When oil producers can't process or transport the natural gas that comes up with the oil, they often burn it off right at the wellhead. This practice, known as gas flaring, is a long-standing solution for a very real problem: managing excess gas safely when infrastructure is lacking.

But what was once a simple operational fix is now a glaring environmental and economic issue. Solutions that capture this wasted gas are turning a liability into a real asset, creating new revenue streams while dramatically cutting down on emissions.

Why Gas Flaring Is a Billion-Dollar Problem

Think of a gas flare as a giant, never-ending pilot light. At thousands of oil wells worldwide, these flames burn 24/7. This is the controlled burn of what's called associated petroleum gas (APG)—the natural gas that comes to the surface along with crude oil. While flaring is sometimes unavoidable for safety, it has become a routine way to get rid of gas with no easy path to market.

This all comes down to logistics and money. Building the pipelines and processing plants needed to capture and transport this gas is a massive undertaking, especially in remote areas. For wells that might only produce for a few years, the investment often doesn't seem to pencil out. So, flaring becomes the default option—the path of least resistance.

The Scale of Wasted Energy

The amount of gas we're losing is hard to wrap your head around. Recent data shows that global gas flaring hit 151 billion cubic meters (bcm), a level not seen in over ten years. That's enough gas to power the entire African continent for a year. It's a staggering waste of a valuable resource, and it’s all going up in smoke while pumping millions of tons of CO2 into the atmosphere.

This waste is a direct hit to the balance sheet. The gas being burned has real market value, meaning potential revenue is literally being set on fire. For any oil and gas operator, that’s an untapped asset that’s actively contributing to operational inefficiency.

Gas flaring isn't just an environmental footnote; it's a direct indicator of economic inefficiency. Every flame represents lost revenue, wasted energy, and a missed opportunity to fuel progress.

More Than Just a Compliance Issue

If you only see flaring as an environmental headache, you're missing half the picture. It's a financial drain that needs a smart, strategic fix. The core problem is simple: inefficiency costs money, whether it's industrial-scale flaring or poor commercial energy saving strategies.

So, why does this problem persist? It boils down to a few key factors:

- Infrastructure Deficits: A simple lack of pipelines and processing plants in remote or new fields means there's no way to move the gas.

- Economic Viability: In some cases, the cost to build the capture infrastructure is seen as higher than the potential return from selling the gas.

- Safety and Pressure Management: Flaring is a crucial safety valve. It helps manage pressure swings and prevent dangerous gas buildups during operations.

By looking at it this way, the incentive to act becomes crystal clear. Investing in modern gas flaring solutions isn't just about ticking a regulatory box or improving a sustainability report. It's about seizing a major opportunity to boost efficiency, create value, and finally turn this long-standing problem into a profitable part of the business.

Understanding the True Cost of Flaring Gas

When you see a flare stack burning, you're not just watching waste gas burn off. You're witnessing a costly problem with deep financial, environmental, and operational roots. Looking at these costs together paints a clear picture of why finding alternatives to flaring isn't just an environmental issue—it's a powerful business decision.

The most obvious hit is to the bottom line. Every flame represents a valuable commodity being intentionally destroyed. That’s a direct loss of revenue that could have been captured and sold to power homes and businesses. For an oil and gas producer, it’s the equivalent of punching a hole in your most valuable storage tank and watching profits burn away, 24/7.

The numbers are staggering. On a global scale, we flare around 151 billion cubic meters of natural gas every single year. At today's market prices, that's an estimated $63 billion in value simply going up in smoke. This isn't a small leak; it's a massive, preventable hemorrhage caused by a lack of infrastructure to capture and use that gas. You can dig deeper into the global scale of flaring and its financial impact to grasp the sheer size of the opportunity being missed.

The Environmental Price Tag

Of course, the cost isn't just measured in dollars. Flaring pumps a cocktail of harmful emissions into the atmosphere, creating problems that affect us all.

- Carbon Dioxide (CO2): The most well-known byproduct, CO2 from flaring is a major contributor to climate change. Each flare is a constant, round-the-clock source of these greenhouse gases.

- Methane (CH4): When a flare burns inefficiently, unburned methane slips through. In the short term, methane is a greenhouse gas over 80 times more potent than CO2, making these "dirty" flares particularly damaging.

- Black Soot (Black Carbon): Those dark plumes aren't just smoke. They're fine particles that worsen local air quality, posing health risks to nearby communities. When this soot settles on snow and ice, it even accelerates melting.

These emissions aren't just abstract figures on a report. They actively undermine corporate sustainability initiatives and directly oppose global efforts to reduce routine flaring.

Operational Inefficiency and Regulatory Risk

From a purely operational perspective, continuous flaring is a symptom of a broken process. It means a high-value resource is being treated as a waste product instead of an asset. This glaring inefficiency is also a magnet for risk.

Regulators across the globe are cracking down. They're setting tougher limits on flaring and hitting non-compliant companies with heavy fines. This is a one-way street; the rules are only going to get stricter as environmental scrutiny grows. Companies that lag behind don't just risk financial penalties; they risk their reputation, which can shake investor confidence and damage public trust.

The decision to flare gas is no longer just an operational choice; it's a strategic risk. The cost of inaction—measured in lost revenue, environmental impact, and regulatory fines—far outweighs the investment required to implement effective capture technologies.

When you add it all up, the true cost of flaring becomes undeniable. The lost revenue is immediate, the environmental damage is long-lasting, and the operational and regulatory risks are growing by the day. This creates a compelling case for investing in practical gas flaring solutions that can turn waste into value, protect the environment, and secure a company's future in a rapidly changing energy world.

Practical Technologies to Capture Flared Gas

So, what can we actually do about flared gas? It's one thing to talk about the problem, but it's another to find practical, on-the-ground solutions. Fortunately, turning flared gas from a liability into a valuable asset isn't science fiction; it’s about applying proven engineering to capture this wasted energy.

The trick is matching the right technology to the specific needs of a site. You have to think about things like gas volume, how remote the location is, and the project's timeline. Instead of just burning off valuable hydrocarbons, operators can put systems in place to redirect that gas for something productive. Each solution offers a different path to the same goal: stop the waste, cut emissions, and improve the bottom line.

Harnessing Gas for On-Site Power Generation

One of the most straightforward ways to use captured gas is to turn it into electricity right where you are. Think of it like setting up a small power plant that runs on fuel you were previously just throwing away.

Specialized generators or turbines are brought in to burn the captured gas, producing electricity that can power the facility's own equipment. This move immediately cuts reliance on the local grid, slashes electricity bills, and often provides a much more stable power source, especially in remote areas. For bigger operations, any extra electricity can sometimes be sold back to the utility, opening up a whole new revenue stream.

Reinjecting Gas for Enhanced Oil Recovery

Another incredibly effective technique is gas reinjection. Picture an oil reservoir as a balloon that's slowly deflating. As you pull oil out, the natural pressure that helps push it to the surface drops, making it harder and more expensive to keep pumping.

Gas reinjection solves this by taking that captured associated gas and pumping it right back down into the reservoir. This accomplishes two critical things at once. First, you're storing the gas safely underground instead of flaring it. Second, and maybe more importantly, you're repressurizing the reservoir. This helps maintain or even boost the rate of oil production. It's a clever, closed-loop system that improves efficiency while getting rid of waste.

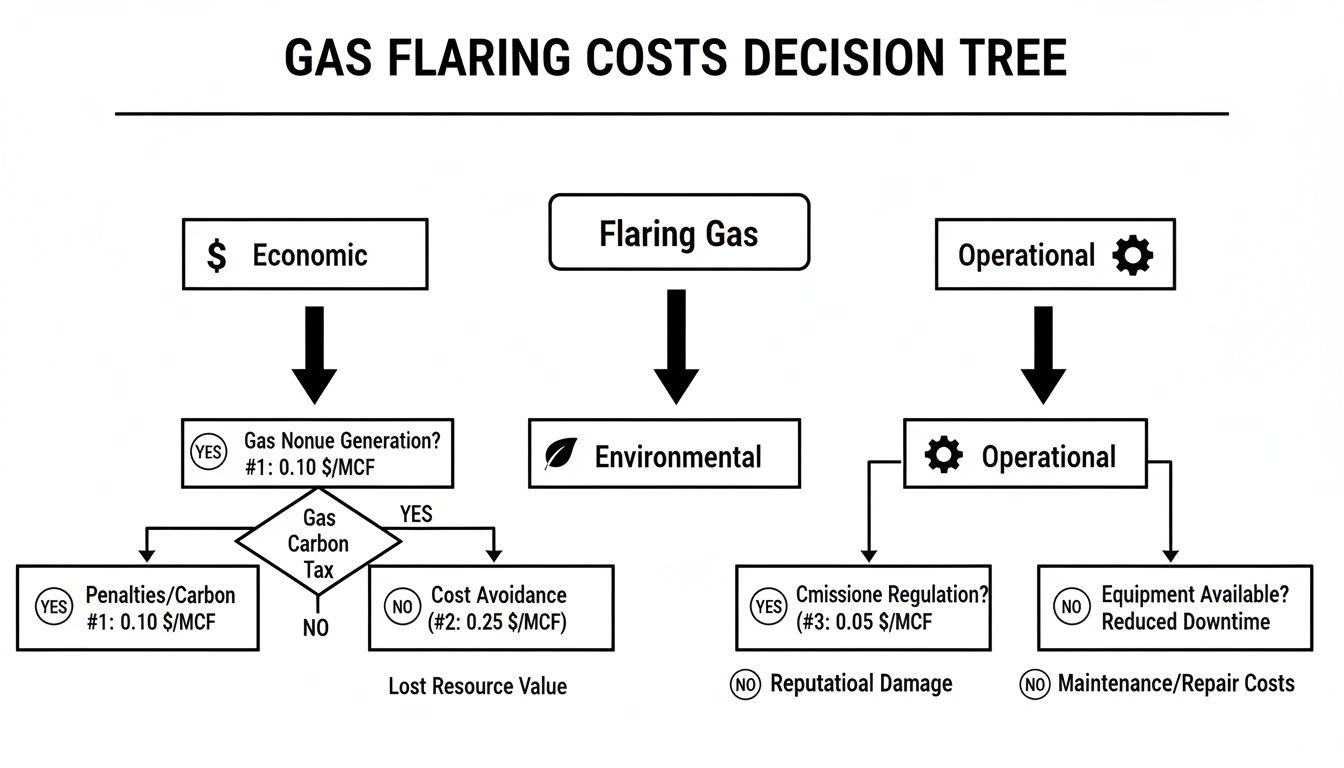

The decision-making process for flaring is complex, weighing economic losses against environmental impact and operational hurdles. The chart below really breaks down why finding a solution is so critical.

As you can see, the negative impacts of flaring spiral out into different, but connected, categories of loss. It’s a powerful visual that shows why a multi-faceted approach to solving it is a must.

Capturing Emissions with Vapor Recovery Units

Not all wasted gas comes from that big, visible flare stack. A surprising amount of hydrocarbon vapors can escape from storage tanks every time they're filled or emptied. Vapor Recovery Units, or VRUs, are designed to tackle this specific problem head-on.

At its core, a VRU is a specialized compression system. It sucks in the low-pressure vapors from storage tanks, recompresses them back into a usable state, and then routes the gas into a pipeline for sale or sends it over to an on-site generator. It’s a highly efficient way to capture emissions that might otherwise just slip away.

The choice of technology is less about finding a single "best" solution and more about selecting the right tool for the job. Each method—from power generation to reinjection—offers a unique set of benefits tailored to different operational and economic scenarios.

To help you see how these options stack up, this table compares the most common gas flaring solutions. It's a quick reference to see what might fit your situation best.

Comparing Gas Flaring Mitigation Technologies

This table compares common gas flaring solutions based on their primary function, ideal use case, capital cost, and key benefits, helping decision-makers choose the right approach.

| Solution | How It Works | Best For | Implementation Cost | Primary Benefit |

|---|---|---|---|---|

| On-Site Power Generation | Uses captured gas to fuel generators, producing electricity for site operations or for sale. | Remote sites without reliable grid access or facilities with high power demands. | Medium to High | Creates a new revenue stream and reduces operational energy costs. |

| Gas Reinjection | Pumps captured gas back into the oil reservoir to maintain or increase pressure. | Mature oil fields where production rates are declining due to pressure loss. | High | Increases oil recovery rates while sequestering gas underground. |

| Vapor Recovery Units (VRUs) | Captures low-pressure gas vapors from storage tanks and recompresses them for use or sale. | Facilities with large storage tank batteries where fugitive emissions are a concern. | Low to Medium | Reduces emissions, improves safety, and recovers a saleable product. |

Ultimately, choosing the right technology requires a hard look at a site’s specific challenges and goals. What they all share, however, is a common purpose: transforming an environmental headache into an economic opportunity. By implementing the right gas flaring solutions, operators can shrink their environmental footprint while unlocking new value from their existing assets.

How Mobile Gas Solutions Create a Virtual Pipeline

Permanent pipelines are the arteries of the natural gas industry, but what happens when those arteries aren't connected yet? Construction delays, planned maintenance, or surprise outages can stop a project dead in its tracks. When the gas can't flow, operators are stuck choosing between expensive downtime or wasteful flaring.

Thankfully, there's a third option that bridges the gap. Mobile natural gas services function as an on-demand energy source, creating what the industry calls a virtual pipeline. Instead of a physical connection, this approach uses specialized trucks to bring compressed natural gas (CNG) or liquefied natural gas (LNG) right where it's needed.

This flexibility is a true game-changer. It means energy can be delivered with surgical precision, sidestepping the rigid limitations of fixed infrastructure. For any project facing a tight deadline or an unexpected interruption, a virtual pipeline supplies the fuel to keep things moving and avoid the steep costs—both financial and environmental—of flaring.

How a Virtual Pipeline Works

The concept is simple but incredibly effective. A virtual pipeline swaps out a physical pipe for a well-oiled logistics chain, guaranteeing a continuous, reliable flow of energy.

It all boils down to three key stages:

- Compression or Liquefaction: First, natural gas from a primary source is either compressed into CNG or chilled into a liquid (LNG). This step dramatically shrinks its volume, making it dense enough to transport efficiently over the road.

- Transportation: The processed gas is then loaded into specially designed, high-pressure tube trailers for CNG or cryogenic tankers for LNG. Think of these mobile units as pipelines on wheels, ready to be dispatched at a moment's notice.

- On-Site Regasification: Once the truck arrives, it connects to on-site equipment that safely depressurizes the CNG or warms the LNG, turning it back into a usable gas. This gas is fed directly into the customer's system, acting as a seamless stand-in for the standard pipeline supply.

This model offers an agile and highly adaptable solution for countless scenarios where the traditional gas supply is unavailable, unreliable, or simply not built yet.

A virtual pipeline transforms natural gas from a location-dependent utility into a mobile, on-demand commodity. This shift gives project managers unprecedented control over their energy supply, ensuring operational continuity even when permanent infrastructure fails.

Real-World Application: A Data Center Commissioning

Picture this: a brand-new data center is ready for its final systems check. The backup power generators, which run on natural gas, have to be tested and commissioned before the facility can get its final occupancy permit. The only problem? The permanent utility gas line is still weeks away from being connected due to unforeseen construction delays.

Without fuel, the entire project hits a wall. The options are bleak:

- Delay the project: This means big financial penalties, a pushed-back launch date, and a domino effect of scheduling nightmares.

- Use other fuels: Alternatives like diesel are more expensive, less efficient, and create more local air pollution, which can complicate environmental compliance.

This is the perfect scenario for a mobile gas solution to provide an elegant workaround. A provider like Blue Gas Express can dispatch a mobile CNG unit straight to the data center. Technicians hook the trailer up to the generator's fuel intake, creating an instant, temporary gas supply.

With the gas flowing, the generators can be fully tested and commissioned. The project secures its permit and stays right on schedule.

In this case, the virtual pipeline did more than just prevent flaring—it prevented project failure. By delivering the right fuel at the right time, it unlinked the project timeline from the utility's construction schedule. This saved time, money, and potential revenue loss for everyone involved, proving how gas flaring solutions can be a proactive strategy for smart energy management.

Navigating Flaring Regulations and Compliance

Let's be blunt: the days of treating gas flaring as a routine, acceptable part of the job are long gone. Staying compliant in a world of ever-tightening environmental standards isn't just a good idea—it's non-negotiable. What was once a footnote in an operational plan has become a central strategic challenge, governed by a complex web of local, national, and international rules.

For any business in this space, this means the goalposts are constantly moving. A proactive approach to compliance is no longer just best practice; it's a matter of survival. Ignoring these standards can hit you where it hurts, with steep financial penalties, forced operational shutdowns, and lasting damage to your company's reputation with both the public and investors.

The Global Push for Zero Routine Flaring

One of the biggest forces behind this shift is the World Bank’s "Zero Routine Flaring by 2030" initiative. This isn't some far-off, aspirational goal. It’s a firm commitment from governments and major energy companies to end the practice of flaring gas during normal oil production. It sends a powerful signal that the global community is done with treating this valuable resource as waste and a major source of pollution.

The results speak for themselves. Progress in curbing gas flaring is directly tied to these kinds of frameworks. Countries that have joined the initiative have dramatically outperformed those who haven't, even as overall global oil production has climbed. For over a decade, the global flaring intensity has stubbornly remained around 5.1 m3 per barrel of oil, showing a clear divide between those taking action and those being left behind. You can dive deeper into the numbers by reviewing the satellite-tracked data and analysis that is shaping the industry's response.

So, what does this global push mean for operators on the ground? It boils down to a few key requirements:

- Accurate Reporting: You have to be able to precisely measure and report every cubic foot of gas you flare. Guesswork won't cut it anymore.

- Emission Reduction Plans: Regulators are no longer satisfied with promises. They want to see detailed, actionable plans showing exactly how you'll reduce and ultimately eliminate routine flaring.

- Technology Adoption: There’s a clear expectation to invest in and implement proven gas flaring solutions, whether that’s vapor recovery units or on-site power generation.

Beyond Fines to Competitive Advantage

While the threat of hefty fines is certainly a motivator, the sharpest companies in the industry see compliance as an opportunity, not just a box to check. Getting ahead of the regulatory curve by adopting advanced gas flaring solutions does more than keep you out of trouble; it builds a stronger, more resilient business.

Think about it. A strong environmental track record is now a massive factor for investors, partners, and even customers. Companies that lead the pack on emissions reduction are seen as more innovative, more efficient, and better managed. Taking a proactive stance here can give you a real competitive edge in a market that puts a growing premium on corporate responsibility.

Adopting modern gas flaring solutions is a strategic investment in the future. It transforms a regulatory burden into a source of operational efficiency, enhanced reputation, and long-term financial stability.

Ultimately, navigating this landscape requires a forward-thinking strategy. This is where options like mobile gas solutions become so valuable. They offer a flexible way to meet—or even beat—emissions targets during temporary events like pipeline maintenance or unexpected construction delays. By preventing flaring during these critical windows, you can prove your commitment to compliance, protect your reputation, and keep your projects on track without sacrificing your environmental goals.

Your Questions About Gas Flaring Solutions, Answered

When you're staring down a pipeline interruption or a project delay, gas flaring can feel like the only option. But it doesn't have to be. Project managers, facility operators, and utility partners often have very practical questions about how modern flaring alternatives work in the real world. Getting straight answers is key to making a smart call that protects your timeline and your budget.

This section tackles the most common questions we hear, focusing on how these solutions actually play out on the ground. Think of it as a field guide to turning a potential flaring problem into a strategic win.

What Is the Most Cost-Effective Solution for Short-Term Flaring Problems?

For temporary situations—think pipeline maintenance, commissioning new equipment, or bridging a construction gap—mobile natural gas solutions like compressed natural gas (CNG) are almost always the most cost-effective path forward. They completely sidestep the massive capital investment and long lead times that come with building permanent infrastructure.

It's a simple analogy: you wouldn't buy a new car just for a weekend road trip. Building a fixed pipeline for a two-week project is the same kind of mismatch. A mobile unit is like the perfect rental; you get exactly what you need, for precisely how long you need it, without the long-term financial baggage.

This "virtual pipeline" approach is a game-changer. It takes gas that would otherwise be flared and burned off—literally lost revenue—and puts it to work. This keeps critical projects on schedule and on budget, making it an easy financial decision for any short-term or unpredictable gas supply issue.

By strategically deploying a temporary solution, you avoid the crippling costs of downtime and keep your operations running smoothly, no matter what's happening with the permanent gas lines. It’s where operational needs and financial smarts meet.

How Quickly Can a Mobile Gas Solution Be Deployed?

Speed is one of the biggest reasons people turn to mobile gas solutions. In time-sensitive situations, the ability to get up and running fast is everything. Depending on the site specifics and location, a mobile CNG or LNG setup can often be delivered, installed, and fully operational in a matter of hours, or at most, a couple of days.

This rapid-response capability is a lifesaver in a few common scenarios:

- Emergency Outages: When a utility line is unexpectedly cut, a mobile unit can be dispatched almost immediately to get the lights back on and the machinery running at critical facilities.

- Meeting Project Deadlines: For a construction project racing to the finish line, mobile gas can be brought in to fire up boilers or generators, helping you pass inspection and get that all-important certificate of occupancy without delay.

- Scheduled Maintenance: During a planned pipeline shutdown, a virtual pipeline ensures downstream customers never even know their primary supply was offline.

When you compare this to the months or even years it takes to permit, plan, and build permanent pipelines, the value is clear. It’s a powerful tool for preventing expensive delays and keeping the business in motion.

Can Mobile Solutions Handle Large Industrial Gas Volumes?

Absolutely. Modern mobile gas solutions are designed to be highly scalable and can easily meet the demands of large industrial operations. When a facility has a huge energy appetite, a provider doesn't just send a single truck. Instead, they deploy a coordinated fleet of CNG trailers or larger LNG storage units.

These units are all hooked together in parallel through a manifold system. This creates a continuous, high-volume flow of natural gas that works just like a pipeline. As one trailer empties, the system automatically and seamlessly switches to a full one. There's zero interruption to your gas supply.

This scalability makes mobile solutions a completely reliable option for powering all kinds of heavy-duty equipment, including:

- Large gas turbines for power generation

- Industrial boilers for manufacturing plants

- Kilns and furnaces in heavy industry

The system is engineered to match the consumption rate of virtually any facility, ensuring even the most energy-hungry operations can run at full tilt during a supply interruption. No project is too big for a virtual pipeline to handle.

Are Mobile CNG and LNG Solutions Safe for My Site?

Safety isn't just a priority; it's the foundation of the entire service. Reputable mobile gas providers operate under incredibly strict safety protocols. The equipment used to transport and deliver CNG and LNG is built to meet or exceed federal safety standards from organizations like the Department of Transportation (DOT) and the National Fire Protection Association (NFPA).

Before a single piece of equipment shows up, a team conducts a thorough site assessment. They’ll walk the ground with you, identify any potential hazards, and map out a detailed safety plan tailored specifically to your facility’s environment.

You’ll find multiple layers of safety built right into the equipment. We’re talking pressure relief valves, emergency shutdown systems, and constant electronic monitoring to make sure everything is operating well within safe limits. On top of that, the technicians who manage the system on-site go through rigorous, continuous training on safe handling procedures.

From the engineering of the trailers to the training of the people, every part of the service is designed around a culture of safety. This gives you the peace of mind to focus on your project, knowing the temporary gas supply is being managed by experts. The goal is always a solution that is as safe as it is effective.

When unexpected delays or planned maintenance threatens your project's timeline, a reliable temporary energy source is crucial. Blue Gas Express delivers scalable and rapid mobile natural gas solutions to keep your operations running without interruption. Don’t let a lack of pipeline access derail your schedule—discover how our virtual pipeline can provide the fuel you need, exactly when you need it at https://bluegasexpress.com.