block for the other terms you'll see on-site.

- SCF (Standard Cubic Foot): This is the industry's universal benchmark. It’s a cubic foot of gas measured under a specific, standardized set of pressure and temperature conditions. This is critical because gas expands when it gets hot and compresses under pressure, so standardization ensures everyone is working from the same playbook.

- CCF (Centi Cubic Foot): This is just a shorthand for 100 cubic feet. You’ll often find it on residential and small commercial utility bills because it's a more manageable number than listing thousands of individual cubic feet.

- MCF (Mille Cubic Foot): This represents 1,000 cubic feet. It's the go-to unit for industrial applications, bulk deliveries, and anything where you're dealing with large quantities of gas.

Knowing your volume units is the first step. It tells you how much gas you have, but it doesn't tell you how much punch it packs.

Energy: What the Gas Can Actually Do

This is where the real value lies. Energy units tell you the actual heating power—the usable work—locked inside a given volume of gas. This is the number that matters when you're sizing a boiler, commissioning a power generator, or calculating how long your temporary fuel supply will last.

Think of energy content as the "potency" of the gas. You could have two identical tankers, both holding the same volume (MCF), but the gas with a higher energy content will deliver more power and run your equipment longer.

This is why we have units specifically for measuring energy.

- BTU (British Thermal Unit): This is the fundamental unit of heat energy. One BTU is the tiny amount of energy needed to raise the temperature of one pound of water by one degree Fahrenheit. Since it's so small, we almost always talk about it in larger bundles.

- MMBtu (Million BTU): This is the workhorse unit for commercial and industrial jobs. As the name implies, one MMBtu equals 1,000,000 BTUs. If you're firing up a large generator or heating a sprawling facility, your calculations will be in MMBtu.

- Therm: A Therm is equal to 100,000 BTUs. It's a common billing unit for utilities, conveniently bridging the gap between the tiny BTU and the massive MMBtu.

Let's quickly recap the most common units you'll encounter.

Common Natural Gas Units at a Glance

This table is a handy cheat sheet for keeping these terms straight. It breaks down whether a unit measures the amount of space the gas occupies (volume) or the power it contains (energy).

| Unit Name | Abbreviation | Measurement Type | Common Application |

|---|---|---|---|

| Cubic Foot | CF | Volume | The base unit for all volume measurements. |

| Standard Cubic Foot | SCF | Volume | Used for standardized engineering and contracts. |

| Centi Cubic Foot | CCF | Volume | Found on residential and small commercial gas bills. |

| Mille Cubic Foot | MCF | Volume | Used for industrial consumption and bulk transport. |

| British Thermal Unit | BTU | Energy | The smallest base unit of heat energy. |

| Therm | Therm | Energy | A common utility billing unit (100,000 BTU). |

| Million BTU | MMBtu | Energy | The standard for large-scale industrial and power generation. |

Mastering both volume and energy is non-negotiable. Volume tells you how much gas you're getting, while energy tells you what you can do with it. With this foundation, you're ready to see how they connect.

The Math Behind Gas Conversions: From Volume to Energy

Alright, now that we’ve got the lingo down, let’s get into the practical math that turns gas volume into real-world energy. These are the core formulas that make any natural gas calculator conversion work. The goal here isn't to memorize equations, but to understand the why behind them. Once you get the logic, you can solve just about any energy problem thrown your way.

Think of these formulas less like algebra and more like simple recipes. You take a known ingredient (your volume of gas), add a key multiplier, and get the result you need—whether that's the total energy available or how much fuel to order for a job.

Turning Volume into Energy: It’s All About the Heating Value

The most common calculation you'll ever do is converting a volume of gas, like SCF, into its energy equivalent, like MMBtu. The bridge connecting the two is the Heating Value. You might also hear it called the BTU factor or energy content.

Simply put, the Heating Value tells you how much energy is packed into one standard cubic foot (SCF) of gas. It’s a measure of its potency.

Now, this number isn't set in stone. It can vary a bit based on the gas source and its specific chemical makeup. But for most day-to-day work, a solid industry average to use is 1,020 to 1,050 BTUs per SCF.

The formula itself is as straightforward as it gets:

Total Energy (BTU) = Gas Volume (SCF) x Heating Value (BTU/SCF)

This is the bedrock of all energy calculations. It’s how the utility company figures out your bill and how a project manager knows if a temporary boiler has enough juice to get through the week.

Let's See It in Action: SCF to MMBtu

Time for a real-world scenario. A construction manager is firing up a temporary heating system and has a mobile CNG trailer on-site with 50,000 SCF of natural gas. The gas supplier’s spec sheet says the Heating Value is 1,030 BTU/SCF.

Here’s how we find out how much energy they have in MMBtu:

First, get the total BTUs:

- 50,000 SCF x 1,030 BTU/SCF = 51,500,000 BTUs

Next, convert those BTUs to MMBtu:

- Remember, one MMBtu is one million BTUs. So, we just divide by 1,000,000.

- 51,500,000 BTUs / 1,000,000 = 51.5 MMBtu

That’s it. The 50,000 SCF of gas holds 51.5 MMBtu of energy. This one simple calculation is vital for everything from checking billing accuracy to making sure a backup generator can handle a long outage.

Quick Conversions for Daily Use

While MMBtu is the standard for big industrial jobs, you’ll definitely run into other units. Therms, for instance, pop up all the time on utility bills and for commercial appliances. The good news is, the formulas are just as simple and build on the same logic.

Here are a couple more essential conversions you'll use constantly:

- SCF to Therms: One Therm is exactly 100,000 BTUs. So, you just find your total BTUs (like we did above) and then divide by 100,000.

- LNG Gallons to SCF: This one is critical when you get a delivery of Liquefied Natural Gas. The key is the expansion ratio: 1 gallon of super-cooled LNG expands into roughly 83 SCF of gas at standard temperature and pressure.

Here’s a quick-glance table for these handy formulas:

| Conversion Task | Formula | Key Factor |

|---|---|---|

| SCF to Therms | (SCF x Heating Value) / 100,000 | 1 Therm = 100,000 BTU |

| LNG Gallons to SCF | Gallons of LNG x 83 | 1 Gallon LNG ≈ 83 SCF |

| MCF to MMBtu | (MCF x 1,000 x Heating Value) / 1,000,000 | 1 MCF = 1,000 SCF |

Getting comfortable with these formulas takes the guesswork out of energy planning. Whether you’re ordering a temporary LNG supply from a company like Blue Gas Express or just double-checking a utility bill, you’ll have the confidence that your numbers are right and your project is on track.

Adjusting for Pressure and Temperature in the Real World

Basic conversions are a good starting point, but out in the field, we have to deal with physics. Natural gas isn't a solid block; it’s a compressible gas, which means its volume changes—sometimes dramatically—based on the surrounding temperature and pressure. Getting this right is what separates a quick guess from a professional-grade natural gas calculator conversion.

Think about a balloon on a cold winter morning. As the air gets colder, the balloon shrinks. Natural gas does the exact same thing. A cubic foot of gas measured in the freezing cold is packed with more molecules—and therefore more energy—than a cubic foot measured on a sweltering summer day. Pressure works the same way.

Why Standard Conditions Are the Gold Standard

To keep things consistent, the industry relies on what we call Standard Conditions. This is a universally agreed-upon baseline for both temperature and pressure, allowing us to compare apples to apples, no matter where or when the gas is measured. It’s the only reliable way to ensure a cubic foot of gas in Texas has the same energy potential as a cubic foot in Alaska.

The idea is simple: by adjusting all measurements back to a standard baseline, we can accurately measure and trade gas based on its actual energy content, not just the space it happens to occupy at that moment.

A cubic foot of gas flowing through a high-pressure industrial pipeline contains far more energy than a cubic foot measured at a low-pressure residential meter. Without standardization, billing and energy planning would be chaotic and unfair. This is where correction factors come in.

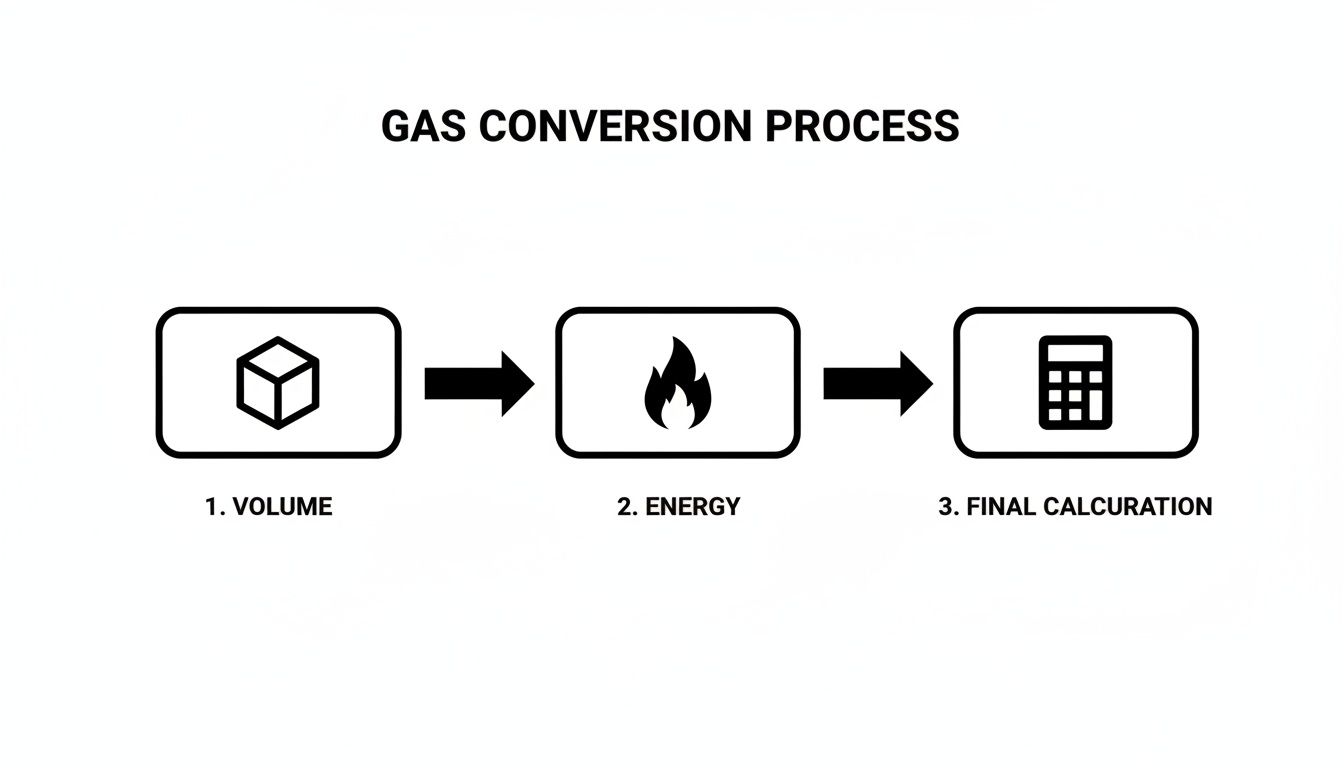

This visual shows how we get from a raw volume reading to a final, corrected energy value that you can actually work with.

The process is always the same: start with the measured volume, apply corrections for real-world conditions to find the true energy content, and you end up with a precise, actionable number.

Applying Pressure and Temperature Correction Factors

Using correction factors isn't just for pipeline engineers; it’s a crucial step for anyone managing temporary energy needs. The meter at your site measures the volume of gas passing through it at the current "line conditions"—the actual pressure and temperature at that moment. To turn this reading into Standard Cubic Feet (SCF), you have to apply these correction factors.

The formula is pretty straightforward:

Volume (SCF) = Volume (ACF) x Pressure Factor x Temperature Factor

Let’s break that down:

- ACF (Actual Cubic Feet): This is the raw number your meter records under the existing, real-world conditions.

- Pressure Factor (Fp): This adjusts for how much the gas is compressed. Higher pressure means a higher correction factor.

- Temperature Factor (Ft): This corrects for the gas's temperature. Colder gas is denser, which also results in a higher factor.

Utilities and gas suppliers use tables or software to pinpoint these factors based on live data. For instance, a pressure factor might be 1.015 and a temperature factor might be 1.030. When you multiply them by the metered volume, you get a corrected number that reflects the true amount of standardized energy you received.

Correction Factors in Practice: From Global to Local

This level of precision is vital for managing supply chains of all sizes. On a global scale, Europe's LNG imports shot up 23.6% in early 2025, a perfect example of how these conversions are used to manage massive shipments across different countries and climates. On a local level, a residential builder facing a maintenance outage knows that 1 MMBtu is roughly 1,000 scf. This lets them precisely order temporary fuel from a provider like Blue Gas Express and prevent a costly project shutdown. As you can see from current insights into the natural gas market, demand is growing, and these calculations are essential for keeping supply chains efficient.

Ignoring these variables can lead to serious mistakes. You might under-order fuel for a critical job and face an emergency shutdown, or you could overpay for energy you never actually received. Mastering these adjustments isn’t optional—it’s a fundamental step for anyone responsible for accurate energy delivery and cost-effective operations. It’s the final piece of the puzzle for a truly accurate natural gas calculator conversion.

Putting Natural Gas Conversions into Practice

All the formulas and correction factors are great on paper, but where the rubber really meets the road is in the field. This is where a sharp understanding of natural gas conversions moves from theory to tangible results.

Let’s walk through a few real-world scenarios where getting the math right was the only thing standing between a successful project and a costly disaster. These stories show how knowing your MMBtus from your Therms solves urgent problems for project managers, facility operators, and businesses every single day.

Case Study 1: Securing a Certificate of Occupancy

A construction manager, Alex, was in a tough spot. His new multi-family building was ready for tenants, but a three-week delay in the permanent gas utility hookup was holding up the final inspection. No gas meant no heat, and no heat meant no Certificate of Occupancy. Every day that ticked by cost him thousands in penalties.

He needed a temporary gas supply, and he needed it yesterday. After a quick call to Blue Gas Express, he knew he could get a mobile CNG trailer on-site, but he had to tell them exactly how much gas he needed.

- The Goal: The building's heating system needed 2,000,000 BTU/hr to meet the temperature requirements for the inspection, which would run for a continuous 72 hours.

- The Math: Alex quickly calculated his total energy demand. First, he found the total BTUs: 2,000,000 BTU/hr x 72 hours = 144,000,000 BTUs. He converted that to 144 MMBtu for easier handling. Finally, he converted BTUs to a volume the supplier could work with: 144,000,000 BTUs ÷ 1,030 BTU/SCF ≈ 139,806 SCF.

- The Result: Alex confidently ordered a CNG unit with 140,000 SCF. The heat ran without a hitch, the inspector signed off, and he got his Certificate of Occupancy, avoiding a massive project overrun.

Case Study 2: Commissioning a Backup Generator

Out at a remote industrial plant, facility manager Maria was preparing for a planned utility outage. Before that happened, she had to commission a brand-new 500 kW backup generator. The problem? The permanent gas line that fed the generator was the same one being shut down for maintenance.

The generator specs were clear: at full load, it burned through 4.9 MMBtu per hour. The commissioning test demanded a solid eight-hour run. Maria had to order the perfect amount of temporary Liquefied Natural Gas (LNG) to get the job done.

This is a high-stakes calculation. Ordering too little fuel would force them to abandon the test and start over, while ordering too much would waste significant budget on unused LNG.

Here’s how Maria figured it out:

- Total Energy Demand: 4.9 MMBtu/hr x 8 hours = 39.2 MMBtu.

- Convert to SCF: 39,200,000 BTUs ÷ 1,030 BTU/SCF ≈ 38,058 SCF.

- Convert to LNG Gallons: Using the standard 83 SCF per gallon of LNG, she got her final number: 38,058 SCF ÷ 83 SCF/Gallon ≈ 459 Gallons.

She ordered a 500-gallon LNG mobile tanker, giving her a small but smart buffer. The commissioning test was a complete success, proving the plant was ready for any future power disruptions.

Case Study 3: Preventing Pipes from Freezing

An unexpected cold snap hit, and the local gas utility announced an emergency supply cut to a commercial property for repairs. The property manager, David, had a serious problem on his hands. With temperatures plummeting, the building’s pipes were in real danger of freezing and bursting—a potential catastrophe.

He had to keep the essential heating loop running for the full 48-hour outage. His records showed that this minimal system consumed 5 Therms per hour.

- The Goal: Keep the heat on for 48 hours to protect the plumbing.

- The Math: First, he found the total Therms needed: 5 Therms/hr x 48 hours = 240 Therms. Next, he converted that to BTUs: 240 Therms x 100,000 BTU/Therm = 24,000,000 BTUs. The final step was converting to SCF for the supplier: 24,000,000 BTUs ÷ 1,030 BTU/SCF ≈ 23,301 SCF.

- The Result: David requested a CNG delivery of 24,000 SCF. The temporary supply kept the building's core temperature stable, protecting the pipes and saving the owner from what could have been tens of thousands of dollars in water damage repairs.

As you can see, a natural gas calculator conversion isn't just an academic exercise. It's a fundamental tool for smart operational planning and risk management in the real world.

To make this even easier, we've put together a quick reference guide for some of the most common scenarios we encounter.

Conversion Cheat Sheet for Common Project Needs

| Project Scenario | Key Metric to Know | Common Conversion Needed | Example Calculation |

|---|---|---|---|

| Building Inspection | Total BTU/hr of heating equipment | BTU/hr → Total MMBtu → SCF | 1,500,000 BTU/hr for 48 hrs = 72 MMBtu = ~69,900 SCF |

| Generator Commissioning | Fuel consumption in MMBtu/hr | MMBtu/hr → Total MMBtu → LNG Gallons | 5.0 MMBtu/hr for 10 hrs = 50 MMBtu = ~585 LNG Gallons |

| Emergency Heating | Boiler rating in Therms/hr | Therms/hr → Total Therms → SCF | 10 Therms/hr for 24 hrs = 240 Therms = ~23,300 SCF |

| Asphalt Plant Operation | Burner rating in MMBtu/hr | MMBtu → SCF or LNG Gallons | 25 MMBtu/hr for an 8-hr day = 200 MMBtu = ~194,175 SCF |

This table helps you quickly connect your on-site needs to the specific numbers a temporary fuel supplier will ask for, saving you time when every minute counts.

Common Questions About Natural Gas Conversion

After digging into the math and seeing how it all plays out in the real world, a few questions always pop up. This is where we tackle those common sticking points that can trip people up.

Getting these details right is the difference between a calculation that’s "close enough" and one that’s spot-on. Let's walk through the questions we hear most often from project managers and facility operators out in the field.

What Is the Difference Between SCF and CCF?

This one is probably the most frequent source of confusion. People see SCF (Standard Cubic Foot) and CCF (Centi Cubic Foot) and assume they're interchangeable, but they measure two very different things.

Think of an SCF as the universal yardstick. It’s a cubic foot of gas corrected to a standard, agreed-upon temperature and pressure. This standardization is crucial because it allows us to compare apples to apples, ensuring that a cubic foot of gas in frigid North Dakota has the same energy value as one in sunny Florida. It’s an engineering unit.

A CCF, on the other hand, is just a billing unit. It simply means "100 cubic feet" of gas as it passed through your meter, uncorrected for pressure or temperature. The utility company then uses a conversion factor (that "BTU factor" on your bill) to turn that raw volume into the actual energy you consumed.

The Bottom Line: SCF is the precise, standardized measure of energy content. CCF is the raw volume your meter records before any corrections are made.

How Do I Convert Between LNG, CNG, and Gaseous Natural Gas?

Switching between the different states of natural gas is all about density. Understanding how much the gas expands or compresses is absolutely critical for logistics, especially when you're scheduling a temporary fuel delivery from a company like Blue Gas Express.

Here’s how the three states stack up in terms of volume for the same amount of energy:

- LNG (Liquefied Natural Gas): To get LNG, you have to chill natural gas down to a frosty -260°F. This turns it into a liquid and shrinks its volume by an incredible 600 times. A solid rule of thumb is that one gallon of LNG expands into about 83 standard cubic feet of pipeline-ready gas.

- CNG (Compressed Natural Gas): Instead of chilling it, CNG is made by storing the gas under immense pressure. This squeezes its volume down by about 100 times compared to its regular gaseous state.

- Gaseous Natural Gas: This is what flows through the pipelines to your facility, measured in familiar units like SCF.

Knowing these expansion ratios is non-negotiable for project managers. It’s how you figure out exactly how much usable energy you're getting in a single LNG tanker or a mobile CNG trailer.

Why Does My Gas Bill Show a BTU Factor or Therm Factor?

Ever noticed that little multiplier on your utility bill, often called a "BTU Factor" or "Therm Factor"? That number is the secret to fair and accurate billing.

The simple truth is that the energy content—the heating value—of natural gas isn't perfectly consistent. It can vary slightly based on where it was sourced and its exact chemical makeup. Your utility doesn’t just guess; they are constantly testing the gas in their system to know its precise energy "potency."

That factor on your bill is their way of converting the volume of gas you used (in CCF) into the actual energy you received (in Therms or MMBtu). It ensures you’re only paying for the heat that powered your boilers and equipment, not just the space the gas took up.

When permanent gas lines aren't an option, having a reliable partner for temporary fuel is critical. Blue Gas Express delivers mobile CNG and LNG solutions to keep your projects on track across the Carolinas, Tennessee, and Virginia. Don't let a utility delay stop your progress. Find your temporary energy solution at https://bluegasexpress.com.