A compressed natural gas (CNG) filling station is essentially a gas station for vehicles that run on natural gas. It takes the same natural gas that might heat your home, pressurizes it, and then pumps it into a vehicle's fuel tank. It’s a simple concept, but it's a game-changer for fleets looking for a cleaner, often cheaper, and domestically sourced fuel.

The Role of a CNG Filling Station in Modern Transportation

Think of a CNG station as the critical link between the vast, unseen network of natural gas pipelines running under our feet and the vehicles driving on our streets. It's not just a pump on a corner; it's a highly engineered facility designed to safely and efficiently make a cleaner fuel source available for everyone.

The station’s main job is to take low-pressure gas from the utility line and give it a serious squeeze. Pipeline natural gas is delivered at pressures far too low to be useful for a vehicle. So, the station uses powerful compressors to crank that pressure way up—often to 3,600 pounds per square inch (psi). This compression packs the gas molecules tightly together, reducing the volume so that enough fuel can be stored onboard to give a vehicle a decent driving range.

Core Functions of a CNG Station

The growing number of CNG stations isn't a coincidence. It's a direct response to the increasing demand for cleaner, more affordable transportation. From city buses to waste management trucks, municipalities and private companies are switching their fleets to CNG to take advantage of major cost savings and environmental perks. For instance, some county fleets have reported paying nearly 40% less for CNG compared to gasoline.

A CNG filling station makes this entire transition possible by handling a few key tasks:

- Receiving and Metering: It safely taps into a local utility pipeline to draw natural gas and accurately measures the amount it receives.

- Compression: This is the heavy lifting. Industrial-grade compressors pressurize the gas, making it dense enough to be a practical vehicle fuel.

- Storage: The highly compressed gas is stored in a series of durable, high-pressure tanks, often arranged in a "cascade system" to ensure fast and complete fills.

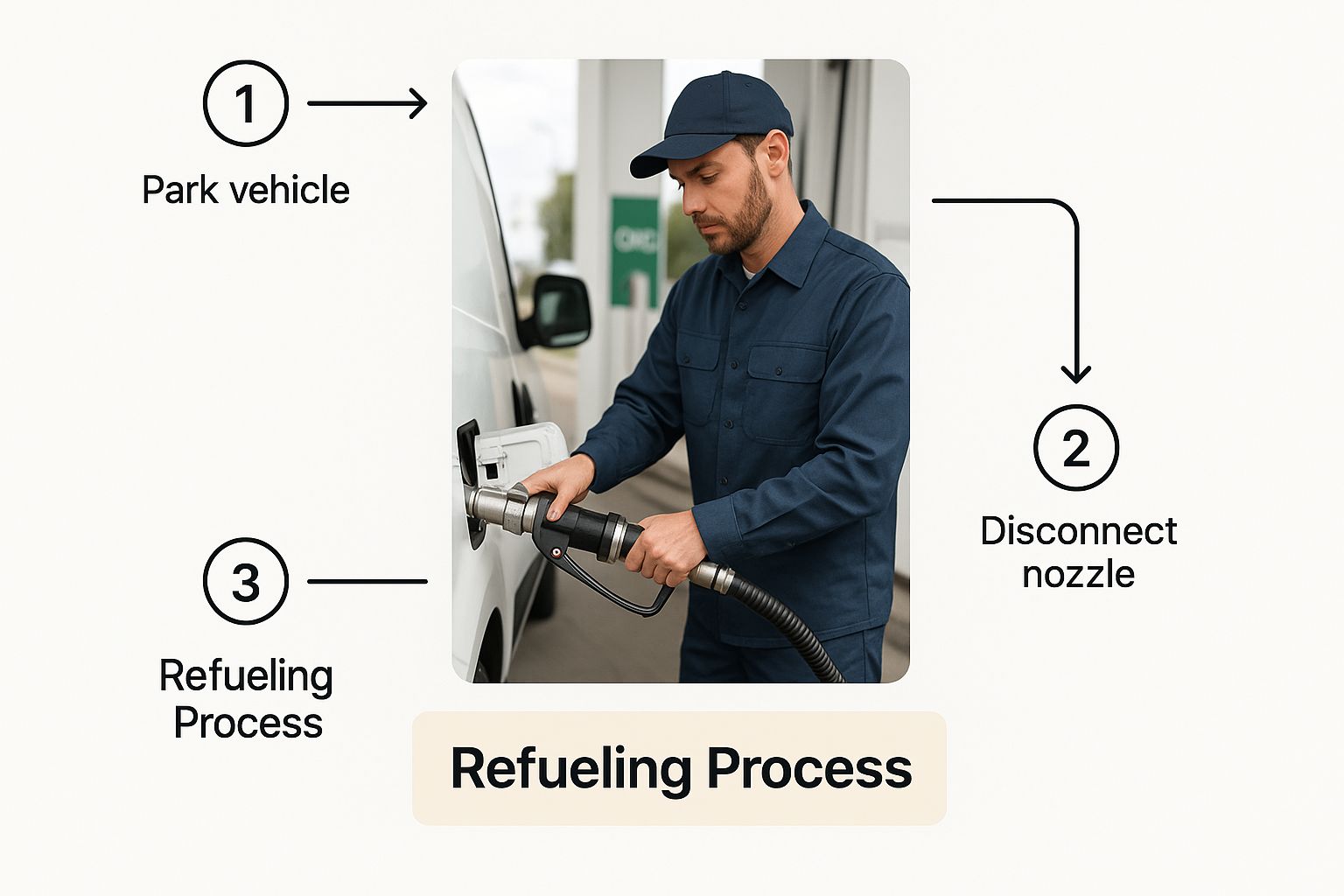

- Dispensing: Finally, the station transfers the CNG into vehicles through a specialized hose and nozzle, much like you'd use at a regular gas pump.

A compressed natural gas filling station is the essential piece of the puzzle that makes CNG a real-world alternative fuel. Without these stations, fleets and drivers would be locked out of the economic and environmental benefits of natural gas.

As emission regulations get tighter and gas prices remain unpredictable, the value of this infrastructure only increases. Every new station that opens is another step toward reducing our dependence on foreign oil and shrinking the carbon footprint of our transportation sector. They aren't just places to refuel; they are gateways to a more sustainable energy future.

How CNG Stations Compress and Dispense Fuel

Ever wonder how natural gas from a simple pipeline gets turned into fuel powerful enough to run a heavy-duty truck? It all happens at a compressed natural gas (CNG) filling station, where the gas undergoes a remarkable transformation.

The process kicks off when natural gas flows into the station from a standard underground pipeline—the same kind that might supply your home. At this point, the gas is at a very low pressure, totally unsuitable for a vehicle. It's the station's job to safely and efficiently crank up that pressure.

This whole operation relies on three key pieces of equipment working in perfect harmony: the compressor, the storage cascade, and the dispenser.

As you can see, what seems like a simple fill-up is actually a sophisticated, high-pressure dance happening behind the scenes.

The Heart of the Station: The Compressor

The compressor is the absolute powerhouse of any CNG station. Think of it as an industrial-strength pump, but instead of air, it's built to handle natural gas. Its sole purpose is to take that low-pressure pipeline gas and pressurize it up to an incredible 4,500 psi.

Why such high pressure? By squeezing the gas molecules that tightly, the compressor packs an enormous amount of energy into a small space. This allows a vehicle to store enough fuel in its onboard tanks to travel a meaningful distance. Without this step, you'd need a ridiculously huge tank.

To do this safely, the compression happens in stages. The gas is forced through a series of cylinders, each one boosting the pressure a little more until it hits the final target. This step-by-step approach keeps the process controlled and efficient.

Storing and Managing High-Pressure Fuel

Once the gas is fully pressurized, it doesn't go straight to a vehicle. Instead, it’s piped into a high-pressure storage system called a cascade. This is a series of large, incredibly durable tanks that act as a ready-to-go reservoir of high-pressure CNG.

The cascade system is cleverly designed to make refueling fast and complete. The storage tanks are split into different pressure "banks"—usually low, medium, and high.

When you start fueling up, the dispenser pulls gas from the lowest pressure bank first. As the pressure in your vehicle's tank starts to match the bank's pressure, the system automatically switches to the medium bank, and then finally to the high-pressure bank to top you off.

This sequential draw is what makes a quick fill-up possible. It ensures a full tank every time without forcing you to wait for the compressor to play catch-up.

Fast-Fill vs. Time-Fill Stations

Not all CNG stations are built the same. They generally fall into two categories—fast-fill and time-fill—and each is designed for a very different job.

A fast-fill station is what most people picture. It uses that big cascade storage system to get you filled up and back on the road in minutes, just like at a regular gas station. This makes them perfect for public retail spots and fleets that can't afford to sit still.

A time-fill station, on the other hand, is a different beast. It often uses a much smaller compressor and skips the large cascade system entirely. Instead, it fills vehicles slowly and directly over several hours, usually overnight. This setup is a great fit for return-to-base fleets, like city buses or garbage trucks, that park in the same spot every night.

As countries around the world push for cleaner air, the market for CNG stations is booming. The fast-fill model, in particular, is seeing major growth as the industry works to make CNG refueling just as convenient as gasoline. You can find more insights about the growing demand for user-friendly CNG stations and the trends driving this expansion.

To make the differences crystal clear, here’s a quick comparison.

Fast-Fill vs Time-Fill CNG Stations

| Feature | Fast-Fill Station | Time-Fill Station |

|---|---|---|

| Refueling Time | 3-5 minutes per vehicle | 6-8 hours for an entire fleet |

| Primary Use Case | Public retail stations, high-traffic fleets | Private, return-to-base fleets (e.g., buses, refuse trucks) |

| Key Components | Large compressor, extensive cascade storage | Smaller compressor, minimal or no storage |

| Cost | Higher initial investment due to storage system | Lower initial investment |

| Benefit | Quick turnaround, serves many vehicles rapidly | Lower operational cost, less wear on compressor |

Ultimately, choosing the right type of station comes down to a fleet's specific needs. Understanding how they operate and what they need to refuel effectively is the first step for any organization looking to make the switch to CNG.

What's In It for Your Fleet? The Big Benefits of CNG

Knowing how a CNG filling station works is one thing. But the real question for any fleet manager is, "Why should I even bother?" The truth is, the reasons to make the switch are powerful and stack up across three key areas: environmental, economic, and operational.

Each of these advantages helps build a more resilient and sustainable business. Let's dig into how changing what you put in the tank can have a massive impact on your bottom line and the world around you.

A Greener Footprint and Cleaner Air

The environmental upside is probably the most well-known benefit of CNG, and for good reason. When you burn natural gas, it’s just plain cleaner than gasoline or diesel, which means far fewer harmful pollutants are being pumped into our air.

Think about this: CNG vehicles slash smog-producing pollutants like nitrogen oxides (NOx) by up to 90% compared to diesel engines. They also produce almost no particulate matter—that nasty, fine soot that creates haze and causes respiratory problems. This makes CNG a game-changer for improving air quality, especially in crowded cities where your fleet does most of its work.

And it doesn't stop there. Switching from gasoline or diesel to CNG can cut your vehicle's carbon dioxide (CO2) emissions by 20-30%. That’s not a rounding error. For a large fleet, this is a huge step toward hitting sustainability targets and staying ahead of environmental regulations.

Serious Savings at the Pump

While going green is a great story, the dollars and cents are what usually seals the deal for fleet operators. The biggest win here is the cost of the fuel itself. Natural gas is consistently cheaper and more stable in price than petroleum.

The difference can be staggering. One county government, for example, reported paying an average of $1.10 per gallon equivalent for CNG while paying $1.91 for regular gasoline. This stability is a huge relief, shielding your budget from the volatile price swings of the global oil market.

"With a $1.40 to $1.50 price difference between CNG and regular gas, the savings offset the conversion cost after 117,000 to 125,000 miles. And that’s assuming regular gas prices stay below $2 a gallon. If not, the payoff will come sooner."

These direct fuel savings add up to a significantly lower total cost of ownership for every vehicle. Yes, there's an upfront cost to convert vehicles or buy new CNG models, but that investment pays for itself surprisingly fast through lower fuel bills. Plus, government incentives and tax credits are often available to soften the initial financial hit, making the move even smarter.

Better Performance and Less Downtime

Beyond the savings and emissions, CNG brings some real-world operational perks that keep your fleet on the road. A major one is how it treats your engines.

Because natural gas burns so cleanly, it leaves behind way less of the carbon gunk and sludge that gasoline and diesel are famous for. This has a fantastic ripple effect:

- Longer Engine Life: Less carbon buildup means less wear and tear on important engine parts. Your engines simply last longer.

- Fewer Service Days: Spark plugs and oil stay cleaner for longer, which means you can stretch the time between scheduled maintenance.

- Quieter Operation: CNG engines are noticeably quieter than their diesel counterparts. This is a huge plus for driver comfort and for reducing noise in residential areas—perfect for waste management trucks or local delivery fleets.

These improvements mean less time in the shop and more time making money. When you combine that with the fuel savings and environmental benefits, you start to see the full picture. Switching to CNG isn't just about changing fuel; it's a strategic decision that makes your entire operation more efficient, cost-effective, and responsible.

What Goes Into a CNG Station? A Look Under the Hood

From the driver's seat, a compressed natural gas filling station looks a lot like a regular gas pump. But behind the scenes, a symphony of powerful, precision-engineered hardware is working in perfect harmony. It’s this core equipment that ensures a safe, fast, and complete fill every single time.

To really understand how it all works, you have to look at the individual pieces. Each component has a critical job, from pressurizing the gas to storing it and finally getting it into your vehicle. Let's pull back the curtain on the anatomy of a typical fast-fill station.

The Powerhouse: A Natural Gas Compressor

The compressor is the undisputed heart of any CNG station. Its job is simple in concept but massive in scale: take low-pressure natural gas from a utility pipeline and squeeze it down to an incredibly high pressure, usually around 4,500 psi.

Think of it like an industrial-grade, multi-stage air compressor on steroids. It has to cram a huge volume of gas into a tiny space so that a vehicle can carry enough fuel to have a practical driving range. This isn't a one-and-done process. The gas moves through a series of cylinders, with each step ratcheting up the pressure. This stage-by-stage approach is essential for managing the intense heat generated and keeping the whole operation safe and efficient.

The Reservoir: High-Pressure Storage Cascade

Once the gas is compressed, it doesn't go straight into a vehicle. That would be far too slow. Instead, it’s routed to a high-pressure storage system called a cascade—a bank of large, reinforced steel tanks that act as a ready-to-go reservoir.

Imagine the cascade system as a series of water towers, each poised to deliver immediate water pressure on demand. The CNG cascade operates on a similar principle, but with pressure levels instead of gravity.

The tanks are usually arranged in three banks: low, medium, and high. This clever setup is the secret sauce behind a fast refueling experience. It allows the dispenser to fill a vehicle's tank quickly and completely without having to wait for the compressor to play catch-up.

Without this on-site storage, every fill-up would be dictated by the compressor's real-time output, which would be painfully slow and totally impractical for a public station.

The Brains of the Operation: The Priority Panel

If the compressor is the heart and the cascade is the muscle, then the priority panel is the brain. This is a complex network of valves, tubing, and sensors that acts as the system's traffic controller, directing the flow of high-pressure gas exactly where it needs to go, right when it needs to get there.

The priority panel juggles a few key responsibilities:

- Directing Compressed Gas: It sends gas from the compressor into the storage cascade, intelligently filling the high-pressure bank first, then the medium, and finally the low.

- Managing Dispensing Flow: When a vehicle hooks up, the panel pulls gas from the cascade in the reverse order—low, then medium, then high. This sequence uses the pressure differentials to get the most gas into the vehicle tank as quickly as possible.

- Ensuring Safety: It's also the central hub for safety, packed with critical valves and pressure monitors to keep everything operating securely.

This automated sequencing is what makes a fast-fill station so effective. It’s how a station can serve one truck right after another without a significant drop in performance.

The Finishing Touch: The Dispenser

Finally, we get to the part everyone sees: the dispenser. It’s the user interface of the whole system and is designed to look and feel familiar, much like a traditional gasoline pump with its hose, nozzle, and payment terminal.

But the technology inside is a different beast entirely. A CNG dispenser is built to handle extreme pressures safely. The specialized nozzle locks onto the vehicle's receptacle to create a perfect seal, preventing any leaks. The dispenser also contains a precision meter that measures the gas transferred, calculating the final cost in Gasoline Gallon Equivalents (GGE).

This technology is constantly evolving. As demand for CNG grows, industry leaders are always refining these systems. You can discover more insights about ongoing upgrades to station components that are pushing the boundaries of efficiency. Together, these essential parts create the reliable, high-performance system that makes CNG a viable and accessible fuel for today's fleets.

Navigating Safety Regulations and Compliance

When you're dealing with natural gas at thousands of pounds per square inch, safety isn't just a priority—it's everything. The entire design and operation of a compressed natural gas filling station are built on a solid foundation of strict safety standards. These rules are in place to protect everyone: the station staff, the drivers pulling up to the pump, and the community around it.

These aren't just suggestions; they are non-negotiable requirements that cover every single detail, from how far apart equipment must be to the specific type of electrical wiring needed. This meticulous approach ensures every station is built to the highest possible safety standard, making them incredibly secure facilities.

The Gold Standard: NFPA 52

In North America, the rulebook for CNG stations is the NFPA 52 Vehicular Gaseous Fuel Systems Code. This document, put out by the National Fire Protection Association, is the bible for anyone designing, building, or operating a CNG station.

Think of NFPA 52 as the master blueprint for safety. It gives engineers and operators a clear, proven roadmap, laying out precise guidelines for critical areas like:

- Equipment Placement: It spells out the exact distances required between compressors, storage tanks, and dispensers to contain any potential issue.

- Ventilation Requirements: The code mandates proper airflow in any enclosed space to make sure gas can never build up.

- Electrical Safety: It requires special explosion-proof wiring and components in any area where gas might be present.

- Emergency Systems: Every station must have layers of redundant safety features designed to trigger an automatic, immediate shutdown if something goes wrong.

Following NFPA 52 isn't optional. It’s the key to getting the permits you need to even break ground, and it creates a consistent, high bar for safety across the entire industry.

By standardizing the engineering and operational practices, NFPA 52 effectively turns safety from a variable into a constant. It ensures that every single station, regardless of its size or location, is built with the same uncompromising commitment to safety.

Thanks to this code, CNG fueling has become an exceptionally safe and reliable process over the last few decades.

Built-In Safety Features

Beyond the regulations, the equipment itself is engineered with multiple layers of protection. These aren't just add-ons; they are integral features designed to stop a problem long before it can start.

Here are a few of the most critical safety technologies you'll find at any CNG station:

- Emergency Shutdown Systems (ESD): You can't miss the big red "E-Stop" buttons placed around the station. Pushing any one of them instantly kills the entire system, stopping the gas flow and cutting power.

- Gas Detection Sensors: These highly sensitive methane detectors are like a 24/7 watchdog. If they sniff even a tiny amount of gas in the air, they automatically sound alarms and shut the system down.

- Breakaway Hoses: We've all seen someone drive away from a gas pump with the nozzle still in their car. CNG hoses are designed for that. A special coupling will safely snap apart, instantly sealing off the gas flow from both the dispenser and the vehicle to prevent a dangerous leak.

These systems all work in concert, creating a powerful, redundant safety net. It's this combination of strict codes and smart, built-in hardware that makes refueling with CNG just as safe—if not safer—than filling up with gasoline.

The Future of CNG and Mobile Refueling

The world of energy is constantly moving, and the familiar compressed natural gas filling station is changing right along with it. As more industries and vehicle fleets look for cleaner and more affordable fuel, the infrastructure has to keep up by becoming smarter and more flexible. The future isn't just about building more stations; it's about bringing the fuel directly to where it's needed most.

This shift isn't just a niche trend—it's backed by some serious numbers. The global CNG market is expected to rocket from roughly $160 billion in 2023 to $345 billion by 2030. That kind of explosive growth signals just how vital CNG is becoming in the worldwide move toward cleaner energy and underscores the pressing need for infrastructure that can adapt on the fly. You can dive deeper into the CNG market growth on grandviewresearch.com.

This momentum is creating an opening for new solutions that break free from the old model of a fixed fueling spot, offering the kind of adaptability that modern businesses desperately need.

The Rise of Mobile CNG Stations

Think about it for a second. Imagine a large construction project out in the middle of nowhere, far from any natural gas pipeline, that needs to power its generators and heavy machinery. Or consider a city rolling out a new bus route through a neighborhood that doesn't have a permanent CNG station yet. A few years ago, these situations would have been a logistical headache.

Today, the answer is a mobile CNG filling station. These are basically self-contained fueling stations on wheels, complete with their own compressors, storage tanks, and dispensers. They can be rolled out to just about any location quickly, providing a dependable CNG supply without the huge upfront investment or long construction delays of a permanent station.

Mobile refueling isn't just a band-aid solution; it's a powerful strategic tool. It gives companies the freedom to test out new markets, support temporary projects, and keep operations running smoothly during pipeline maintenance or unexpected outages. This flexibility closes the gap between immediate fuel demand and the time it takes to build permanent infrastructure.

Practical Applications in the Real World

The true value of mobile CNG really comes to life when you look at real-world situations where being nimble is everything. Companies like Blue Gas Express are experts at deploying these mobile units to solve pressing energy needs for businesses across the Southeast.

Here are a few common scenarios where this approach shines:

- New Construction: A developer needs to get a building’s HVAC system commissioned to receive an occupancy permit, but the permanent gas line isn't live yet. A mobile unit can be brought on-site to supply temporary gas, ensuring the project stays on track.

- Emergency Fleet Support: When a natural disaster strikes, a city might send its fleet of CNG-powered emergency vehicles into an area where the local station is out of commission. A mobile refueler can tag along, making sure those vehicles stay on the road.

- Seasonal Demand: A large farm might only need CNG to power its equipment during the busy harvest season. A mobile station offers a smart, cost-effective solution without the burden of maintaining a permanent facility year-round.

This on-demand fuel delivery model is completely changing how businesses approach their energy logistics. It's making CNG more accessible than ever before, giving fleets the confidence to expand their routes and industries the freedom to operate in new territories.

Got Questions About CNG Filling Stations? We've Got Answers.

So, you're getting the hang of how CNG works, but you probably still have a few practical questions kicking around. It’s completely normal. Let's tackle some of the most common ones we hear from people thinking about making the switch.

How Long Does It Take to Fill Up a CNG Vehicle?

This is probably the number one question on everyone's mind: "Am I going to be stuck at the pump forever?" The short answer is no. At a modern fast-fill station, the experience feels a lot like filling up with regular gasoline.

For a standard car or a light-duty pickup, you’re looking at just 3 to 5 minutes from empty to full. Heavier vehicles, like a city bus or a garbage truck, will naturally take a bit longer, but the system is designed to get them back on their routes quickly. We're talking minimal downtime.

Is Compressed Natural Gas Actually Safer Than Gasoline?

Yes, and the science behind it is pretty straightforward. Natural gas is lighter than air. In the unlikely event of a leak, it doesn't pool on the ground like gasoline or diesel—it rises and dissipates into the atmosphere. This simple fact dramatically lowers the risk of a ground-level fire.

Beyond that, the fuel systems themselves are built like tanks—literally.

The storage cylinders are constructed from high-strength steel or advanced carbon fiber composites. They're engineered to handle impacts and pressures that go way beyond anything they'd see in normal day-to-day use, making them incredibly tough and secure.

What’s the Difference Between CNG and LNG?

It's easy to get these two mixed up since they're both natural gas, but the difference comes down to their physical state: gas versus liquid.

- CNG (Compressed Natural Gas): This is natural gas squeezed under high pressure, but it stays a gas. It's stored at whatever the outside temperature is.

- LNG (Liquefied Natural Gas): This is natural gas that’s been super-chilled to a frosty -260°F (-162°C) until it becomes a liquid.

Cooling it down makes LNG much denser, so you can pack more fuel energy into the same size tank. This is why you often see LNG used for long-haul semi-trucks that need to cover huge distances. For local or regional fleets that come back to a home base each night, CNG is usually the perfect fit.

Of course, each fuel requires its own specialized setup—either a compressed natural gas filling station or an LNG facility—to handle its unique properties safely.

When you’re waiting on permanent pipeline access but your project can’t afford to stop, you need a solid backup plan. Blue Gas Express delivers mobile CNG and LNG right to your site, ensuring your operations keep running smoothly. Get on-demand natural gas and stay on schedule.