At its most basic, a gas compressor system is a piece of machinery built to do one thing: squeeze a gas into a smaller space to crank up its pressure. But that simple function is the powerhouse behind much of our modern world. Think of it as the unseen heart of industry, pumping life into everything from energy pipelines to manufacturing plants.

So, What's the Big Deal About Compressing Gas?

The whole point of a gas compressor system is to take in gas at a low pressure and send it out at a much higher one. This isn't just about cramming more gas into a tank; it's about making gas useful. By increasing its pressure, we can move it efficiently, store it compactly, and create the perfect conditions for all sorts of industrial jobs.

It’s this process that lets us shuttle natural gas across entire continents. It’s what powers the air tools on a construction site and provides the precise pressures needed for things like food packaging. Without compression, gas is just… there. With it, it becomes a powerful tool.

The Engine of Industry

You can tell how critical these systems are just by looking at the market. The demand for reliable gas compression mirrors global energy needs and industrial growth. The global market for gas compressors was recently valued somewhere between USD 5.1 billion and USD 5.84 billion. Projections show it could climb to nearly USD 7.9 billion by the early 2030s.

That kind of money isn't just abstract—it’s tied directly to real-world work. You can dig into more data on the global gas compressors market to see just how fast this sector is expanding.

To make this concept a bit more concrete, let's look at what these systems are actually doing out in the field.

The table below breaks down the main jobs of a gas compressor system.

Core Functions of a Gas Compressor System

| Function | Description | Common Application Example |

|---|---|---|

| Gas Transportation | Increases pressure to push gas through long-distance pipelines, overcoming friction and elevation changes. | Moving natural gas from a processing facility to a power plant hundreds of miles away. |

| Energy Storage | Reduces the volume of gas so large quantities of energy can be stored in a manageable space. | Compressing natural gas into CNG tanks to fuel a fleet of city buses. |

| Industrial Processes | Creates specific high-pressure environments needed for chemical reactions or manufacturing tasks. | Supplying pressurized nitrogen for creating fertilizers or plastics. |

Ultimately, whether it's for moving, storing, or using gas, a compressor system solves the fundamental problem of getting gas to do what we need it to do.

Here's a simple way to think about it: A gas compressor is like a bicycle pump on an industrial scale. Your hand pump pressurizes a little bit of air to fill a tire. A gas compressor system does the same thing, but with massive volumes of gases like natural gas or hydrogen, and with incredible precision and power.

Without this capability, our modern energy and industrial infrastructure would grind to a halt. It’s as simple as that.

How a Gas Compressor System Actually Works

At its heart, a gas compressor system works on a surprisingly simple principle. Think about squeezing a wet sponge. The harder you clench your fist, the more you reduce its volume, and the more water is forced out under pressure. A compressor does the same thing, just with gas. It mechanically shrinks the space the gas can occupy, which in turn ramps up its pressure.

This process, called compression, is what turns low-pressure gas into a high-energy, useful resource. The entire system is a carefully orchestrated dance of mechanical parts, all working together to get the job done safely and efficiently.

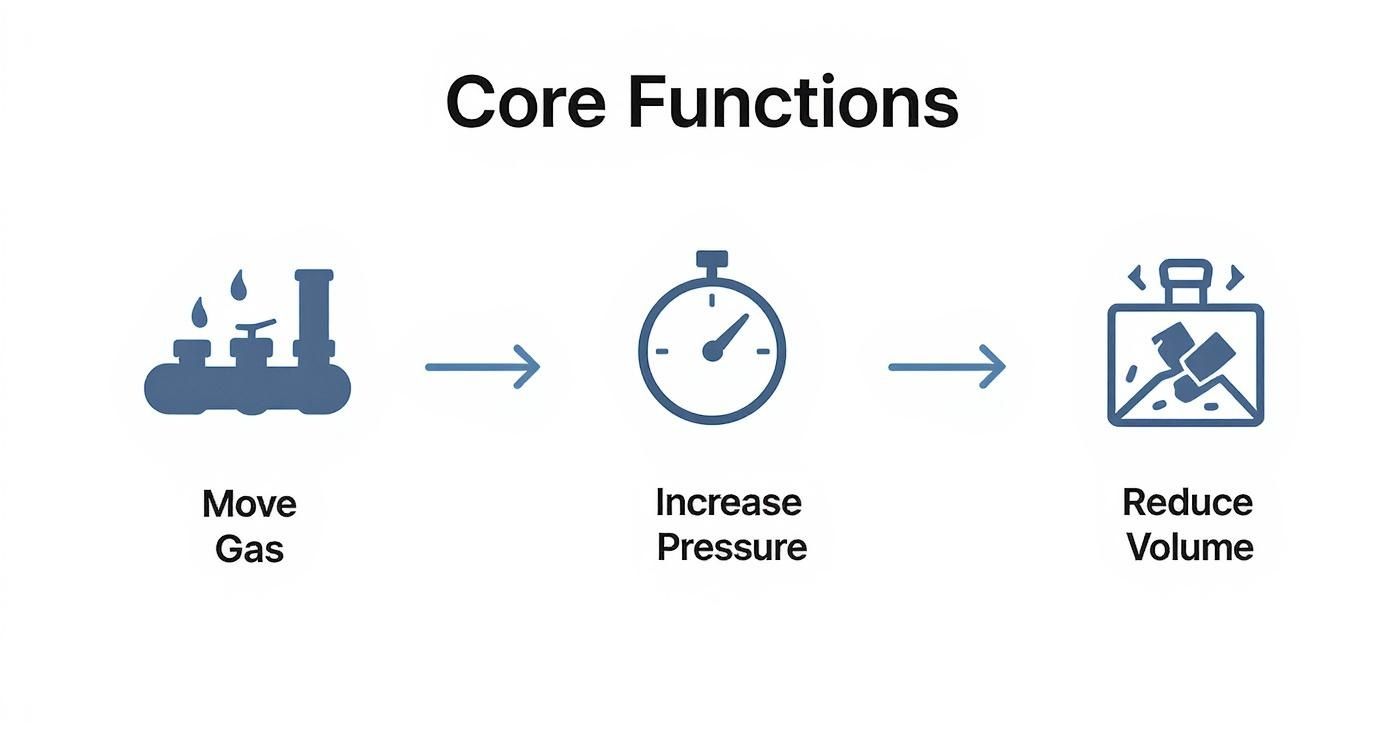

This infographic neatly sums up the core functions in three basic steps.

As you can see, the process is straightforward: gas goes in, its volume is reduced, and the pressure goes up. It's a direct cause-and-effect relationship.

The Key Players in the System

A gas compressor system isn't just a single machine; it's a team of specialized components, each playing a critical role. To really get how gas gets pressurized, you have to understand how these parts work together.

Here’s a breakdown of the main components you’ll find in almost any setup:

- The Driver: This is the muscle of the whole operation. It’s the engine or motor—whether it's powered by electricity, diesel, or natural gas—that provides the raw mechanical energy needed to make everything run.

- The Compressor Unit: This is where the magic happens. The compressor unit is the heart of the system, containing the pistons, screws, or impellers that physically squeeze the gas.

- Heat Exchangers (Coolers): A natural side effect of compressing gas is heat—a lot of it. Forcing molecules closer together generates serious thermal energy. Heat exchangers, or coolers, are there to pull that heat away and keep the system from overheating.

- Control Systems: This is the brain of the operation. Sophisticated electronic systems monitor and manage everything from pressure and temperature to flow rates. They're also responsible for safety shutdowns if something goes wrong.

You can think of it like an orchestra. The driver is the powerful percussion section, the compressor unit is the strings section creating the melody, the coolers are the woodwinds moderating the tone, and the control system is the conductor, making sure every part plays in perfect harmony.

A Step-by-Step Journey Through the System

Let's follow a single molecule of natural gas on its trip through a typical compressor system. This little journey shows how each component contributes to the high-pressure gas that comes out the other end.

1. Gas Intake: The process kicks off at the inlet valve. Here, low-pressure gas from a wellhead or pipeline is drawn into the compressor. Before it gets there, it usually passes through scrubbers and filters that clean out any liquids or solid debris that could damage the machinery.

2. The Compression Stage: Once inside, the driver kicks into gear. In a reciprocating compressor, a piston moves back and forth inside a cylinder, trapping and squeezing the gas with each stroke. In a rotary screw compressor, two big interlocking screws spin together, pushing the gas into an ever-tighter space.

3. Cooling and Recirculation: As soon as the gas is compressed, its temperature shoots up. It’s immediately sent through a heat exchanger, where air or water draws the excess heat away. For systems needing really high pressures, this is just the first step. The cooled gas is then sent to another, smaller cylinder for a second round of compression.

An integrated control system is the central nervous system that ensures everything runs smoothly. It uses sensors to collect real-time data on pressure, temperature, and flow, automatically adjusting operations to maintain efficiency and trigger safety protocols if any reading goes outside of its designated safe range.

4. Final Discharge: After the last round of compression and cooling, the gas—now at high pressure—passes through an outlet valve. From there, it’s ready to go. It might be sent down a long-distance pipeline, stored in a CNG tank, or used to power an industrial facility. Every step is meticulously managed to deliver the gas at the exact pressure and temperature the end-user needs.

The Two Main Families of Gas Compressors

When you get into the world of gas compression, you quickly realize it's not a one-size-fits-all game. The machine needed to fill a single CNG vehicle tank is worlds apart from the colossal equipment used to push natural gas across an entire country through a pipeline.

At the highest level, every gas compressor system belongs to one of two major families: Positive Displacement or Dynamic.

Think of the difference like this: a Positive Displacement compressor is like a bicycle pump. It traps a specific, fixed amount of air in a chamber and then physically shrinks that chamber's volume. That action forces the same amount of gas into a smaller space, which directly cranks up the pressure. It’s a direct, mechanical squeeze.

On the other hand, a Dynamic compressor works more like a powerful jet engine turbine or a boat propeller. Instead of trapping gas, it uses high-speed rotating blades to accelerate the gas, flinging it outward and converting its velocity (kinetic energy) into pressure. It builds pressure through speed, not by squeezing.

Positive Displacement Compressors: The High-Pressure Specialists

Positive Displacement compressors are the real workhorses for jobs that demand high pressures, even if they don't involve massive flow rates. Because they work by trapping and squeezing a set volume of gas with each cycle, they deliver a very steady, consistent flow regardless of the final pressure.

This reliability makes them perfect for applications where unwavering pressure is non-negotiable.

You'll most often run into two main types in this family:

- Reciprocating Compressors: These use a piston moving back and forth inside a cylinder, almost exactly like the engine in your car. Each forward stroke of the piston compresses the gas. They are masters at achieving extremely high pressures, which is why you see them in CNG fueling stations and critical industrial gas processing.

- Rotary Screw Compressors: Inside these machines are two big, interlocking helical screws. As they spin, they pull gas into the gaps between their threads, pushing it down the length of the screws. The space gets progressively smaller, compressing the gas until it's discharged at the other end.

The key takeaway here is that Positive Displacement compressors trap a fixed volume of gas with each rotation or stroke. This design is what gives them their high-pressure punch, but it generally means they can't move the same massive volumes as their dynamic cousins.

Dynamic Compressors: The High-Volume Movers

Dynamic compressors operate on a completely different principle. They are built for one main purpose: moving enormous volumes of gas. Instead of trapping and squeezing, they use spinning impellers to blast energy into a continuous stream of gas, getting it moving incredibly fast.

They are the undisputed champions of high-flow, lower-to-medium-pressure applications.

The demand for these high-volume machines is huge and growing. The global gas compressor market, valued at around USD 18.72 billion recently, is expected to climb past USD 23 billion in the near future, growing at a rate of roughly 4.2% to 4.4% annually. This growth is fueled by power plants, petrochemical facilities, and factories needing modern, efficient infrastructure. You can dig deeper into the numbers in this gas compressor market forecast.

The two main players in the dynamic compressor category are:

- Centrifugal Compressors: These use a rapidly spinning impeller with curved blades that sucks gas in at the center and slings it outward at high speed. The gas then hits a diffuser, which is designed to slow it down, converting that raw speed into steady pressure. Imagine a spinning playground merry-go-round pushing you toward the outside edge—it's the same fundamental force at work.

- Axial Compressors: You'll find these in jet engines and massive industrial gas turbines. Axial compressors use a series of rotating airfoil blades to push gas straight through the machine along its axis. Each set of blades, or "stage," adds a bit more pressure, and by lining up many stages, they can achieve high compression for truly immense volumes of gas.

To make the distinction crystal clear, let's break down the core differences between these two compressor families.

Positive Displacement vs Dynamic Compressors

| Attribute | Positive Displacement Compressors (e.g., Reciprocating, Screw) | Dynamic Compressors (e.g., Centrifugal, Axial) |

|---|---|---|

| Operation | Traps a fixed volume of gas and reduces its space to increase pressure. | Uses rotating blades to accelerate gas, converting velocity into pressure. |

| Flow Rate | Lower to medium flow; delivers a constant, non-pulsating flow. | Very high to massive flow rates; flow is continuous. |

| Pressure | Can achieve very high pressure ratios per stage. | Lower pressure ratio per stage; better for large volume, moderate pressure. |

| Best For | High-pressure, low-flow needs like CNG stations, refrigeration, and small industrial plants. | High-volume, continuous-flow needs like pipelines, LNG plants, and large chemical processing. |

Ultimately, choosing the right type of compressor boils down to the specific demands of the job—are you trying to achieve sky-high pressure in a small system, or move a river of gas across a continent?

Compressor Applications in the Real World

Knowing the theory behind compressor families and mechanics is one thing, but seeing a gas compressor system in action is where its true value really clicks. These powerful machines are the invisible workhorses behind countless industries, solving critical challenges and driving the processes that define modern life. From the energy that heats our homes to the materials that build our world, compressors are almost always part of the story.

They are the unsung heroes humming away in remote gas fields, sprawling chemical plants, and high-tech manufacturing facilities. Each application brings a unique puzzle to solve—whether it’s moving immense volumes of gas over vast distances or creating intensely precise pressures for delicate operations. Looking at these real-world scenarios shows you just how fundamental this technology really is.

Powering the Global Energy Supply Chain

You’ll find no industry more reliant on gas compressors than oil and gas. They are absolutely essential at every single stage, from pulling resources out of the ground to delivering finished fuel to your local utility. The entire natural gas infrastructure we depend on simply wouldn't exist without them.

Think about these key jobs:

- Gas Gathering: Natural gas doesn't just cooperate and flow out of a well at the perfect pressure. Compressors at the wellhead are needed to gather low-pressure gas from multiple sources, giving it enough of a push to get it into a central processing facility.

- Pipeline Transmission: How do you move gas across states or even continents? You have to overcome thousands of miles of friction. Massive centrifugal compressors are installed in stations all along pipelines to re-pressurize the gas, acting like booster pumps to keep the flow strong and steady.

- Gas Storage and Distribution: When energy demand is low, gas gets injected into huge underground storage reservoirs. It takes powerful reciprocating compressors to force the gas into these spaces. Later, they help pull the gas back out and send it into the local distribution networks that feed our homes and businesses.

A single cross-country natural gas pipeline can have dozens of compressor stations, each a critical link in the chain. A failure at just one station can disrupt the energy supply for an entire region, which really underscores how important the whole system is.

Creating the Building Blocks of Modern Life

The petrochemical industry is another world where gas compressors are non-negotiable. Many of the chemical reactions needed to produce plastics, fertilizers, and other essentials can only happen under specific, high-pressure conditions. A gas compressor system is the tool that creates and holds those environments with pinpoint accuracy.

Take the production of ammonia, for instance. It's a key ingredient in the agricultural fertilizers that help feed billions, and making it depends on compressing hydrogen and nitrogen gases to extreme pressures. In the same way, creating the polyethylene for plastics requires compressors to manage volatile gases safely and effectively. In these plants, the compressor isn't just a piece of utility equipment; it's a core part of the chemical reactor itself.

Ensuring Reliability in Power Generation

Modern power plants, especially those that run on natural gas, lean heavily on compressors to function. The gas turbines that generate electricity need their fuel delivered at a very specific and consistently high pressure. A dedicated gas compressor system makes sure the turbine gets a steady diet of fuel gas, letting it run at peak efficiency and produce reliable electricity for the grid.

These fuel gas boosting systems are critical for grid stability. They have to respond instantly to changes in electricity demand, adjusting the fuel flow to the turbines without a single hiccup in pressure. This job demands not just raw power but also incredible responsiveness and control. It’s a perfect example of where sophisticated integrated control systems, which centralize the management of complex industrial processes, really shine.

Advancing Manufacturing and Industrial Processes

Looking beyond the massive scale of energy and chemicals, gas compressors are vital cogs in nearly every kind of manufacturing. They power the pneumatic tools on assembly lines, provide the ultra-pure air needed for making electronics, and create the nitrogen used in food packaging to keep products fresh.

As factories become more connected and data-driven, the role of all equipment—compressors included—is evolving. To get a sense of how these machines fit into the factory of the future, it helps to explore the broader context of Augmented Reality and Industry 4.0 in Manufacturing. This kind of integration paves the way for predictive maintenance and smarter operational monitoring, making these essential machines even more dependable. From shaping glass bottles to fabricating metal, the controlled force delivered by compressed gas is a fundamental manufacturing tool.

How Compressors Are Powering the Energy Transition

When you think of a gas compressor system, you might picture old-school fossil fuel infrastructure. But these machines are actually becoming one of the most important tools we have for building a cleaner energy future. Instead of becoming obsolete, they’re being re-engineered to solve the unique problems of sustainable energy, making them the workhorses behind things like hydrogen fuel, biogas, and large-scale carbon capture.

This evolution is absolutely critical. As the world pushes for decarbonization, compressors act as a bridge technology. Their basic job—pressurizing and moving gases—is just as essential for clean molecules like hydrogen as it is for natural gas.

Making the Hydrogen Economy Possible

Hydrogen gets a lot of hype as the fuel of the future, but it comes with a major logistical headache. It’s the lightest element in the universe, which means its low density makes it a real challenge to store and move around efficiently. That's where specialized process gas compressors step in.

Engineers are now creating advanced systems built specifically to handle hydrogen's tricky properties. These compressors have to be incredibly tough to manage the immense pressures required to make hydrogen dense enough for pipeline transport or for storage in the tanks of fuel cell vehicles.

- Transportation: Moving hydrogen through pipelines, whether new or retrofitted, requires powerful compressor stations along the way to keep the gas flowing at the right pressure. It’s a lot like the system we use for natural gas today.

- Storage: To power a car or truck, hydrogen gas has to be squeezed into tanks at incredibly high pressures—sometimes up to 10,000 psi.

- Production: Compressors are also a key part of making "green hydrogen," where they handle the gas produced by electrolysis that's powered with renewable energy.

A Key Player in Carbon Capture and Biogas

Beyond hydrogen, compressors are vital for other important decarbonization efforts. Take Carbon Capture, Utilization, and Storage (CCUS) projects. They depend on massive compressors to grab CO2 emissions from industrial plants, pressurize the gas until it behaves like a liquid, and then inject it deep underground for permanent storage.

It’s a similar story in the biogas world. Compressors are used to upgrade raw biogas into renewable natural gas (RNG). The process involves compressing the gas to help strip out impurities, cleaning it up so it's pure enough to be injected right into existing natural gas pipelines.

The fundamental job of a gas compressor system—pressurizing gas so it can be moved and used—hasn't changed. What is changing is the kind of gas it’s handling. This adaptability is exactly why compressors are so central to the energy transition.

The market reflects this reality. The global process gas compressor market, recently valued at around USD 6.3 billion, is expected to jump to USD 10.3 billion in the next ten years. That impressive 5.7% annual growth is being driven directly by the build-out of green hydrogen infrastructure and other clean energy projects. You can find more details about this expanding market on custommarketinsights.com.

The Future is Smarter and More Efficient

The technology inside the compressor is getting a major upgrade, too. Today’s systems are becoming smarter, more efficient, and far more reliable, which helps reduce their own environmental impact.

Here are a few of the key advancements:

- AI-Powered Monitoring: Artificial intelligence can sift through real-time performance data to spot signs of trouble before a component fails. This kind of predictive maintenance cuts downtime and, just as importantly, prevents methane leaks from failing equipment.

- Digital Twins: Engineers can now build a "digital twin," or a perfect virtual copy, of a physical compressor. This lets them run simulations to fine-tune performance and test new operating strategies in a completely risk-free environment.

- IoT-Enabled Controls: With the Internet of Things (IoT), sensors constantly feed data back to operators, allowing for remote monitoring and real-time adjustments. This ensures the system is always running at peak efficiency and using the least amount of energy possible.

As we look at how gas compressors are enabling this shift, it helps to understand the other low carbon technologies that are also part of the solution. This bigger picture reveals how different innovations are all working in concert. In the end, the modern gas compressor is a perfect example of technological evolution, proving that even long-established machinery can be reimagined to help power a cleaner world.

Flexible CNG and LNG Solutions for Modern Needs

While stationary compressors are the workhorses of permanent industrial facilities, some of the most innovative applications today are happening on wheels. Mobile compression for Compressed Natural Gas (CNG) and Liquefied Natural Gas (LNG) is solving tough logistical challenges by bringing energy where permanent pipelines just aren't feasible.

These setups are essentially "virtual pipelines," delivering natural gas on demand. Picture a complete gas compressor system, neatly packaged on a truck or trailer, ready to deploy at a moment’s notice. This approach is a game-changer for energy access, particularly for remote job sites or temporary projects.

Consider a new housing development that needs natural gas to pass its final inspection for an occupancy permit. If the utility pipeline is still months from completion, a mobile CNG unit can bridge the gap. It provides the necessary fuel to keep the project moving forward and sidestep expensive delays.

The Power of On-Demand Energy

The real magic of this model is its incredible adaptability. Instead of waiting on the massive, costly process of building out infrastructure, companies get the energy they need, precisely when and where they need it. This on-demand approach offers some serious advantages.

Here’s what makes a modern, mobile gas compressor system so effective:

- Rapid Deployment: These units can be on-site and running in a matter of hours. That's a huge benefit for handling pipeline maintenance outages or sudden supply interruptions.

- Scalability: Need temporary heat for a small commercial building? Fuel for commissioning massive generators at an industrial plant? The solution scales up or down to meet the exact demand.

- Lower Upfront Costs: It completely avoids the steep capital investment and regulatory headaches of building permanent pipelines, making it a smart financial choice for short-term or intermittent needs.

This flexibility is what it’s all about. A mobile gas compressor system acts as a reliable energy bridge, ensuring businesses that can't afford to wait can keep their operations running. It’s a practical fix for real-world problems.

Imagine a large factory losing its main gas line during a brutal cold snap. A mobile LNG vaporization unit can be dispatched immediately, hooking into their system to prevent equipment from freezing and keep production lines from shutting down. Fixed infrastructure simply can't offer that kind of rapid response.

Vehicle fleets are another perfect example. A company launching a new distribution center can bring in a mobile CNG fueling station to power its trucks from day one, long before a permanent station could ever be built. It's this kind of agility that's making natural gas more versatile and accessible than ever before.

Of course. Here is the rewritten section, designed to sound completely human-written and natural.

Common Questions About Gas Compressors

As we've gotten into the nuts and bolts of gas compressor systems, a few practical questions always seem to pop up. Let's tackle some of the most common ones to clear up any confusion and really nail down these concepts.

Gas Compressor vs. Water Pump: What’s the Difference?

It’s easy to mix up the terms "compressor" and "pump" because they both increase pressure. But physically, they’re doing two very different things. The real difference comes down to what they're moving.

A gas compressor is built specifically for gases—substances you can actually squeeze. Its whole job is to take a certain amount of gas and force it into a much smaller space, which in turn skyrockets its pressure.

A pump, on the other hand, deals with liquids, which are largely incompressible. Think about it: you can’t really crush a bottle of water into a smaller volume. A pump’s main goal isn't to change the liquid's density; it’s simply to move that liquid from point A to point B. It increases pressure just enough to get the fluid flowing.

How Do You Choose the Right Compressor Type?

Picking the right gas compressor system isn't like grabbing one off the shelf. The choice has to match the job perfectly. Getting it wrong means wasting energy, spending too much money, or finding out your equipment can't even do what you need it to.

To land on the right one, you have to weigh a few key factors:

- How much pressure do you need? If you need to hit extremely high pressures for something like CNG storage, you're likely looking at a positive displacement compressor, such as a reciprocating model. For more moderate pressure, like pushing gas through a pipeline, other options might be better.

- What kind of flow rate is required? Are you moving a massive amount of gas, like in an LNG facility? When you need high volume, dynamic compressors—especially centrifugal ones—are the clear winners.

- What gas are you handling? The gas itself matters a lot. Is it corrosive? Flammable? Does it need to stay completely free of oil? The compressor’s materials and design must be able to handle the specific gas safely.

- What’s the actual application? The end-use is everything. The needs for running simple pneumatic tools are worlds apart from what's required to feed a complex petrochemical reactor.

It really boils down to balancing pressure and flow. High-pressure, low-flow jobs usually point you toward positive displacement compressors. High-flow, lower-pressure applications are a perfect fit for dynamic compressors.

What Are the Main Safety Concerns with Gas Compressors?

When you’re dealing with a gas compressor system, you're managing enormous amounts of pressure and often, flammable materials. Safety can't just be an afterthought; it has to be the top priority. These machines are incredibly powerful, and cutting corners can lead to disaster.

Every compressor installation must have a few non-negotiable safety features. Robust pressure relief systems are at the top of the list—they’re designed to automatically vent any excess pressure and prevent a catastrophic failure.

Proper ventilation is also crucial, especially when you're working with gases like natural gas or hydrogen that could create an explosive atmosphere if they build up. But maybe the most important safety measure of all is a strict commitment to regular maintenance carried out by qualified pros. Consistent inspections and preventative repairs are the single best way to keep a gas compressor system running safely and reliably for years to come.

Facing a delay in your natural gas line installation or a maintenance outage? Blue Gas Express provides reliable, temporary CNG and LNG solutions to keep your projects on track across North Carolina, South Carolina, Tennessee, and Virginia. Don't let infrastructure delays cost you time and money—get the on-demand energy you need and keep your operations running smoothly.