LNG fueling stations are facilities built specifically to store and dispense liquefied natural gas for vehicles, offering a cleaner and often more affordable alternative to diesel. As emissions rules get tougher across the globe, these stations are becoming a critical piece of the puzzle for heavy-duty trucking and logistics.

The Shift to LNG Fuel Stations in Modern Transport

The transportation world is in the middle of a massive shake-up, pushed by a one-two punch of environmental pressure and real-world economics. For years, diesel was the undisputed king of the road for heavy-duty fleets. That’s changing.

Tighter emissions regulations and unpredictable fuel costs are forcing fleet operators to find smarter, more sustainable ways to operate. This is where LNG fueling stations enter the picture.

Think of it like a business upgrading its entire IT infrastructure. The upfront cost might feel steep, but the long-term payoff in efficiency, security, and being ready for the future is clear. Switching to LNG isn't just about swapping out one fuel for another; it’s a strategic move toward building a more resilient and cost-effective operation.

Why the Move to LNG Is Accelerating

The growing interest in LNG isn't a fluke. It's a direct response to very real industry pressures and the clear benefits natural gas brings to the table. Fleet managers are realizing that sticking with diesel is no longer the safe bet it once was.

Here’s what’s pushing the change:

- Tougher Environmental Rules: Governments everywhere are cracking down on emissions. LNG burns much cleaner than diesel, drastically cutting pollutants like nitrogen oxides (NOx) and soot, which helps fleets meet today's strict standards and prepare for tomorrow's.

- Cost Stability and Savings: Diesel prices can swing wildly, making budgeting a nightmare. Natural gas prices, on the other hand, have historically been much more stable. This predictability makes long-term financial planning easier and often leads to significant savings on fuel over a truck's lifespan.

- Hitting Sustainability Targets: Companies are under more pressure than ever from investors and customers to go green. Bringing LNG trucks into a fleet is a tangible way to shrink a company's carbon footprint and show a real commitment to sustainability.

This global push for cleaner energy is fueling serious growth. The market for LNG filling stations was valued at around USD 2.30 billion and is expected to keep climbing, thanks to these environmental and economic drivers. You can explore more about this market expansion on maximizemarketresearch.com.

This guide will walk you through everything you need to know, from the nuts and bolts of how these stations work to the business case for making the switch. Our goal is to give fleet operators, logistics managers, and other decision-makers the clear, practical information needed to navigate this important industry shift.

How an LNG Fuel Station Works

At first glance, an LNG fuel station might seem like something out of a science fiction movie, but the process is surprisingly straightforward once you break it down. Think of it less like a standard gas station and more like a high-tech Thermos with a very sophisticated tap. Every part is designed to work together to safely and quickly move super-chilled liquid fuel into a vehicle's tank.

It all starts with a delivery. LNG arrives from a production plant and is carefully transferred into the heart of the station: the cryogenic storage tank. This isn't just a big steel drum; it's a massive, double-walled, vacuum-insulated vessel engineered to keep the LNG at an incredibly cold -260°F (-162°C). Keeping the fuel at this temperature is non-negotiable, as it maintains its dense liquid state, which is 600 times more compact than when it's a gas.

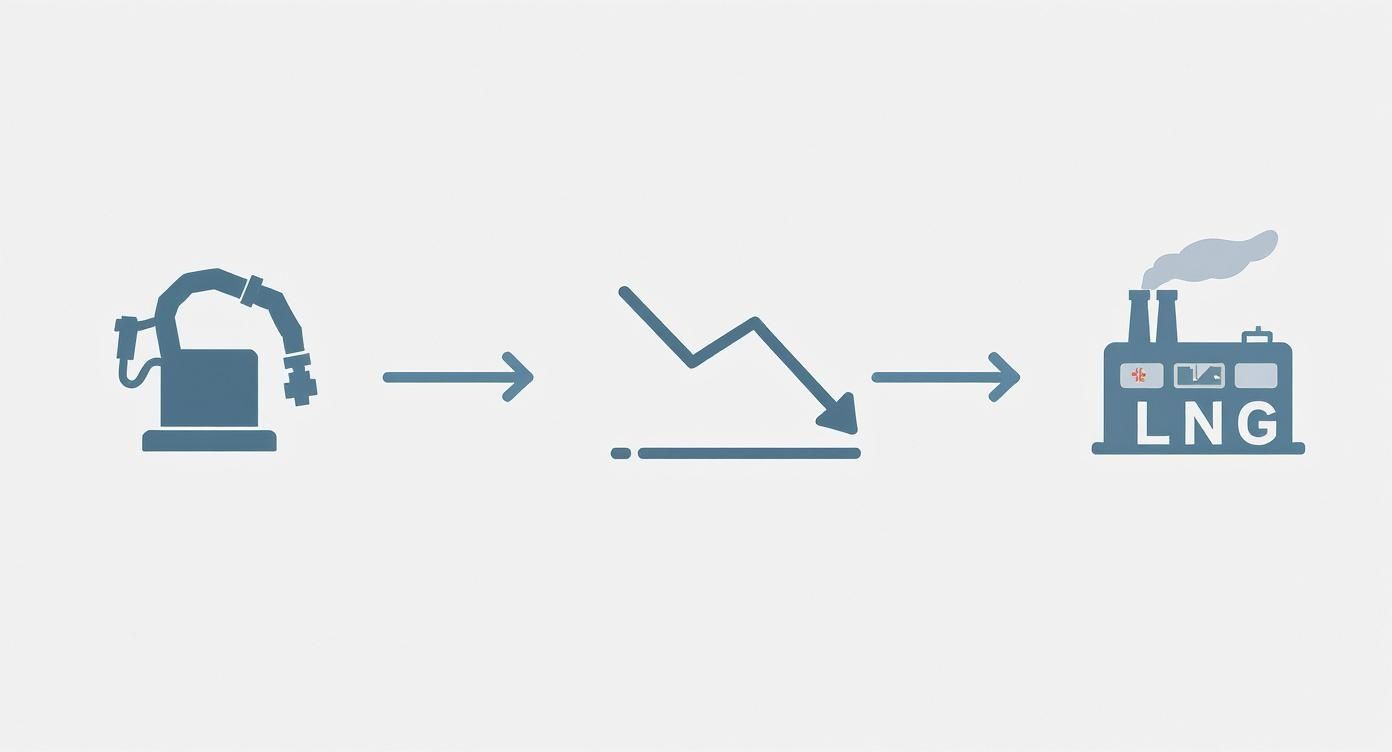

This visual shows how economic and environmental pressures are pushing the transportation industry away from old-school fuels and toward modern infrastructure like LNG.

The infographic perfectly illustrates how challenges with traditional fueling are accelerating the switch to advanced solutions like lng fuel stations.

From Tank to Truck: The Fueling Journey

When a truck is ready to refuel, a specialized cryogenic pump kicks into gear, moving the LNG from the main storage tank toward the dispenser. This isn't your average pump; it's built to operate in extreme cold without a hitch.

As the LNG moves through the pipes, a little bit naturally warms up and turns back into gas. This is a normal process called "boil-off," and it’s managed very carefully. The vapor can be vented safely, used to power equipment on-site, or even re-liquefied. This approach minimizes waste and keeps the pressure inside the system stable and safe.

The secret to any LNG fuel station is its mastery over extreme temperatures and high pressures. The whole setup is a closed-loop system. This means the fuel is never exposed to the open air, which prevents contamination and dramatically increases safety during fueling.

What Makes It All Tick? The Core Components

To really get a feel for how these stations run so smoothly, it helps to look at the individual pieces of the puzzle. Each component has a critical job, and together they create a refueling experience that’s often just as fast as pumping diesel.

Here’s a simple breakdown of the essential parts and what they do to keep everything running safely and efficiently.

Key Components and Their Functions in an LNG Fuel Station

| Component | Analogy | Primary Function |

|---|---|---|

| Cryogenic Storage Tank | A Giant Thermos | This double-walled, vacuum-sealed tank is the station's main fuel reservoir, keeping LNG at its ultra-low temperature. |

| Cryogenic Submerged Pump | The Heart | Sitting inside the storage tank, this powerful pump pushes the frigid liquid fuel out into the delivery lines for dispensing. |

| Vaporizer | The Pressure Manager | Uses the surrounding air to gently warm a small amount of LNG, turning it into gas to help pressurize the vehicle’s tank. |

| Dispenser & Nozzle | The Final Handshake | This is what the driver uses. It measures the fuel and connects securely to the truck, ensuring a leak-proof transfer. |

Each of these components is vital, working in concert to make the complex process of handling a cryogenic liquid feel simple and safe for the end user.

The Unseen Guardian: Safety and Control Systems

Behind the scenes, a sophisticated network of safety and control systems acts as the station's brain and nervous system. These aren't just extra features; they're woven into the very fabric of the station’s design.

From the moment LNG is delivered to the final click of the nozzle, everything is monitored in real-time. Automated sensors keep a constant watch on temperature, pressure, and flow rates. If any of these readings ever fall outside of safe limits, an Emergency Shutdown (ESD) system is instantly triggered.

This system can shut down pumps and close valves in a fraction of a second, isolating any potential problem before it escalates. On top of that, gas leak detectors are positioned at key points across the facility. These layers of protection give fleet managers and drivers the peace of mind they need to confidently embrace cleaner fuel technology.

Permanent vs. Mobile LNG Stations

When it comes to fueling with liquefied natural gas, one of the first big decisions you'll face is choosing the right kind of station. It’s not a one-size-fits-all situation. The two main paths, permanent and mobile, serve very different needs and strategic goals. Your choice really boils down to your long-term vision versus your immediate operational demands.

Think of a permanent LNG station as putting down roots. It’s a major, long-term asset—a central hub built for high-volume, predictable fueling. These facilities are constructed on-site with massive cryogenic storage tanks and multiple dispensers, making them the workhorse for large fleets running consistent routes day in and day out.

On the flip side, a mobile LNG station is more like a pop-up shop for fuel. These are self-contained units, often mounted on a trailer or skid, that bring LNG directly to where you need it, when you need it. This agility makes them perfect for temporary projects, getting fuel to remote sites, or even running a pilot program to see if LNG is the right fit before you commit to a major build.

The demand for both types of LNG fuel stations is a clear signal of where the industry is heading. The market is expected to jump from USD 0.90 billion to USD 1.56 billion by 2030, a surge fueled by the push for cleaner fuels and favorable government policies. You can dig deeper into this trend in the LNG station market analysis on marketsandmarkets.com.

The Case for Permanent LNG Stations

A permanent station is the backbone of a serious, long-term LNG strategy. It's a significant investment that signals a full commitment to transitioning a fleet. While the initial price tag is higher and the construction takes longer, the payoff for an established, high-demand operation is undeniable.

Here's where a permanent setup really shines:

- High Fueling Capacity: These stations are built to store and pump huge volumes of LNG, easily servicing dozens, if not hundreds, of trucks every day. That kind of scale is non-negotiable for large, centralized fleets.

- Lower Operational Costs: Once the station is up and running, the per-gallon cost of fueling is often lower. This is thanks to economies of scale in bulk fuel delivery and efficient on-site storage.

- Infrastructure for Growth: You can design a permanent site with the future in mind, leaving room to add more storage or dispensers as your LNG-powered fleet expands.

A permanent station is the end-game for fleets that have already proven the business case for LNG. It's an investment in stability, scale, and the reliable, high-throughput fueling hub needed to support daily operations.

The Strategic Value of Mobile LNG Stations

Mobile stations, on the other hand, offer a level of flexibility that fixed infrastructure just can't touch. Their ability to be deployed quickly makes them a powerful tool for all sorts of situations, from bridging a short-term fuel gap to strategically testing a new market. For companies like Blue Gas Express, this nimble approach is their entire business model, delivering essential temporary natural gas wherever it's needed.

Mobile stations are the perfect solution when you need:

- Speed of Deployment: Forget waiting months or years for permits and construction. A mobile unit can be up and running in a matter of days or weeks.

- Lower Initial Investment: The upfront capital is a fraction of a permanent build, which dramatically lowers the financial risk of exploring LNG.

- Site Flexibility: They can be dropped off at construction sites, remote mining operations, or serve as a temporary fueling solution while your permanent station is being built.

- Pilot Programs: This is where they truly excel. A fleet can test a handful of LNG trucks on real-world routes without having to bet the farm on a full-scale infrastructure project.

This "try-before-you-buy" capability is a game-changer. It allows you to gather hard data on fuel consumption, vehicle performance, and driver feedback before making a much larger financial commitment. This adaptability is key to navigating the transition to alternative fuels with confidence and minimal risk.

Demystifying LNG Fueling Safety Standards

Whenever a new fuel source comes into the picture, safety is always the first question—and rightly so. The idea of handling a cryogenic fuel like liquefied natural gas can sound complex, but the truth is that LNG fuel stations are built on some of the most mature and stringent safety protocols in the entire energy industry.

These aren't experimental setups. They’re the result of decades of real-world experience from the industrial gas sector, where handling cryogenic liquids is just another day at the office. All that know-how has been channeled directly into the design, construction, and daily operation of every modern LNG station.

It's best to think of the safety measures not as a single barrier, but as a series of protective layers. Each one is designed to prevent, detect, and contain any potential problems, ensuring everything runs smoothly and securely.

Safety by Design: Built-In Engineering

The most fundamental layer of safety is engineered directly into the station’s hardware. From the moment LNG arrives to the instant it fills a vehicle's tank, the entire process happens inside a completely sealed and controlled system.

This proactive safety starts with the most critical component: the storage tank.

- Double-Walled Cryogenic Tanks: Picture a high-tech thermos. These units are essentially a tank built inside another tank, with a vacuum in between. This design provides incredible thermal insulation and, just as importantly, a built-in secondary containment layer.

- Pressure Management Systems: LNG naturally creates a small amount of vapor as it sits, a process called "boil-off." Stations are equipped with automated systems that safely vent or use this vapor to keep the tank's internal pressure well within safe operating limits at all times.

A common misconception is that LNG is explosive in its liquid form. In reality, liquid LNG won't ignite. It only becomes flammable once it vaporizes and mixes with air within a very narrow window—between 5% and 15% concentration. This makes a major, uncontrolled fire event extremely unlikely.

The Digital Watchdog: Automated Systems and Smart Controls

Beyond the heavy-duty construction, LNG stations operate with a sophisticated network of automated controls that acts as a 24/7 watchdog. These systems monitor the station’s vital signs in real-time and are programmed to react instantly if anything deviates from the norm.

At the core of this digital safety net is the Emergency Shutdown (ESD) system. It’s connected to sensors that constantly track pressure, temperature, and flow rates. If any of these metrics go outside a pre-set safe range, the ESD system automatically kicks in, shutting down pumps and closing valves to isolate the issue immediately.

This automated response takes human error out of the equation during a critical moment and is a non-negotiable feature of modern station design.

Regulations and Training: The Human Element

The final layers of safety involve strict regulatory oversight and comprehensive training for every person on site. You can't just decide to build an LNG station; the entire process is governed by rigorous codes that dictate everything from design and placement to daily operations.

Two of the key standards governing these facilities are:

- NFPA 59A: The official standard for producing, storing, and handling Liquefied Natural Gas.

- ISO 16924: The international standard specifically for natural gas fueling stations.

These regulations create a high, consistent bar for safety across the industry. Just as important, only highly trained and certified technicians are allowed to operate and maintain these stations. They need to understand the properties of LNG inside and out, follow precise fueling procedures, and know exactly how to respond in any situation.

Of course, overall facility safety goes beyond the fuel itself, encompassing everything from standard operational protocols to having the proper safety equipment for working at height. This total approach—combining smart engineering, automated controls, strict regulations, and expert training—is what makes LNG fueling a proven, reliable, and exceptionally safe technology.

When it comes down to it, the technical diagrams and engineering specs don't make the final decision. For any fleet operator, the only question that truly matters is this: what’s the real-world impact on my business? Moving to LNG fuel isn't just about changing what you pump; it’s a strategic move that affects your finances, your environmental standing, and your fleet's performance.

The case for LNG is really built on three core benefits: long-term cost savings, hitting sustainability targets, and getting more out of your trucks. While setting up the infrastructure, whether permanent or temporary, requires an upfront investment, the payoff is driven by predictable fuel costs and efficiencies that diesel just can't touch.

Driving Down Costs with Stable Fuel Prices

The first thing most operators notice is a break from the rollercoaster of diesel prices. Historically, natural gas has been far more stable and often cheaper than petroleum fuels. This isn't just a minor perk—it's a massive advantage for long-term budgeting and forecasting.

Think about it. While your competitors are scrambling to adjust prices or eat losses during a diesel price spike, your fleet's fuel costs remain steady. Over the life of a heavy-duty truck, the savings really add up, often covering the initial cost of the vehicle and the fueling setup. To get the full financial picture, it's crucial to accurately calculate commercial construction costs for the station itself.

Meeting Sustainability Goals and Boosting Your Brand

These days, corporate responsibility isn't just a buzzword; it’s a critical part of doing business. Customers, investors, and regulators are all looking closely at environmental, social, and governance (ESG) performance. Switching to LNG is one of the most direct ways for a transportation company to shrink its carbon footprint.

Key Environmental Wins with LNG:

- Reduced CO2 Emissions: LNG can cut carbon dioxide emissions by up to 25% compared to diesel.

- Near-Zero Particulate Matter: It practically eliminates the soot and particulate matter that cause so much air pollution.

- Drastic NOx Reduction: You can slash nitrogen oxide emissions by as much as 90%, which is huge for meeting tough air quality standards.

Making this shift sends a powerful message. It strengthens your brand and makes you a more attractive partner for environmentally-conscious clients and a better place to work for top talent.

The move to LNG isn't happening in a vacuum. It's a key part of the global push toward cleaner energy. As of early 2023, the worldwide LNG trade has grown to connect 20 exporting countries with 48 importing infrastructures. This expansion shows that major markets are embracing LNG for its clear cost and environmental benefits. You can get more insights on this global energy shift on lngindustry.com.

Improving Fleet Performance and Longevity

The benefits of LNG don't stop at the pump; they extend right into the engine. Because it's a cleaner-burning fuel, LNG is much gentler on engine components than diesel.

This translates into tangible performance gains:

- Less Maintenance: Cleaner combustion means less carbon buildup, which can stretch out the time between service appointments.

- Longer Engine Life: With less stress on engine parts, the entire vehicle can have a longer operational lifespan.

- Quieter Operation: LNG engines are noticeably quieter than their diesel counterparts. This helps reduce driver fatigue and cuts down on noise pollution in residential or urban areas.

Put together, these advantages keep your trucks on the road longer and lower the total cost of ownership. It makes the investment in LNG fuel stations a smart, forward-thinking decision that will pay off for years.

Common Questions About LNG Fuel Stations

Making a big operational change always brings up questions. It's only natural. When fleet managers start seriously looking at liquefied natural gas, they want to know how it's all going to work on the ground, day in and day out. Getting straight answers to these practical concerns is what builds the confidence needed to make the switch.

Let's dig into some of the most common questions we hear about LNG fuel stations and clear up the real-world logistics of adopting this cleaner, more price-stable fuel.

How Long Does It Take to Refuel an LNG Truck?

This is usually one of the first questions asked, and for good reason. Downtime is the enemy of any fleet, so refueling speed is a make-or-break detail. The good news? Fueling a heavy-duty truck with LNG is impressively fast and right on par with diesel.

You can expect the whole process to take just 10 to 15 minutes. Modern LNG dispensers are designed for high flow rates, so the fuel transfers quickly and safely. This means fueling with LNG slots right into a driver's normal routine without throwing off tight schedules.

The whole point of a well-designed LNG station is to make fueling feel as familiar and fast as diesel. You connect the nozzle, authorize, fill up, and get back on the road. No major learning curve, no lost time.

Are LNG Fuel Stations Safe in Extreme Weather?

Absolutely. Reliability and safety are baked into every part of an LNG station, and that includes the ability to perform perfectly no matter the weather. These facilities are built tough enough to handle everything from bitter cold winters to scorching summer heat.

It all comes down to the design of the core components, especially the cryogenic storage tanks.

- Top-Notch Insulation: The tanks have a double-walled, vacuum-insulated design that’s incredibly good at shielding the LNG from outside temperatures.

- Smart Pressure Management: Automated systems are always watching and managing the pressure inside the tanks. If any excess vapor builds up on a hot day, it's safely vented off.

Every station has to be built according to strict safety codes that demand they account for local climate conditions, guaranteeing they operate safely all year long.

What Is the Difference Between L-CNG and LNG Stations?

This is a common point of confusion, but the answer is pretty simple. It really just depends on what kind of trucks you're running.

An LNG station is exactly what it sounds like: it stores LNG and pumps it directly into trucks that have LNG engines. Straightforward.

An L-CNG station, on the other hand, is a bit more versatile. It also stores the fuel as super-chilled LNG, but it has extra gear—a vaporizer and a high-pressure compressor—bolted on. This extra equipment lets the station turn some of that liquid back into a gas, allowing it to dispense Compressed Natural Gas (CNG) as well. This makes L-CNG stations the perfect fit for mixed fleets that have both LNG and CNG vehicles operating out of the same depot.

Can I Convert My Existing Diesel Trucks to Run on LNG?

Yes, you can. Converting a diesel engine to run on LNG is a popular way to get started with natural gas without buying a whole new fleet. This is usually done with dual-fuel conversion kits, which let the engine burn a mix of diesel and natural gas at the same time.

It’s a great option, but it’s worth thinking through. A conversion can be a smart first step, but a brand-new truck built from the ground up to run on LNG will almost always be more efficient and perform better. Your best move depends on the age of your fleet, your budget, and what your long-term goals are.

Facing delays with permanent gas infrastructure? Don't let your project grind to a halt. Blue Gas Express provides reliable, mobile LNG and CNG solutions to keep your operations running. Find out how we can deliver temporary natural gas directly to your site at https://bluegasexpress.com.