Picture this: a gas station that comes directly to you. In a world of tight deadlines and job sites that are often miles from anywhere, the old way of sending vehicles off-route just to fuel up is becoming a serious drain on time and money. That's where a CNG mobile refueling unit changes the game. It's essentially a self-contained, transportable fueling station that delivers cleaner energy right to your fleet.

The Rise of On-Demand Fleet Fueling

For any modern commercial fleet, efficiency is the name of the game. Industries like logistics, construction, and public works need to be nimble, but they're often tied to the old model of fixed fueling stations. This traditional setup creates a ton of unnecessary downtime, pulling expensive equipment and skilled operators off their actual work just for a refuel.

This is exactly the kind of operational headache a CNG mobile refueling unit is built to solve. Think of it as a giant, portable power bank for your entire fleet, giving you fuel precisely when and where you need it. This on-demand approach keeps your vehicles productive and your projects moving forward without a hitch.

A Strategic Shift to Mobile Energy

Moving to mobile fueling isn't just about convenience—it's a smart strategic response to how business works today. As companies push into new areas where there isn't any established natural gas infrastructure, these mobile units are the perfect way to bridge that gap. They give you immediate access to cleaner, cheaper fuel without the massive upfront cost of building a permanent station.

This kind of flexibility is a game-changer for all sorts of operations:

- Remote Construction Sites: You can power heavy machinery right on-site without stopping the workflow.

- Logistics Hubs: Refuel an entire fleet of delivery trucks overnight so they're fully loaded and ready to hit the road at dawn.

- Municipal Fleets: Service garbage trucks or city buses at a central depot, keeping them on their routes and serving the public.

The growing demand for compressed natural gas reflects this shift, with environmental concerns and supportive government policies pushing things forward. The market, valued at USD 12.5 billion, is expected to hit USD 22.5 billion by 2032. This shows just how quickly cleaner fuels are being adopted. You can learn more about the growth of the CNG market and the trends behind it.

By breaking the link between fueling and a fixed location, a CNG mobile refueling unit gives businesses more control and flexibility. It turns a logistical bottleneck into a real competitive edge, making sure your fleet's energy needs never slow you down again.

How a Mobile CNG Refueling Unit Works

Picture a complete, high-tech gas station shrunk down and mounted on the back of a truck. That’s essentially what a CNG mobile refueling unit is—a self-contained system designed to deliver compressed natural gas wherever your fleet is. While the technology might sound complicated, it really boils down to three core components working in perfect sync.

The whole point is to get vehicles refueled safely and quickly, minimizing downtime and getting them back on the road.

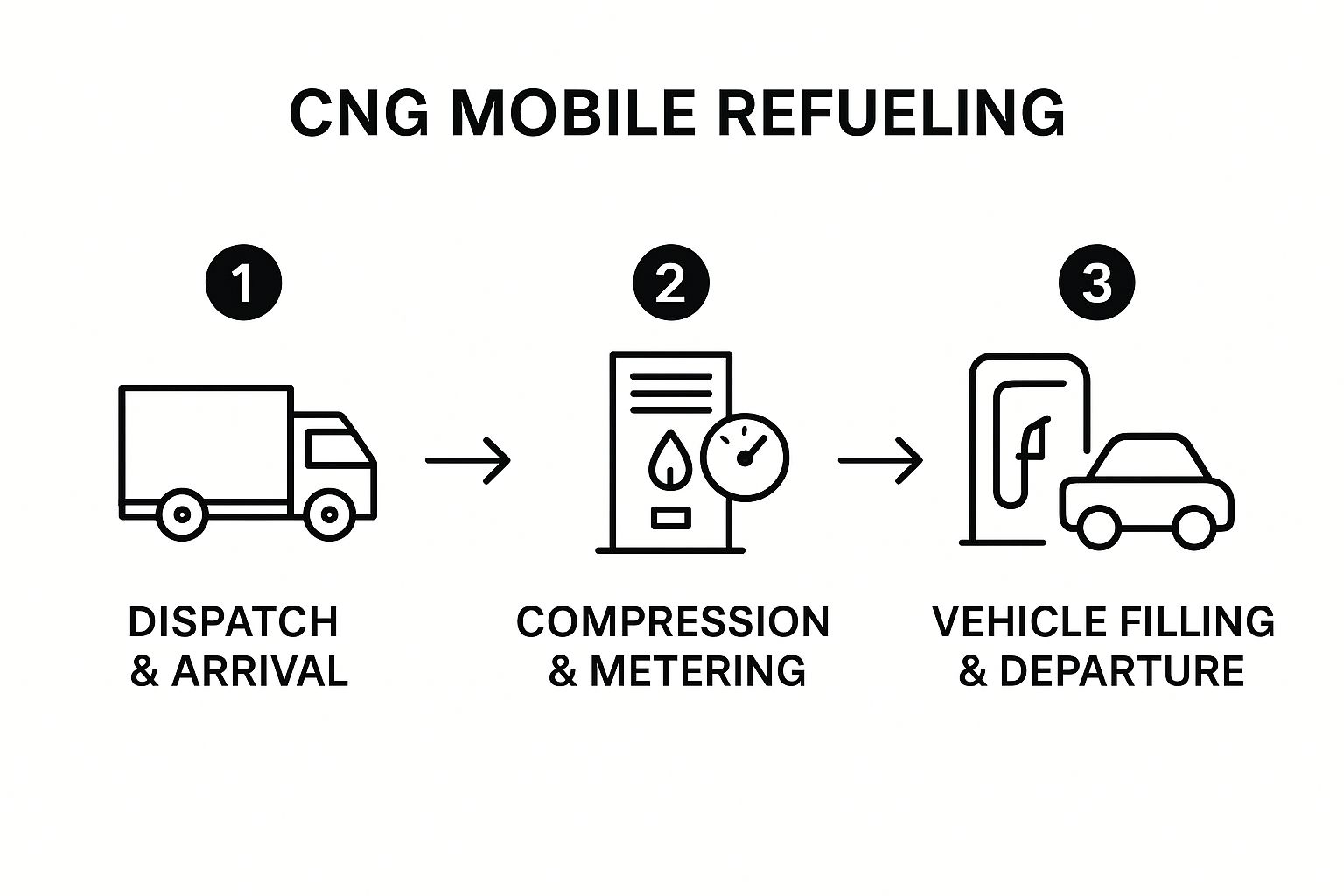

This infographic lays out the straightforward, three-step process that makes it all happen.

As you can see, the CNG mobile refueling unit turns what could be a logistical headache into a simple, repeatable workflow—from the moment it arrives on-site to when the fully fueled vehicle drives away.

The Key Components Onboard

The heart of any mobile unit is its bank of high-pressure storage cylinders. These aren't just your average tanks; they're specially engineered vessels built to safely contain huge amounts of compressed natural gas. They are organized in what’s known as a cascade system, which is just a smart way of grouping the cylinders into high, medium, and low-pressure banks.

Think of it like a set of connected scuba tanks, each filled to a different pressure. When you start filling a vehicle, the system pulls gas from the highest-pressure bank first. This gives you a fast, strong initial fill. As the pressure in the vehicle’s tank starts to build up and equalize, the system automatically switches to the medium-pressure bank, and finally to the low-pressure one.

This cascading approach is incredibly efficient. It ensures a consistently high flow rate from start to finish and makes sure almost every last cubic foot of gas in the mobile unit gets used.

A typical refueling is a well-practiced routine. The unit pulls up, the operator grounds the equipment to prevent static discharge, securely connects the dispensing hose to the vehicle, and starts the fill. The whole time, an onboard metering system tracks exactly how much gas is transferred, which is vital for accurate billing and fuel management.

The Dispensing and Safety Systems

The part that connects the unit to the vehicle is the dispensing system. This includes a durable, high-pressure hose, a specialized nozzle, and a digital meter to precisely measure the gas delivered. For fleet managers, that precise data is gold. The nozzle itself is designed to lock onto the vehicle's fuel port, creating a tight, leak-proof seal before any gas starts flowing.

Of course, safety is built into every step. Advanced control systems are constantly monitoring pressure and flow rates. If they detect anything out of the ordinary—a leak, a malfunction, or even a sudden drop in pressure from a damaged hose—an emergency shutdown system kicks in instantly, cutting off the gas supply.

This layered safety design means every fill from a CNG mobile refueling unit is as safe as it is efficient, giving you total confidence no matter where the job takes you.

Key Advantages Over Fixed Fueling Stations

Choosing to move beyond traditional, fixed fueling stations isn't just a minor tweak—it's a strategic decision driven by some very clear operational and financial wins. While a permanent station certainly has its place, a CNG mobile refueling unit brings an entirely different level of agility to the table, which is exactly what modern fleets need. It completely flips the script from "where do we have to go for fuel?" to "the fuel comes right where we are."

That simple shift cuts out all the hidden costs that come with fueling. Think about it: wasted driver hours, extra miles on the odometer that aren't generating revenue, and added vehicle wear and tear, all from making runs to a distant station. Instead of breaking up the workday, mobile fueling slots right into your existing operations, maximizing vehicle uptime and keeping your projects on track and on budget.

Operational Flexibility and Uptime

Hands down, the biggest perk of a mobile unit is its ability to go where you need it. A fixed station is, well, fixed. A mobile unit, on the other hand, can be sent out to construction sites, temporary fleet yards, or even remote agricultural fields, delivering fuel exactly where the work is happening.

This on-demand refueling is a game-changer for keeping things moving. Picture a fleet of refuse trucks getting refueled overnight right at their depot. By morning, every single vehicle is full and ready to start its route without a single delay. That’s a level of logistical efficiency a fixed station just can't match.

The global numbers tell the same story. Mobile refueling units are the dominant force in the market, making up over 76% of all natural gas refueling station types worldwide. They've become essential for overcoming logistical headaches in industrial zones and for municipal services where keeping fleets running is absolutely critical. You can explore more data on the natural gas refueling stations market on Market.us.

Significant Cost and Scalability Benefits

Let’s talk money. Building a permanent CNG station is a massive project. We're talking millions in capital investment, navigating a maze of permits that can take forever, and acquiring a significant piece of land. A CNG mobile refueling unit sidesteps all of that, offering a much more accessible and cost-effective way to get into natural gas fueling.

This lower financial hurdle means businesses can put their capital to better use—like buying more CNG vehicles. It also makes growing your fueling capacity incredibly straightforward. As your fleet expands, you can simply add more mobile units to the mix without pouring a single yard of concrete.

By bringing the fuel directly to the fleet, you eliminate non-productive downtime and convert what was once a logistical cost center into a source of operational efficiency and competitive advantage.

This approach is perfect for launching pilot programs or for businesses whose fuel needs change from season to season. It lets you prove out the benefits of CNG for your operation without locking yourself into a long-term, high-cost commitment.

Mobile CNG Refueling vs Fixed CNG Stations

To really see the difference, it helps to put the two options side-by-side. Each has its role, but for fleets valuing flexibility and controlled costs, the mobile unit often comes out ahead.

| Feature | CNG Mobile Refueling Unit | Fixed CNG Station |

|---|---|---|

| Initial Investment | Low to moderate (cost of the unit) | Very high (land, construction, permits) |

| Setup Time | Minimal; ready to operate quickly | Months or even years |

| Location | Flexible; can be moved anywhere | Permanent and immovable |

| Scalability | Easy; add more units as needed | Difficult and expensive to expand |

| Best For | New fleets, pilot programs, remote sites | Large, centralized, high-volume fleets |

| Operational Impact | Fuels vehicles during downtime, boosting uptime | Requires vehicles to travel, causing downtime |

Ultimately, the table shows a clear distinction: mobile units are about operational agility, while fixed stations are about high-volume, centralized infrastructure.

Environmental Impact and Accessibility

Finally, mobile units are a big win for sustainability. By making cleaner-burning CNG available in areas that lack permanent infrastructure, they give more companies a practical way to hit their emissions reduction targets and embrace corporate responsibility.

Every trip to a far-off fueling station that you eliminate is also a reduction in unnecessary carbon emissions. So, a CNG mobile refueling unit doesn't just deliver a cleaner fuel; it creates a cleaner, more efficient fueling process from beginning to end.

How Mobile Fueling Works in the Real World

It’s one thing to understand the specs of a CNG mobile refueling unit, but it’s another thing entirely to see how it solves real, expensive problems on the ground. This is where the technology truly proves its worth—not just by delivering fuel, but by stamping out downtime and keeping operations moving forward.

Think about a massive construction project unfolding miles from the nearest town or pipeline. Every single hour that an excavator or loader sits idle, waiting for a fuel truck to arrive, burns through thousands of dollars and pushes deadlines back. A mobile unit flips this scenario on its head. It brings the fuel right to the job site, topping off the entire fleet during lunch breaks or after the crew clocks out for the night. The bottleneck simply disappears.

Keeping Essential Services on the Road

This same logic has a huge impact on municipal services. Take a city’s fleet of garbage trucks. They all need to be ready to go at the crack of dawn. Without a mobile solution, drivers might have to stagger their start times to line up at a central, fixed fueling station, creating a logistical headache.

A mobile refueler can swing by the depot overnight and service the entire fleet right where they’re parked.

The result? Every single truck is full and ready for its route first thing in the morning. This maximizes efficiency and makes sure residents don’t have to deal with service delays. The advantages are crystal clear across the board:

- Construction: Powers heavy machinery right on-site, preventing work from grinding to a halt.

- Logistics: Fills up delivery vans and trucks at distribution centers overnight so they’re ready for the morning rush.

- Agriculture: Services tractors and harvesters directly in the field, which is a lifesaver during peak season.

The growth of CNG is really a story about infrastructure. For example, the Asia Pacific region dominated the market in 2023, pulling in a massive 48.3% revenue share. This was driven by serious government investment and a major push to convert vehicle fleets to natural gas. Discover more insights about the global CNG market on grandviewresearch.com.

Conquering Tricky Logistics

In farming, timing is everything. When it's time to harvest, every minute is precious. The last thing a farmer wants is to pull a combine out of the field and waste time hauling it back to the barn just for fuel.

A CNG mobile refueling unit can be sent out to wherever the work is happening, following the harvest from one field to the next and fueling equipment right on the spot. It’s a game-changer.

All of these examples point to the same core benefit: a mobile unit turns a logistical nightmare into a smooth, integrated part of the daily workflow. By freeing fueling from a fixed address, businesses get the flexibility they need to hit tight deadlines, slash those sneaky hidden costs, and stay ahead of the competition. It’s a direct and powerful solution for some of the toughest operational hurdles out there.

Understanding Safety and Regulatory Standards

When you're dealing with any kind of fuel, trust starts and ends with safety. For a CNG mobile refueling unit, this isn't just an afterthought—it's woven into every layer of its design, from the heavy-duty engineering to the strict operational rules and in-depth training. These units are far more than just tanks on a trailer; they're sophisticated systems where safety is the number one priority.

Think of each unit as having a built-in "watchdog." It's equipped with a whole suite of automated safety features that constantly monitor what's going on. This means potential problems are often stopped before they even have a chance to start, giving everyone on-site, from the operators to the project managers, genuine peace of mind. When handled by professionals, mobile CNG is a mature, reliable, and incredibly secure technology.

Engineered for Maximum Protection

The best way to ensure safety is to build it right into the hardware. Modern mobile refuelers are packed with robust, automatic mechanisms that work together to keep every single refueling operation secure.

Here are some of the key safety components you’ll find:

- Automatic Shutdown Systems: These are the brains of the operation, constantly checking pressure and gas flow. If they sense anything unusual—like a sudden drop in pressure that might signal a leak—they instantly cut off the gas supply.

- Pressure Relief Devices: Every cylinder has a safety valve. If the pressure inside ever climbs beyond a safe level, these devices automatically vent the excess gas in a controlled way, preventing any risk of a rupture.

- Breakaway Hoses: We've all seen someone at a gas station almost drive off with the nozzle still in their car. These hoses are designed for that exact scenario. If a vehicle pulls away while connected, the hose separates cleanly, and internal valves instantly seal both ends to prevent any gas from escaping.

Every aspect of a CNG mobile refueling unit, from its construction to its operation, is guided by strict industry standards. The big one is the National Fire Protection Association (NFPA), whose codes dictate everything from how cylinders are built and spaced to the specific safety valves and electrical grounding required.

The Human Element: Operational Protocols

Great engineering is only half the battle. The other half comes down to the person running the equipment. Safety protocols are built around highly trained operators who follow a precise checklist every single time.

Before any fuel is dispensed, the operator performs a full site assessment. They check the area to make sure it's secure, clear of any potential ignition sources, and ready for the task. The very first step, always, is to properly ground the unit to eliminate any chance of a static electricity spark.

On top of that, every operator goes through comprehensive training that covers the A-to-Z of the unit's function. They know how to conduct routine inspections, follow proper connection procedures, and, most importantly, execute emergency response protocols if needed. This dedication to combining advanced engineering with rigorous human oversight is what makes the CNG mobile refueling unit a fueling solution you can genuinely depend on.

What's Next for Mobile Energy Delivery?

Don't think of mobile CNG refueling as just a temporary patch. It's quickly becoming a strategic cornerstone in the way we think about energy distribution. The CNG mobile refueling unit we see on the road today is really just the beginning. The next wave of innovation is all about making on-demand fueling smarter, faster, and lighter.

We're already seeing advancements that are changing the game. Engineers are working on new, lighter composite cylinders that can hold more fuel without tacking on extra weight, which is a huge boost for efficiency. At the same time, faster dispensing technologies are shaving precious minutes off refueling times, keeping vehicles on the road and earning their keep.

Smarter and Greener Logistics on Wheels

The next big leap is plugging these units into smart technology. Picture this: a CNG mobile refueling unit that’s fully integrated with your fleet management software. The system could automatically send a refueler out to a truck the moment its fuel gauge hits a certain level. That's a completely hands-off, optimized fueling chain.

This technology isn't just about convenience; it's a vital bridge to a cleaner energy future. These mobile units are perfectly designed to deliver renewable natural gas (RNG), a low-carbon fuel that works seamlessly in any CNG engine.

This flexibility also sets the stage for the fuels of tomorrow. The core concept of mobile delivery is already being adapted for hydrogen. This means the CNG mobile refueling unit isn’t just a tool for today—it’s a foundational piece of the zero-emission infrastructure we'll rely on in the future. It’s an investment in being more agile, cutting carbon, and building resilience in an industry that never stands still.

Frequently Asked Questions

When you're thinking about bringing fueling on-site, a lot of practical questions come to mind. How does a CNG mobile refueling unit really work day-to-day? Let's walk through some of the most common things fleet managers want to know.

How Fast Can a Mobile Unit Refuel a Vehicle?

You'll be surprised at how quick it is. The whole point of these units is to minimize downtime, so speed is built into their design. They're designed to be just as fast, if not faster, than a trip to a public station.

For a typical heavy-duty truck or a transit bus, you’re looking at a fill-up time of just 5 to 15 minutes. The exact time can vary a bit based on the size of the vehicle's tanks and the specific dispensing power of the mobile unit, but it's always impressively fast.

Are Mobile Units Compatible with All CNG Vehicles?

Absolutely. Think of it like a universal charger for your fleet. A professional CNG mobile refueling unit comes equipped with the same industry-standard nozzles and connectors (like the NGV1 and NGV2) that you’d find at any permanent station.

This means you don't have to worry about compatibility issues. They're built to service a diverse mix of vehicles, including:

- Class 8 semi-trucks

- City buses

- Work vans

- Even specialized equipment like street sweepers

This plug-and-play approach ensures the unit integrates right into your existing CNG fleet without any need for special adapters or modifications.

What Is the Fuel Capacity of a Typical Mobile Unit?

There isn't a single "typical" size, and that’s a good thing. The capacity of a mobile unit is designed to be flexible to match different operational demands.

A smaller trailer-mounted unit might hold a few hundred gasoline gallon equivalents (GGEs) of CNG, which is perfect for topping off a small group of vehicles at a temporary job site. On the other end of the spectrum, a large truck-based refueler can carry thousands of GGEs—enough to service an entire depot's worth of buses or trucks in one go.

The total cost of ownership is often much lower for fleets using mobile fueling. While the direct fuel cost per gallon might be slightly different, mobile delivery eliminates the significant "hidden costs" of driver wages, fuel, and vehicle wear incurred during trips to a fixed station.

Is Mobile Refueling More Expensive Than Public Stations?

When you look at the big picture, it’s almost always more cost-effective. While the price per gallon might be slightly different, the real savings come from eliminating "deadhead" trips to a fixed station.

By bringing the fuel directly to your yard, you turn non-productive time—driving to and from the station, waiting in line—into productive, on-the-clock time for your drivers and vehicles. That boost in efficiency delivers a powerful return on investment that far outweighs any small variance in the fuel price.

At Blue Gas Express, our job is to deliver reliable, on-demand CNG that keeps your operations moving and your projects on track. If you’re dealing with fueling delays or just need a more flexible solution in the Carolinas, Tennessee, or Virginia, we’re here to help. See how our mobile units can eliminate downtime and keep your fleet rolling.