When you hear "mobile gas," you might think of a small truck refueling a car on the side of the road. But in the industrial and commercial world, it means something entirely different—and on a much larger scale.

A mobile gas company service is essentially a pipeline on wheels. It’s a specialized energy solution that delivers natural gas directly to a job site using trucks, completely bypassing the need for a physical, in-ground pipeline. This "virtual pipeline" provides either Compressed Natural Gas (CNG) or Liquefied Natural Gas (LNG) for projects with temporary or remote energy demands.

Understanding The Virtual Pipeline

Picture this: you’re managing a massive construction project, but the permanent utility lines won't be active for months. Your timeline can't wait. This is the exact scenario where a gas company mobile service becomes a game-changer, bringing the power source directly to you.

We're not talking about small-scale refueling here. This is an industrial-grade solution where specialized trucks transport massive volumes of CNG or LNG, ensuring your operations hum along without costly delays. It’s a capability that's becoming absolutely essential in today's energy landscape.

The market backs this up. The global natural gas distribution sector has seen explosive growth, jumping from $908.12 billion to $967.58 billion in a single year. That powerful 6.5% increase highlights a major shift toward more flexible energy delivery, where mobile solutions are closing the "last-mile" gap for sites both in bustling cities and in the middle of nowhere. You can learn more about the growth of the mobile gas station market and its forecasts to see just how big this trend is.

How The Technology Works On-Site

When the natural gas arrives, it isn't as simple as hooking up a hose. The gas is in a highly compressed or super-cooled liquid state and needs to be carefully prepared for use at a standard, usable pressure. This is where specialized on-site hardware and expert technicians come into play.

A typical setup involves several critical components working together to transform the transported gas into a ready-to-use fuel source. The entire process is managed by highly trained pros who ensure everything runs safely and efficiently from start to finish.

A mobile natural gas service essentially replicates the function of a permanent utility connection. It provides the same reliable, clean-burning energy but with the flexibility to be deployed anywhere, anytime.

Core Components Of A Mobile Gas Solution

To get a clearer picture of what happens on the ground, it helps to break down the essential equipment. Each piece has a specific job in safely converting the stored gas into a steady supply for your project's needs.

Here's a quick look at the key hardware that makes up a temporary natural gas station.

Core Components of a Mobile Gas Solution

| Concept | Description | Analogy |

|---|---|---|

| CNG/LNG Trailers | These are the large, high-pressure tube trailers or cryogenic tankers that transport the gas to your location. | Think of it as a high-capacity power bank for your entire project site. |

| Pressure Reduction Skid | This unit safely reduces the high pressure of the stored gas down to the specific pressure your equipment requires. | It’s like the water pressure regulator on a house, ensuring a gentle, steady flow instead of a firehose blast. |

| Gas Heater/Vaporizer | This component warms the gas. For CNG, it prevents freezing during pressure reduction; for LNG, it turns the liquid back into a gas. | Like a kettle boiling water, it turns a liquid into a usable vapor (gas). |

| Odorization System | A critical safety unit that injects mercaptan, the chemical that gives natural gas its distinct "rotten egg" smell for leak detection. | It's the alarm on a smoke detector, adding a clear warning signal to something otherwise invisible and odorless. |

Together, these components create a self-contained, temporary gas utility right on your site. This system allows a gas company mobile service provider to deliver a seamless energy supply tailored precisely to your project's specifications, whether you're heating a new high-rise or commissioning massive power generators.

When Does it Make Sense to Use Mobile Natural Gas?

So, you know what mobile natural gas is. The real question is, when do you actually need it? Let's get into the practical, on-the-ground situations where these services aren't just a nice-to-have, but an absolute game-changer. Mobile gas shines whenever permanent pipelines are out of reach, unreliable, or temporarily down for the count.

Think of it like this: a permanent gas line is your home's Wi-Fi—stable, always on, and built-in. A mobile natural gas service is like bringing a powerful 5G mobile hotspot to a remote cabin. It delivers a strong, dependable connection exactly where you need it, for precisely how long you need it, and not a moment more.

Keeping Pipelines Healthy and Safe

The massive network of natural gas pipelines that crisscross the country needs regular check-ups to stay safe and efficient. This involves maintenance procedures like hydrotesting, where a section of pipe is pressure-tested with water, and pigging, which uses specialized tools (called "pigs") to clean and inspect the inside of the line.

Both of these jobs require a steady, powerful stream of gas to push the water or pigs through the pipe. When a specific section is taken offline for maintenance, a mobile gas unit can be brought right to the site to supply that pressure. This allows crews to get their work done without having to shut down a huge portion of the pipeline network.

By providing a localized, high-pressure source, mobile natural gas allows utility companies to perform essential maintenance with surgical precision, minimizing downtime and keeping the broader network stable.

This targeted approach means maintenance can be done methodically and safely, preventing the kind of widespread service interruptions that can affect thousands of people.

Fueling Construction Off the Grid

One of the most common jobs for mobile gas is powering remote construction sites. Picture a new housing development, a hospital, or an industrial park being built miles from the nearest utility hookup. The project still needs a reliable energy source for generators, temporary heating in the winter, and other heavy equipment.

While diesel is an option, natural gas is often a cleaner and more budget-friendly choice. Mobile CNG or LNG units can be set up to power large-scale generators for weeks or even months, keeping the project humming along until the permanent gas lines are finally connected.

This is a huge deal in booming industrial areas. The mobile gas station market is growing fast precisely because it can deliver fuel to these remote operations, with some projections showing it could become a $9 billion industry by 2033. Just look at the Permian Basin, where mobile fuel units are indispensable for oil production, helping cut machinery downtime by as much as 40%. You can dive deeper into the growth of mobile fuel delivery systems on datainsightsmarket.com.

An Emergency Lifeline During Outages

Let's face it, accidents happen. A construction crew might accidentally hit a pipeline, or a critical piece of equipment could fail without warning. When that happens, a major gas line can go down, threatening to leave entire communities in the cold and dark.

In these emergency situations, a mobile natural gas provider like Blue Gas Express can be a true first responder. They can quickly set up a "virtual pipeline" that bypasses the damaged section of pipe. By injecting natural gas back into the system just past the point of failure, they can keep the gas flowing to homes and businesses while repair crews work safely.

This ability to respond in a crisis is invaluable for utility companies, helping them prevent massive disruptions and protect public safety.

Commissioning Mission-Critical Facilities

Before a new hospital, data center, or factory can open its doors, its backup power systems have to be proven reliable. This process is called generator load bank testing, and it's a non-negotiable step to ensure the backup generators can actually handle the building's full electrical load during a power outage.

Many times, this testing needs to happen before the permanent natural gas line is even active. A mobile gas service can deliver the high volume of fuel required to run these massive generators at full throttle for hours on end. This confirms that the facility's emergency systems are 100% reliable from day one. When deciding if mobile gas is the right fit, it's useful to look at the bigger picture of the strategic considerations of mobile versus stationary energy solutions across different sectors.

The Mobile Gas Project Journey From Start to Finish

So, how does a temporary natural gas solution actually get from a phone call to a fully operational site? It might seem complicated, but it's a well-defined and methodical process. A professional provider handles every step, turning what could be an energy headache into a controlled, predictable operation.

Think of it as a partnership. It starts with your unique energy problem and ends with your project running smoothly on a dependable, temporary fuel source. Let's walk through the five key phases of a typical mobile gas project.

Phase 1: Project Discovery and Engineering

Everything kicks off with a deep dive into what you actually need. This isn't about grabbing a one-size-fits-all solution off a shelf; it’s a completely custom-engineered plan. In this first stage, engineers work directly with you to get the full picture.

They'll need to know things like:

- How much natural gas will you need each day?

- What delivery pressure does your equipment require?

- How long do you expect the project to last?

- Are there any tricky site challenges, like tight access roads or specific terrain?

With this information, the engineering team calculates your exact energy demands and designs a site-specific layout. They map out precisely where the trailers, pressure reduction skids, and other gear will go for the safest and most efficient setup. This initial engineering is the foundation for the entire project.

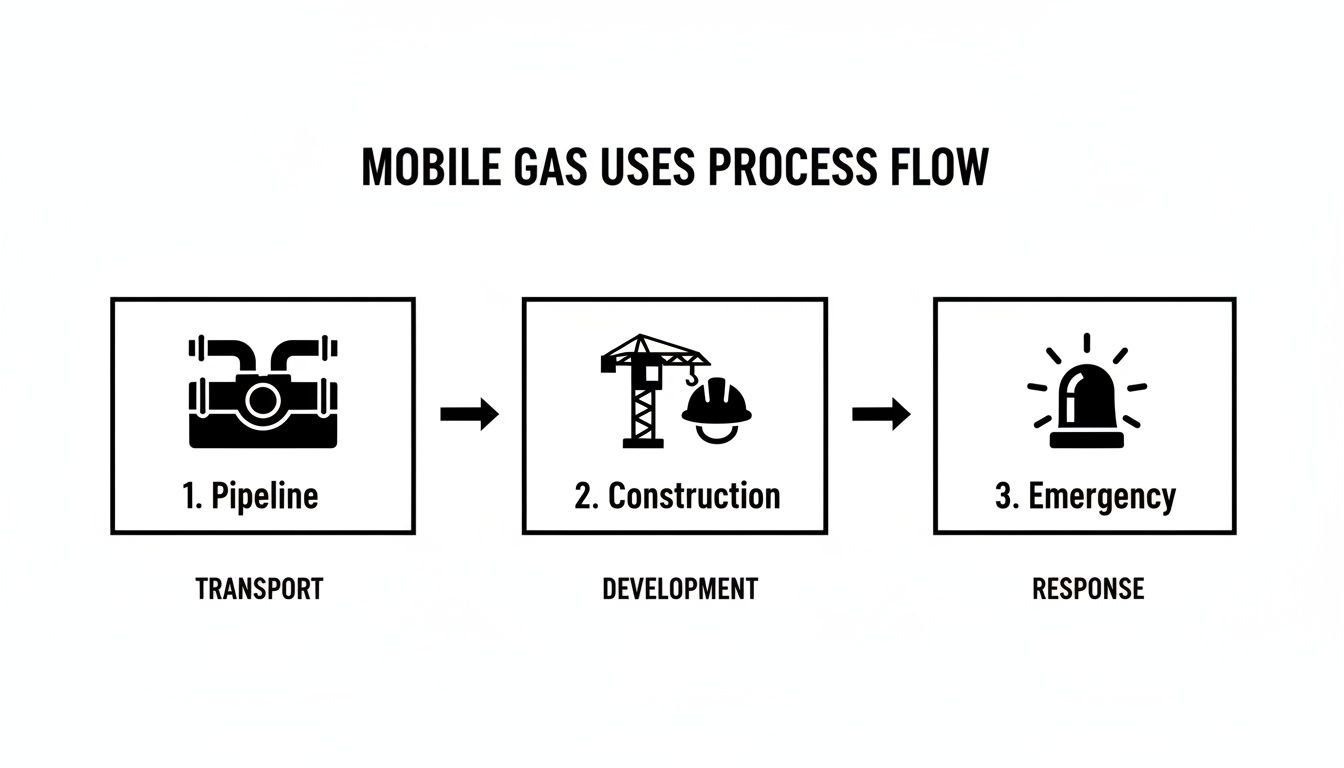

This diagram shows just how versatile mobile gas can be—from keeping pipelines running during maintenance to fueling new construction and stepping in during emergencies.

It’s a great visual for understanding how one flexible solution can solve a wide range of industrial challenges, making it a critical tool for energy continuity.

Phase 2: Logistics and Permitting

Once the engineering plan is locked in, the focus shifts to getting everything moving and making sure it’s all above board. Hauling tons of specialized equipment to your site takes serious coordination. A dedicated logistics team handles all the transportation, making sure the CNG or LNG trailers and support hardware show up right on schedule.

At the same time, another team is navigating the maze of permits. This can mean working with local authorities, fire marshals, and utility companies. An experienced provider like Blue Gas Express takes all this paperwork off your plate, securing every necessary approval. This whole phase is about clearing the way for a smooth, legal on-site setup.

Phase 3: On-Site Mobilization

This is where the plan comes to life. The mobilization phase kicks off the moment the trucks roll onto your prepared site. Technicians get to work right away, carefully placing each piece of equipment exactly as shown in the engineering diagrams.

With everything in position, the team connects the entire system—hoses, regulators, safety monitors, the works. They then run a series of rigorous checks, including leak and pressure tests, to confirm the integrity of the setup. Not a single cubic foot of gas flows until every connection is proven to be 100% secure and ready to go.

Phase 4: Operations and Monitoring

The system is commissioned, and the gas starts flowing. Your project now has the steady, reliable supply of natural gas it needs to keep moving forward without a hitch. But the provider's job isn't done yet—not by a long shot.

The operational phase is all about proactive management. It’s not just about supplying gas; it’s about ensuring an uninterrupted flow through constant monitoring and perfectly timed logistics.

Technicians often use remote systems to keep a close eye on gas consumption and system performance in real-time. Long before a gas trailer runs low, a new, full one is already on its way to the site for a seamless swap. This guarantees you never have a break in your fuel supply.

Phase 5: Demobilization

When your project wraps up or the permanent gas line is finally connected, the last phase begins. The demobilization is handled with the same care and precision as the initial setup.

The team safely purges and disconnects all the equipment. Then, they systematically remove every single component from your property, from the massive trailers down to the last hose. The goal is to return your site to its original condition, leaving nothing behind but the memory of a successful project.

Prioritizing Safety and Regulatory Standards

When you’re dealing with natural gas, safety isn't just another box to check—it’s the bedrock of the entire operation. Any professional gas company mobile service worth its salt operates under a heavy blanket of safety protocols and government regulations. These rules are there for a reason: to protect people, property, and the environment at every single stage.

This isn't something you can be casual about. From the moment a specialized CNG or LNG trailer is filled at the terminal to the final disconnection at your job site, every move is deliberate and guided by strict standards. It's a culture built on caution, ensuring a temporary gas solution is every bit as safe as a permanent utility line.

Key Regulatory Oversight

Mobile gas operations don't happen in a vacuum; they fall under the jurisdiction of several key regulatory bodies. In the U.S., the big one is the Department of Transportation (DOT), which lays down the law for the design, maintenance, and handling of the high-pressure tube trailers and cryogenic tankers used for transport.

These aren't light suggestions. The regulations cover everything from the specific metals used in the tanks to mandatory pressure testing schedules. Once on-site, operations also have to align with local fire codes and national standards set by groups like the National Fire Protection Association (NFPA). While country-specific, looking at comprehensive frameworks like the Australian workplace safety standards gives a good sense of the thorough, multi-layered approach required everywhere.

This web of regulations ensures every piece of equipment and every procedure has been thoroughly vetted for safety.

A reputable mobile gas provider doesn't just aim to meet these standards; they build their entire operational philosophy around them. Safety isn't an obstacle to overcome—it's the core of the service.

Built-In Equipment Safeguards

Today's mobile gas equipment is engineered with safety hardwired into its DNA. We're talking about multiple, redundant systems that are designed to prevent an incident from ever happening, and to contain it immediately if it does.

Think of it as layers of protection. Key technologies include:

- Emergency Shutdown (ESD) Systems: These are the big red buttons. They allow technicians to instantly kill the flow of gas if any problem is detected.

- Advanced Methane Detectors: Small sensors are placed strategically around the equipment to constantly sniff the air. If they detect even a trace of a gas leak, they trigger loud alarms and flashing lights.

- Pressure Relief Valves: A crucial failsafe. If system pressure ever creeps above its designed limit, these valves automatically and safely vent the excess gas to prevent over-pressurization.

These systems all work together, creating a secure environment that is constantly self-monitoring.

The Human Element of Safety

All the best regulations and hardware in the world don't mean much without sharp people on the ground. The most critical safety component is the team managing your mobile gas supply. Every technician undergoes extensive, ongoing training and holds certifications for handling high-pressure gas, hazardous materials (HazMat), and emergency response.

Before a single valve is turned, the team conducts a detailed site-specific hazard assessment and a pre-job safety briefing. This huddle makes sure everyone on location—including your own crew—is on the same page about the plan and safety protocols. It’s this human-led, detail-oriented approach that turns a complex energy delivery into a controlled and predictable process. This focus on getting it right is driving the whole sector forward, with the market for mobile gas compressors seeing an average year-over-year growth of 4-6% globally.

How to Choose the Right Mobile Gas Partner

Picking the right mobile gas provider is probably the most critical decision you'll make for your project's energy needs. Get it right, and you’ll have a partner who feels like an extension of your own team, making sure everything runs smoothly behind the scenes. Get it wrong, and you could be looking at expensive delays, serious safety risks, and logistical headaches you never saw coming.

This isn't just about finding someone who can drop off a trailer of gas. It's about securing a specialist. Think of it this way: you wouldn't ask a general family doctor to perform a complex heart surgery. For a high-stakes project, you need a proven expert who has successfully handled situations just like yours, time and time again.

Evaluate Their Experience and Expertise

First things first, dig into their track record. A slick website is nice, but it means nothing without a portfolio of real-world projects that look a lot like yours. A seasoned gas company mobile provider won't hesitate to share case studies or connect you with past clients.

Don't be shy about asking tough questions to see how deep their knowledge really goes:

- Can you show me projects you've managed with similar gas volume and pressure demands?

- Do you have direct experience in our industry, whether it's data center commissioning or pipeline integrity testing?

- How do you handle difficult site conditions, like remote locations or extreme weather?

Their answers will tell you everything you need to know about whether they can anticipate problems or if they'll just be reacting to them.

Assess Their Equipment Fleet and Technology

Let's be clear: not all equipment is created equal. A provider’s fleet is a direct window into their commitment to safety, reliability, and efficiency. You want to see a company that invests in modern, well-maintained gear.

Ask to review maintenance logs and find out the age of their trailers, pressure reduction units, and vaporizers. Older, neglected equipment is a huge red flag—it dramatically increases the risk of a mechanical failure that could bring your entire operation to a grinding halt. You should also ask about their tech, like remote monitoring systems that can track gas consumption in real-time to make sure trailer swaps happen exactly when they need to.

Choosing a partner is an investment in certainty. A company with a robust, modern fleet and deep engineering talent isn't an expense—it's insurance against the immense costs of project downtime.

Verify Their Engineering and Customization Capabilities

Your project has its own unique set of challenges, so your mobile gas solution shouldn't be off-the-shelf. Steer clear of providers pushing a one-size-fits-all package. A top-tier partner will have a strong in-house engineering team ready to design a custom setup for your site's specific needs.

This means they do the heavy lifting upfront—running detailed calculations for flow rates, pressure drops, and consumption forecasts. True experts can engineer solutions for the most complex scenarios, ensuring the system is not only effective but also fine-tuned for safety and efficiency. This ability to build a bespoke solution is what separates a simple supplier from a true energy partner.

Scrutinize Their Safety Record and Culture

When you're working with natural gas, there is absolutely no room for compromise on safety. Don't just take their word for it; ask for their documented safety statistics, like their Total Recordable Incident Rate (TRIR). A low TRIR is a solid indicator of a company that lives and breathes safety, from the leadership team all the way down.

Look for evidence of a proactive safety culture. Are their technicians undergoing constant, rigorous training? Do they conduct thorough, site-specific hazard analyses and hold pre-job safety meetings for every single deployment? A partner who weaves safety into every step of the process is one you can trust to protect your people, your assets, and your reputation.

Demand Responsive 24/7 Support

Problems don't operate on a 9-to-5 schedule, and your mobile gas provider shouldn't either. Before you sign anything, get confirmation that they provide genuine 24/7/365 operational support and have a clear, established protocol for handling emergencies.

You can even test their responsiveness while you're still vetting them. When you call or email, how long does it take to get a thoughtful response from someone who knows what they're talking about? That first interaction is often a sneak peek of the service you’ll get when a critical issue pops up at 2 a.m. on a holiday weekend. You need a partner who is ready to act at a moment's notice to keep your project moving forward.

Before making your final decision, a side-by-side comparison can bring a lot of clarity. This checklist is designed to help you organize your findings and evaluate potential partners on the criteria that matter most.

Mobile Gas Provider Evaluation Checklist

Use this framework to compare potential mobile gas companies and select the best fit for your project's specific needs.

| Evaluation Criterion | What to Look For | Why It Matters |

|---|---|---|

| Industry Experience | Case studies, references, and demonstrated success in your specific industry (e.g., data centers, utilities). | A partner with relevant experience understands your unique operational challenges and regulatory hurdles. |

| Equipment & Technology | Modern, well-maintained fleet (trailers, skids, vaporizers), remote monitoring capabilities, and maintenance records. | High-quality equipment minimizes the risk of failure and downtime. Technology ensures efficient fuel management. |

| Engineering Expertise | In-house engineering team, custom solution design, detailed flow/pressure calculations, and problem-solving skills. | A "one-size-fits-all" approach rarely works. Custom engineering ensures the solution is safe, efficient, and perfectly suited to your site. |

| Safety Record | Low Total Recordable Incident Rate (TRIR), documented safety programs, continuous technician training, and site-specific safety plans. | A strong safety culture is non-negotiable. It protects your personnel, your assets, and your project's reputation. |

| 24/7/365 Support | A clear emergency response plan, dedicated points of contact, and tested responsiveness. | Energy needs don't stop after business hours. You need a partner who is always available to handle any issue, anytime. |

| Contract & Pricing | Transparent pricing structure, flexible contract terms, and a clear scope of work with no hidden fees. | Clarity on costs and terms prevents budget overruns and ensures the partnership is built on trust and transparency. |

By systematically vetting each potential provider against these points, you can move beyond the sales pitch and identify a company that has the proven expertise, resources, and commitment to become a reliable long-term partner for your project.

Seeing Mobile Gas Solutions in Action

It's one thing to talk about how mobile gas works in theory, but it’s another thing entirely to see it solve a massive, high-stakes problem in the real world. These aren't just hypotheticals; they're stories of how a flexible energy partner can turn a potential disaster into a scheduled success.

Let's look at two completely different situations where having a mobile natural gas solution made all the difference.

Powering a Data Center Against the Clock

Imagine this: a brand-new, multi-million dollar data center is ready to go live, but the permanent natural gas pipeline is delayed by three months. This isn't just an inconvenience—it's a critical failure point. Without gas, they can't perform the essential load bank testing on their dozens of backup generators. No testing, no certification.

Every single day of delay was costing them hundreds of thousands in lost revenue. The challenge was huge. They needed to supply a massive volume of natural gas, basically a small utility's worth, for an extended period to get their entire generator fleet commissioned.

The answer was a carefully planned mobile LNG (Liquefied Natural Gas) deployment. Because LNG is so much more energy-dense than compressed gas, it meant fewer trailers were needed to handle the data center's enormous fuel appetite. A specialized team from Blue Gas Express engineered a system using dual vaporizers, which guaranteed a steady, high-volume flow of gas capable of running multiple 4-megawatt generators all at once.

This wasn’t just a fuel delivery; it was a mission-critical utility service. The mobile setup allowed the data center to finish its commissioning on schedule, go live, and start bringing in revenue, completely bypassing the pipeline delay.

For weeks, the mobile system ran without a hitch. A 24/7 operations team managed seamless trailer swaps, ensuring the fuel supply never dipped. The data center hit its certification deadlines, dodged costly penalties, and onboarded its first clients right on time. The mobile gas solution bridged that three-month gap, turning a potential financial crisis into a smooth launch.

Averting an Industrial Shutdown

Now for a different kind of emergency. An industrial manufacturing plant, located in a remote area, got word that its only natural gas pipeline would be shut down for 72 hours for critical maintenance. For them, a three-day shutdown was unimaginable—it meant a huge hit to production and revenue. They needed a temporary gas supply to keep their boilers and process heaters fired up without a single interruption.

This time, the provider designed a mobile CNG solution specifically for this "pipeline bypass." The plan involved setting up a pressure reduction station that would inject natural gas directly into the plant’s system, just past the maintenance shut-off valve. Multiple high-pressure CNG trailers were brought to the site, lined up, and connected to create a continuous, reliable flow.

Before the pipeline was ever touched, the mobile system was connected, tested, and running in parallel with the main line. The transition was so smooth that when the utility company closed the main valve, no one inside the plant even noticed. The mobile gas partner kept the facility fully operational for the entire maintenance window, preventing a costly and disruptive shutdown.

Common Questions About Mobile Gas Services

Even after seeing how it all works, you probably have a few practical questions kicking around. Let's tackle some of the most common ones we hear from clients trying to figure out if a mobile gas solution is the right move for their project.

What Is the Difference Between Mobile CNG and LNG?

The biggest difference boils down to how the gas is stored, which affects its energy density. CNG (Compressed Natural Gas) is exactly what it sounds like—gas crammed into a tube under very high pressure. LNG (Liquefied Natural Gas), on the other hand, is chilled to an incredibly cold liquid.

Here's a simple way to think about it: CNG is like stuffing clothes into a suitcase. You can get a lot in there, but it takes up a good bit of room. LNG is like using vacuum-sealed bags; you can pack a whole lot more into the same space.

Because of this, LNG is almost always the choice for big, power-hungry jobs that run for a while, like commissioning a new data center. A single LNG trailer holds way more energy than a CNG trailer, which means fewer interruptions for trailer swaps. CNG is often a perfect fit for shorter jobs with lower gas demands.

How Long Does It Take to Set Up a Mobile Solution?

Timelines can vary quite a bit depending on how complex your project is. If you're in a real bind, we can sometimes get a simple setup mobilized and on-site in under 48 hours.

For a more standard project that involves some engineering and permitting, you're typically looking at 2 to 4 weeks from the moment we sign an agreement to the first gas delivery. For more involved industrial jobs, the planning phase might stretch to 4 to 8 weeks to make sure every single detail is buttoned up and all safety protocols are meticulously handled.

How Is the Service Priced?

Pricing for a mobile gas service is always custom-quoted. There's no one-size-fits-all rate because no two jobs are exactly alike.

Your final cost will hinge on a few key things:

- Total Gas Volume: Simply, how much natural gas you'll need.

- Service Duration: The total time you'll need us on-site.

- Site Location: How far your site is from our gas sourcing terminal.

- Equipment Needs: The specific gear required to hit your pressure and flow rate targets.

Any good provider will give you a transparent, itemized proposal that breaks everything down. You should see clear costs for mobilization, equipment rental, and the gas itself—no surprises.

Ready to keep your project on schedule with a reliable, temporary natural gas supply? The experts at Blue Gas Express can design a custom mobile solution to meet your exact needs. Contact us today for a project consultation.