You can think of a CNG fueling station as the clean energy version of the corner gas station. It’s the critical piece of infrastructure that gets compressed natural gas—a cleaner, cheaper alternative to gasoline and diesel—into the tanks of vehicles. These stations are a fundamental part of the bigger move toward more sustainable transportation.

Understanding the Role of CNG Fueling Stations

At its heart, a CNG fueling station has one job: to move natural gas into a vehicle’s fuel tank safely and quickly. But it’s not as simple as pumping liquid gasoline. The process involves some serious pressure.

Think of it like filling a scuba tank before a dive. You have to compress a huge amount of air into a small, sturdy tank. A CNG station does the exact same thing, just with natural gas.

It pulls natural gas from a standard utility pipeline, cleans it up, and then pressurizes it to somewhere between 3,000 and 3,600 pounds per square inch (psi). This highly compressed gas is then pumped into vehicles built to run on CNG. This entire setup is the backbone that makes natural gas vehicles a practical reality.

Why This Infrastructure Matters

The importance of CNG fueling stations goes way beyond just refueling. They represent a real, physical step away from our reliance on traditional petroleum fuels. For vehicle fleets—think city buses, garbage trucks, and long-haul semis—these stations open up two massive benefits:

- Economic Savings: Natural gas is usually cheaper and has more stable pricing than gasoline or diesel. For fleets that rack up a lot of miles, this translates into major savings on operational costs.

- Environmental Benefits: CNG burns a lot cleaner. It significantly cuts down on greenhouse gas emissions and other nasty pollutants like nitrogen oxides and particulate matter, which is great news for air quality, especially in cities.

A CNG fueling station isn't just a place to refuel; it's an access point to a more sustainable and cost-effective transportation future. It enables the practical, everyday use of a cleaner domestic energy source.

This isn't just a niche trend, either. The global push for cleaner energy is fueling serious market growth. The global Compressed Natural Gas (CNG) market, valued at USD 92.21 billion in 2024, is projected to hit USD 121.42 billion by 2032. You can find a deeper dive into these numbers in the latest CNG market expansion report from Data Bridge Market Research. That kind of growth is a direct result of tougher environmental rules and a real demand for better fuel options.

Without a solid network of CNG fueling stations, the whole idea of switching to cleaner transportation would just be talk. These facilities give cities and businesses the confidence to invest in CNG fleets, knowing they’ll have the support they need to keep their vehicles running.

To quickly summarize the core ideas, this table breaks down the essentials of a CNG fueling station.

| Aspect | Description |

|---|---|

| Fuel Source | Natural gas from standard utility pipelines. |

| Primary Function | Compresses and dispenses natural gas into vehicles. |

| Pressure Range | 3,000 to 3,600 psi—similar to a scuba tank. |

| Key Benefit 1 | Economic: Often cheaper than gasoline or diesel. |

| Key Benefit 2 | Environmental: Burns cleaner, reducing harmful emissions. |

| Target Users | Primarily commercial and municipal fleets (buses, trucks). |

Each of these elements plays a part in making CNG a viable and attractive alternative fuel.

How a CNG Fueling Station Works

Ever pulled up to a CNG fueling station and wondered what’s happening behind the scenes? It’s more than just a pump and a hose. The process is a clever bit of engineering that turns the same natural gas that heats your home into a powerful vehicle fuel. Let's trace the journey from the utility pipeline right into a vehicle's tank.

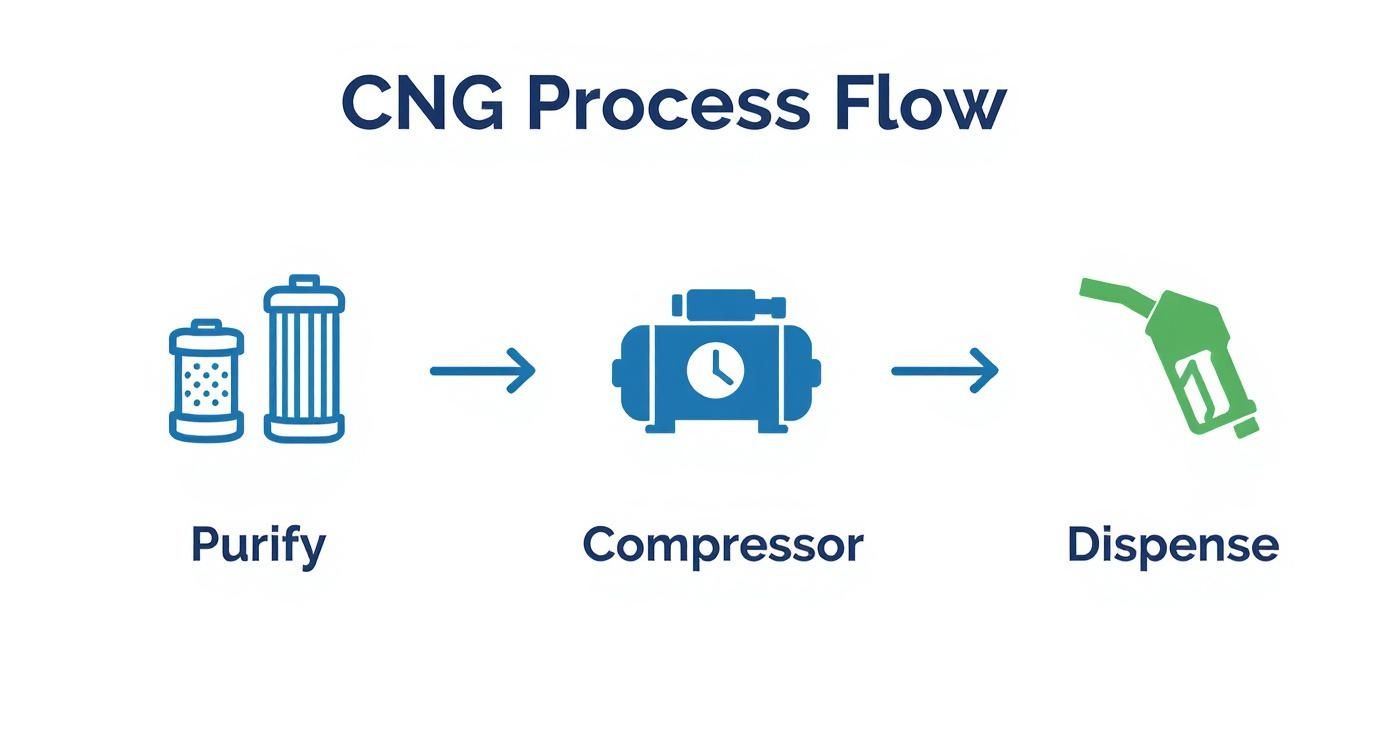

The whole operation boils down to three distinct stages. Each one is absolutely vital for making sure the gas is clean, safe, and packed tightly enough to give a truck or bus the range it needs.

Stage 1: The Arrival and Cleanup

It all starts with natural gas flowing into the station from a local utility line. But this gas isn't quite ready for an engine yet. It arrives at a pretty low pressure and has tiny amounts of moisture and other gunk that could cause serious problems for sensitive engine parts.

You can think of this first step as a quality control checkpoint. The gas immediately gets pushed through a specialized dryer and filter system. This system acts like a microscopic bouncer, catching water vapor and any other particles before they can go any further.

- The Gas Dryer: This is a crucial piece of equipment that pulls moisture out of the gas. Without it, you’d risk ice forming inside high-pressure components (a big no-no) and corrosion in the vehicle's fuel system.

- The Filters: A series of filters is also in place to grab any oil, dirt, or other stray contaminants. This ensures only pure methane moves on.

This purification step is non-negotiable. It protects the expensive station equipment and the vehicle's engine, ensuring a clean and efficient fuel.

Stage 2: The Compression Process

Once the gas is clean, it's time for the main event: compression. This is where a CNG fueling station really flexes its muscles. The purified gas is fed into a massive, multi-stage compressor—the true heart of the entire facility.

Picture a bicycle pump on an industrial-strength dose of steroids. The compressor squeezes the gas with immense force, taking it from a mellow 50 psi all the way up to a staggering 3,600 psi or more. This incredible pressure is what makes it possible to store a practical amount of fuel in a vehicle’s onboard tanks.

The compressor is what makes CNG possible. It pressurizes the gas to over 70 times its original pipeline pressure, packing a huge amount of energy into a compact space for vehicle storage.

At this point, the gas is officially "compressed natural gas" and is ready to be stored until a vehicle needs to fill up.

Stage 3: Storage and Dispensing

Now, that highly pressurized gas doesn't go straight to the dispenser. Instead, it’s sent into a series of large, high-pressure storage tanks arranged in what's called a "cascade system." This system is the secret sauce behind fast fill-ups, making the experience at CNG fueling stations feel a lot like a traditional gas station.

The cascade system is a smart setup of three (or more) storage tanks, or "banks," each held at a slightly different pressure.

- High-Pressure Bank: This tank stores gas at the absolute highest pressure. It's used at the very end of the fill to make sure the vehicle's tank is topped off completely.

- Medium-Pressure Bank: This bank starts the refueling process, quickly getting a large volume of gas into the empty vehicle tank.

- Low-Pressure Bank: This tank is used first for just a moment at the beginning of the fill and is constantly being refilled by the compressor.

When a driver connects the nozzle to their vehicle, the station's control system takes over. It opens the valves in a specific sequence—low, medium, then high pressure. This sequential, relay-like approach pushes gas into the vehicle as quickly as possible and ensures a complete, full-tank fill.

And just like that, the gas has completed its journey from a humble utility pipeline to a clean, powerful transportation fuel, ready to get vehicles back on the road.

Comparing Fast-Fill and Time-Fill Stations

When you start digging into CNG fueling stations, you'll quickly realize they come in two main flavors, each built for a completely different job. It's not about which one is better overall, but which one is the right tool for your specific needs. The two core types are fast-fill and time-fill stations.

Think of a fast-fill station as the CNG version of the corner gas station you're used to. It's designed for speed and convenience, perfect for public access. These stations use a high-pressure storage system to top off a vehicle in just a few minutes, mimicking the experience of pumping gasoline. That's why they're ideal for retail settings or taxi fleets that can't afford to wait around.

On the other hand, a time-fill station is the slow-and-steady workhorse. Instead of a quick burst, these systems refuel an entire fleet of vehicles at the same time, usually overnight. This methodical approach is a perfect fit for private fleets—think city buses, garbage trucks, or delivery vans—that all return to a central depot after their shifts are done.

No matter the type, the basic process of getting the gas from the pipeline into the vehicle follows the same fundamental steps.

Whether filling fast or slow, the core job of purifying, compressing, and dispensing the natural gas is universal for all cng fueling stations.

How Fast-Fill Stations Work

The secret to a fast-fill station's speed is its storage system. It keeps a large volume of highly compressed gas ready to go in a "cascade" of tanks. When a vehicle hooks up, the system releases that pre-compressed gas, delivering a full tank in about 5-10 minutes.

Of course, that speed comes with a higher price tag. The infrastructure is more complex, needing a bigger compressor and the sophisticated cascade storage setup to make it all work.

Key Takeaway: Fast-fill stations are built for high-turnover environments where every minute counts. They are the clear choice for public retail stations and fleets that operate nearly 24/7.

The Simplicity of Time-Fill Stations

Time-fill stations are a much simpler beast. A smaller compressor runs for hours, slowly and steadily pushing gas directly into a fleet of parked vehicles through individual hoses. You don't need the big, expensive cascade storage system because time is on your side.

The big win here is the cost. Both the initial investment and the ongoing operational expenses are much lower. The trade-off is refueling time, which can take anywhere from 6 to 8 hours. This makes it a non-starter for anything but fleets with predictable, long stretches of downtime.

- Best Fit: A municipal bus fleet that parks overnight at a central depot.

- Key Equipment: A smaller compressor and multiple fueling posts. No large storage tanks are needed.

- Main Advantage: Dramatically lower upfront capital and maintenance costs compared to fast-fill.

Fast-Fill vs Time-Fill Station Comparison

To make the choice clearer, let’s break down the key differences side-by-side. The right option really depends on your fleet's daily routine, budget, and refueling needs.

| Feature | Fast-Fill Station | Time-Fill Station |

|---|---|---|

| Refueling Time | 5-10 minutes per vehicle | 6-8 hours for a fleet |

| Best Use Case | Public retail stations, taxi fleets, vehicles needing quick turnarounds. | Private fleets with centralized overnight parking (e.g., buses, delivery vans). |

| Infrastructure | Large compressor, high-pressure cascade storage tanks, sophisticated controls. | Smaller compressor, multiple fueling posts, minimal to no storage. |

| Upfront Cost | High | Low to Moderate |

| Operational Cost | Higher (due to larger equipment and energy demand for rapid compression). | Lower (smaller compressor runs efficiently over a longer period). |

| Footprint | Larger, to accommodate storage vessels and complex equipment. | Smaller and more flexible in layout. |

Ultimately, fast-fill offers convenience that feels like a traditional gas station, while time-fill provides incredible cost efficiency for fleets that can plan their refueling overnight.

This growing infrastructure is part of a much bigger trend. The global CNG refueling station market was valued at around USD 15 billion in 2025 and is projected to grow at a healthy clip of about 8% through 2033. This growth is being fueled by the widespread adoption of CNG vehicles in public transit and freight. You can dive deeper into this trend by exploring the full market research on CNG refueling stations.

Choosing between fast-fill and time-fill is one of the most critical decisions a fleet manager makes when moving to CNG. It all comes down to your unique operational rhythm, vehicle types, and financial planning.

The Upside of Building Out CNG Infrastructure

Making the switch to a new fuel source is a big deal for any fleet or business. It’s a decision that goes far beyond just what you put in the tank. But the move toward compressed natural gas isn't happening by accident—it’s driven by a powerful trio of advantages that address the biggest challenges modern fleets face: cost, environmental impact, and keeping vehicles on the road.

For most, the conversation starts with the bottom line. CNG presents a compelling financial argument, especially for high-volume fuel users. From there, the environmental and operational perks seal the deal, creating a strong case for leaving diesel and gasoline behind.

Major Economic Advantages

The first and most noticeable benefit of adopting CNG is a dramatic drop in fuel costs. Per gallon equivalent, natural gas is almost always cheaper than gasoline or diesel. More importantly, its price is far more stable. While diesel prices can swing wildly based on global oil markets, natural gas prices are largely tied to domestic supply, giving you a predictable budget line you can actually count on.

This stability is a game-changer for operations that burn a lot of fuel—think city buses, garbage trucks, and delivery fleets. For them, fuel is a massive operating expense, and saving even a few cents per gallon quickly adds up to millions of dollars over the life of the vehicles.

A fleet that switches to CNG can often slash its fuel costs by 30-50% compared to diesel. That’s direct savings that can be funneled back into the business, whether it's for new equipment, better training, or just a healthier bottom line.

The market data backs this up. CNG fueling stations already command over 76.4% of the natural gas refueling market share in 2024, showing just how widespread adoption has become. With the market valued at USD 2.1 billion in 2024 and forecast to nearly double by 2034, it’s clear that organizations see a powerful return on this investment. You can get more details about this expanding market and its drivers on market.us.

Significant Environmental Improvements

Beyond the financials, CNG offers a huge win for the environment. It's a much cleaner-burning fuel, which means it pumps far fewer harmful emissions into the air compared to diesel or gasoline. This is a critical advantage for companies and cities trying to hit sustainability targets and improve the air quality in their communities.

Just look at how it stacks up against diesel:

- Nitrogen Oxides (NOx): Emissions are slashed by up to 90%. This is huge for cutting down on the smog that plagues urban areas and contributes to respiratory problems.

- Particulate Matter (PM): CNG engines produce virtually none of the fine, black soot that you see coming from older diesel trucks.

- Greenhouse Gases: Fleets can expect a 20-30% reduction in carbon dioxide (CO2) emissions, providing a straightforward way to shrink their carbon footprint.

This cleaner performance doesn't just help with regulatory headaches; it also strengthens a company's reputation as a good corporate citizen.

Key Operational Gains

The advantages of CNG also show up in the day-to-day grind, making operations smoother and more reliable. One of the first things drivers notice is the noise—or lack thereof. CNG engines are significantly quieter than their diesel counterparts, which is a welcome relief for drivers and a big plus for running routes through residential neighborhoods early in the morning.

Because CNG burns so cleanly, it’s also easier on the engine. You don't get the same heavy carbon buildup, so engine oil stays cleaner longer, and some maintenance needs are reduced. This means less downtime for your vehicles and lower maintenance bills over the long haul. For any piece of modern infrastructure, including a fueling station, it's smart to think about overall energy use. Looking into strategies for commercial building energy efficiency can help trim long-term operating costs even further. Ultimately, this built-in reliability is a massive asset, keeping your fleet on the road and getting the job done.

The Rise of Mobile CNG Fueling Solutions

Permanent cng fueling stations are fantastic for established fleets with predictable routes, but what about everyone else? What happens when your fueling needs are temporary, remote, or just plain unpredictable? The old way of thinking—building permanent infrastructure—just doesn't fly in those scenarios. This is exactly where mobile CNG fueling solutions are changing the game.

Picture a complete, self-contained fueling station built right onto a trailer, ready to go wherever you need it. That's the heart of mobile CNG. These systems bring the fuel directly to your fleet, sidestepping the long timelines and steep costs of permanent construction. It’s essentially a plug-and-play approach to energy.

This kind of flexibility is a lifeline for industries where work is temporary or off-grid. Think of massive construction projects, remote mining operations, or even pop-up depots for emergency response crews. In these cases, building a permanent station makes zero sense, but the need for clean, affordable fuel is still there.

How Mobile CNG Bridges the Gap

A mobile CNG unit is basically a miniaturized version of a permanent station, packing its own compressors, storage, and dispensers into one tidy package. They act as a "virtual pipeline," delivering a steady stream of natural gas without needing a physical connection to a utility line.

The biggest win here is speed. A mobile unit can be hauled to a site and be up and running in a matter of hours—not months. That kind of rapid deployment is crucial for projects with tight deadlines or for businesses needing a fill-in solution while they wait for a permanent gas line.

Imagine a major highway construction project stretching for miles through the countryside. The heavy equipment—excavators, loaders, haul trucks—all need fuel to keep moving. Instead of wasting hours (and money) driving that machinery to a distant station or relying on costly diesel deliveries, the project manager can bring a mobile CNG unit right to the work zone.

This on-site availability pays off in a big way:

- Reduced Downtime: Equipment gets refueled quickly, right where it’s working. That keeps projects on schedule.

- Lower Logistical Costs: You cut out the fuel and labor costs of trucking vehicles back and forth to a fixed station.

- Enhanced Scalability: As the project grows, you can simply bring in more mobile units to keep up with demand.

Mobile fueling transforms the logistics of energy. Instead of bringing your fleet to the fuel, you bring the fuel to your fleet, unlocking operational efficiency in locations previously considered inaccessible for CNG.

This adaptability makes mobile solutions from providers like Blue Gas Express a vital tool for keeping operations running smoothly, especially when permanent infrastructure is delayed or just not an option.

Real-World Applications and Advantages

The usefulness of mobile cng fueling stations goes far beyond construction sites. They are proving their worth in all sorts of industries where flexibility is the name of the game.

For instance, a new distribution center might be ready to launch its fleet of CNG delivery trucks, but the local utility is months away from finishing the pipeline connection. A mobile fueling service can bridge that gap, letting the company start operations immediately and begin saving money with CNG from day one.

It’s the same story in agriculture. During the critical harvest season, large farming operations can use mobile units to refuel tractors and other equipment right in the field, preventing costly downtime when every minute counts.

The key advantages that make mobile CNG so attractive are pretty straightforward:

- Flexibility and Portability: The fueling infrastructure moves when you do, from one job site to the next.

- Rapid Implementation: You can have a fueling solution up and running in a tiny fraction of the time it takes to permit and build a permanent station.

- Cost-Effective for Temporary Needs: It avoids the massive upfront investment of a permanent facility for projects that only last a few months or years.

- Disaster Recovery Support: After a natural disaster knocks out traditional fuel supplies, mobile CNG units can be deployed quickly to power emergency vehicles and generators.

By offering a nimble and responsive alternative to fixed infrastructure, mobile CNG is making clean energy more accessible than it’s ever been. It’s a practical, powerful solution that meets the dynamic demands of modern industry, ensuring the benefits of compressed natural gas can be put to work anywhere, anytime.

What's Next for CNG Fueling?

The world of CNG fueling stations isn't standing still. Far from it. This is a field buzzing with innovation aimed at making CNG more efficient, smarter, and even greener. The goal isn't just to build more stations; it’s about building them better.

This evolution is really pushing forward on three main fronts: upgrading the core hardware, bringing in cleaner fuel sources, and using smart data to make everything run smoother. Each one of these is key to building a more resilient and sustainable fueling network for the future.

Smarter, More Efficient Compressors

The compressor is the heart and soul of any CNG station, and that’s where some of the most practical improvements are happening. Engineers are rolling out next-gen compressors that are leagues ahead in energy efficiency. It's like swapping out an ancient, energy-guzzling window AC unit for a modern, high-efficiency system—it does the same job but with a fraction of the electricity.

For station owners, that translates directly to lower operating costs. It also shrinks the carbon footprint of the fueling process itself. On top of that, these advanced compressors are being engineered for quicker refueling, inching fast-fill stations closer to the familiar speed of a traditional gas pump.

The Rise of Renewable Natural Gas

If there’s one development that's truly changing the conversation, it’s the growing use of Renewable Natural Gas (RNG). RNG is a game-changer. It's a pipeline-ready gas that's created from organic waste—think landfill gas, agricultural byproducts, or even wastewater. Chemically, it's the same as conventional natural gas, but it comes from a completely renewable cycle.

By capturing methane that would otherwise just vent into the atmosphere, RNG creates a fuel cycle that can be carbon-neutral or even carbon-negative. This elevates a CNG fueling station from just a "cleaner" choice to a genuinely sustainable one.

The best part? Fleets can run on RNG using their existing CNG vehicles with zero modifications. It’s an instant, dramatic cut to their emissions profile. This shift positions CNG not just as a bridge fuel, but as a real weapon in the fight against climate change.

Smart Stations Powered by IoT

The final piece of this forward-thinking puzzle is integrating smart technology. Modern CNG fueling stations are becoming connected hubs, using Internet of Things (IoT) sensors and data to fine-tune every aspect of their operation. This gives station operators a powerful set of tools.

- Remote Equipment Monitoring: Technicians can keep an eye on compressor health, storage pressure, and dispenser status from a single dashboard. That means fewer site visits and faster responses.

- Predictive Maintenance: The system can analyze data to flag a component that’s starting to wear out, allowing for maintenance to be scheduled before a costly breakdown happens.

- Smarter Fueling Schedules: For time-fill depots, smart systems can be programmed to refuel vehicles during off-peak hours when electricity is cheapest, squeezing even more savings out of the operation.

These intelligent systems maximize uptime, improve safety, and lower expenses across the board. They are making the entire CNG network more reliable and efficient, proving that this technology isn't just keeping up—it's actively shaping the future of energy.

Common Questions About CNG Fueling

Diving into a new fuel source always brings up a few questions. When it comes to CNG fueling stations, most of the curiosity circles around three things: safety, speed, and savings. Let's clear the air and look at what making the switch to CNG really means.

A common first thought is about safety—is it really a good idea to compress a gas to such high pressures? The short answer is a resounding yes. The entire industry is built on a foundation of strict engineering and safety protocols that make it a reliable choice.

Is CNG a Safe Fuel Source?

Many experts actually consider CNG to be just as safe, if not safer, than gasoline or diesel. This isn't by accident; it's the result of a multi-layered safety approach designed into the vehicles and the fueling equipment.

- Tanks Built Like Bunkers: CNG is stored in incredibly tough, thick-walled tanks made from steel or advanced carbon fiber composites. They're engineered to handle severe impacts far beyond what would rupture a typical gasoline tank.

- Smart Shut-Offs: Both the dispensers at CNG fueling stations and the vehicle's own fuel system are equipped with automated shut-off valves. If they detect a leak or a sudden drop in pressure, they instantly stop the flow of gas.

- Lighter-Than-Air Properties: Here's a key difference from gasoline. Gasoline vapor is heavy and can pool on the ground, creating a serious fire risk. Natural gas is lighter than air, so in the rare event of a leak, it simply rises and dissipates into the atmosphere.

How Long Does Refueling Take?

The time it takes to refuel really depends on the type of station. A public "fast-fill" station operates much like the gas station you're used to, filling up a vehicle in about 5-10 minutes.

On the other hand, a "time-fill" station is designed for commercial fleets. These systems work overnight, slowly refueling multiple vehicles at once over a 6-8 hour period. This ensures the entire fleet is topped off and ready to hit the road first thing in the morning.

How do you compare fuel costs? The industry uses a simple standard called the Gasoline Gallon Equivalent (GGE). One GGE of CNG delivers the same energy as one gallon of gasoline, which makes it easy to see the real price difference at a glance.

Is CNG Cheaper Than Gasoline or Diesel?

Yes, and this is where CNG really shines for many users. The cost savings are significant. To make a fair comparison, CNG is priced in Gasoline Gallon Equivalents (GGE).

Historically, one GGE of CNG has consistently been 30-50% cheaper than a gallon of diesel or gasoline. This price stability can be a game-changer for high-mileage fleets, offering predictable fuel budgets and a real way to get a handle on operating costs.

Ready to bring the benefits of natural gas directly to your job site without the wait? Blue Gas Express provides mobile CNG and LNG solutions to keep your projects powered, on schedule, and within budget. Learn how our rapid deployment services can solve your temporary energy needs by visiting us at https://bluegasexpress.com.