When you need to add a new connection to a pipeline that’s under pressure and can’t be shut down, you need a hot tap. It’s a specialized, highly engineered method for safely cutting into an active pipeline without disrupting service.

This technique is the key to avoiding incredibly costly shutdowns during upgrades, repairs, or expansions.

What Is Hot Tapping and Why Is It So Important?

Think of it like a surgeon performing a keyhole procedure on a major artery without ever stopping the patient’s blood flow. That’s essentially what hot tapping does for a pipeline. It lets technicians add a new branch connection, install a sensor, or perform other modifications on a live line carrying anything from natural gas to water, all while the system keeps running at full tilt.

For any utility, construction project, or industrial facility, this means zero operational downtime.

Shutting down a critical pipeline, even for a few hours, can set off a chain reaction of problems. You’re looking at lost revenue, logistical nightmares trying to work around the outage, and major service disruptions for customers. Hot tapping services are the answer, allowing you to modify and upgrade essential infrastructure without the financial pain and operational headaches.

The Growing Need for No-Shutdown Solutions

This isn't a new concept, but the demand for it has exploded since its early days. What started as a niche maintenance trick in the 1960s has grown into a global service market now valued at over US$1.0 billion. It's projected to hit nearly US$1.5 billion by 2031, a trend tied directly to our aging global pipeline infrastructure.

Just look at the United States—federal data shows that over 60% of gas transmission pipelines were put in the ground before 1970. That creates a constant, pressing need for methods to modify these lines while they’re still in service. You can dig deeper into this market's growth and the factors behind it in this detailed industry analysis.

In this guide, we'll walk you through the entire process, covering things like:

- The step-by-step technical process of a hot tap.

- The critical safety standards and how risks are managed.

- Real-world examples in construction and facility management.

- What to look for when choosing a qualified contractor.

By understanding how hot tapping works, project managers and facility operators can make smart decisions that protect both their assets and their bottom line. It turns a potentially massive disruption into a seamless, controlled procedure.

The Hot Tapping Process Step by Step

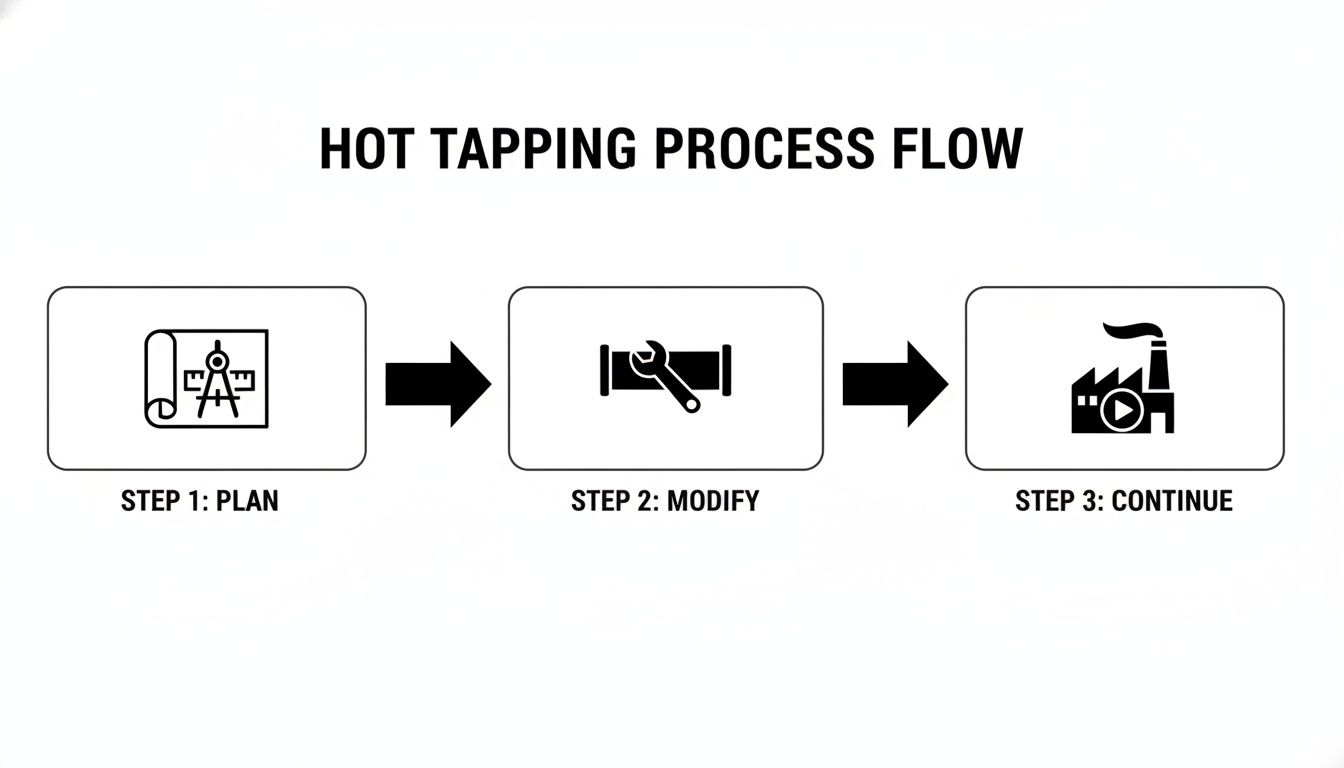

Pulling off a successful hot tap is less about brute force and more like a carefully choreographed industrial procedure. It demands meticulous planning, highly specialized equipment, and a seasoned team that knows how to make every single move with precision and safety in mind.

While the idea of drilling into a live, pressurized pipeline sounds intense, the actual process is incredibly methodical. It's broken down into a series of distinct, manageable phases that build on one another. The goal? To create a new, secure connection without ever shutting down the system.

Think of it as a step-by-step playbook where each action sets the stage for the next, all leading to a seamless tie-in that keeps the product flowing.

Phase 1: Site Preparation and Safety Audits

Before a single piece of equipment shows up, the most important work begins: the planning. This starts with a deep-dive site evaluation and a rigorous safety audit. Engineers will analyze everything about the pipe—its material, wall thickness, operating pressure, and the specific gas or liquid flowing through it.

This isn't just a visual inspection. It often involves non-destructive testing (NDT), like ultrasonic scans, to confirm the pipe is structurally sound and can handle the stress of welding and tapping. From there, a detailed execution plan is drafted, mapping out every action, contingency, and safety protocol. This groundwork is what makes the entire operation safe and successful.

Phase 2: Welding the Fitting and Installing the Valve

With a solid plan approved, the hands-on work starts. A custom-engineered hot tap fitting, which will form the new branch connection, is carefully welded directly onto the live pipe. This weld is the single most critical structural element of the job and must be perfect.

Once the fitting is in place, a permanent valve is bolted onto it. This valve is the gatekeeper; it will eventually control the flow into the new line and, for now, serves as the mounting point for the tapping machine itself.

The quality of the weld determines the long-term integrity of the new connection. Certified welders follow strict procedures to ensure the weld penetrates properly without compromising the parent pipe's strength, all while it remains in service.

Phase 3: Mounting and Pressurizing the Tapping Machine

With the valve securely installed, the hot tapping machine is mounted directly onto it. This isn't just a drill; it’s a sophisticated piece of gear with a sealed housing, a boring bar, and a pilot drill with a specialized cutter.

After mounting, the space between the pipeline valve and the machine's cutter is pressure-tested, typically with nitrogen or water. This is a crucial check to ensure every seal is leak-proof before the pipe wall is ever breached. The pressure is then carefully equalized with the pipeline's internal pressure to create a stable, controlled environment.

This reliance on advanced hardware is fueling major growth. The market for the hot tapping machines and fittings that make these jobs possible was valued at around US$900 million in 2023 and is projected to hit nearly US$1.6 billion by 2032. Today's equipment can handle pipe diameters from 1–2 inches up to 48 inches or more, along with extreme pressures and temperatures. For facility managers and construction crews, this means a wider catalog of standard tools is available, cutting mobilization times from weeks down to just days. You can dig into the numbers in this detailed report on hot tapping machines.

Phase 4: Executing the Tap and Cutting the Pipe Wall

This is where the action happens. The main valve on the fitting is opened, and the operator slowly advances the boring bar until the cutter makes contact with the pipe. With a steady hand, the machine is engaged, and it begins to cut cleanly through the pipe wall.

The cutter is cleverly designed with a retention mechanism to hold onto the piece of pipe it removes, known as a coupon. It works just like a hole saw that keeps the wood plug it cuts. This brilliant feature prevents the coupon from dropping into the pipeline, where it could cause a blockage or damage downstream equipment like pumps and compressors.

Phase 5: Retrieving the Cutout and Securing the Connection

Once the cut is complete, the operator smoothly retracts the boring bar, pulling the cutter—and the captured coupon—back up through the open valve. As soon as the cutter is clear, the valve is closed, instantly and safely isolating the tapping machine from the live pipeline.

The machine can then be depressurized and removed. The new branch connection is now live, fully integrated, and ready for the new pipeline to be tied in. The entire operation is done without spilling a drop or interrupting service for a single moment.

To give you a clearer picture, here’s a breakdown of the entire workflow.

Key Stages of a Hot Tapping Operation

This table summarizes the main phases of a typical hot tapping project, from initial planning to final connection.

| Phase | Objective | Key Activities |

|---|---|---|

| 1. Planning & Prep | Ensure a safe and feasible operation. | Site evaluation, NDT, material verification, safety audits, and development of a detailed execution plan. |

| 2. Installation | Create the permanent branch connection point. | Welding the split-tee or saddle fitting onto the live pipe and bolting the permanent valve in place. |

| 3. Machine Mounting | Prepare the equipment for the cut. | Mounting the hot tapping machine to the valve, performing pressure tests, and equalizing pressure with the pipeline. |

| 4. Execution | Breach the pipe wall in a controlled manner. | Opening the valve, advancing the cutter, drilling through the pipe, and capturing the pipe section (coupon). |

| 5. Completion | Finalize the new connection. | Retracting the cutter, closing the valve, depressurizing and removing the machine, making the new branch available. |

Each stage is a critical link in the chain, ensuring that the final result is a safe, reliable, and seamless addition to the existing infrastructure.

Critical Safety Standards and Risk Mitigation

Think of a hot tap as the industrial equivalent of performing open-heart surgery. It's a highly engineered procedure where the stakes couldn't be higher, demanding meticulous planning and an almost obsessive commitment to safety. This isn't just about bolting on some equipment; it's a calculated process governed by strict industry standards designed to prevent catastrophic failures.

Every single aspect of a hot tapping services project is guided by established codes and best practices. These aren't just suggestions—they are the non-negotiable rules of the road that ensure the integrity of the pipeline and the safety of every person on site.

Adhering to Industry Codes

To ensure predictable and, most importantly, safe outcomes, the entire hot tapping process is standardized. Two of the most critical sets of guidelines come from leading industry authorities that anyone in this field lives by:

- API RP 2201 (Safe Hot Tapping Practices): Published by the American Petroleum Institute, this is the bible for hot tapping in the petroleum and petrochemical world. It lays out everything from essential procedures and equipment specs to the qualifications required for the crew performing the work.

- ASME B31 (Code for Pressure Piping): This code from the American Society of Mechanical Engineers is all about the design, fabrication, and inspection of pressurized piping systems. Its guidelines make certain that any modification, like a hot tap fitting, maintains the pipeline's structural integrity.

These standards provide a proven framework that takes the guesswork out of the equation. They are the reason this high-stakes operation can be executed with such a high degree of reliability, time and time again.

Practical Risk Management on Site

Following the codebook is just the beginning. Real-world risk mitigation involves a series of practical, on-the-ground checks and balances. Before a single piece of metal is cut, a detailed, site-specific execution plan is developed. This isn't a generic template; it's a custom roadmap that accounts for the unique conditions of that specific job.

Here are a few key elements you'll find in that plan:

- Non-Destructive Testing (NDT): Technicians use tools like ultrasonic testing (UT) to get a precise measurement of the pipe wall thickness. This is how we confirm the pipe is structurally sound enough to support the new welded fitting and handle the stress of the tapping process.

- Flow and Pressure Calculations: Before we get anywhere near the pipe, engineers are crunching the numbers. They verify that the flow rate is high enough to carry heat away from the weld zone but not so high that it causes vibrations or other problems for the equipment.

- Weld Procedure Specification (WPS): Every weld follows a specific, pre-approved procedure to the letter. This guarantees a strong, fully-fused connection that doesn't weaken the parent pipe material, which is, of course, still under pressure.

Each of these steps acts as another layer of safety, ensuring potential risks are found and solved long before the tapping machine ever starts turning.

The Golden Rule of Hot Tapping: Every tap is an engineered project, not just a mechanical task. This mindset is the most critical safety control of all, reinforcing the need for qualified professionals, meticulous planning, and zero shortcuts.

Ultimately, this rigorous focus on standards and proactive risk management is what makes hot tapping a safe, viable solution for modifying live pipelines. It transforms a potentially hazardous job into a controlled, predictable, and successful engineering procedure, allowing facilities to make critical upgrades without shutting down or compromising safety.

The theory behind hot tapping is impressive, but where it really proves its worth is out in the field, solving expensive and complicated real-world problems. This technique is a game-changer in situations where shutting down a pipeline isn’t just an inconvenience—it's financially or logistically impossible.

From expanding city infrastructure to commissioning mission-critical equipment, hot tapping services are the key to making essential modifications without ever stopping the flow. Let's look at a few common scenarios to see how this engineered solution goes from a clever concept to a powerful problem-solving tool.

Expanding Infrastructure Seamlessly

Picture this: a new commercial development is going up right next to an established neighborhood. The project needs to tap into the main natural gas line to service the new buildings. The old way would mean shutting down that main, cutting off gas to hundreds of homes and businesses for hours, or even days. This is a perfect job for hot tapping.

Instead of a massive, disruptive shutdown, technicians can perform a hot tap directly on the live gas main. They weld on a fitting, mount a valve, and create the new connection point—all while gas continues to flow to existing customers without a flicker of interruption. The new development gets its gas supply on time, and the community never even knows the work was done.

Performing Emergency Repairs Without Shutdowns

A section of a critical process pipe inside a manufacturing plant is corroded and needs to be replaced immediately. Traditionally, this would demand a full plant shutdown, bringing production to a screeching halt and costing thousands of dollars for every hour of downtime. This is where hot tapping, often paired with line stopping, becomes an operational lifesaver.

Crews can perform two hot taps, one on each side of the damaged section. Then, they insert line stops to temporarily block the pipe, isolating the compromised area while diverting the flow through a temporary bypass. With the product still moving, the damaged pipe can be safely cut out and replaced. The rest of the plant just keeps running.

A Real-World Example: A data center needed to connect its new backup generators to the main gas line. Shutting down the system wasn't an option. Hot tapping provided the connection point while keeping the facility's primary power and cooling systems online, ensuring zero operational disruption.

This approach turns a potential crisis into a controlled, manageable repair, minimizing the financial bleeding.

Commissioning New Equipment and Systems

Connecting brand-new, large-scale equipment to an existing utility supply is another common challenge. A hospital, for example, might be commissioning a new backup power generator that runs on natural gas. To make sure it's ready for an emergency, it has to be connected to the main gas supply and tested thoroughly.

Shutting down the gas supply to an entire hospital campus is simply out of the question. Using hot tapping services, a dedicated connection can be created from the main line directly to the new generator. This lets the commissioning and testing proceed without affecting anything from the kitchen's stoves to the patient wings' heating.

The same idea applies to:

- Adding new cooling tower connections in a factory.

- Installing fire suppression system tie-ins without depressurizing the water main.

- Integrating new manufacturing lines that need a steady supply of chemicals or gas.

Gas pipeline hot tapping is a huge part of this field, with North America accounting for about 37% of global use. A well-planned hot tap on a gas main can prevent service cuts to thousands of users, avoiding enormous revenue losses for utilities and keeping sensitive projects on schedule. In fact, the specialized market for remote hot tapping services has grown to between US$1.2 billion and US$1.84 billion, which shows just how valuable these non-disruptive methods are. You can learn more by exploring the market research on remote hot tapping services.

Upgrading Systems with Modern Technology

Finally, hot tapping is a fantastic way to modernize older infrastructure. Imagine a water utility that needs to install new flow meters or pressure sensors on an aging water main to get better data on system performance and leak detection.

With hot tapping, these sensors can be installed directly into the live pipeline. This allows for immediate system upgrades and data collection without the headaches and costs of a service interruption to an entire district. It’s a practical way to ensure our vital infrastructure keeps up with modern efficiency and safety standards.

How to Choose the Right Hot Tapping Contractor

Picking the right partner for a hot tapping job is probably the single most important decision you'll make for the project. This is a far cry from a standard plumbing gig; it's a high-stakes, precision-engineered operation where deep experience and a rock-solid commitment to safety are absolutely essential. Gambling on an under-qualified team can lead to catastrophic failures, massive budget overruns, and, worst of all, serious injuries.

So, how do you make the right call? It’s about looking past the lowest bid and really digging into a contractor’s actual capabilities. A top-tier provider doesn’t just show up with a machine. They bring a complete, integrated approach covering everything from initial engineering and safety management to clear communication that keeps you in the loop from day one.

Proven Experience and Real-World Case Studies

First things first: look for a long and verifiable track record. When it comes to hot tapping, there’s simply no substitute for hands-on experience out in the field. A qualified contractor should have no problem showing you detailed case studies or project histories that mirror your own project's scope, pipe material, and operating conditions.

Don't be shy about getting into the nitty-gritty. Ask them to walk you through the most complex hot tap they’ve ever pulled off and what specific challenges they had to solve. Their answer will tell you a lot about their practical, on-the-fly problem-solving skills—something you’ll be grateful for when the unexpected inevitably happens.

Safety Records and Certifications

A serious safety culture isn't just a nice-to-have; it's a non-negotiable requirement. You want a contractor who lives and breathes safety, and they should be able to prove it with industry-recognized certifications and compliance management systems.

Here are a few key credentials to check:

- ISNetworld or Veriforce Membership: These third-party platforms are the gold standard for vetting contractors on their safety programs, procurement processes, and regulatory compliance.

- Total Recordable Incident Rate (TRIR): A low TRIR is one of the clearest indicators of an effective safety program. Ask for their numbers for the last few years and see how they stack up against the industry average.

- Site-Specific Safety Plans: A real pro will develop a detailed safety plan tailored specifically for your site and your job. If they hand you a generic, one-size-fits-all template, that’s a red flag.

A contractor’s safety record is a direct reflection of their operational discipline. A team that puts safety first is also a team that values precision, planning, and quality in every single thing they do.

In-House Engineering and Meticulous Planning

This is a big one: does the contractor have their own engineers, or do they farm out the critical calculations and planning? A company with in-house engineering capabilities can offer a much more seamless and responsive service. They can run calculations, design custom fittings, and create detailed welding procedures without the delays and communication gaps that come with using third parties.

This in-house expertise is what ensures every part of the project—from material selection to pressure calculations—is done strictly by the book, following all relevant API and ASME standards. A great question to ask is, "What's your process for verifying pipe integrity before you even think about starting work?" You want to hear a thorough answer grounded in solid engineering principles.

Quality Equipment and Clear Communication

Finally, take a look at the quality of their gear and their approach to project management. Well-maintained, modern hot tapping machines are safer, more reliable, and simply perform better. Ask to see maintenance logs or find out how they invest in keeping their equipment up to date.

Just as critical is clear and consistent communication. You need a partner who keeps you informed every step of the way, from the first planning meeting to the final project sign-off. A transparent contractor will give you a clear schedule, assign dedicated points of contact, and be upfront about any potential challenges. That level of professionalism is what separates the best from the rest.

Hot Tapping Contractor Evaluation Criteria

Choosing a hot tapping contractor requires a structured evaluation. Use this checklist to compare potential partners and ensure you're looking at the factors that truly matter for a safe and successful project.

| Evaluation Criterion | What to Look For | Questions to Ask |

|---|---|---|

| Experience & Track Record | Verifiable projects similar to yours in scope, pressure, and material. | "Can you provide case studies for 3 similar projects completed in the last 5 years?" |

| Safety Performance | Low TRIR, active membership in ISNetworld/Veriforce, robust safety manual. | "What is your TRIR for the past 3 years? Can we review your site-specific safety plan?" |

| Engineering Capabilities | In-house P.E. stamped calculations, custom fitting design, weld procedure specs (WPS). | "Who performs your engineering calculations and designs? Are they in-house?" |

| Quality Control | Documented QC program, material traceability, post-weld NDT procedures. | "What is your process for non-destructive testing on welds before the tap?" |

| Equipment & Maintenance | Modern, well-maintained equipment with clear service records and certifications. | "Can you provide maintenance logs for the machine designated for our project?" |

| Insurance & Liability | Adequate liability coverage specific to high-risk industrial work. | "What are your general and pollution liability insurance limits?" |

| Project Management | A dedicated point of contact, clear communication plan, detailed schedule. | "Who will be our primary contact, and how will project updates be communicated?" |

| Certifications | Welder certifications (e.g., ASME Section IX), technician qualifications. | "Are all of your welders and technicians certified for this type of work?" |

Making a thorough, informed choice based on these criteria will give you confidence that you have a capable and reliable partner on your side. It's an investment in getting the job done right the first time.

Your Hot Tapping Questions, Answered

Even after you’ve got the basics down, it’s natural to have a few more questions about how hot tapping services really work on a job site. Let's dig into some of the most common things people ask to clear up any lingering details before you start planning.

Getting a handle on these key distinctions is the first step toward a smooth, successful operation.

Hot Tapping Versus Line Stopping

It’s easy to get these two confused. People often hear "hot tapping" and "line stopping" mentioned in the same breath and figure they’re interchangeable. While they're frequently used together on the same project, they do two completely different jobs.

- Hot Tapping is all about adding something. It’s how you create a new, permanent branch connection on a live pipe. Think of it like building a new on-ramp onto a busy highway without ever closing a lane.

- Line Stopping is about blocking something. It's a way to temporarily stop the flow inside a live pipeline. This is more like setting up a secure, temporary roadblock that safely reroutes traffic so you can work on a section of the road.

A classic example is replacing a faulty valve. You can’t just shut the whole system down. Instead, you'd perform two hot taps—one on each side of the bad valve. Then, you insert line stops through those new connections to completely isolate that section, bringing it to zero pressure for a safe repair.

Are There Limits on What Can Be Hot Tapped?

Hot tapping is an incredibly flexible technique, but it’s not a magic bullet for every situation. The entire process is built on a foundation of strict engineering and safety rules that tell us whether a tap is even possible. Any good contractor will run a full evaluation of these factors before they even think about bringing equipment to your site.

The feasibility of any hot tap comes down to a mix of material science, fluid dynamics, and operational safety. There's no "one-size-fits-all" answer; every single project requires a custom engineering review to guarantee a safe outcome.

Here are some of the key limitations we always have to consider:

- Pipe Contents: You simply can't hot tap lines carrying certain substances. Systems with highly hazardous or volatile materials, like pure oxygen or chlorine, are usually off-limits due to the extreme safety risks.

- Pipe Material: Some pipe materials just don’t play well with welding. Things like cast iron or internally lined pipe can be extremely difficult, if not impossible, to safely weld a fitting onto.

- Pressure and Temperature: Every piece of hot tapping equipment has its limits. The machines and fittings are all rated for a specific maximum pressure and temperature, and the operation has to stay well within those design boundaries.

- Pipe Condition: We can't tap into a pipe that's on its last legs. If a pipe is heavily corroded or structurally weak, it’s a non-starter. We always have to verify the pipe's wall thickness with non-destructive testing first.

How Long Does a Hot Tapping Operation Take?

This is a bit of a trick question. The on-site work—the actual drilling of the hole—is surprisingly quick. It often takes just a few hours from start to finish.

But that’s just the final step. The real work is in the preparation, which can take anywhere from a few days to several weeks. This "pre-game" phase includes everything from site walk-downs and detailed engineering calculations to fabricating the custom fitting and writing a site-specific safety plan. Rushing this critical groundwork is never an option.

What Information Do I Need for a Hot Tapping Quote?

To get a quote you can actually count on, you’ll need to give your contractor a clear picture of the job. The more information you can provide right out of the gate, the better. Be ready to share these five key details:

- Pipe Size: The nominal diameter of the pipe.

- Pipe Material: What’s the pipe made of? (e.g., carbon steel, stainless steel)

- Pipe Contents: What’s flowing inside? (e.g., natural gas, water, jet fuel)

- Operating Pressure and Temperature: What are the normal and maximum conditions in the line?

- Location and Accessibility: Where exactly is the tap point, and are there any tight spaces or other constraints?

Giving a contractor these details upfront allows them to provide a realistic estimate and get started on the initial engineering assessment right away.

When your project hits a snag because of gas line installation delays or utility outages, keeping your operation moving is all that matters. Blue Gas Express provides mobile CNG and LNG solutions to bridge that gap, ensuring your construction, commissioning, or facility needs are met without missing a beat. Learn how our temporary gas services can keep your project on schedule.