Ever wonder how natural gas gets from a remote well to your stove? The answer, in a word, is compression. Methane gas compression is the process of taking a massive volume of gas and squeezing it into a much smaller, higher-pressure space. Think of it like pumping up a bicycle tire—you're forcing a lot of air into a compact area. This is the foundational step that makes natural gas, which is mostly methane, easy to transport and store.

What Is Methane Gas Compression and Why Does It Matter

At its heart, methane gas compression is the engine that drives the entire natural gas supply chain. When methane comes out of the ground, it's at a pretty low pressure and takes up a huge amount of space. Trying to move it in that state would be incredibly inefficient. Imagine trying to ship a mountain of fluffy cotton balls—you'd have a much easier time if you could first press them into dense, manageable bales.

That's exactly what compression does for methane. Powerful machines, called compressors, force the gas molecules closer together. This shrinks the volume and makes the gas dense enough to be pushed efficiently through thousands of miles of pipelines or stored in special tanks until it's needed.

The Foundation of Energy Delivery

Without effective methane gas compression, our modern energy grid simply couldn't exist. It's the critical connection between far-flung gas fields and the homes and industries that rely on that energy. This process isn't just about moving gas; it's about making energy accessible and reliable on a massive scale. Every time you fire up a gas appliance, you're reaping the benefits of a complex chain of compression stages.

Here are a few of the key roles compression plays:

- Pipeline Transportation: To keep gas moving through long-distance pipelines, "booster" stations are set up along the route to re-compress the gas and maintain the necessary pressure and flow.

- Gas Storage: To prepare for spikes in demand, natural gas is compressed and pumped into huge underground storage areas, like old, depleted gas fields or salt caverns.

- Liquefied Natural Gas (LNG) Production: Compression is the crucial first step before the gas is chilled down to a mind-boggling -260°F (-162°C), turning it into a liquid that can be shipped overseas on tankers.

- Fueling Vehicles: To create Compressed Natural Gas (CNG) for vehicles like buses and trucks, methane has to be compressed to extremely high pressures so it can be stored safely in onboard fuel tanks.

In essence, compression transforms methane from a raw, bulky resource into a refined, high-density energy product. It’s the essential, often unseen, process that ensures energy is available where and when it’s needed.

The equipment that gets this job done is highly specialized. You'll find everything from massive centrifugal compressors at LNG plants to smaller reciprocating units right at the wellhead, with each machine engineered for a specific task. Getting a handle on how this technology works is the first step in understanding the incredible journey gas takes to get to you. This guide will walk you through the equipment, processes, and applications that define the world of methane gas compression.

The Workhorses of Methane Gas Compression

When it comes to methane gas compression, the industry really leans on two main types of machinery. Each one works on a completely different principle, which makes them perfect for specific jobs all along the energy supply chain. These are the powerful engines that take low-pressure methane and turn it into a high-energy product that's ready to be moved and used.

Think of them as two distinct tools in a mechanic's toolbox: the reciprocating compressor and the centrifugal compressor. You wouldn't use a sledgehammer to drive a finishing nail, right? It's the same idea here. Engineers pick the right compressor for the job based on exactly what they need to get done.

The Power of Positive Displacement: Reciprocating Compressors

Picture a bicycle pump, but built on a massive, industrial scale. That's the core concept behind a reciprocating compressor. It uses a piston that slides back and forth inside a cylinder to pull in, trap, and then literally squeeze the methane gas. This method is what we call positive displacement—it compresses a set volume of gas with every single stroke.

This design is what makes reciprocating units so good at hitting very high pressures, even when they aren't working with huge volumes of gas. They are the specialists for tasks that need a powerful, targeted push. Because of this, you’ll see them pop up in places like:

- Wellhead Compression: Giving raw gas a pressure boost right as it comes out of the ground.

- Gas Gathering Systems: Pulling gas from a bunch of different wells and shoving it down the line to a central plant.

- CNG Fueling Stations: Squeezing methane down to the incredibly high pressures required for vehicle fuel tanks.

What makes them so versatile is their ability to handle fluctuating flow rates and different gas makeups. The trade-off? The constant back-and-forth motion of pistons, rods, and valves means there are a lot of moving parts, which can lead to more frequent maintenance.

The Speed of Dynamic Force: Centrifugal Compressors

Now, let's switch gears. A centrifugal compressor works more like a super-powered, high-speed fan. It has a spinning wheel, called an impeller, with angled blades that suck gas into the center and then sling it outward with incredible force. As the gas is thrown outward and then slowed down in a part called a diffuser, its pressure builds up. This is a dynamic process.

Centrifugal compressors are built for one thing above all else: moving massive volumes of gas efficiently. They provide a smooth, continuous flow, which is a world away from the pulsing action you get with a reciprocating unit. This makes them the undisputed champions for big-time operations where high flow is everything.

A centrifugal compressor is the go-to choice for major infrastructure like cross-country pipelines and massive LNG facilities. It excels at handling huge quantities of gas where consistent, high-volume throughput is the name of the game.

Their design is simpler, with fewer moving parts, which usually means they are more reliable and don't need as much attention. The catch is that they're less flexible when conditions change and really hit their stride only within a specific flow and pressure sweet spot.

Reciprocating vs Centrifugal Compressors for Methane

Choosing between a reciprocating and a centrifugal compressor is a critical engineering decision, never a random guess. The choice always comes down to the nitty-gritty details of the job: how much gas needs to be moved (flow rate), how high the pressure needs to be (discharge pressure), and the properties of the gas itself.

This table breaks down their core differences to make it clear where each one shines.

| Feature | Reciprocating Compressor | Centrifugal Compressor |

|---|---|---|

| Operating Principle | Positive Displacement (Piston-driven) | Dynamic (Impeller-driven) |

| Best For | High pressure, lower flow rates | High flow rates, moderate pressure |

| Pressure Ratio | High per stage | Lower per stage |

| Flow | Pulsating, intermittent | Smooth, continuous |

| Efficiency | Highly efficient across a wide range of conditions | Most efficient within a narrow operating range |

| Common Use Cases | Gas gathering, CNG stations, gas storage | Pipeline transmission, LNG plants, large refineries |

| Maintenance | More frequent due to more moving parts | Less frequent, generally more reliable |

In the end, our natural gas infrastructure simply couldn't function without both. Reciprocating compressors bring the high-pressure muscle needed for the initial push and specialized jobs, while centrifugal compressors are the long-distance runners that keep massive amounts of energy moving across continents.

A Look Inside the Gas Compression Cycle

To really get a handle on methane gas compression, it helps to picture a single gas molecule making its way through a compressor station. It’s not just a simple squeeze. The process is a highly engineered, multi-stage ballet designed for peak efficiency and safety.

Let's follow the gas from its low-pressure arrival to its high-pressure, transport-ready state. The entire cycle boils down to a sequence of cleaning, compressing, and cooling. Each step is critical, building on the one before it to prepare the methane for its final destination.

Stage 1: The Scrubbing and Inlet Phase

Before we can even think about compressing the gas, we have to clean it up. As the raw methane flows into the compressor station, its first stop is a series of filters and separators, often called "scrubbers."

Think of this as a mandatory pre-flight check. Scrubbers are there to catch and remove impurities that would wreak havoc on the sensitive, high-speed machinery downstream. These contaminants typically include:

- Liquids: Droplets of water, oil, or other hydrocarbons that have condensed out of the gas stream.

- Solid Debris: Tiny particles of rust, dust, or pipe scale that have broken free inside the pipeline.

This initial cleanup ensures that only pure, dry gas moves on to the compressor. It’s a crucial step that prevents expensive wear and tear and keeps the whole operation running smoothly.

The scrubbing phase is non-negotiable. Forcing contaminated gas through a compressor is like pouring sand into a car engine—a recipe for catastrophic failure and costly downtime.

Stage 2: Multi-Stage Compression and Cooling

With the gas cleaned up, it enters the heart of the system: the compressor. When a big pressure jump is needed, this is almost always a multi-stage process. Instead of trying to hit the target pressure in one giant leap, the work is divided into several smaller, more manageable stages.

After the first stage of compression, the gas gets hot. Really hot. That's just physics—squeezing a gas generates heat. This is where intercoolers come into play.

An intercooler is essentially a heat exchanger placed between the compression stages. It's a cool-down station, dropping the gas temperature before it heads into the next stage. This cooling is vital for two key reasons: it makes the next compression stage more efficient and it keeps equipment temperatures within safe operating limits.

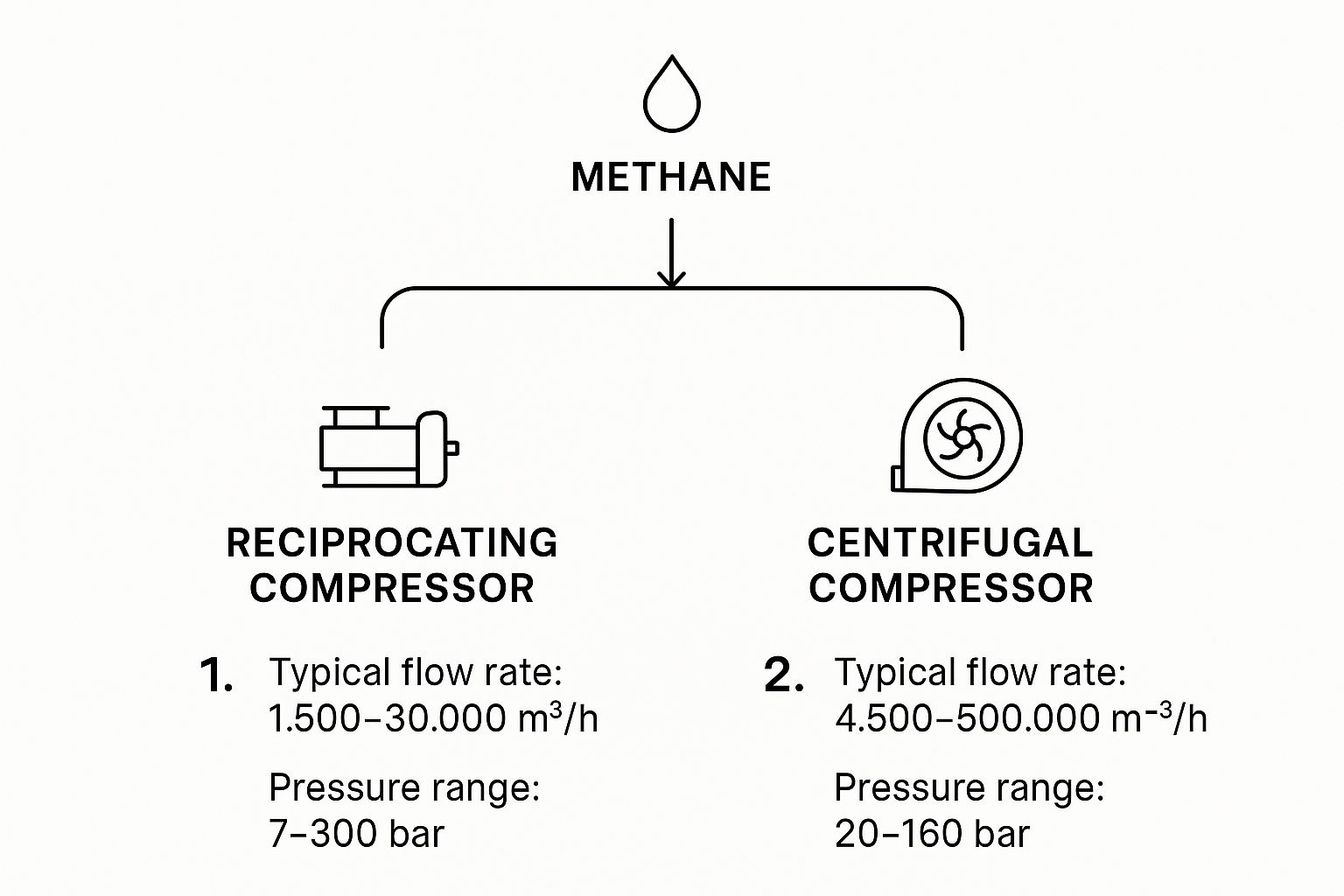

The infographic below shows the two main types of compressors and where they excel in terms of flow and pressure.

As you can see, centrifugal compressors are the workhorses for moving massive volumes of gas, while reciprocating compressors are the specialists when you need to reach extremely high pressures.

Stage 3: Final Cooling and Discharge

After the gas leaves the final compression stage, it's at its target pressure but also at its hottest point. Before it can be sent down the line, it needs one last cool-down.

An aftercooler, working on the same principle as an intercooler, is used to bring the gas temperature down to a safe, stable level. This prevents thermal stress on the pipeline and ensures the gas meets the strict quality standards for transportation.

Finally, the clean, cool, high-pressure methane gas flows through a discharge valve and back into the pipeline or into a storage vessel. It now has the pressure it needs to travel hundreds of miles. From a low-energy stream to a powerful product, the transformation is complete.

Managing Safety and Environmental Impact

Let's be direct: handling a flammable substance like methane at incredibly high pressures is serious business. When it comes to methane gas compression, the stakes couldn't be higher. This demands an absolute, unwavering commitment to both operational safety and environmental protection. It isn't just about ticking boxes on a checklist; it's about fostering a culture where every single action is weighed against its potential impact.

The entire process operates under immense pressure, and the gas itself is highly combustible. That combination means robust safety systems aren't just nice-to-haves—they are the core framework protecting workers, expensive equipment, and the surrounding community from what could go wrong.

Building a Fortress of Safety Protocols

At any modern compression facility, safety is built in layers. Think of it as a fortress, with multiple automated and manual safeguards designed to stop an incident long before it can even start. These systems are the vigilant guardians, constantly monitoring the operation for any sign of trouble. If a single parameter drifts outside its safe operating window, they react instantly.

Key safety components are engineered for one thing: reliability and immediate response.

- Pressure Relief Valves (PRVs): These are the ultimate safety nets. If pressure inside a vessel or pipeline spikes beyond a set limit, a PRV automatically opens to vent the excess gas, preventing a catastrophic failure. Simple, but incredibly effective.

- Emergency Shutdown (ESD) Systems: This is the big red button for the whole operation. An ESD system can be triggered manually or, more importantly, automatically by sensors detecting fire, gas leaks, or critical pressure drops. It immediately isolates equipment and shuts down the process safely.

- Gas and Fire Detection: A sophisticated network of sensors continuously "sniffs" the air for even the faintest trace of methane. If a leak is detected, alarms blare and the ESD system kicks in, providing that crucial early warning needed to prevent a fire or explosion.

Of course, technology is only half the battle. Rigorous training and strict adherence to procedures are just as critical. Regular drills, meticulous maintenance schedules, and a culture of constant vigilance work together to minimize human error and ensure every team member knows exactly what to do in an emergency.

Safety in methane compression is a proactive discipline, not a reactive measure. It’s about anticipating risks and engineering robust, redundant systems to neutralize them long before they can escalate into a serious incident.

Given the sheer power of the machinery involved, controlling noise is also a major factor. Putting together an effective noise management plan is essential for protecting worker health and minimizing the impact on nearby communities. It's about being a good neighbor.

Tackling the Challenge of Fugitive Emissions

On the environmental side of things, the focus is squarely on one major challenge: fugitive emissions. These are the small, unintentional leaks of methane gas that can escape from equipment like valves, seals, and pipe connections. An individual leak might seem tiny, but when you add them all up, their cumulative effect is a big deal.

Methane is a potent greenhouse gas, so stopping these leaks is a top environmental priority. The push to reduce methane emissions is global and intense, largely because its global warming potential is over 80 times that of CO2 over a 20-year period. While compression is vital for moving natural gas, we can't ignore the losses. In 2023 alone, the International Energy Agency (IEA) reported that around 196 billion cubic meters of gas were lost worldwide from flaring, venting, and leaks—some of which occur during compression.

To combat this, the industry relies on some pretty smart strategies and technology.

- Leak Detection and Repair (LDAR): These programs are systematic "seek and destroy" missions for leaks. Technicians use specialized infrared cameras that literally make invisible methane plumes visible, allowing them to pinpoint and fix even the smallest sources of fugitive emissions.

- Advanced Sealing Technology: Modern compressors don't just use basic gaskets. They feature advanced systems like dry gas seals, which are high-tech components that create an incredibly effective barrier to stop gas from leaking out around the spinning compressor shaft. They keep the methane where it belongs.

By pairing proactive safety engineering with diligent environmental stewardship, the methane gas compression industry works to ensure this vital energy process is handled as safely and responsibly as humanly possible.

Where Methane Compression Shows Up in the Real World

The term methane gas compression might sound like something straight out of an engineering textbook, but you'd be surprised how much it shapes our daily lives. This isn't just an abstract industrial process; it's the invisible workhorse that makes our energy system function. It’s the critical step that transforms raw methane from a localized resource into a fuel we can actually use.

Think of it this way: without compression, methane’s vast energy potential would be stuck at the source. It’s compression that gives methane the density and pressure needed to power everything from cross-country pipelines to city buses. Let’s take a look at where this technology is making a real impact.

Keeping the National Gas Grid Humming

By far, the most common application for methane compression is in our natural gas pipelines. These pipelines are the arteries of our nation's energy infrastructure, but the gas doesn't just flow through them on its own. It needs a push.

That's where compressor stations come in. You'll find one of these powerful facilities every 40 to 100 miles along a major pipeline. Their job is simple but essential: as gas travels, it loses pressure due to friction. These stations act like booster pumps, taking in the low-pressure gas, re-compressing it, and sending it on its journey with renewed force.

- Maintaining Momentum: Without these stations, the flow of gas would eventually slow to a trickle, failing to reach the communities that depend on it.

- Ensuring a Reliable Supply: They give grid operators the flexibility to meet fluctuating demand, like pushing more gas toward a city during a sudden winter cold snap.

These massive stations, often powered by a tiny fraction of the gas they're moving, are the unsung heroes keeping our homes heated and power plants online.

Fueling Cleaner Trucks and Buses

Methane compression is also the key to creating Compressed Natural Gas (CNG), a much cleaner alternative to gasoline and diesel. To make it practical as a vehicle fuel, natural gas has to be squeezed down to incredibly high pressures, typically between 3,000 and 3,600 psi.

This intense compression shrinks the gas's volume by over 99%, which is how you can store a useful amount of energy in a vehicle's onboard tanks. You’ve likely seen CNG-powered vehicles without even realizing it:

- City transit buses

- Garbage and recycling trucks

- Local delivery fleets

By running on CNG, these vehicles produce far fewer harmful emissions, like nitrogen oxides and soot, than their diesel counterparts. The compression technology at the fueling station is what makes this leap to cleaner transportation possible.

Compression takes low-pressure methane and turns it into a dense, high-energy fuel. Whether the goal is to move that gas across a continent or power a local bus, the principle is the same: pack more energy into a smaller space.

Making Global Energy Trade Possible with LNG

How do you get natural gas across an ocean where there are no pipelines? You turn it into Liquefied Natural Gas (LNG). And the very first step in this highly sophisticated process is, you guessed it, compression.

Before the gas can be chilled to a mind-boggling -260°F (-162°C), it has to be compressed. This initial step purifies the gas and gets it ready for the intense cooling process. It’s a foundational piece of the entire LNG supply chain, enabling energy to be traded between continents.

Powering the Green Energy Transition

Finally, methane compression plays a vital role in the renewable energy sector. Methane captured from organic sources—think landfills, dairy farms, or wastewater treatment plants—is known as Renewable Natural Gas (RNG) or biomethane.

This captured biogas starts out as a low-pressure, impure gas. Compression is absolutely essential for cleaning it up and pressurizing it enough to be injected into the existing natural gas grid. In doing so, we take a potent greenhouse gas that would otherwise harm the atmosphere and turn it into a valuable, carbon-neutral energy source.

Going Mobile: The New Frontier in Methane Compression

The future of methane compression isn't just about building bigger, more powerful permanent stations. It's about getting smarter, faster, and more flexible. This exact need is what sparked the rise of mobile compression solutions, and it's been a genuine game-changer for how the energy industry operates.

Think of it this way: what if you could put an entire compressor station on the back of a truck and drive it wherever it's needed most? That’s the simple but brilliant idea behind "compression on wheels." These units are built for rapid deployment, ready to tackle on-demand jobs at a moment's notice. Forget waiting months or even years for new infrastructure; a mobile unit can be on-site and running in a matter of hours.

Meeting Energy Demands on the Fly

This kind of agility solves a ton of real-world problems. For instance, think about remote well sites, especially those in newer fields that are miles from the nearest pipeline. Mobile compression units can pull right up, capture the gas at the source, and pressurize it for transport. This completely sidesteps the need for wasteful flaring and turns what was once a stranded asset into a valuable product.

These mobile systems are absolute workhorses for tasks like:

- Emergency Pipeline Support: Quickly providing temporary compression when a section of pipeline goes down for maintenance, repairs, or an unexpected outage.

- Reaching the Unreachable: Making it possible to capture and sell gas from wells that are just too far from existing infrastructure to be profitable otherwise.

- Building Virtual Pipelines: Creating a flexible supply chain by trucking compressed methane directly to customers who aren't hooked up to the main grid.

In essence, mobile methane compression creates a "virtual pipeline." It gives you the on-the-ground flexibility of a truck combined with the energy-moving power of a pipeline, guaranteeing gas gets where it needs to go, right when it's needed.

This is precisely how companies like Blue Gas Express are changing the energy delivery game. By supplying temporary CNG and LNG, they keep the lights on and the heat running for everything from construction projects and industrial plants to entire communities during a supply interruption. These nimble solutions are a perfect example of how the industry is adapting to modern demands for efficiency and an immediate response.

Got Questions About Methane Compression? We've Got Answers.

Even after covering the fundamentals, you're bound to have some practical questions about methane gas compression. Let's dig into some of the most common ones that come up in the field. We'll get straight to the point on everything from equipment choices to the role compression plays in the future of energy.

Getting these details right helps paint a clearer picture of how this process works in the real world. It also gives you a better appreciation for the engineering and operational decisions that teams across the energy sector have to make every single day.

Single-Stage vs. Multi-Stage Compression

So, what's the real difference between single-stage and multi-stage compression? The best way to think about it is like this: are you trying to take one giant leap or simply walk up a set of stairs?

A single-stage compressor does all the work in one go. It squeezes the gas to its final pressure in a single piston stroke or impeller rotation. This approach works just fine for jobs that only need a modest pressure boost. It's simple and effective.

Multi-stage compression, on the other hand, breaks the task into manageable steps. The gas gets partially compressed, then routed through an intercooler to get rid of the heat it just picked up, and then it’s sent on to the next stage for another squeeze.

Think of multi-stage compression like climbing a tall staircase instead of trying to jump to the top in one go. It is far more energy-efficient and safer for reaching the very high pressures needed for major pipelines and LNG production.

This step-by-step method keeps the equipment from overheating and actually uses less total energy to hit the final pressure target. For any high-pressure methane gas compression application—where efficiency and safety are non-negotiable—it's the industry standard for a reason.

Methane Compression's Role in Renewable Energy

How does this fit into the renewable energy picture? Methane compression is absolutely essential for making Renewable Natural Gas (RNG) a viable energy source. RNG, or biomethane, is what you get when organic waste from farms, landfills, and wastewater treatment plants breaks down.

The raw biogas from these sources is at a very low pressure and is full of impurities. Before you can do anything with it, it has to be purified and then compressed—a lot. This compression step is what makes it possible to:

- Inject RNG into existing natural gas pipelines, where it blends perfectly with conventional gas.

- Create bio-CNG, a clean, carbon-neutral fuel for vehicles like city buses and long-haul trucks.

Compression is the key that unlocks the value in this gas. It transforms a potentially harmful greenhouse gas emission into a clean, practical energy resource, playing a direct part in helping us decarbonize.

What are the Main Costs of Running a Compression Facility?

When you look at the budget for a compression facility, two big-ticket items always stand out: energy and maintenance.

These compressors are incredibly powerful machines, and they are thirsty for energy. That power typically comes from the electrical grid or, quite often, from using a small amount of the natural gas they’re compressing to fuel their own engines.

Maintenance is the other major cost. The constant high-pressure, high-speed work puts a ton of stress on all the mechanical parts. To keep things running safely and reliably, you need a strict maintenance schedule. This covers everything from simple lubrication and oil changes to eventually replacing major components like seals, bearings, and valves.

When an unexpected pipeline issue pops up or a new project needs fuel now, waiting around isn't an option. Blue Gas Express delivers mobile, scalable CNG and LNG solutions right to your site, making sure your operation continues without missing a beat. See how our rapid deployment services can keep your project moving forward by visiting https://bluegasexpress.com.