Here’s a scenario I’ve seen play out a hundred times: your new construction project is right on the home stretch, but the permanent gas line connection is stuck in red tape, weeks or even months behind schedule. That single delay can bring everything to a grinding halt, from commissioning the HVAC system to getting that all-important occupancy permit. It's a classic bottleneck that costs serious time and money.

This guide is about the definitive solution: mobile natural gas.

Keeping Your Project Moving When Gas Lines Are Delayed

Utility delays are one of the most common and frustrating realities in construction. When the permanent gas infrastructure isn't ready, project managers are suddenly staring down a domino effect of costly problems. Without a reliable fuel source, essential tasks get pushed back, deadlines are blown, and subcontractor schedules are thrown into chaos.

The real challenge is simply keeping the project moving forward. Think of a mobile natural gas service as a temporary bridge that spans this infrastructure gap. It’s an on-demand energy source, delivered right to your job site, giving your project the fuel it needs to stay on schedule. What could have been a crisis becomes just another logistical step to manage.

The Role of Expert Fabrication

For any mobile gas setup to work reliably, the hardware itself has to be rock-solid. This is where the foundational expertise of companies like CTJ Energy Solutions comes into play. They are master fabricators, engineering the high-quality, rugged equipment that makes dependable mobile gas delivery a reality. Their work ensures the systems are safe, efficient, and built to perform day in and day out under tough field conditions.

Mobile gas isn't just a backup plan; it's a strategic tool for project continuity. By providing immediate access to natural gas, it empowers contractors to meet critical milestones, from testing backup generators to heating a building for interior finishes.

Bridging the Energy Gap

This guide will walk you through everything you need to know about using temporary natural gas to sidestep those frustrating delays. We'll cover the essentials:

- How mobile CNG (Compressed Natural Gas) and LNG (Liquefied Natural Gas) systems actually work.

- Common situations where this service is an absolute project-saver.

- What you can expect during the deployment and on-site setup.

By the end, you'll understand not only how these services operate but also appreciate the expert fabrication from specialists like CTJ Energy Solutions that makes it all possible. This is your playbook for navigating utility holdups and keeping your projects running without missing a beat.

The Unseen Backbone: Who Is CTJ Energy Solutions?

When a mobile gas trailer pulls up to a job site, it's easy to focus on the immediate solution it provides. But the real story—the story of reliability and safety—starts long before, in a workshop, with the hardware itself. That’s where a company like CTJ Energy Solutions comes in.

To be clear, they don’t provide the mobile gas service. Instead, they’re the master fabricators, the expert welders, and the engineers who build the rugged, industrial-grade equipment that makes the whole system work. Think of them as the people who build the engine, not the ones who drive the car.

They specialize in custom fabrication, turning raw steel into the mission-critical infrastructure that oil and gas producers, power plants, and data centers depend on daily. The same uncompromising standards needed for a permanent natural gas facility are forged into the mobile units you see on-site.

From a Garage Workshop to Major Energy Player

The story of CTJ Energy Solutions starts small, back in 2007, with a talented welder in a little Texas garage. The business originally focused on custom welding for restaurants, but a major shift occurred when they started taking on projects for the demanding oil and gas industry.

That move was a game-changer. Today, the company brings in $5.1 million in annual revenue by designing and building essential, ASME-certified equipment. You can dig deeper into their growth and core business on their company profile. This history proves one thing: they know how to engineer hardware that performs safely under extreme pressure.

Their core fabrication work includes:

- Modular Skids: These are like self-contained, pre-built process systems on a frame. They arrive with all the piping, valves, and controls already connected, making on-site installation incredibly fast.

- Pressure Vessels: Simply put, these are heavy-duty, certified tanks built to safely contain gases or liquids at high pressure.

- Gas Production Units (GPUs): These are complex pieces of machinery designed to do one of the most fundamental jobs in the oilfield: separating oil, gas, and water right at the wellhead.

In essence, CTJ Energy Solutions is in the business of building certainty. The integrity of their welds and the precision of their components are what ensure energy systems—both permanent and temporary—run safely and predictably.

Why This Matters for Your Mobile Gas Project

So, what does a stationary equipment builder have to do with your temporary gas needs? Everything.

The mobile gas trailers and vaporization skids deployed by service providers are built on the exact same engineering principles. The valves have to hold, the pipes can't fail, and the pressure controls must be absolutely perfect to guarantee a steady, safe flow of natural gas.

The deep expertise CTJ Energy Solutions has in building permanent, heavy-duty infrastructure is what gives mobile systems their durability. When a temporary CNG or LNG unit shows up, you're not just getting a tank of gas. You're getting a piece of equipment that is the product of years of fabrication know-how, ensuring the "power bank for your building" is every bit as reliable as the utility grid it’s standing in for.

How Mobile Natural Gas Fills the Infrastructure Gap

So, how does this all work on a real job site? The simplest way to picture it is like a massive, industrial-strength power bank for your building’s natural gas system. It's a completely self-contained energy source on wheels, delivered right where you need it, ready to plug in.

This setup brilliantly sidesteps the need to wait for a live underground utility connection, giving you fuel on day one. The magic is in how the natural gas is transported—it's brought in as either Compressed Natural Gas (CNG) or Liquefied Natural Gas (LNG). Both methods pack a huge amount of energy into specialized, high-pressure tanks mounted on a standard trailer.

Once the trailer arrives, certified technicians connect it directly into your building’s existing gas piping. It’s a surprisingly seamless hookup using standard connection points, so you don't need to make any special modifications to your permanent infrastructure. The whole system is engineered to perfectly replicate the pressure and flow you'd get from a utility main.

The On-Demand Energy Workflow

Getting a temporary gas supply up and running is a straightforward process built for speed. Every project is a little different, of course, but the general path from your first call to a steady gas flow is pretty consistent. That efficiency is a game-changer when deadlines are looming.

Here’s a play-by-play of the typical steps:

- Initial Assessment: You reach out to a provider like Blue Gas Express and lay out your project’s energy demands, location, and timeline. Their team will crunch the numbers on your required gas load (measured in BTUs or cubic feet per hour) to spec out the right-sized unit for the job.

- Logistics and Scheduling: Next, the provider schedules the delivery of the CNG or LNG trailer to your site. Safety is always the top priority, so they'll work with you to find a secure, accessible spot for the equipment that meets all local fire codes.

- On-Site Hookup: A certified gas technician shows up with the unit. They’ll run through a full safety check of the area before connecting a flexible, high-pressure hose from the trailer's regulation system to your building’s main gas inlet.

- System Activation and Monitoring: The technician carefully opens the valves, brings the line up to pressure, and coordinates with your own on-site crew (like your HVAC contractor) to safely fire up appliances and make sure everything is running perfectly. Many providers also offer remote monitoring to keep an eye on fuel levels and automatically schedule refills.

The goal here is simple: deliver an uninterrupted, utility-grade supply of natural gas so your project can move forward without a hitch. The technology behind it is sophisticated, but the result for you is just reliable energy, exactly when you need it. This keeps projects on schedule and avoids the punishing costs of sitting idle.

Real-World Scenarios Where Temporary Gas Saves the Day

So, we've talked about what mobile gas is, but where does the rubber really meet the road? Its true value shines in those high-stakes moments when project timelines and budgets are on the line. Think of mobile natural gas less as a simple backup and more as a strategic tool to keep things moving when the pipeline just isn't ready.

Let’s get specific. Here are the common, real-world situations where a temporary gas service, built with dependable hardware from expert fabricators like CTJ Energy Solutions, becomes an absolute game-changer. These are the moments that separate a successful project from a costly one.

Securing Your Certificate of Occupancy

Getting that final Certificate of Occupancy (CO) is one of the biggest hurdles in any construction project. An inspector won't sign off on a building until they can see every essential system—especially the HVAC and hot water heaters—running perfectly. But if the permanent gas line isn't active yet, you're stuck. You can't prove your systems work, and the entire project grinds to a halt.

This is where a mobile CNG or LNG unit saves the day. It connects right into your building’s piping, giving you the fuel to fire up boilers, commission rooftop units, and show inspectors everything is fully operational. This simple step can shave weeks off a project schedule, letting you close out permits and hand the keys over to the owner right on time.

Commissioning Generators and Backup Systems

For places like hospitals, data centers, or advanced manufacturing plants, backup power is non-negotiable. Before a brand-new natural gas generator gets the green light, it has to be put through its paces with rigorous load bank testing. This proves it can handle the facility's full electrical demand during an emergency, but it requires a massive and steady supply of natural gas.

When the permanent utility connection is delayed or just doesn't have enough pressure, a mobile gas solution is often the only way to get the job done. It delivers the exact volume and pressure needed to run these enormous generators at 100% capacity, ensuring they pass their certification without a hitch. It's a critical step that keeps mission-critical projects on track.

Mobile gas effectively de-couples your critical path from the utility's schedule. Instead of waiting for the grid, you bring the grid to you, ensuring milestones like system commissioning and final inspections are met on your timeline, not someone else's.

Responding to Unexpected Outages

Whether it’s a planned utility curtailment or a surprise pipeline issue, an outage can shut down operations in an instant. For an industrial facility, a sudden loss of natural gas means stopping production lines and losing serious revenue. In the dead of winter, it can even become a safety issue if the building's heat goes out.

In these emergencies, a rapid-response mobile gas provider is a lifeline. A team can be on-site within hours, connecting a temporary unit to keep boilers firing, processes online, and the facility warm. This quick action turns a potential crisis into a manageable problem, minimizing downtime and financial loss. That kind of reliability is built on the quality fabrication work of companies like CTJ Energy Solutions, ensuring the equipment is ready to perform when you need it most.

Let's break down how these solutions map directly to common project challenges.

Mobile Gas Solutions for Common Project Milestones

This table shows how temporary mobile gas services provide a direct solution to some of the most common and costly project delays.

| Project Challenge | Affected Milestone | Mobile Gas Solution |

|---|---|---|

| Delayed Utility Connection | Certificate of Occupancy (CO) Inspection | Provides on-demand gas to demonstrate full functionality of HVAC and hot water systems, satisfying inspectors. |

| Insufficient Pipeline Pressure | Backup Generator Commissioning | Delivers high-pressure gas for load bank testing, ensuring the generator meets certification requirements. |

| Unplanned Gas Outage | Continuous Plant Operation | Acts as an emergency fuel source to keep production lines running and prevent costly shutdowns. |

| Pipeline Maintenance Event | Building Heat & Process Integrity | Supplies temporary fuel to maintain essential services like heating and critical manufacturing processes. |

As you can see, the right mobile solution directly addresses the bottleneck, allowing you to bypass the delay and keep your project moving forward.

What to Expect from a Mobile Gas Deployment

Knowing what happens during a mobile natural gas deployment helps take the guesswork out of the equation, giving you total confidence in the solution. From the moment you make the call to the final connection, the entire process is built for speed, safety, and keeping your project on track. Think of it as a well-rehearsed operation run by certified pros.

The whole thing kicks off with a detailed site assessment. A technician will work directly with you to nail down your project's specific energy needs, calculating the exact gas volume and pressure required. At the same time, they'll sort out the site logistics, pinpointing the safest and most efficient spot to park the mobile unit.

This upfront planning is what makes the rest of the job go so smoothly. When you're getting ready for a mobile gas deployment, having the right essential pipeline accessories is absolutely critical for both safety and performance.

Transportation and On-Site Positioning

With the plan in place, a specialized CNG or LNG trailer heads to your location. These aren't just any trucks; they're transported under strict safety protocols to ensure they arrive ready to go. Once on-site, the technician carefully maneuvers the trailer into the designated spot and secures it for the job.

Before a single hose is connected, safety perimeters are set up, and the entire area is double-checked to make sure it meets all local and federal regulations. This methodical approach is the bedrock of a safe, reliable temporary gas supply.

A professional mobile gas deployment turns a potential crisis into a manageable task. The goal is to have you up and running within hours, not days, transforming an energy gap into a seamless part of your project's workflow.

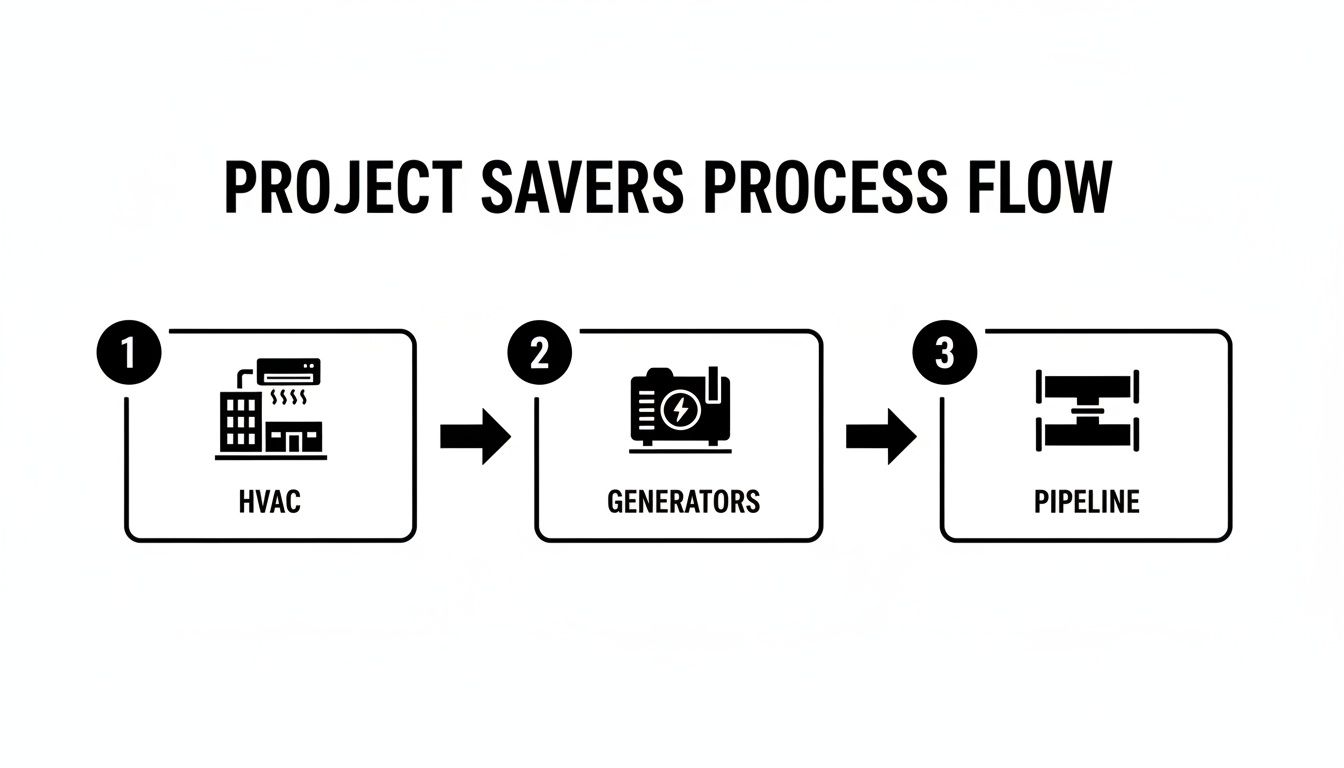

The infographic below shows how these mobile solutions can support different phases of a project, from firing up HVAC systems to testing pipelines.

As you can see, a single mobile unit can be the key to hitting one project milestone after another without interruption.

Connection and Gas Flow Initiation

The final step is making the connection. A certified gas technician will use high-pressure, flexible hosing to link the mobile unit’s regulator system directly to your building’s gas piping. Every fitting and connection is meticulously leak-tested before any gas starts to flow.

From there, the technician carefully brings the line up to pressure and works hand-in-hand with your crew to get your systems online. This whole process is incredibly fast, thanks in large part to the quality of the components. For utilities and construction firms, the rapid fabrication work done by specialists like CTJ Energy Solutions can shorten project timelines by as much as 40%, preventing the revenue loss that comes with delays. It's the same kind of efficiency you see in mobile services for generator commissioning and freeze protection.

Choosing the Right Temporary Energy Partner

Picking a mobile gas provider isn't just about finding a company with a trailer full of fuel. When you're dealing with temporary natural gas, your choice of partner can make or break your project's timeline, budget, and safety record.

Think of it like hiring any other critical subcontractor for your job site. You wouldn't hire an electrician without seeing their license or a crane operator without checking their certs. The same diligence applies here. Rushing the decision can lead to costly delays, serious compliance headaches, or worse, a dangerous situation on-site.

What to Look for in a Provider

So, how do you separate the pros from the rest? You need to dig deeper than a sales pitch and evaluate their actual operational capabilities. Asking every potential partner the same tough questions is the only way to make a true apples-to-apples comparison.

Here’s what you should be asking:

Speed and Reach: When the clock is ticking, how fast can you get here? What's your guaranteed service area? A partner who can get a truck rolling in hours, not days, is essential for handling unexpected outages.

The Right Tool for the Job: Do you have the right size equipment for my specific energy needs? A one-size-fits-all approach doesn't work. You need a partner with a flexible fleet of both CNG and LNG units to match your load precisely. Always ask about the condition of their gear—well-maintained equipment is a non-negotiable sign of professionalism.

Real-World Expertise: Are your technicians certified to work with high-pressure gas systems? Tell me about their training. You need people on your site who know exactly how to handle connections, regulation, and troubleshooting under pressure.

Safety and Compliance Record: Let's talk about safety. Can you provide your documented safety history? How do you ensure compliance with local fire codes and federal transportation rules? A reputable provider will have these answers ready.

Choosing a temporary energy partner is really an investment in project continuity. The right company doesn't just deliver gas; they deliver peace of mind, backed by a proven track record of safety, reliability, and technical skill.

Using this framework helps you move beyond a simple price quote. It gives you a structured way to ensure the provider you choose—whose systems may be built with hardware from expert fabricators like CTJ Energy Solutions—is a true partner dedicated to your project's success.

Got Questions About Mobile Gas? We've Got Answers.

When you're dealing with temporary power, you're bound to have some questions. It's a specialized field. Let's tackle some of the most common ones we hear about mobile natural gas and the folks who build the rigs.

So, What Exactly Does CTJ Energy Solutions Do?

Think of CTJ Energy Solutions as the master builders behind the scenes. They specialize in fabricating the heavy-duty, ASME-certified hardware that the entire energy industry relies on.

They're the experts who construct the pressure vessels, modular pipe skids, and gas production units. In short, they build the rock-solid systems that mobile gas providers like us depend on to deliver energy to your site safely and reliably.

How Long Will a Mobile Gas Trailer Actually Last on My Job Site?

That really comes down to two things: your site’s specific gas consumption and the capacity of the trailer we bring out.

But here’s the key—you don’t have to worry about running out. Good providers monitor the fuel levels remotely, 24/7. Long before a trailer gets low, we schedule a seamless "swap-out" with a full one, ensuring you have a completely uninterrupted supply for as long as you need it, whether that’s a few days, several weeks, or even months.

The whole point is to make it feel just like a permanent utility connection. We handle all the logistics behind the scenes so that from your perspective, the gas just works.

When Does It Make Sense to Use CNG vs. LNG?

The big difference between Compressed Natural Gas (CNG) and Liquefied Natural Gas (LNG) boils down to energy density. Think of it like a small fuel tank versus a massive one—each has its place.

CNG (Compressed Natural Gas): This is the go-to choice for most commercial construction projects, generator commissioning, and any short-to-medium-term energy need. It's incredibly flexible and perfect for typical job site demands.

LNG (Liquefied Natural Gas): Because it’s so much denser, LNG is really built for massive industrial projects—think huge manufacturing plants or utility-scale needs that require a high, continuous flow of energy over a much longer period.

What Are the Big Safety Requirements for Having a Unit On-Site?

Safety is non-negotiable, and it’s the first thing we think about. The on-site setup always involves a few critical steps.

We establish a secure, clearly marked safety zone around the entire unit, ensure everything is properly grounded electrically, and only allow certified technicians to handle any connections or disconnections. The entire installation is designed to meet or exceed all local fire codes and federal regulations, which is a core part of the service any professional provider will manage for you.

Need a temporary gas solution to get that Certificate of Occupancy or keep your project moving? The team at Blue Gas Express delivers reliable, rapid-response mobile CNG and LNG services to bridge any utility gap. Check out our on-demand energy solutions to see how we can help.