When it comes to cutting construction costs, the real work happens long before the first shovel hits the dirt. The most substantial savings are found in meticulous planning, smart sourcing, and making your operations as efficient as possible. Think of it this way: a detailed blueprint is your single most powerful tool for controlling the budget.

Your Blueprint for Pre-Construction Savings

The biggest mistake I see project owners make is rushing through the planning stage. It's easy to get excited about getting equipment on-site and moving dirt, but every hour and dollar you invest upfront can save you ten times that amount later. This isn't just about drafting plans; it's about building a financial fortress around your project.

A solid plan does more than just outline the building. It anticipates problems and bakes the solutions right in from the start. It’s a strategic roadmap where you’ve already mapped out and budgeted for every potential detour.

Building a Bulletproof Budget

A good budget isn't just a list of expenses. It has to be a living document that reflects the realities of construction, where surprises are basically guaranteed. Your job is to make sure those surprises don't break the bank.

Here’s how to build a budget that actually works in the real world:

- Get Granular with Estimates: Don't just plug in high-level numbers. Break down the cost of everything—from foundation rebar and framing labor to city permits and final site cleanup. This level of detail shows you exactly where every dollar is supposed to go.

- Contingency is Not Optional: You absolutely must set aside 10-15% of your total budget for a contingency fund. This isn't "extra" money. It's a planned financial cushion for the inevitable, like a sudden spike in lumber prices, discovering poor soil conditions, or losing a week to bad weather.

- Stop Scope Creep in its Tracks: Get the project scope clearly defined in writing and have all stakeholders sign off on it. Any requested change, no matter how small it seems, needs to go through a formal review process to assess its impact on the budget and the timeline.

A project without a contingency fund is a project that's planned to fail. That buffer is your first and best defense against the budget overruns that can completely derail a build.

To help you stay on track from the very beginning, I've put together a simple checklist. Think of this as your guide to making smart financial decisions before you commit to major expenses.

Pre-Construction Cost Control Checklist

This table highlights the crucial actions to take during your planning phase. Getting these right will directly reduce your expenses and prevent costly surprises down the road.

| Action Item | Potential Cost Impact | Best Practice Tip |

|---|---|---|

| Comprehensive Site Analysis | High | A thorough geotechnical report can prevent major foundation redesigns, saving tens of thousands. |

| Early Team Collaboration | High | Involve GCs and key subs during design to identify value engineering opportunities early. |

| Detailed Scope Definition | Medium-High | A signed, detailed scope document is your best tool to prevent expensive scope creep. |

| Secure a Contingency Fund | Critical | Earmark 10-15% of the total budget. This fund absorbs unexpected costs without derailing the project. |

| Material & Lead Time Research | Medium | Pre-ordering materials with long lead times avoids costly project delays and rush shipping fees. |

Following these steps sets a strong financial foundation, making the rest of the project much smoother and more predictable.

The Power of Early Collaboration

Getting your team in the same room early on is one of the smartest cost-saving moves you can make. Don’t wait until the architectural drawings are 100% complete to bring in your general contractor or the lead HVAC and plumbing subs.

When you collaborate from the get-go, planning becomes a team sport focused on one thing: finding savings.

For instance, your contractor might look at the plans and point out that shifting a non-load-bearing wall by just six inches could straighten out and simplify the HVAC runs, saving thousands in both materials and labor. Or an engineer might review the soil report and suggest a different foundation technique that avoids thousands in excavation and soil remediation.

These are the kinds of game-changing insights you only get when the experts are involved from day one. If you're looking to go deeper into financial planning and learn the foundational strategies for project success, mastering construction cost management is a fantastic resource to build on these concepts.

Nailing Your Material and Supplier Strategy

Let's be blunt: materials and labor are the two giants that can make or break your construction budget. With market volatility a constant threat, just one price spike can turn a profitable job into a financial nightmare. Your best defense isn't just about chasing the lowest bid; it's about building a smart, resilient supply chain that shields your project from costly delays and sudden price hikes.

The first rule? Ditch the single-supplier habit. Putting all your eggs in one basket for a critical material like steel or lumber is a rookie mistake. If your go-to supplier hits a snag, their problem instantly becomes your problem. Instead, diversify your sourcing. I always make it a point to vet and build solid relationships with at least two or three suppliers for every key material. It creates healthy competition and, more importantly, gives you a Plan B when—not if—something goes wrong.

Smart Procurement in Practice

Getting your costs down often boils down to how you buy. Securing materials is more than a simple transaction; it's a strategic play that demands foresight. The real goal is to lock in predictable costs and have materials show up on-site exactly when you need them—not a day early to get stolen or a day late to cause a work stoppage.

Here are a few tactics that have worked for me time and time again:

- Go Big with Bulk Purchasing: For the staples you'll be using constantly—think drywall, insulation, or concrete—negotiate a bulk purchase agreement upfront. You'll almost always get a better per-unit price and insulate yourself from future market increases.

- Buy Direct from the Source: For specialty items or massive orders, see if you can buy directly from the manufacturer. It can save you a decent chunk by cutting out the middleman's margin. Just be ready for longer lead times and higher minimum order quantities.

- Master Just-in-Time Delivery: This one requires a finely-tuned schedule and suppliers you can trust, but the payoff is huge. It slashes on-site storage costs and dramatically lowers the risk of materials getting damaged or walking off the job site.

Dealing with a Volatile Market

The construction world today is anything but predictable. We're all feeling the squeeze from inflation and supply chain headaches, which makes procurement more critical than ever. With global construction costs projected to climb by 5-7% in early 2025—driven by shaky prices for steel, lumber, and electrical components—you can't afford to be passive. You can dig deeper into these trends and learn how to stay ahead by checking out the latest construction cost research on Mastt.com.

A piece of advice I always give: never accept the first quote. Treat every major purchase like a negotiation. Always ask about volume discounts, early payment incentives, or bundled pricing. You'd be surprised where you can find savings.

Think Outside the Box with Materials

Sometimes, the biggest savings come from simply changing what you build with. Traditional materials are reliable, but innovative alternatives can offer a fantastic balance of cost and quality.

For instance, I’ve used reclaimed wood for non-structural elements like flooring and accent walls. It adds incredible character to a space for a fraction of what new high-end lumber would cost. On the structural side, Cross-Laminated Timber (CLT) can be a surprisingly cost-effective and faster substitute for steel or concrete in the right situation. Just be sure to run any alternative material by your engineers to ensure it meets all structural and code requirements for the project.

Putting Technology to Work for Your Budget

In today's construction world, technology isn't just a nice-to-have; it's your secret weapon for keeping costs in check. When you move past old-school spreadsheets and paper blueprints, you start to spot problems sooner, talk to your team more clearly, and make sharp, data-driven decisions that directly protect your bottom line.

The trick isn't just about grabbing the latest shiny tool. The real win comes from matching the right digital solution to a specific job site problem. That’s how you turn a potential budget-buster into a planned saving.

Using BIM as a Digital Rehearsal

One of the biggest game-changers I've seen is Building Information Modeling (BIM). I tell my clients to think of it like a full-dress rehearsal for the entire project, all done on a computer. BIM creates a detailed 3D model that's so much more than a floor plan—it's a living database for every single component of the building.

What does that mean in practice? Before any dirt is moved, you can see exactly how the HVAC ducts will snake around the structural steel. You can spot where plumbing lines are about to clash with electrical conduits. Fixing these issues in a digital model costs next to nothing. Finding them after the concrete is poured? That can easily set you back tens of thousands in rework and killer delays.

By running through the entire build virtually, BIM lets you find and fix expensive conflicts before they ever happen on site. This is a fundamental shift from reactive problem-solving to proactive planning, and it's key to cutting construction costs.

The Rise of AI and Data Analytics

Technology is also getting smarter about how we estimate and manage money. Artificial intelligence and data analytics aren't just buzzwords anymore; they're becoming practical tools that can analyze historical data from thousands of similar projects to give you incredibly accurate initial cost estimates.

This data-first approach takes a lot of the guesswork out of the equation. Instead of just relying on gut feelings, you can see exactly how a different siding material or a design tweak impacted the final cost on ten other projects just like yours. That kind of insight is gold during pre-construction.

Adopting smart construction methods isn't a gamble—it's a proven strategy. Research shows that AI and advanced data can deliver cost savings between 10% and 15%. These tools also give you much tighter design reviews and cost estimates, which can slash budget and schedule overruns by as much as 10-20%. Deloitte's global construction industry report digs into these financial impacts if you want to learn more.

Centralizing Communication with Software

Let's be honest: miscommunication is a notorious budget killer. A missed email, an old set of drawings, or a verbal instruction that gets twisted—it all leads to rework, wasted materials, and schedule slips. This is exactly where modern project management software earns its keep.

These platforms create one single source of truth. Everyone, from the architect in the office to the subcontractor out in the field, is looking at the exact same, up-to-the-minute information.

- Real-Time Updates: The latest plans, change orders, and RFIs are instantly available on a phone or tablet. No more excuses.

- Clear Accountability: Tasks get assigned with deadlines, so everyone knows who's responsible for what and when it's due.

- Improved Documentation: Every message and decision is automatically logged. This creates an airtight paper trail that can save you from costly disputes down the road.

When you centralize all that information, you dramatically cut the odds of someone building off an old plan—one of the most common and painfully expensive mistakes you can make on a job site.

Streamlining Your On-Site Operations

An efficient job site is a profitable one. This is where your careful planning turns into tangible, real-world savings. Boosting labor productivity and fine-tuning daily workflows aren't just buzzwords; they're how you protect your budget in the field, especially when skilled labor is scarce.

So, how do you make it happen? One of the biggest shifts I've seen in the industry is rethinking where the actual work gets done.

Moving major parts of the build off-site into a controlled factory setting through prefabrication and modular construction is a game-changer. This approach directly slashes on-site labor hours, sidesteps weather delays, and dramatically cuts down on material waste. It's a powerful answer to keeping construction costs in check on a tight timeline.

Embracing Lean Construction Principles

Beyond prefabrication, adopting lean construction principles provides a solid framework for rooting out waste. And I'm not just talking about leftover drywall. Lean thinking targets the hidden costs that bloat a project: wasted time, unnecessary movement, and processes that just don't add value.

Putting lean principles into practice means every single action on-site has a clear purpose. It often involves:

- A Smarter Site Layout: Think about how you organize materials and equipment. The goal is to minimize how much time crews spend walking back and forth just to grab what they need.

- Just-in-Time Deliveries: Scheduling material drops for the exact moment they're needed is a pro move. It reduces site clutter and lowers the risk of materials getting damaged or stolen.

- Daily Huddles: These quick, focused meetings are invaluable. They get crews aligned, identify immediate roadblocks, and keep the project’s momentum going.

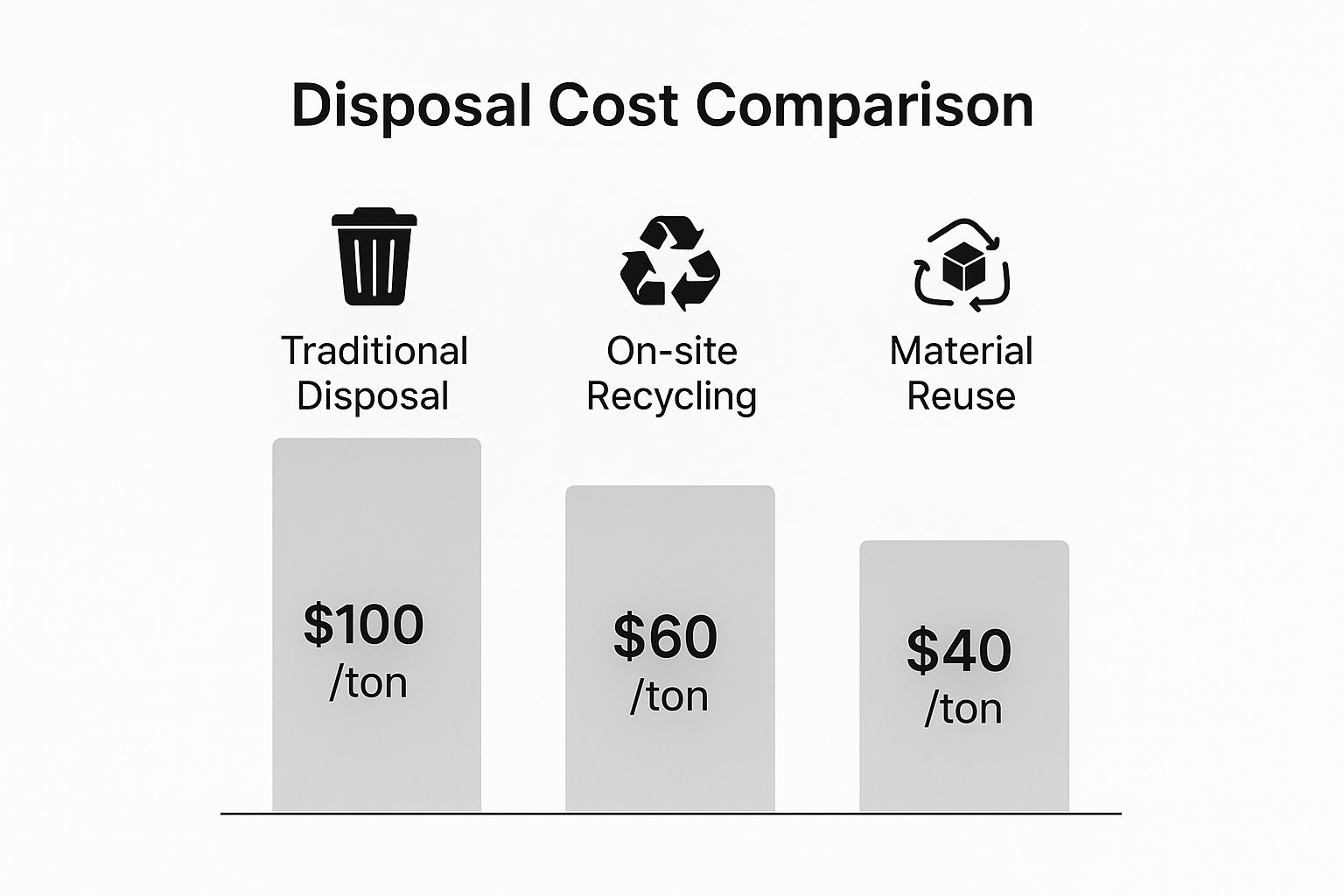

The image above highlights a critical part of lean thinking: waste management. Reusing materials isn't just an environmental feel-good; it's a direct financial win that can slash your disposal costs.

On-Site Efficiency Method Comparison

Modern methods offer significant advantages over traditional "stick-built" construction right on the job site. The table below breaks down how these approaches stack up, highlighting where you can find major savings in both time and money.

| Method | Primary Benefit | Typical Cost Savings | Best For |

|---|---|---|---|

| Traditional On-Site | Maximum design flexibility | 0-5% (baseline) | Unique, custom projects where standardization is not possible. |

| Prefabrication | Reduced on-site labor & waste | 5-15% | Projects with repeatable components like wall panels or trusses. |

| Modular Construction | Speed of completion | 10-25% | Standardized structures like hotels, apartments, or schools. |

As you can see, shifting even parts of the construction process to a controlled environment can yield substantial benefits, making your entire operation more predictable and cost-effective.

Smart Scheduling to Maximize Productivity

Idle time is the absolute enemy of a construction budget. Every hour a crew waits for materials or a pricey piece of rental equipment sits unused is money straight down the drain.

Smart scheduling prevents these costly bottlenecks by ensuring a logical, continuous flow of work. It’s about more than just a calendar—it's about choreographing the entire project from start to finish.

An optimized schedule ensures that as soon as the foundation crew is done, the framers are ready to start. It’s a domino effect where efficiency breeds more efficiency, keeping your project on time and on budget.

Continuously looking for ways to improve daily operations is critical for long-term success. For a deeper dive, there are plenty of proven strategies to reduce operational costs and boost efficiency. This mindset is more important than ever.

Uncovering Hidden Savings in Site Utilities

It’s easy to gloss over temporary utilities as just another small line item in a massive budget. But honestly, this is one of the most overlooked areas for real, tangible cost savings. Power, heat, and water are absolute must-haves on any job site, but how you get them can make a huge difference to your bottom line.

If you're not paying close attention, you're just leaving cash on the table. The key is to stop thinking of utilities as a bill you just have to pay and start managing them like any other critical project resource. Take a hard look at what you actually need. Is that massive diesel generator really necessary around the clock, or could a smarter, more targeted solution get the job done for a fraction of the cost?

Rethinking Your Temporary Heat Strategy

When your project stretches into the colder months, temporary heat can quickly become a budget-buster. Most crews default to what they know: electric or propane heaters. They’re familiar, sure, but they are also incredibly inefficient and expensive to run day in and day out. This is a perfect spot to make a change that pays off big.

Switching to temporary natural gas services is a game-changer for controlling heating costs and boosting site safety. You get a steady, reliable source of heat that’s almost always more affordable than propane or electricity, especially when you're trying to keep a large building warm for something like a concrete cure. Plus, you get to ditch the logistical nightmare and safety hazards of having huge propane tanks scattered around your site.

Don't just write off temporary utilities as a fixed cost. You have to challenge the old way of doing things. Take a few minutes to compare the true lifecycle costs of different energy sources—the savings from swapping a diesel generator for temporary natural gas can easily run into thousands of dollars over the life of a project.

Get Your Utility Providers on the Phone Early

Here’s a mistake I see all the time: project managers waiting until the last possible second to get local utility providers lined up for the permanent hookups. All that delay does is force you to stay on expensive temporary power for weeks or even months longer than you need to.

Make coordinating with the utility companies a top priority during pre-construction. Getting them involved from the start lets you:

- Align Schedules: You can sync their installation timeline with your own construction schedule, which dramatically shortens the time you're stuck on temporary power.

- Identify Infrastructure Needs: They can tell you right away if you need extra trenching or upgrades, so you can build those costs into the budget from day one instead of getting hit with a surprise change order.

- Accelerate Hookups: Building a good relationship with the utility reps can often help grease the wheels and get you connected faster.

By getting out in front of it, utility planning stops being a last-minute fire drill and becomes a genuine cost-saving strategy that puts money back into your project's budget.

Answering Your Toughest Questions on Construction Costs

Trying to rein in a construction budget can feel like a constant battle. As an owner or project manager, you’re always looking for smart ways to trim the fat without sacrificing quality. Let's tackle some of the most common questions that come up when it's time to get serious about reducing construction expenses.

This isn't about high-level theory. It's about practical, field-tested advice you can put to work on your next project, whether it's a small commercial fit-out or a sprawling industrial complex.

My Budget Is Blown Before We Even Break Ground. Where Do I Start?

If your initial estimates are coming in way over budget, stop right there. The single most effective place to find savings is in the pre-construction and design phase. It costs nothing to move a wall on a blueprint, but it costs a fortune to tear down a physical one.

Your first instinct might be to downgrade material quality, but that's often a mistake. The smarter move is to dig into value engineering. This is simply a systematic process of reviewing the plans to find less expensive alternatives that still get the job done right.

Here's where I'd tell my team to look first:

- Simplify the Footprint: Are there complex angles or curves that could be straightened out? Every corner, jog, and intricate roofline adds a surprising amount to your labor and material costs.

- Be Strategic with Finishes: High-end finishes are great for making an impression, but do they need to be everywhere? Put the premium tile in the main lobby, but go with a durable, cost-effective VCT in the back-of-house areas.

- Challenge the Structure (Politely!): Have a conversation with your structural engineer. Ask if there are other systems to consider. Could pre-engineered wood trusses work instead of steel? Can the slab thickness be optimized?

Does My Savings Strategy Change with the Size of the Project?

Absolutely. The way you approach cost savings on a small retail build-out is completely different from how you'd tackle a massive warehouse project.

On smaller projects, savings are all about surgical precision. You're looking for specific, targeted wins. Maybe you source some unique reclaimed wood for a feature wall or find a local fabricator who can do the metalwork for less. On these jobs, every single decision feels bigger because its impact on the bottom line is magnified.

For larger projects, your power comes from economies of scale. The big wins aren't found in tiny details but in broad strokes:

- Bulk Purchasing: Buying all your drywall, steel, or concrete from one supplier can unlock discounts you'd never get otherwise.

- Subcontractor Negotiations: You have the leverage to negotiate more favorable long-term rates with your key trades.

- On-Site Efficiencies: Investing in a piece of equipment that saves just 2% on labor can translate into hundreds of thousands of dollars in savings across the entire project schedule.

The real trick is matching your tactics to your scale. On a huge job, spending a week negotiating a 5% discount on structural steel is a massive victory. On a small job, you'd be better off spending that time finding a local supplier for discounted lumber.

How Do I Cut Costs Now Without Paying for It Later?

This is the classic dilemma in construction. It's always tempting to pick the cheapest option upfront, but that often leads to a building that's expensive to own and operate. You save a dollar today only to spend ten on maintenance, repairs, and energy bills down the road. This is what we call the total cost of ownership.

The key is to think strategically. Figure out which parts of the building have the longest lifespan and the biggest impact on your operating budget. This is where you invest your money.

For example, don't skimp on the building envelope—that means your roofing, windows, and insulation. A tighter, better-insulated building will cost more to build, but the energy savings over the next 30 years will pay you back many times over.

On the other hand, you can be more budget-conscious with things that are easier and cheaper to change later. Think about interior light fixtures, paint colors, or landscaping. You can start with good, basic options and plan to upgrade them in five or ten years when you have more capital. This lets you control those initial costs without compromising the long-term integrity of the building itself.

At Blue Gas Express, we know that every line item counts, especially when it comes to on-site utilities. Making the switch to temporary natural gas from more expensive fuels like propane is a straightforward way to manage your operational budget without sacrificing power or heat. Learn how our dependable temporary gas solutions can help you keep your project on track and under budget.