Imagine your fleet's fueling schedule actually working for you, not against you. Instead of your drivers losing precious time—and burning fuel—just to get to a distant CNG station, the station comes directly to your yard.

That’s the simple, powerful idea behind mobile CNG fueling. It's a logistical game-changer that's quickly becoming essential for modern fleets.

The Gas Station That Comes to Your Fleet

This whole concept directly tackles one of the biggest headaches for fleets switching to cleaner fuels. While compressed natural gas (CNG) is a fantastic way to cut costs and emissions, the lack of public fueling stations can be a real operational nightmare. Mobile fueling is the bridge that closes that infrastructure gap.

Overcoming Infrastructure Hurdles

Think of it as fueling on demand. It’s a flexible, scalable solution that gives you all the benefits of on-site fueling without the massive capital investment of building a permanent station. This makes it a perfect fit for a few key scenarios:

- Fleets in remote areas where the nearest public CNG station is miles out of the way.

- Businesses with temporary needs, like a major construction project or a seasonal spike in operations.

- Companies piloting CNG vehicles and wanting to test the waters before committing to permanent infrastructure.

The rise of this service is happening for a reason. The global CNG market was valued at around USD 211.06 billion in 2025 and is expected to hit USD 333.94 billion by 2029. With more fleets making the switch to save money and meet environmental standards, flexible fueling solutions aren't just a convenience—they're becoming a necessity. You can see more on the compressed natural gas market growth for a deeper dive into the numbers.

By bringing the fuel directly to the vehicles, mobile services turn downtime into productive refueling time. This simple shift maximizes driver hours, reduces off-route mileage, and boosts overall fleet efficiency.

At the end of the day, this approach lets businesses adopt cleaner, more affordable fuel on their own terms. It’s a smarter, more agile way to manage a modern fleet and paves the way for a more sustainable operation.

How On-Site CNG Refueling Actually Works

The idea of bringing a fueling station directly to your fleet might seem like a massive undertaking, but the reality is surprisingly simple and elegant. Forget the image of building a permanent station in your yard. Instead, think of it as a highly specialized, just-in-time fuel delivery service.

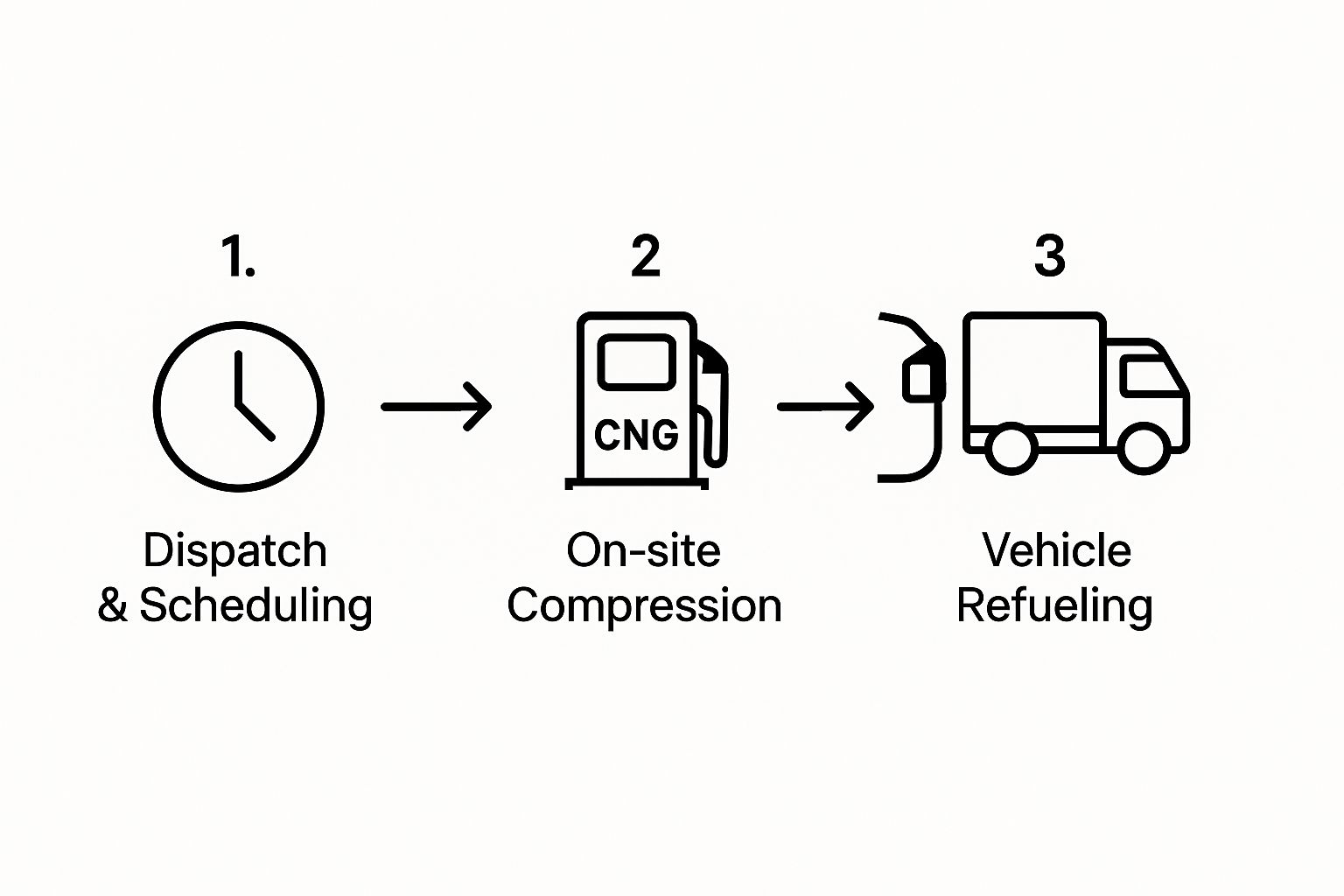

The entire mobile CNG fueling process is built around efficiency and safety, designed to slot right into your operational downtime without causing a ripple. It starts with a simple schedule and ends with your entire fleet fueled and ready to roll for the next shift.

This infographic lays out the basic steps, from the initial scheduling to the moment the last vehicle is filled.

As you can see, it's a seamless cycle. The goal is to turn those idle, non-productive hours—like overnight parking—into the perfect window for refueling.

The Journey From Pipeline to Vehicle Tank

It all begins at a permanent compression station, where natural gas is pulled from a pipeline and compressed into a mobile tanker. This tanker, often called a "tube trailer," is essentially a rolling pipeline made up of a series of high-pressure storage cylinders. These trucks are the backbone of the whole operation, safely bringing large volumes of CNG right to your doorstep.

When the mobile fueling unit arrives, a trained and certified operator takes charge. Their first job is always safety. They'll run through a checklist, securing the area and inspecting all the gear—hoses, connections, and even the fueling port on your vehicle—to make sure everything is perfect before a single cubic foot of gas flows.

With the safety checks complete, the operator connects a dispenser hose from the trailer to the vehicle. This is where the real magic happens. The system is engineered to precisely manage the pressure difference, letting the compressed gas flow from the high-pressure cylinders on the truck into the vehicle's onboard tanks until they're full.

The secret sauce is managing a controlled pressure differential. It's the same basic principle as air rushing out of a high-pressure balloon into the lower-pressure room, but the entire process is meticulously controlled for absolute safety and efficiency.

Key Hardware and Dispensing Technology

The gear used for mobile CNG fueling is purpose-built to handle the immense pressures involved. You'll find a lot of specialized components working in concert, including systems like the various Wiggins Service Fast Fueling Systems. Here are the critical pieces of the puzzle:

- High-Pressure Hoses: These aren't your typical pump hoses. They are heavily reinforced to safely manage the 3,600 psi (pounds per square inch) pressure standard for CNG.

- Dispensing Nozzles: Engineered for a perfect, leak-proof seal, these nozzles lock securely onto a vehicle's fueling port. Most also have breakaway safety features that instantly stop the gas flow if a truck were to pull away unexpectedly.

- Pressure Regulators and Meters: This is the onboard "brain" of the fueling unit. It constantly monitors the gas flow, measures the exact amount dispensed, and prevents any chance of over-pressurizing a vehicle's tanks.

This whole procedure is then repeated for every vehicle in the fleet, usually on a schedule that aligns with your slowest periods, like late at night. This simple shift means every driver starts their day with a full tank, completely wiping out the lost time and wages from mid-route fueling stops. It’s a finely tuned system that brings peak efficiency directly to you.

The Business Case for Mobile CNG Fueling

Any new fueling strategy is a big decision, but the move to mobile CNG is backed by a solid return on investment. The logic is pretty straightforward and comes down to three key advantages: serious operational improvements, direct cost savings, and a much clearer path to hitting sustainability goals. It’s a smart move that benefits the entire operation.

For any fleet manager, the first thing you'll notice is how much more efficient everything becomes. The old way of sending drivers out to a fixed station eats up time and money. Every minute spent driving to the pump is a minute that truck isn't on the road earning. Mobile CNG fueling completely changes that game.

When the fuel comes directly to your yard, you eliminate all that wasted travel. Your vehicles can be refueled overnight or during planned downtime, meaning every truck is ready to roll at the start of the day with a full tank. That simple shift can give you back hundreds of hours of productive time across your fleet each year.

Driving Down Costs and Boosting ROI

Beyond the time savings, the numbers just make sense. Compressed natural gas consistently costs less per gallon equivalent than diesel, which means you start saving money on your biggest variable expense right away. It's a win-win, really—good for the budget and good for the environment. With diesel prices always fluctuating and clean energy policies gaining ground, the U.S. CNG market is only getting bigger.

And here’s the kicker: mobile services let you avoid the massive capital investment of building a permanent on-site station. We're talking about a project that can easily run into the millions.

By partnering with a mobile provider, you turn a huge upfront capital expense into a predictable, manageable operating cost. This keeps your cash free for other important parts of the business, like upgrading your fleet or investing in driver training.

Getting the most out of every drop of fuel is key for any fleet. While mobile CNG is a huge step, you can always find more ways to boost semi-truck fuel economy and stack up the savings.

When considering a switch, it helps to see the differences side-by-side.

Mobile CNG Fueling vs Traditional Fueling Methods

Here’s a look at how bringing the fuel to your fleet stacks up against the traditional model of driving to a fixed station.

| Feature | Mobile CNG Fueling | Traditional Diesel/Gasoline Station |

|---|---|---|

| Capital Investment | Zero upfront cost for building infrastructure. | Extremely high; building a station can cost millions of dollars. |

| Operational Efficiency | High. Refueling happens during downtime, eliminating non-productive travel. | Low. Drivers lose time and burn fuel traveling to and from the station. |

| Fuel Cost | Lower. CNG is consistently cheaper per gallon equivalent than diesel. | Higher and more volatile. Diesel and gasoline prices fluctuate significantly. |

| Scalability & Flexibility | Highly flexible. Service can be scaled up or down based on your fleet's needs. | Fixed. You are limited by the station's capacity and location. |

| Environmental Impact | Significantly lower emissions (NOx, particulate matter, GHG). | High emissions, contributing to air pollution and a larger carbon footprint. |

| Implementation Speed | Fast. Service can be started quickly, often within weeks. | Very slow. Permitting, planning, and construction can take a year or more. |

The contrast is clear: mobile CNG offers a more agile, cost-effective, and environmentally responsible solution for modern fleets.

Meeting Sustainability Goals

Finally, you can’t ignore the environmental argument. Switching from diesel to CNG is one of the most impactful things a fleet can do to reduce its carbon footprint. This is more than just feeling good about corporate responsibility—it’s about meeting tougher regulations and satisfying customers who want to see greener supply chains.

- Reduced Emissions: CNG burns cleaner, producing far lower levels of nasty stuff like nitrogen oxides (NOx), particulate matter, and greenhouse gases.

- Quieter Operation: CNG engines are noticeably quieter than diesel ones, which is a big plus for reducing noise pollution in the communities you serve.

- Regulatory Compliance: As emissions standards tighten, CNG gives you a reliable way to stay compliant and avoid potential fines.

This blend of operational agility, smart financial planning, and environmental leadership makes mobile CNG fueling a powerful choice for any fleet looking to get ahead.

Where Mobile CNG Makes a Real-World Impact

The idea behind mobile CNG is solid, but its real power shines when you see it solving actual operational headaches out in the field. This isn't some niche, one-size-fits-all solution; it’s a flexible tool that tackles very specific challenges for all sorts of essential industries. From busy city depots to far-flung construction sites, mobile fueling brings the energy right where it’s needed most.

Let's look at how different sectors are putting this on-demand service to work. By seeing how it solves their problems, you can start to imagine how it might streamline your own fleet operations. Each use case highlights a different strength, whether that's keeping critical public services running without a hitch or making sure heavy machinery is always ready to go.

Waste Management and Municipal Fleets

For a waste management company, a truck that isn't on its route is a truck that's losing money. These vehicles run grueling stop-and-go schedules and have to be ready to roll at the crack of dawn. Mobile CNG fueling slots perfectly into this rhythm.

- Fueling After Hours: Instead of drivers wasting time at a central station after a long day, a mobile unit comes to the depot and refuels the entire fleet overnight.

- More Time on the Route: Every truck starts the day with a full tank. That means no more detours for fuel, which keeps collection schedules tight and cuts down on wasted miles.

- Less Traffic Headaches: It keeps bulky refuse trucks out of public fueling stations, which helps ease congestion and keeps the community happy.

This "fuel while you sleep" approach has become a go-to strategy for municipal fleets, too—think street sweepers and public works vehicles. It ensures they are always primed for the day's work.

Public Transit and School Bus Operations

Talk about tight schedules. Transit authorities and school districts have zero room for delays, and keeping a massive fleet of buses fueled and on time is a huge logistical puzzle. This is especially true if their depots weren't built with permanent CNG infrastructure.

Mobile CNG acts as a vital bridge. It allows transit agencies to start cleaning up their fleets without having to make a massive, multi-million-dollar investment in a fixed station right away.

This flexibility is everything. A mobile provider can adjust the service as more CNG buses are added to the fleet, offering a practical, cost-effective way to hit emissions targets while keeping services reliable for riders.

The market is moving in this direction, too. As more CNG vehicles hit the road, the demand for refueling infrastructure is booming, and mobile units are a critical piece of that puzzle for fleets without a home base station. You can learn more about the expanding global CNG market and the infrastructure supporting it.

Construction and Agriculture

Construction sites and large-scale farms often pop up in remote areas, miles away from any kind of established infrastructure. The problem is, their heavy equipment—from haul trucks to tractors—burns through fuel relentlessly.

Mobile CNG fueling brings a temporary, self-contained energy source directly to the job site or field, and it can move as the project progresses. This completely cuts out the costly and time-sucking chore of hauling equipment to an off-site station. It keeps projects on track and farming operations humming during those critical planting and harvesting windows.

Understanding CNG Safety and Regulations

Anytime you're working with fuel, safety comes first. No exceptions. While the thought of handling natural gas under high pressure might seem a bit daunting, the truth is that mobile CNG fueling is a remarkably safe and mature industry. It's governed by a comprehensive set of strict standards that ensure every single fill-up is as safe as possible.

This isn't some new, unproven technology. The equipment and procedures have been battle-tested and refined over many years. In many ways, the system is designed to be even safer than conventional gasoline or diesel fueling. Every piece of hardware, from the storage cylinders to the hoses, is specifically engineered to handle the unique properties of CNG with a massive safety margin built right in.

Engineered for Maximum Safety

At its core, the safety of mobile CNG comes down to smart engineering. The high-pressure cylinders that store and transport the gas are absolute workhorses, built from incredibly tough materials like steel or advanced carbon fiber composites. These aren't just thrown together; they go through an insane amount of testing—including pressure cycling and even ballistic tests—to prove they can handle impacts far beyond anything they'd see in the real world.

But it’s not just about the tanks. The entire mobile fueling rig is layered with redundant safety features. These aren't just nice-to-haves; they are integrated, non-negotiable parts of the system.

- Emergency Shut-Off Valves: These can be triggered manually or automatically to instantly cut the flow of gas if something goes wrong.

- Breakaway Hoses: If a driver accidentally pulls away with the nozzle still attached, these hoses safely disconnect and seal both ends, preventing a gas leak.

- Pressure Relief Devices: Think of these as a last line of defense. In the extremely unlikely scenario of over-pressurization, they safely vent the gas to prevent a tank from rupturing.

It's a lot like the safety systems in a modern car. You don't just have one thing protecting you; you have seatbelts, airbags, and anti-lock brakes all working in concert. Mobile CNG units are built with that same layered approach to protect people, equipment, and the environment.

The Role of Regulations and Operator Training

All of this robust engineering is backed by strict regulations from organizations like the National Fire Protection Association (NFPA). Standards like NFPA 52 lay out the rulebook, providing a detailed and legally enforceable code for the design, construction, and operation of all CNG fueling systems, mobile units included.

Of course, the best equipment in the world is only as good as the person running it. That's why only highly trained and certified technicians are allowed to operate mobile CNG fueling equipment. Their training is intensive, covering everything from pre-fueling safety checklists and proper dispensing techniques to knowing exactly what to do in an emergency. This ensures an expert is watching over every step of the process, making sure every safety protocol is followed, every single time.

How to Choose the Right Fueling Partner

Finding the right mobile CNG fueling partner is about more than just a line item on a budget. You’re looking for a company that acts as a true extension of your own team—someone you can count on to be there, on time, every time. The goal isn't just to get fuel; it's to get peace of mind.

To get there, you need to know what questions to ask and what to look for beyond the price tag.

Start with the Non-Negotiables

Before you even talk about logistics or cost, you have to cover safety and compliance. These are the absolute deal-breakers. A professional, trustworthy provider will be upfront about their safety record and should have no problem showing you documentation proving they meet all industry standards, like those from the NFPA.

Don't be shy about asking for proof of insurance or the certifications for their operators. Any hesitation is a major red flag.

Dig Into Their Operations

Once you've established their commitment to safety, it's time to look at how they actually run their business. The quality of their equipment, for instance, says a lot about their reliability. Ask them about the age and maintenance schedule of their mobile fueling units. Modern, well-maintained gear is simply less likely to break down and leave you stranded.

When you're comparing providers, make sure to get clear answers on these points:

- Fuel Supply Reliability: Where do they get their natural gas? More importantly, what’s their backup plan if that primary source has an issue? You need a partner who has built redundancy into their supply chain.

- Service Level Agreement (SLA): Get into the details of the contract. What are their guaranteed fueling times? What happens if they miss one? A solid SLA protects your operation.

- Pricing Structure: Is the pricing model easy to understand? Whether it’s a flat rate, a per-GGE fee, or something else, make sure you know exactly what you’re paying for and that there are no hidden charges waiting to surprise you.

The single most powerful question you can ask a potential partner is, "Can I speak to a few of your current clients in my industry?" Talking to a fleet manager who already relies on them will give you the unvarnished truth about their performance.

Ultimately, you’re looking for flexibility. Your fleet's needs will change, and you need a mobile CNG fueling partner who can adapt with you. The best companies will work alongside you to tweak schedules and figure out logistics, making sure their service is a genuine asset to your business.

Got Questions? We've Got Answers

It makes sense to have a few questions before diving into a new way of fueling your fleet. Even when the benefits are clear, it's the practical, day-to-day details that really matter. Let's walk through some of the most common questions fleet managers have about switching to mobile CNG fueling.

Is It As Fast As a Traditional Gas Station?

This is probably the number one question we get, and the answer isn't just about the pump's speed. While a single fill-up might take a few minutes longer than a diesel pump, the real magic of mobile fueling is how it completely changes your operational clock.

The big win comes from cutting out the travel time to and from a fixed station. Instead of your drivers wasting valuable time in transit, refueling happens during scheduled downtime, usually overnight. So, while the nozzle might be on the truck a little longer, your entire fleet is full and ready to roll the second the workday starts.

It’s not about how fast the pump is; it's about how efficient your entire fueling process becomes. Mobile CNG turns unproductive downtime into productive refueling time, which is a huge win for any schedule.

How Does the Initial Setup Work?

Getting started is surprisingly straightforward. The first step is a quick site visit from the provider. They'll just need to make sure you have a safe and accessible spot to park the mobile fueling unit.

From there, you'll map out a fueling schedule that fits right into your existing operations. The provider takes care of everything else—they bring the equipment, manage the natural gas supply, and handle the refueling. It's a completely turnkey service, meaning you get all the benefits of CNG without the headaches and high costs of building a permanent station.

What Kind of Vehicles Can Use It?

Think universal compatibility. Mobile CNG fueling units are built to work with just about any vehicle equipped with a standard CNG system.

This includes a wide range of fleet vehicles:

- Light-duty work vans and pickups

- Heavy-duty semi-trucks and garbage trucks

- Transit buses and school buses

The equipment, from the nozzles to the pressure settings, all adheres to strict industry standards. This ensures every connection is safe, secure, and effective, no matter what kind of CNG vehicle you're running.

Ready to eliminate fueling downtime and simplify your fleet's operations? Blue Gas Express provides reliable, on-demand CNG and LNG solutions across the Southeast. Discover how our mobile fueling services can keep your projects on schedule without the need for permanent infrastructure. Visit us at https://bluegasexpress.com to learn more.