Energy supply chain management is the intricate system that moves energy from where it’s found to where it's needed. It’s the entire journey, from pulling raw materials out of the ground to getting refined fuels and electricity into our homes and businesses.

Think of it as the world’s circulatory system for power. It’s a non-stop, high-stakes operation that has to be reliable, stable, and incredibly resilient to keep the lights on globally.

Understanding the Energy Supply Chain

At its heart, the energy supply chain is a massive, interconnected network. It’s what keeps modern life moving. But managing the flow of energy isn't like managing a typical supply chain for, say, t-shirts or electronics. The product itself is often volatile, the infrastructure is enormous and expensive, and the market is in constant flux.

The path from a remote drilling site to the outlet in your wall is a logistical and engineering masterpiece. To really get a handle on it, it helps to break the journey down into its three main stages. Each part has its own unique activities, challenges, and players.

The Three Core Stages

It all starts with the Upstream stage. This is where companies find and extract raw energy resources—the exploration and production phase. We're talking about everything from conducting geological surveys to pinpointing reserves, drilling wells for oil and natural gas, mining for coal, or setting up massive solar and wind farms. The companies here are the explorers and producers, often taking on huge financial risks to tap into new energy sources.

Next up is the Midstream stage. This part of the chain is the critical bridge connecting the raw materials to the processors. It’s all about transportation and storage, acting as the logistical backbone of the entire system. This includes vast pipeline networks that crisscross countries, fleets of tanker ships and rail cars, and giant storage facilities like underground salt caverns that hold natural gas reserves. Midstream operators are focused on getting a steady, safe flow of resources from the production fields to the processing plants.

Finally, we have the Downstream stage, which is all about getting the finished energy product to the end-user. This is where crude oil is refined into gasoline, natural gas is processed for utility companies, and electricity is generated and sent out. The raw resource becomes the product you actually use. This final leg includes local utility grids, gas stations, and even the delivery services that bring propane to rural homes.

The strength of this entire system is everything. We’ve seen in recent years just how fragile it can be. Disruptions have cost companies an average of 8% of their annual revenues. The good news is that the industry is adapting. Global supply chain losses have recently dropped by 88% to about $184 billion, which shows a huge improvement in managing risk. You can learn more about how supply chains are bouncing back at ProcurementTactics.com.

To wrap it all up, here’s a quick breakdown of how these three stages fit together.

Key Stages of the Energy Supply Chain

| Stage | Primary Activities | Examples of Energy Sources |

|---|---|---|

| Upstream | Exploration, drilling, extraction, and production of raw materials. | Crude oil, natural gas, coal, solar, wind, geothermal. |

| Midstream | Transportation, storage, and initial processing of raw energy. | Pipelines, tanker ships, rail transport, LNG terminals. |

| Downstream | Refining, processing, marketing, and distribution to consumers. | Gasoline, diesel, jet fuel, electricity, natural gas utilities. |

Each stage is a world unto itself, but they are all completely dependent on one another. A bottleneck or failure in one area can send shockwaves across the entire system.

The Workflow from Wellhead to Wall Socket

The journey of energy is an incredible logistical puzzle. It’s about moving raw power across continents and transforming it into the electricity that lights our homes and the fuel that runs our industries. To really get a handle on energy supply chain management, you have to follow that path from its source to the final user.

Let's trace the journey of natural gas. It starts deep underground, trapped in rock, and ends at a wall socket or a gas stove. It's a complex, multi-stage process that requires massive scale, incredible technology, and pinpoint coordination.

From Extraction to Processing

First things first, you have to get the resource out of the ground. For natural gas, this often means hydraulic fracturing, or “fracking.” A high-pressure blend of water, sand, and chemicals is shot into rock formations to release the trapped gas. This isn't just guesswork; engineers use sophisticated tools like seismic imaging to find the best spots, which saves time and boosts how much they can recover.

But the gas that comes out of the ground is far from pure. It’s a mix of methane (what we want), other hydrocarbons like propane, and a bunch of impurities. So, the next stop is a processing plant. Here, the raw gas gets cleaned up and separated. The methane is isolated and gets prepped for the next leg of its journey.

The Midstream Transportation Network

Once purified, the gas has to travel—often for thousands of miles. This is where the midstream sector comes in, acting like the circulatory system for the entire energy industry. The most common way to move it is through a massive, interconnected web of pipelines.

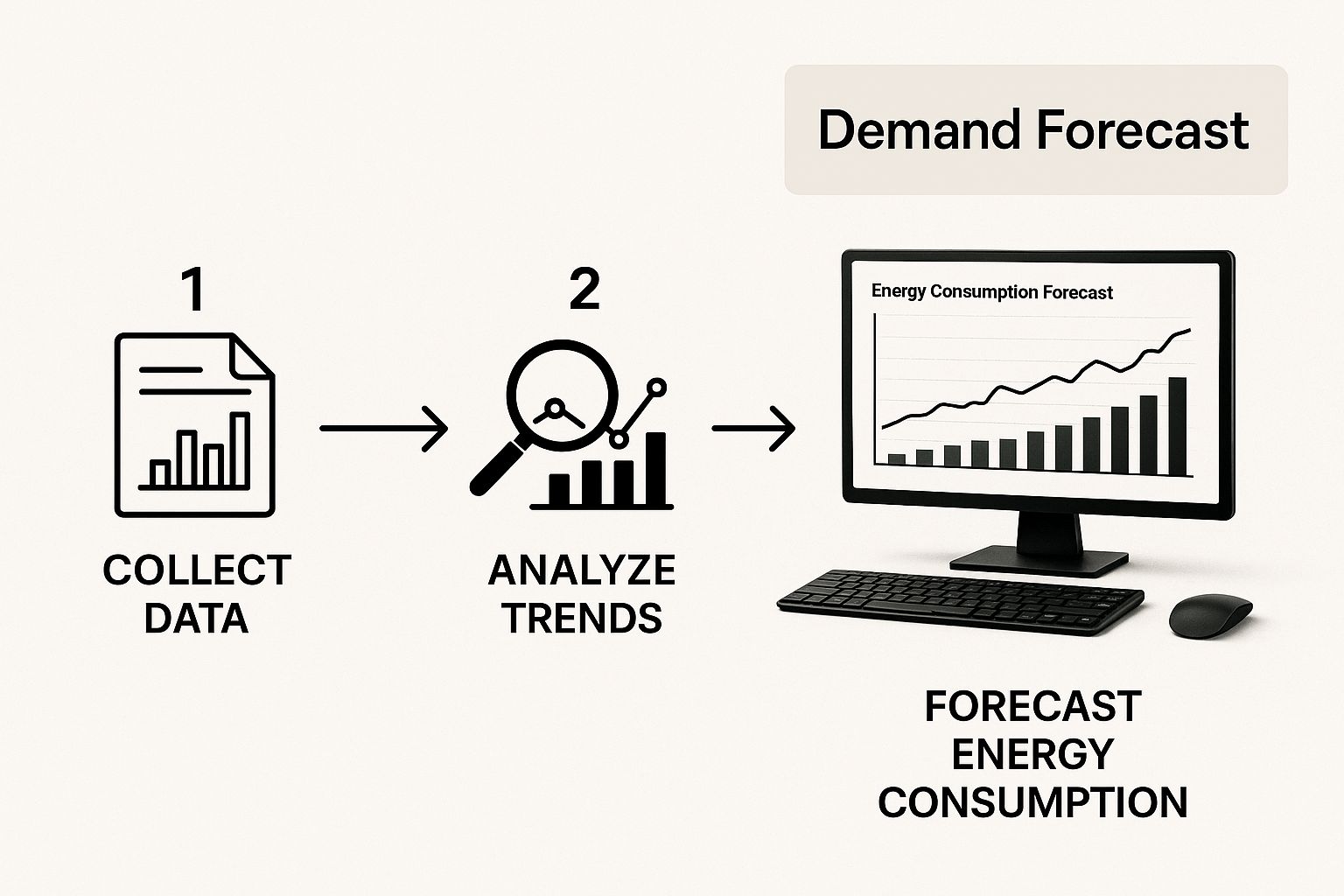

The flow through this network isn't random. It’s managed with incredible precision, using data to forecast demand and keep things moving smoothly.

This kind of data-driven management helps operators anticipate a region's energy needs and adjust the flow to prevent shortages or oversupply.

Pipelines are the arteries of energy supply chain management, but they aren't the only option. To ship natural gas overseas, it’s cooled to a frigid -260°F (-162°C). This turns it into Liquefied Natural Gas (LNG), shrinking its volume by an astonishing 600 times and making it practical to transport on massive, specialized tankers.

Before it reaches its final destination, the gas often makes a pit stop at a storage facility. These aren't just big tanks; they're often huge underground salt caverns or depleted gas fields. Storing gas this way gives companies a buffer, allowing them to balance supply with demand and ensure there’s enough power ready for peak times, like a freezing winter morning.

Final Distribution to End Users

The last leg of the journey is distribution, or the downstream process of getting the energy into the hands of the consumer. After traveling hundreds or thousands of miles, the gas arrives at a "city gate" station. Here, the pressure is lowered, and for safety, an odorant is added—natural gas is naturally odorless, so this gives it that distinct "gas" smell.

From there, a local utility company takes over. They manage a complex web of smaller, lower-pressure pipelines that run under our streets and connect directly to homes, businesses, and power plants.

This entire workflow, from a wellhead deep underground to a wall socket in a building, is a continuous, high-stakes ballet of production, transportation, and delivery. A single failure at any point—a pipeline issue, a storage problem, or a processing plant shutdown—can have immediate and widespread consequences.

The final use of the gas can look a few different ways:

- For Electricity: The gas is sent to a power plant, where it's burned to heat water into steam, which then spins turbines to generate electricity for the grid.

- For Heating: It flows right into a furnace in a home or office building, providing heat and hot water on demand.

- For Industry: Factories use it as both a fuel source for operations and a raw material for making products like plastics and fertilizers.

Every single step in this intricate chain depends on a flawless handoff to the next, which is exactly why effective supply chain management is so critical.

What Happens When the Pipeline Isn't an Option?

Sometimes, a physical pipeline just won’t work. A facility might be miles from the nearest main, an unexpected outage could shut down a primary gas line, or a sudden cold snap might spike demand beyond what the existing grid can handle. In these critical moments, the energy supply chain management model has to get creative. The answer? A "virtual pipeline."

This isn't some futuristic concept; it's a highly practical, logistics-heavy system for delivering Compressed Natural Gas (CNG) and Liquefied Natural Gas (LNG) without any physical pipes. Instead, it uses a coordinated fleet of specialized trucks to create a mobile, flexible energy bridge. Think of it as calling in a rapid-response team for your energy needs.

From Gas to Liquid and Back Again

The virtual pipeline process starts at a production or storage facility that’s tied into a major gas supply. This is where natural gas undergoes a dramatic change to make it road-ready.

- Shrinking the Gas: First, the natural gas is either squeezed into CNG or super-chilled to a mind-boggling -260°F (-162°C), turning it into a liquid (LNG). This is the key step. It dramatically shrinks the gas's volume, making it practical and cost-effective to haul over the road.

- Hitting the Road: Next, the processed gas is loaded into highly specialized containers. For CNG, that means high-pressure tube trailers. For LNG, it’s all about cryogenic tankers—essentially giant thermoses on wheels built to keep the liquid incredibly cold for the entire journey.

- Returning to Gas On-Site: Once a truck arrives at its destination—whether that’s a hospital, a remote construction site, or an industrial plant—the final piece of the puzzle falls into place. A mobile regasification unit gently heats the LNG back into a gaseous state, or a different unit decompresses the CNG. This gas is then fed directly into the customer's on-site system at just the right pressure and flow, seamlessly taking over for the standard pipeline supply.

The entire sequence is a masterclass in coordination. It demands precise timing, real-time monitoring, and a deep understanding of thermodynamics to pull off a safe, continuous delivery.

Real-World Scenario: The Hospital on Standby

Picture this: a regional hospital gets a call that its main natural gas pipeline is shutting down for 48 hours for emergency repairs. This is more than a simple inconvenience; it’s a potential crisis. The hospital depends on that gas for everything from heating and hot water to sterilizing equipment and firing up backup generators. Going offline is simply not an option.

This is exactly where a virtual pipeline provider like Blue Gas Express comes in. Within hours, a team is on the move. A cryogenic LNG tanker pulls up and connects to a mobile regasification unit already set up on the hospital grounds. The unit gets to work, converting the LNG back to gas and feeding it straight into the hospital's internal piping.

For the entire 48-hour maintenance window, the hospital hums along without a single interruption. The lights stay on, critical systems function perfectly, and patient care is never compromised. The virtual pipeline becomes a true lifeline, ensuring complete continuity when permanent infrastructure goes down.

Tackling Unique Logistical Hurdles

Running a virtual pipeline is a whole different ball game compared to standard trucking logistics. Success hinges on mastering several key areas of energy supply chain management.

- Uncompromising Safety: Moving CNG and LNG around is serious business. You’re dealing with materials under extreme pressure or at cryogenic temperatures, which means following incredibly strict safety rules for equipment, driver training, and all on-site procedures. There's no room for error.

- Smarter Route Planning: You can't just plug the destination into a GPS. Every route has to be meticulously planned to navigate road conditions, traffic, low bridges, and local regulations for hauling hazardous materials. The goal is always the fastest and safest path from A to B.

- Perfectly Timed Deliveries: Unlike a pipeline that flows constantly, this model runs on a cycle of deliveries. Dispatchers have to watch the customer's gas consumption in real time. They need to schedule the next truck to arrive well before the current one runs low, preventing a costly—and potentially dangerous—"run-dry" situation.

This mobile, on-demand solution is a powerful example of how flexible and resilient modern energy logistics have become. It’s the ultimate proof that even without a physical connection, vital facilities can get the power they need, right when they need it.

Navigating Critical Disruptions in Energy Logistics

The energy supply chain is a modern marvel, but it’s a fragile one. Unlike industries with predictable rhythms, energy supply chain management happens in a high-stakes world where stability is always under threat. These aren't just minor bumps in the road; they're major events that can derail operations, send costs through the roof, and jeopardize energy security for entire regions.

You can think of the energy supply chain as a complex, finely tuned machine. If one gear breaks—whether it's a political conflict, a hurricane, or a sudden policy change—the whole thing can grind to a halt. The fallout is almost immediate, setting off a chain reaction of logistical and financial problems that requires real expertise and a steady hand to manage.

Geopolitical Instability

Geopolitical tension is one of the biggest disruptors out there. A conflict flaring up in a key shipping channel can redraw maritime maps overnight, forcing LNG tankers on longer, more expensive detours. Suddenly, a dispute in a major transit chokepoint can add thousands of miles and weeks of travel to a single voyage, ballooning fuel costs and delaying critical deliveries.

This kind of conflict breeds massive uncertainty. New sanctions can instantly block access to major oil and gas suppliers, leaving companies scrambling to find new sources and completely rework their supply networks. It’s more than just a logistical nightmare—this volatility hits market prices hard, causing price swings that can make or break a company’s bottom line.

The Unpredictable Force of Nature

Mother Nature is another constant, and growing, threat. A hurricane roaring through the Gulf of Mexico doesn’t just damage an offshore platform; it can shutter coastal refineries that are the lifeblood of a nation's fuel supply. In the same way, a long drought can drop river levels so low that barges carrying coal or petroleum simply can't get through.

These events can paralyze essential infrastructure, often with very little warning. The impact is immediate and severe:

- Production Halts: Damaged facilities can take weeks, or even months, to get back online, creating significant supply gaps.

- Transportation Gridlock: Flooded highways, wrecked rail lines, and closed ports leave energy resources stranded, far from the communities that need them.

- Skyrocketing Costs: Companies are hit with a triple whammy of repair bills, expensive rerouting, and having to source energy from more distant and costly suppliers.

What makes this even trickier is that these disruptions are happening as global energy demand keeps climbing. Total demand has now reached nearly 650 exajoules (EJ), and emerging economies are responsible for over 80% of that growth. With the world hungrier for energy than ever, any interruption packs a much bigger punch. You can dig into the latest data on global consumption from the International Energy Agency.

Regulatory Shifts and Compliance Hurdles

Finally, you have the ever-changing world of regulations. New environmental laws, updated safety standards, or shifting trade agreements can create a maze of compliance rules that require big operational shifts. For example, a new emissions standard might force a company to pour millions into upgrading its entire truck fleet or retrofitting its processing plants.

And simply ignoring these changes isn't an option. The price of non-compliance can be steep: heavy fines, losing your license to operate, and serious damage to your reputation. For anyone in energy supply chain management, staying on top of regulatory changes is just as critical as watching the weather or monitoring global politics. It demands constant vigilance and a proactive game plan to keep the entire operation secure, compliant, and ready for whatever comes next.

Building a Resilient Energy Supply Chain

Dealing with constant disruptions takes more than just good crisis management. It’s about intentionally building an energy supply chain management system that can see trouble coming, take a hit, and adapt on the fly. A resilient supply chain isn’t just about getting through a tough week—it's about creating a real strategic advantage through smart planning and targeted investments.

The old model of just reacting to problems as they pop up is broken. The modern approach is to build in layers of defense to guarantee reliability, even when one piece of the puzzle fails. This means thinking beyond today’s logistics and designing a network that's tough and flexible from its very foundation.

Fortifying the Foundation with Diversification

The first rule of resilience is one we all know: don't put all your eggs in one basket. Relying on a single energy source, one supplier, or a single transportation route creates a massive vulnerability. A political spat overseas or a hurricane at home can sever your supply in an instant, causing chaos for everyone who depends on you.

To get ahead of this, smart energy supply chain management is all about diversification.

- Vary Your Energy Sources: Instead of being 100% dependent on natural gas from one pipeline, a business might bring solar, propane, or other fuels into its energy portfolio. This creates a ready-to-go buffer when the primary fuel source is interrupted.

- Broaden Your Supplier Network: Working with several suppliers in different parts of the country or world protects you from regional risks. If one supplier has an outage, the others can pick up the slack, keeping your operations humming.

- Establish Redundant Infrastructure: This is all about having backup systems and alternate routes. For instance, having a virtual pipeline service from a provider like Blue Gas Express on standby gives you a critical fallback when your main pipelines are down for maintenance or an emergency.

This isn't just about having a Plan B. It's about having a Plan C and D already mapped out and ready to deploy.

The Game-Changing Role of Technology

In today's world, technology is the nervous system of a resilient energy supply chain. It delivers the visibility, data, and automation you need to stop being reactive and start being predictive. Putting money into the right tools gives managers the power to spot problems on the horizon and act before they become full-blown crises.

This shift has been happening fast. In the wake of recent global disruptions, a staggering 82% of supply chain organizations increased their IT spending, pouring money into digital tools and AI. At the same time, 74% of executives ramped up investments in automation and IoT to navigate labor shortages and boost efficiency. You can explore more of these supply chain trends over at ProcurementTactics.com.

By embracing technology, organizations aren't just plugging holes. They are fundamentally rewiring their supply chains to be smarter, more agile, and more secure. This proactive mindset is quickly becoming the new gold standard in the industry.

So, how are specific technologies making a real difference? Let's break it down.

Modern tech gives you the tools to move from reacting to problems to anticipating them. Here’s a look at some of the key players and how they shore up the supply chain.

Technology Solutions for Supply Chain Resilience

| Technology | Primary Application | Key Benefit |

|---|---|---|

| IoT Sensors | Real-time monitoring of pipeline pressure, temperature, and equipment health. | Catches leaks or potential failures early, allowing for preventative maintenance before you're forced into a costly shutdown. |

| AI Analytics | Predictive modeling for demand forecasting and equipment failure analysis. | Optimizes inventory, prevents stockouts, and schedules maintenance proactively, which cuts downtime and operational costs. |

| Blockchain | Creating a secure, transparent, and unchangeable ledger for all transactions. | Boosts traceability and security, giving all parties a trusted, single source of truth for energy trades and movements. |

| Automation | Automating routine tasks in storage facilities, processing plants, and logistics. | Frees up your skilled people to focus on more complex, strategic work by handling repetitive tasks, which also reduces human error. |

By weaving these technologies into the very fabric of energy supply chain management, companies can build a network that’s not only tough enough to handle today’s challenges but also smart enough to get ahead of tomorrow’s. This blend of strategic diversification and technological foresight is the blueprint for a truly resilient energy future.

The Future of Energy Supply Management

The world of energy supply chain management finds itself at a crossroads, caught between two massive, competing forces. On one hand, global energy demand just keeps climbing, pushed higher by economic growth and thirsty new technologies. On the other, the urgent global shift toward cleaner, more sustainable energy is fundamentally changing how the grid works. The future belongs to the managers who can walk this tightrope.

This new reality creates logistical puzzles on a scale we've never seen before. Take renewables, for instance. Integrating intermittent sources like wind and solar isn't as simple as plugging them into the network. Their output ebbs and flows with the weather, which makes for a highly variable supply. This unpredictability means energy storage solutions—everything from huge battery farms to pumped hydro storage—are no longer just a nice-to-have. They’re absolutely critical for keeping the grid stable and reliable.

New Demands on a Modernizing Grid

Adding another layer of complexity is a massive spike in demand from sectors that were barely on the radar a decade ago. The explosion of AI, for example, is driving the construction of data centers that consume as much electricity as small cities. These facilities need a perfectly consistent, high-quality power supply, 24/7, putting incredible strain on local grids and the supply chains that support them.

At the same time, the push for greater energy independence is bringing clean technology manufacturing back home. By 2030, demand from these cleantech plants is expected to add around 11 gigawatts (GW) of new load, all thanks to reshoring efforts. You can dig deeper into the numbers in this renewable energy industry outlook. It’s a bit of an ironic twist—we face new logistical hurdles just to power the very factories that are building our green future.

The energy supply chain is no longer a one-way street from a massive power plant to the consumer. It’s becoming a decentralized, two-way network where a home with solar panels can sell power back to the grid and a factory can run its own microgrid.

The Evolving Role of the Supply Chain Manager

This dynamic environment is completely rewriting the job description for energy supply chain management. The role is shifting away from traditional logistics and becoming all about strategic data analysis and seeing the entire system as a whole. The manager of tomorrow needs to be fluent in a whole new set of skills to keep up.

Here are the abilities that will define the next generation of energy logistics leaders:

- Advanced Data Analytics: Being able to use predictive analytics to see demand coming, figure out the best time to dispatch renewable power, and manage grid stability in real time.

- Renewable Energy Logistics: Truly understanding the unique challenges of sourcing, moving, and integrating wind, solar, and battery storage into the larger energy mix.

- Carbon Accounting and Reporting: Skillfully tracking the carbon footprint across the entire supply chain to meet regulations and hit sustainability targets.

- Decentralized Grid Management: Overseeing a complex web of distributed energy resources, from industrial microgrids all the way down to residential solar panels.

When it comes down to it, the future of energy logistics is about being nimble, data-smart, and always looking ahead. Success will mean building a supply chain that isn’t just efficient, but also resilient and sustainable enough to power the world to come.

Got Questions? We've Got Answers

Even after diving deep into the details, a few questions always seem to pop up. Let's tackle some of the most common ones to help solidify these concepts.

What Really Separates an Energy Supply Chain From a Regular One?

The biggest difference comes down to the product itself and the massive infrastructure needed to move it. You can’t just box up energy and ship it like a new pair of sneakers. We're talking about a volatile commodity that demands highly specialized, incredibly expensive infrastructure like pipelines, processing plants, and massive tankers to get from point A to point B safely.

On top of that, the energy world is swimming in geopolitical risk, wild price swings, and a mountain of safety and environmental regulations. All this complexity makes managing the flow of energy a completely different ballgame than managing the flow of consumer goods.

The core distinction is volatility and scale. An interruption in a retail supply chain might mean your package is a day late. An interruption in the energy supply chain can mean a city-wide blackout. The stakes are simply on another level, demanding serious resilience and foresight.

How Is Technology Like AI Actually Helping an Energy Supply Chain?

Technology, especially AI, is making a huge difference in keeping the energy moving efficiently and reliably. For instance, it's used for predictive maintenance on critical equipment like turbines and pumps, spotting potential problems long before they cause a catastrophic failure. This ounce of prevention saves a ton of money and avoids unplanned, chaotic downtime.

AI is also a game-changer for logistics, finding the most efficient shipping routes for LNG tankers to cut down on fuel and time. It's also getting incredibly good at forecasting energy demand. When you can accurately predict what’s needed and where, you can balance supply much better, slash waste, and react faster when the market throws a curveball. It's about making the whole network smarter.

Why Would Anyone Need Temporary CNG and LNG?

Temporary CNG or LNG supply, often brought in through a "virtual pipeline" of trucks, is a critical problem-solver in a few key situations. Think of it as the ultimate backup plan. It keeps the lights on for homes, hospitals, and businesses during planned pipeline maintenance or, more urgently, during an unexpected outage.

It’s also called upon to meet huge spikes in demand, like during a brutal cold snap when the regular grid just can’t keep up. Finally, it’s the go-to solution for powering industrial sites, remote construction projects, or even entire communities that aren't hooked up to the main gas grid yet. It’s a flexible, mobile energy bridge that fills the gaps.

When a pipeline interruption puts your project on the line, you can’t afford to wait. Blue Gas Express delivers mobile CNG and LNG to keep your operations humming without missing a beat. Don't let an energy gap derail your schedule—secure your temporary energy supply with Blue Gas Express today.