The simple truth about hydrogen's energy content? It packs more punch per pound than any fuel we commonly use, but it's incredibly lightweight and takes up a ton of space.

Imagine you're going on a long hike. Hydrogen is like a feather-light, high-tech backpack stuffed with calorie-dense energy bars. Natural gas is the classic, heavy-duty canvas pack—it’s bulkier, weighs more, and carries less energy for its weight.

Unpacking Hydrogen's Energy: Mass vs. Volume

For anyone working in construction, utilities, or temporary gas delivery, fuel conversations always boil down to two practical questions: "How much energy am I getting for the weight?" and "How much energy am I getting for the space it takes up?"

This distinction is everything when it comes to hydrogen. It's the core of every logistical and engineering decision you'll make.

Hydrogen’s superstar quality is its energy per mass (gravimetric energy density). On this front, it's a true champion, holding between 120 and 142 megajoules per kilogram (MJ/kg). To put that in perspective, it’s nearly three times the energy of natural gas, which sits around 50 MJ/kg. This incredible efficiency is why it’s a focal point in the future of energy, a topic you can explore further in market trend reports.

But here's the catch: its biggest challenge is a miserably low energy per volume (volumetric energy density). As the lightest element in the universe, a balloon full of hydrogen gas at atmospheric pressure has very little energy. This is precisely why we have to either compress it to extreme pressures or chill it into a liquid to make it useful.

When you're planning a project, this trade-off is the central puzzle to solve. Hydrogen delivers amazing efficiency if you have the space and budget for advanced storage. Natural gas, on the other hand, is a much simpler, denser package, even if it offers less energy pound for pound.

Hydrogen vs Natural Gas Energy At a Glance

Let's make this crystal clear with a direct comparison to natural gas (mostly methane), a fuel everyone in the industry knows inside and out. The table below gives you a quick, side-by-side look at their energy values in different states.

| Fuel Type | Energy per Mass (MJ/kg) | Energy per Volume (MJ/L) – Gaseous | Energy per Volume (MJ/L) – Liquid |

|---|---|---|---|

| Hydrogen | ~120 | ~0.01 | ~8.5 |

| Natural Gas (Methane) | ~50 | ~0.03 | ~22.2 |

This comparison immediately throws the core challenge into sharp relief. Even as a liquid, hydrogen still packs less energy into a one-liter bottle than Liquefied Natural Gas (LNG) does. Getting a solid grip on these numbers is the first and most important step in figuring out if, and how, hydrogen can work for your operation.

The Power of Hydrogen's Energy Per Kilogram

When you're trying to figure out the logistics for a job site, one of the first questions you ask is, "How much power can I get there in one trip?" This is where hydrogen really shines. Its secret weapon is its gravimetric energy density—a fancy term that just means it packs more punch per kilogram than any other fuel.

Think of it like this. You have two identical trucks, one filled with natural gas and the other with hydrogen. If you put them on a scale, they weigh the same. But the truck carrying hydrogen is delivering a far more powerful payload. That superior energy-to-weight ratio is a game-changer for any job that needs mobile energy.

This isn't just a number on a spec sheet; it has real-world consequences for your budget and schedule. You'll need fewer trips to deliver the same amount of energy, which means lower transportation costs, fewer hours for your drivers, and a smaller carbon footprint for your supply chain. For a big construction project or a utility company dealing with an outage, those efficiencies add up to serious savings and a much simpler operation.

Understanding HHV and LHV

To get your fuel calculations right, you need to know the difference between two key terms: Higher Heating Value (HHV) and Lower Heating Value (LHV). Both measure the energy released when a fuel burns, but there’s a crucial distinction.

The difference comes down to water. When hydrogen is combusted, it creates water vapor.

- Higher Heating Value (HHV) is the total energy you get if you capture everything, including the extra heat released when that water vapor cools down and condenses back into liquid. Think of it as the maximum theoretical potential.

- Lower Heating Value (LHV) is the energy you get without capturing the heat from condensation. In the real world, equipment like generators and heaters has hot exhaust, so the water escapes as steam. This makes LHV the practical number you should be using.

For project managers and utility planners, LHV is the number that matters. It’s the honest, real-world measure of usable energy you’ll get from each kilogram of fuel, which keeps you from overestimating your power supply.

Getting this right is critical. If you base your plan on HHV, you might think you have more energy than you really do, which could leave you in the dark at the worst possible moment. Always, always base your operational math on the LHV to make sure your equipment runs as expected.

Hydrogen's Kilogram Advantage in Numbers

Let's put some hard numbers to this. Hydrogen’s LHV is roughly 33.3 kWh/kg.

Compare that to natural gas, which typically offers an LHV between 13-15 kWh/kg. That’s a staggering difference, and it’s a big reason why hydrogen is getting so much attention for energy transport and storage. It’s also driving major growth in global hydrogen markets, as many believe green hydrogen is reshaping the energy sector.

Bottom line: one kilogram of hydrogen can do more than twice the work of a kilogram of natural gas. For a temporary power setup, that could mean running a heavy-duty generator for much longer with the same weight of fuel. This huge gap in gravimetric density is exactly why industries are looking so closely at hydrogen to make their mobile energy operations more efficient.

But while its power per kilogram is unbeatable, that's only half the equation. The other side of the coin is figuring out how to handle a fuel that’s incredibly light and takes up a lot of space—a challenge we'll explore next.

Here's the rewritten section, designed to sound completely human-written and natural.

The Problem with Hydrogen's Energy Per Litre

While hydrogen is the undisputed champion of energy by weight, its energy content by volume tells a very different story. This is the practical hurdle that engineers, utility managers, and construction planners have to clear: in its natural gas form, hydrogen is incredibly light and diffuse, meaning it takes up a massive amount of space for the energy it holds.

Think of it this way. Energy content by weight (mass energy density) is like the quality of your camping gear—hydrogen is the ultralight, top-of-the-line stuff. But energy content by volume (volumetric energy density) is your backpack. In its natural state, hydrogen is like a giant, fluffy sleeping bag that hasn't been put in its compression sack. It’s high quality, but it won’t fit anywhere.

To make it a practical fuel for things like temporary site generators or fleet vehicles, we have to "pack" it down—a lot. That's where the real engineering challenge comes in.

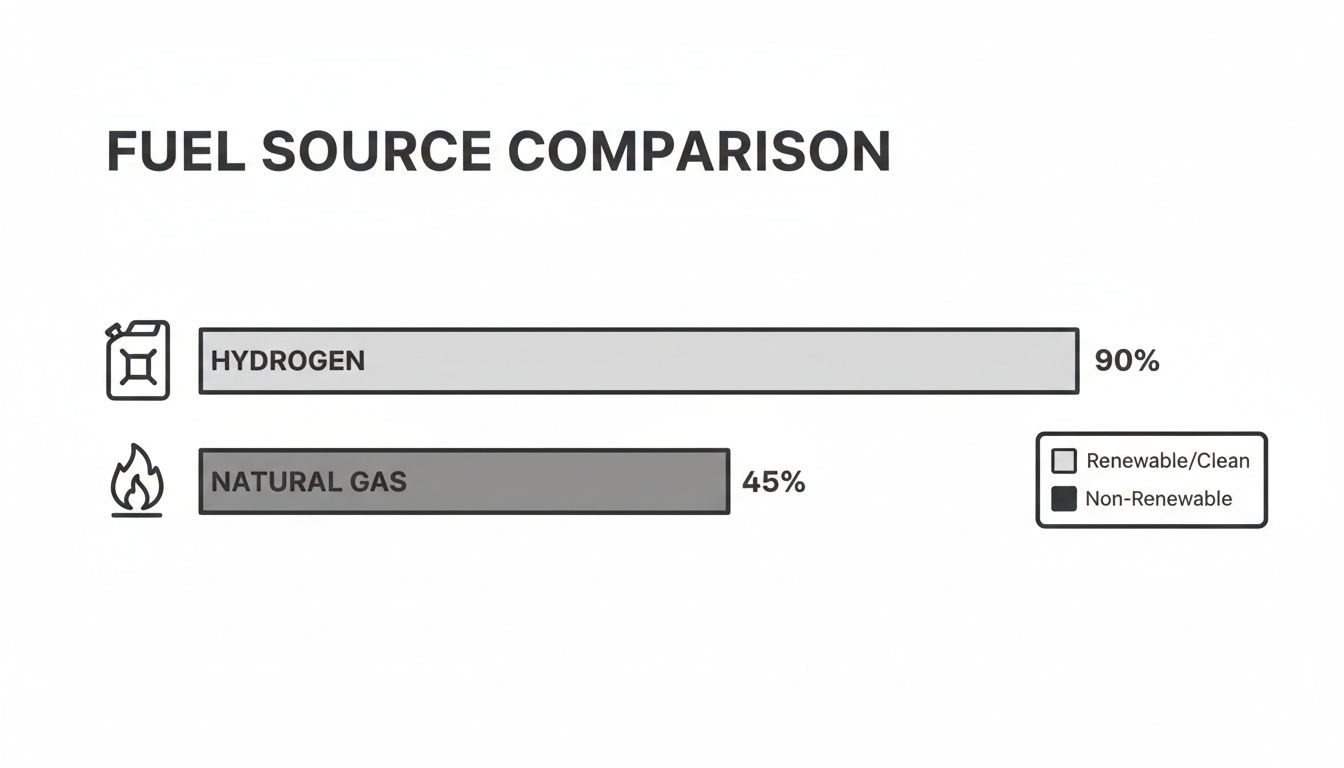

This chart highlights some of the key differences in how hydrogen and natural gas stack up as fuel sources.

As you can see, while hydrogen offers a much cleaner profile, its physical properties demand entirely different storage and handling strategies than what we're used to with traditional fuels.

Solving the Storage Puzzle: Pressure and Cold

So, how do we solve this "fluffy sleeping bag" problem? There are two main approaches: squeeze it or freeze it.

Squeezing It: The Compression Method

The most common way to increase hydrogen’s volumetric energy density is through compression. By pressurizing the gas, we physically force the molecules closer together, allowing us to pack a lot more fuel into the same size tank.

If you’ve worked with Compressed Natural Gas (CNG), the concept is very similar. Hydrogen is typically compressed into specialized, high-strength tanks at two standard pressures:

- 350 bar (around 5,000 psi): This is a common pressure for heavy-duty applications like buses, trucks, and larger-scale temporary power setups.

- 700 bar (around 10,000 psi): You’ll find this higher pressure in light-duty vehicles like cars, where cramming more fuel into a smaller space is key to extending the driving range.

Compressing hydrogen to 700 bar boosts its volumetric energy density by hundreds of times compared to its unpressurized state. Suddenly, our fluffy pile of fuel is vacuum-sealed into a tight, manageable package. The trade-off? It requires robust, heavy, and often expensive carbon-fibre-wrapped tanks to handle that immense pressure, adding to the system's overall weight and cost.

For a project manager, the choice between 350 and 700 bar is a classic balancing act. Higher pressure gives you more energy and longer run times, but it comes with stricter engineering requirements and higher equipment costs.

Freezing It: The Liquefaction Method

The other powerful solution is liquefaction—chilling hydrogen gas down to an incredibly cold -253°C (-423°F) until it turns into a liquid. This process packs the molecules even tighter than compression, giving you the highest possible volumetric energy density for pure hydrogen.

Liquid hydrogen (LH2) is the go-to for applications where both weight and space are absolutely critical, like in aerospace and rocketry. The logistics are a bit like handling Liquefied Natural Gas (LNG), but the temperatures are far more extreme. For comparison, LNG only needs to be cooled to -162°C (-260°F).

That huge temperature difference means storing and transporting LH2 requires highly specialized, super-insulated cryogenic tanks to minimize "boil-off"—the slow process of the liquid warming up and turning back into a gas. While it's the most compact way to store hydrogen energy, the energy needed to liquefy it in the first place and the specialised equipment make it a more complex and costly option for many ground-based applications.

To put this all into perspective, the table below shows just how dramatically hydrogen's energy content per litre changes depending on how it's stored.

How Storage Method Impacts Hydrogen's Volumetric Energy

| Hydrogen State | Pressure / Temperature | Volumetric Energy Density (MJ/L) |

|---|---|---|

| Gaseous (Ambient) | 1 atm / 20°C | 0.01 |

| Compressed Gas (CGH2) | 350 bar (5,000 psi) | 2.5 |

| Compressed Gas (CGH2) | 700 bar (10,000 psi) | 4.5 |

| Liquid (LH2) | -253°C (-423°F) | 8.5 |

This shift is what makes hydrogen a viable, portable fuel. At standard conditions, its energy density is just 3 kWh/m³, a fraction of natural gas's 10 kWh/m³. But once compressed or liquefied, it can deliver between 2-8 kWh/L, making it a serious contender. These numbers are exactly why the industry is growing so fast, and you can explore the full hydrogen market analysis to see how these trends are playing out.

Putting Hydrogen Up Against CNG and LNG in the Real World

If you’re in construction or manage utility services, you already know the ins and outs of getting temporary gas to a site. You’re used to the logistics of Compressed Natural Gas (CNG) and Liquefied Natural Gas (LNG). But when hydrogen enters the picture, it brings a whole new playbook.

While compressed hydrogen feels a bit like CNG and liquid hydrogen seems similar to LNG, the day-to-day operational details are worlds apart. It’s not just about the energy content of hydrogen; it’s about the entire process, from the truck that delivers it to the equipment that uses it. Let's break down the practical trade-offs.

The Pressure Cooker: Gaseous Hydrogen vs. CNG

If you’re a CNG user, you’re no stranger to high-pressure cylinders. Compressed gaseous hydrogen (CGH2) follows the same basic idea but cranks the pressure way, way up.

- CNG Tanks: Your standard CNG setup runs at about 250 bar (3,600 psi). These are the familiar, rugged steel cylinders that have been the workhorse of the industry for years.

- CGH2 Tanks: Hydrogen needs a much tighter squeeze. Industrial applications often use 350 bar (5,000 psi) tanks, while vehicles require an even more intense 700 bar (10,000 psi).

This massive jump in pressure means you can't just swap out the gas. You need entirely different tanks. Instead of steel, hydrogen tanks are typically built from advanced composite materials like carbon fiber. They have to be incredibly strong to handle the pressure safely without becoming impossibly heavy to transport. So, the tube trailers and on-site storage for CGH2 are a big step up in technology and cost from what you're used to with CNG.

The bottom line is simple: even though hydrogen is the lightest element, the gear needed to hold it as a compressed gas is heavier and more sophisticated. For every unit of energy you need, the containment system for CGH2 is a more complex piece of engineering than its CNG equivalent.

The Deep Freeze: Liquid Hydrogen vs. LNG

When a job demands a huge amount of energy, LNG is often the answer. This is where the comparison with liquid hydrogen (LH2) really highlights the engineering challenges involved, turning into a game of extreme temperatures and managing fuel loss.

Turning a gas into a liquid makes it incredibly dense, which is great for storage and transport. But hydrogen demands a much, much deeper freeze than natural gas.

You get LNG by cooling natural gas down to -162°C (-260°F). That’s seriously cold, but it’s a temperature we’ve mastered with well-established cryogenic technology. Liquid hydrogen, however, needs to be chilled to an almost unbelievable -253°C (-423°F). That isn't just a few degrees colder—it's a massive technological leap that requires super-insulated, highly specialized cryogenic tanks called dewars.

Boil-Off: The Reality of Storing Liquid Fuels

That extreme cold introduces a constant headache: boil-off. It’s impossible to build a perfectly insulated tank. A tiny bit of heat always finds its way in, causing some of the liquid hydrogen to warm up, turn back into a gas, and escape.

LNG experiences this too, but the problem is much bigger with LH2. The massive temperature difference between the liquid hydrogen and the outside world means it boils off much faster. This makes LH2 a poor choice for long-term storage where the fuel might sit unused. It’s best suited for high-demand jobs where you're burning through the fuel almost as fast as it's delivered.

Here’s a quick look at how these mobile gas solutions stack up:

| Feature | Compressed Natural Gas (CNG) | Compressed Hydrogen (CGH2) | Liquid Hydrogen (LH2) |

|---|---|---|---|

| Storage Pressure | ~250 bar (3,600 psi) | 350-700 bar (5,000-10,000 psi) | N/A (Cryogenic) |

| Storage Temperature | Ambient | Ambient | -253°C (-423°F) |

| Primary Challenge | Moderate volumetric density | Heavy, expensive tanks | Boil-off; extreme cold |

| Best Use Case | Established, reliable supply | High-pressure mobile power | Weight-sensitive, high-use |

Ultimately, making the switch from familiar fuels like CNG and LNG isn't just a simple substitution. It requires a completely new way of thinking about equipment and logistics. The unique physics of hydrogen—its low density and extreme cold liquid state—demand new infrastructure, updated safety protocols, and careful planning to manage challenges like boil-off effectively.

What Hydrogen Energy Means for Your Job Site

It’s one thing to understand the numbers behind hydrogen energy content on a spreadsheet, but it’s another thing entirely to make it work on a busy construction site or within a complex utility network. The unique physics of hydrogen creates a ripple effect, touching everything from the size of your pipes to the safety signs you post.

So let's get practical. How does this shift from theory to reality affect your daily operations? Whether you’re trying to power a temporary generator or blending hydrogen into an existing gas line, the details are what make or break the project.

Sizing Power for Construction and Temporary Sites

Picture this: you need to power a large generator for a remote project. If you were using natural gas, you’d have a solid playbook for calculating your fuel needs. With hydrogen, you have to throw that playbook out the window. The culprit is its incredibly low volumetric density.

Because a cubic foot of hydrogen gas carries only about a third of the energy of natural gas, you'll need to supply roughly three times the volume to get the same job done. This isn't just a minor adjustment; it has immediate, tangible consequences for your site.

- Higher Flow Rates: Your entire gas delivery system—pipes, regulators, valves—has to be sized for a much higher flow. Trying to run hydrogen through standard natural gas equipment would be like trying to breathe through a coffee stirrer; you'd simply starve your generator of fuel.

- Larger Storage Footprint: Getting the same amount of energy on-site means bringing in more compressed gas cylinders or larger tube trailers. That takes up valuable space on an already crowded site.

- Fuel Delivery Logistics: You’ll be scheduling fuel deliveries far more often just to maintain the same uptime. That means more trucks, more coordination, and higher transportation costs.

Get the sizing wrong, and you’re looking at underpowered equipment, frustrating delays, and expensive retrofits. While the high hydrogen energy content by mass is great for transporting it efficiently, its low density by volume is what dictates the on-site reality.

The core takeaway for site managers is this: a switch to hydrogen isn't a simple fuel swap. It requires a complete re-evaluation of your gas delivery system, from the supply connection all the way to the burner tip.

Blending Hydrogen into the Natural Gas Grid

For gas utilities, blending hydrogen into the existing pipeline network is a popular decarbonization strategy. But this is where things get really tricky, as hydrogen's physical properties introduce a host of new challenges.

Even a modest blend of 5-20% hydrogen by volume fundamentally changes the gas mixture being delivered to homes and businesses. This seemingly small tweak has major implications that cascade through the entire network.

Impact on Appliance Performance and Safety

Think about every furnace, water heater, and industrial burner connected to the grid. They were all designed and calibrated for the specific combustion properties of natural gas. When you introduce hydrogen, which burns hotter and faster, you change the game.

The Wobbe Index, a critical measure of whether different fuels can be used in the same equipment, is wildly different for hydrogen. A hydrogen-blended gas could potentially damage appliances not built to handle it. Older equipment, in particular, might need to be retrofitted or replaced entirely to run safely and efficiently.

Metering and Billing Accuracy

Here’s a problem that hits the customer's wallet directly. The meters on the side of every building measure the volume of gas passing through, not the energy it contains. Since a cubic foot of a hydrogen-natural gas blend delivers less energy than a cubic foot of pure natural gas, the old way of billing no longer works.

Unless utilities recalibrate every meter or install new ones that can measure actual energy content (using something like a calorimeter), customers would be paying for a certain volume of gas but getting less energy for their money. That’s a recipe for billing nightmares and unhappy customers.

Upgrading Safety Protocols and Infrastructure

Hydrogen just doesn't behave like natural gas, and that means safety procedures need a complete overhaul. Hydrogen molecules are the smallest in the universe, allowing them to wiggle through seals and fittings that would easily contain the much larger methane molecules of natural gas.

Putting hydrogen into the system requires some serious safety upgrades:

- Enhanced Leak Detection: Your standard methane detectors are useless for finding a hydrogen leak. Sites and networks need specialized sensors built to detect the tiny, odorless, and colorless gas.

- Infrastructure Assessment: Hydrogen can make some metals brittle over time—a phenomenon called hydrogen embrittlement. Utilities have to conduct thorough assessments of their existing steel pipelines to see if they can handle it without becoming dangerously fragile.

- Ventilation and Handling: Hydrogen is about 14 times lighter than air, so when it leaks, it shoots straight up. This completely changes ventilation requirements and the emergency protocols for how to handle a leak safely.

At the end of the day, putting the power of hydrogen energy content to work in the real world is a complex engineering and logistical challenge. It’s a shift that demands careful planning, significant investment, and a deep respect for the unique properties of the fuel itself.

What This Means for Mobile Energy

So, what does all this mean for keeping a construction site powered or a utility running during an outage? The conversation is shifting, moving from today’s rock-solid solutions to what’s coming next. For anyone managing a project, keeping the power on isn't just a goal—it's everything.

Project delays from gas line interruptions or planned maintenance are budget killers. That’s why mobile natural gas services, delivered by providers like Blue Gas Express, have become such a critical part of the toolkit. They are the here-and-now answer to keeping the lights on and the heat running.

Think of mobile CNG and LNG as the reliable workhorses. They're the proven technology that prevents costly downtime today, making sure projects stay on track and occupancy permits get signed. For dependable, temporary energy, they are the gold standard.

Looking Ahead: The Hydrogen Transition

But the future is pointing toward hydrogen. Its incredible energy content by mass opens up a whole new world of possibilities. We're talking about a future where one fuel delivery could power a job site for far longer, which means fewer trucks on the road and a smaller carbon footprint.

This shift won't happen overnight. It’s not like flipping a switch. We’re stepping into a transitional period where the old guard and the new contender will work side-by-side.

Here’s what that hybrid approach might look like in the real world:

- Today's Projects: You'll continue to lean on the robust, established infrastructure of mobile CNG and LNG. It’s the smart play for guaranteed uptime.

- Pilot Programs: You might start bringing in hydrogen for specific tasks—powering a new generation of quiet generators or fueling a small fleet of equipment—to see how it performs in your environment.

- Future-Proofing: When designing new sites, you'll start thinking about infrastructure that can handle both fuel types. This prepares you to make a smooth switch when hydrogen becomes more widely available and cost-effective.

This isn't an "either/or" situation. It's about using the best of both worlds. You get the reliability of natural gas for today's needs while strategically planning for the powerful potential of hydrogen tomorrow.

Working with an experienced mobile energy partner makes navigating this evolution much easier. You get someone who not only understands the practical demands of today’s fuel needs but is also deeply invested in what’s next. It’s the best way to ensure your operations are ready for every step of the energy transition.

Your Top Questions About Hydrogen Energy Answered

Getting a handle on hydrogen's properties can feel like a lot, especially when you're trying to figure out what it means for a construction site or utility hookup. Let's break down the most common questions with some straight-to-the-point answers.

Does Hydrogen Have More Energy Than Natural Gas?

When you compare them pound for pound (or kilogram for kilogram), hydrogen is the clear winner. It packs a serious punch.

A single kilogram of hydrogen holds about 120 megajoules (MJ) of usable energy. For comparison, natural gas offers around ~50 MJ/kg. That means on a weight basis, hydrogen carries nearly three times the energy.

But that’s only half the story. The real challenge comes when you stop thinking about weight and start thinking about space.

Why Does Volumetric Energy Density Matter So Much?

Here's where things get tricky. While hydrogen is energy-rich by weight, it's incredibly light and diffuse as a gas. A cubic foot of hydrogen gas contains only about one-third the energy of a cubic foot of natural gas.

Think of it this way: to get the same amount of energy, you have to move a much larger volume of hydrogen through your pipes. This is a game-changer for infrastructure. It means you'll need higher flow rates and potentially bigger pipes, regulators, and generators to deliver the same power as you would with natural gas.

It’s a critical calculation for any project, directly affecting the size and cost of your on-site equipment.

Is It Better to Use Compressed or Liquid Hydrogen?

There’s no single "best" answer—it all comes down to the job and the budget.

Compressed Hydrogen (CGH2): This is the more common method, much like how we handle CNG. It works well for many ground-based uses, but storing it requires heavy, expensive tanks built to withstand immense pressure (up to 700 bar or 10,000 psi).

Liquid Hydrogen (LH2): If you need the most energy in the smallest possible space, liquid is the way to go. But it comes with a major catch: it has to be kept at a mind-bogglingly cold -253°C (-423°F). This cryogenic storage is complex and expensive, making it better suited for specialized applications where weight is the biggest concern. You also have to account for fuel "boil-off" as it warms.

Can I Just Swap Hydrogen into My Natural Gas Equipment?

Definitely not. Trying to run pure hydrogen through equipment built for natural gas is a recipe for trouble.

Hydrogen behaves very differently—it burns hotter and faster, and its low density means you need to push a lot more of it through the system. Using it in an unmodified appliance can damage the equipment, run inefficiently, and create serious safety hazards. A proper switch requires re-engineering the system with new burners, regulators, seals, and other components designed specifically for hydrogen's unique properties.

At Blue Gas Express, we know that keeping your project moving is what matters most. While the world gets ready for a hydrogen-powered future, we deliver the reliable mobile CNG and LNG you need right now to keep your operations online and avoid costly delays.

Ensure your project stays powered with our temporary gas solutions.