Think of mobile CNG fuel delivery as a power grid on wheels. It’s a smart, on-demand way to get industrial-grade energy delivered right to your doorstep, no matter how far you are from a physical gas main. This service, which we call a virtual pipeline, keeps businesses running without the hassle of permanent infrastructure.

How Natural Gas Gets to Your Job Site

Bringing CNG fuel directly to you is a well-oiled machine, designed to bridge the gap for businesses that need clean, affordable energy but aren't connected to a pipeline. The entire system is built from the ground up for safety and reliability, making sure your operations never skip a beat.

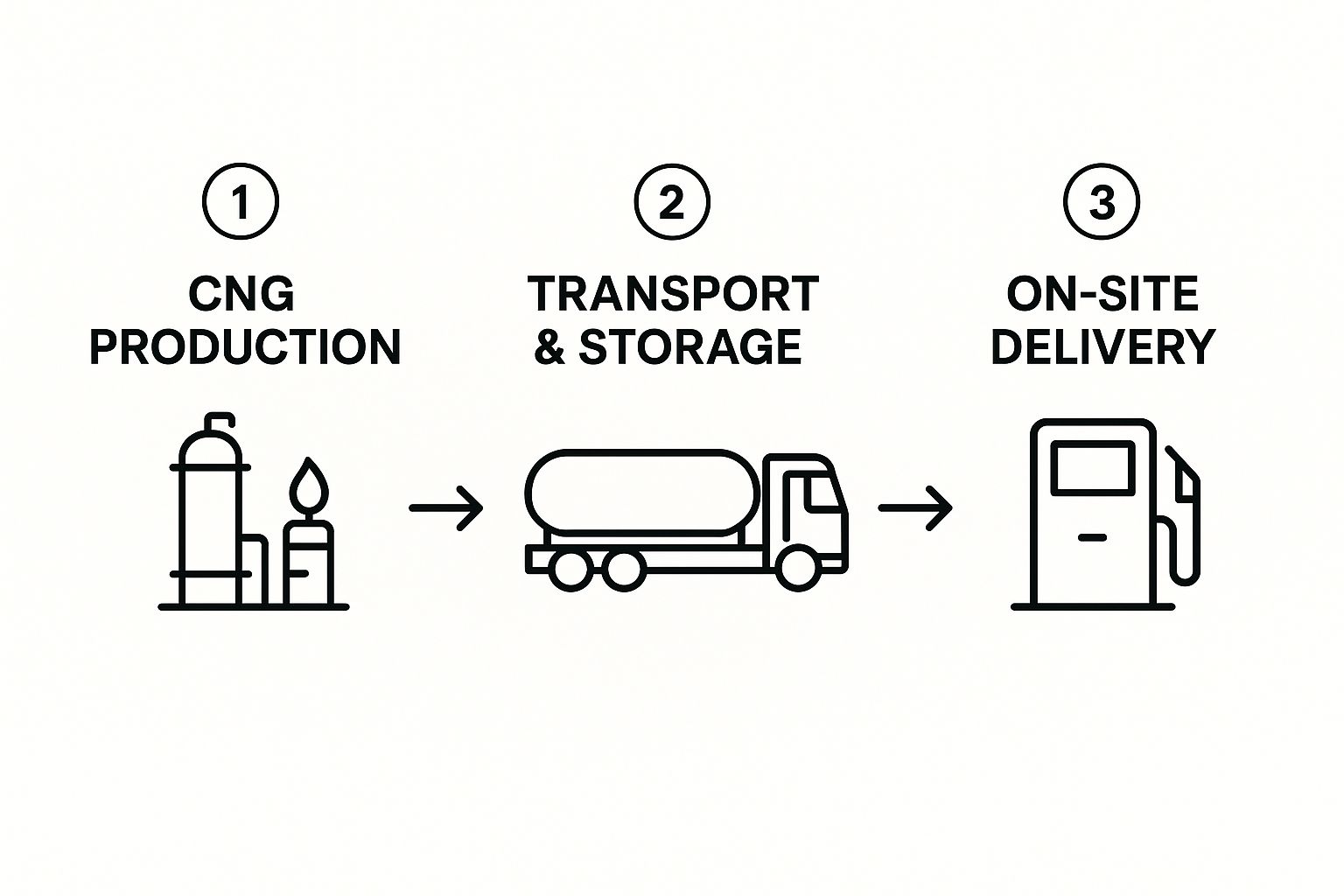

The process boils down to three key stages: compression, transportation, and on-site delivery. Each step is meticulously managed to create a "plug-and-play" energy solution that works for just about any industry. It's literally a pipeline on wheels, moving massive amounts of energy from the source straight to where you need it most.

Here’s a quick overview of how it works.

The CNG Fuel Delivery Process at a Glance

This table breaks down the three core stages of our mobile CNG fuel delivery service, outlining the actions taken and the key benefits at each step for clarity.

| Stage | Action | Key Benefit |

|---|---|---|

| 1. Compression | Natural gas is drawn from a pipeline and its pressure is increased, reducing its volume by over 99%. | Massively increases energy density, allowing large quantities of fuel to be stored and transported efficiently. |

| 2. Transportation | The compressed gas (CNG) is loaded into high-pressure tube trailers and hauled by truck to your location. | Creates a "virtual pipeline" that offers total logistical flexibility, reaching sites inaccessible to traditional pipelines. |

| 3. On-Site Delivery | A technician connects the trailer to a pressure reduction unit (PRU) that lowers the gas pressure to your equipment’s specifications. | Provides a seamless, ready-to-use energy supply that integrates directly into your existing operations. |

Let's dig a little deeper into what happens at each stage.

From Pipeline to Portable Power

The journey starts at a permanent natural gas pipeline. We tap into this source and channel the gas into a powerful compressor station. Here, the gas is squeezed until its volume shrinks by more than 99%. This is the secret sauce—it’s how we pack an enormous amount of energy into a compact, mobile form.

The core idea is simple: by compressing natural gas, we can package vast amounts of energy into specialized containers, making it mobile and ready for deployment anywhere, anytime.

Once compressed, the CNG is loaded into high-pressure tube trailers. These aren't just any trailers; they are the heart of our cng fuel delivery service. They act as safe, robust, mobile storage vessels designed to handle the rigors of the road.

The Virtual Pipeline in Action

This is where the "virtual pipeline" really comes to life. Our specialized trucks haul the tube trailers from the compression station directly to you—whether you're at a remote construction project, an industrial park, or a utility substation. This flexibility is a game-changer compared to fixed pipelines, which are incredibly expensive and take forever to build.

The appeal of CNG isn't just for stationary power; it's rapidly growing in the transportation sector, too. For instance, sales of CNG vehicles in India shot up by 38% between the 2023 and 2024 fiscal years. This boom highlights just how cost-effective and clean CNG is. The global market reflects this, projected to climb from $187.95 billion in 2024 to $211.06 billion in 2025. You can explore more on this trend in market insights from GII Research.

This infographic gives you a great visual of the entire three-stage process.

As you can see, it's a continuous, reliable loop designed to keep your energy supply flowing without interruption.

On-Site Delivery and Use

When our trailer arrives, the real work begins. A trained technician connects the trailer to a pressure reduction unit (PRU) at your site. This device is the final, crucial step—it safely dials down the gas pressure to the exact level your equipment needs, whether you're running generators, industrial heaters, or commercial ovens.

Once connected, you have a steady, dependable flow of natural gas, just as if you were hooked up to a permanent pipeline. It's that simple.

A Look Inside Virtual Pipeline Technology

The term "virtual pipeline" might sound like something from a science fiction movie, but it's the real-world technology that makes on-demand CNG fuel delivery possible. It’s a complete system of specialized equipment working together to bring massive amounts of energy to your doorstep without a single trench being dug. This system is the heart and soul of mobile natural gas, guaranteeing a safe and steady fuel supply right where you need it.

Think of it as an energy delivery service on wheels. The system's core components—the tube trailers, the onboard monitoring tech, and the pressure reduction units—are what make the whole thing work seamlessly. Getting to know how these pieces fit together shows just how reliable this technology is for powering even the most demanding jobs.

High-Pressure Tube Trailers: The Mobile Storage Solution

The first thing you’ll notice is the high-pressure tube trailer. These aren’t just standard tanks; they are highly engineered mobile storage units built for safety and capacity. Each trailer is a rolling energy vault, made up of a series of interconnected, incredibly strong cylinders.

Built from tough materials like steel or modern composites, these cylinders are designed to hold natural gas safely at pressures up to 3,600 psi. It’s this incredible pressure that allows us to pack a huge amount of energy into a single trailer—enough to replace a long stretch of physical pipeline. Every design is rigorously tested to meet or beat strict federal safety regulations, so you know they can handle the rigors of the road.

The real power of the virtual pipeline is its flexibility. One tube trailer can hold enough CNG to run a large commercial site for days. When it runs low, we just swap it out for a full one. No downtime, no interruptions.

On-Board Monitoring: The Brains of the Operation

Keeping that much compressed energy safe and stable is our top priority. That's why every tube trailer is outfitted with advanced on-board monitoring systems. Think of them as the 24/7 watchdogs for the fuel, tracking critical data in real time from the moment it leaves our facility until it arrives at yours.

This technology keeps a constant eye on several key factors:

- Pressure Levels: Making sure the gas stays within a safe, designated pressure range during the entire trip.

- Temperature Readings: Gas pressure and temperature are closely linked, so monitoring both is crucial for stability.

- Gas Volume: We know exactly how much fuel is left at all times, which helps us schedule your next delivery perfectly and avoid any surprises.

This stream of live data is fed back to our central dispatch, giving our team a bird's-eye view of the entire fleet. If any reading ever falls outside the normal range, automated alerts and safety measures like emergency shut-off valves kick in instantly. This proactive safety management provides peace of mind with every CNG fuel delivery.

Pressure Reduction Units: The Final, Crucial Step

Once a trailer is on your site, the final piece of the puzzle is the Pressure Reduction Unit, or PRU. This device is the handshake between our high-pressure trailer and your equipment. Its entire job is to safely "step down" the gas from its storage pressure of 3,600 psi to a usable level for your operations, which is typically between 5 and 250 psi.

The PRU is all about control. It carefully regulates the gas flow and pressure to match exactly what your equipment needs. These units often have built-in heaters to counteract the natural cooling that happens when gas expands, along with filters to ensure you're getting nothing but pure fuel. This final step guarantees you get a consistent, reliable, and safe supply of natural gas, completing the virtual pipeline's journey.

Who Benefits from Mobile CNG Delivery

The virtual pipeline is more than just a clever piece of engineering—it's a practical answer to some very real energy headaches. Its real strength is flexibility. On-demand CNG fuel delivery becomes a lifeline for any operation that needs clean, dependable power but doesn't have a traditional pipeline nearby.

This could be for any number of reasons. Maybe the location is too remote, the pipeline is temporarily down for maintenance, or it's simply not practical to build one. From firing up heavy machinery on a distant construction site to keeping a factory floor running during a utility outage, the uses are as diverse as they are crucial.

Think of it as achieving energy independence. Instead of being handcuffed to the limitations of the grid, businesses can get a steady supply of natural gas precisely when and where they need it. This opens up new possibilities for growth and, just as importantly, ensures work doesn't grind to a halt when the unexpected happens.

Construction and New Development Projects

Construction sites are almost always ahead of the curve, breaking ground in areas long before permanent utilities like gas mains are even planned. This creates a classic catch-22: you need a ton of power to build, but the infrastructure to deliver that power doesn't exist yet. This is exactly where mobile CNG steps in.

Rather than falling back on expensive and dirty diesel generators, developers can use mobile CNG to power everything from temporary heaters for curing concrete to the generators running site offices. It allows projects to stick to tight schedules, even when they’re miles from the nearest utility hookup.

We see it used all the time for:

- Temporary Building Heat: Absolutely essential for keeping work going through the winter and making sure materials like paint and drywall cure properly.

- Powering Generators: It's a clean way to get electricity for tools, lighting, and trailers without the noise and fumes of diesel.

- Ground Thawing: In cold climates, hydronic heaters fueled by natural gas can prep frozen ground for excavation, preventing costly delays.

This ability to bring the pipeline directly to the project is what makes cng fuel delivery from a provider like Blue Gas Express such a game-changer. It bridges that critical energy gap, letting builders get to work without waiting for the grid to catch up.

Industrial and Manufacturing Facilities

For any industrial plant, a stable energy supply isn't just nice to have—it's the absolute lifeblood of the operation. An unexpected cut in their natural gas supply can trigger catastrophic production losses, easily costing thousands of dollars for every hour of downtime. Mobile CNG is their insurance policy.

During planned pipeline maintenance or an unforeseen emergency outage, a virtual pipeline can be deployed in a matter of hours. This ensures that process heaters, boilers, and other mission-critical equipment keep running without a single hiccup in production.

It also opens up new possibilities. Facilities that would have been limited by geography can now be built in more logistically strategic locations, using mobile CNG as their primary fuel. It's a clear path to maintaining 100% operational uptime, no matter what's happening with the local pipeline.

Gas Utilities and Pipeline Integrity

It might seem counterintuitive, but even the utility companies themselves depend on mobile CNG delivery. When a section of their pipeline needs repairs, upgrades, or inspections, they have to shut off the gas flow. In the past, this meant cutting service to every home and business downstream.

Today, they use a smarter approach called a "pipeline bypass." A virtual pipeline is brought in to feed gas back into the system just past the maintenance area. This creates a seamless flow of energy for customers while crews can safely work on the isolated pipe. It's a win-win that keeps the public safe and the customers happy.

Global energy markets also underscore the need for this flexibility. For instance, while global natural gas demand saw modest growth in early 2025, major supply shifts, like a new LNG facility coming online, sent ripples worldwide. These changes forced European countries to increase their LNG imports by over 20% to make up for reduced pipeline flows. It’s a perfect example of why adaptable distribution methods like mobile CNG are so vital for energy security. You can read the full gas market report from the IEA for a deeper dive.

Commercial and Agricultural Operations

The benefits don't stop with heavy industry. A huge range of commercial and agricultural businesses have unique energy demands that mobile CNG is perfectly suited to meet.

Just think about these scenarios:

- Greenhouses: A commercial greenhouse operator needs constant, reliable heat to protect valuable crops. A mobile CNG setup provides that thermal security, especially in rural areas far from a gas main.

- Asphalt Plants: These plants need a massive amount of heat to produce asphalt. Mobile CNG offers a cleaner and often more affordable alternative to traditional fuel oil or propane.

- Grain Drying: After a harvest, farmers need to dry their grain quickly to prevent it from spoiling. Natural gas dryers are incredibly efficient, and mobile delivery makes them a viable option for any farm.

In every one of these cases, mobile cng fuel delivery offers a clean, cost-effective, and dependable source of energy, empowering businesses to operate at peak efficiency, regardless of their address.

The Real Advantages of On-Demand CNG

Choosing an energy source goes far beyond just keeping the lights on. It’s a strategic move that directly impacts your budget, your environmental goals, and how resilient your operations are. Switching to on-demand CNG fuel delivery isn't just swapping one fuel for another; it's a genuine upgrade across the board. The benefits are clear and compelling, stacking up across three key areas: cost savings, environmental impact, and operational power.

When you look at it through these three lenses, you get a complete picture of why a virtual pipeline is simply a smarter way to handle modern energy needs.

Driving Down Costs With Economic Advantages

The first thing you’ll notice when switching to CNG is the positive impact on your bottom line. Natural gas is consistently more affordable than diesel or propane when you compare them based on energy output (MMBtu). For any high-consumption operation, this translates into major fuel cost reductions—often between 25-40%.

Beyond the direct savings, you also get much-needed price stability. We all know how volatile diesel and propane prices can be, tied as they are to unpredictable global oil markets. Natural gas, on the other hand, is mostly sourced domestically and its price is far more stable. This predictability makes budgeting a whole lot easier and shields your business from the sudden price hikes that can tank profitability.

The global compressed natural gas market was valued at approximately $43.84 billion in 2025 and is projected to grow steadily, driven by its economic and environmental benefits over traditional fuels. This trend highlights a worldwide shift toward more stable and cleaner energy sources.

This growth isn't just a forecast; it reflects a real-world consensus on CNG's value. As more industries look for an escape from volatile oil prices, the demand for reliable CNG fuel delivery keeps climbing. You can dig deeper into the expanding global CNG market and its drivers to see where the industry is headed.

Achieving Sustainability With Environmental Benefits

The financial wins are huge, but the environmental advantages are just as powerful. CNG is the cleanest-burning fossil fuel available, meaning it produces dramatically fewer harmful emissions than petroleum-based fuels. For any company serious about corporate responsibility and meeting stricter regulations, this is a game-changer.

Making the move from diesel to natural gas yields some impressive results:

- Carbon Dioxide (CO2): You can cut CO2 emissions by about 25%, taking a significant bite out of your carbon footprint.

- Nitrogen Oxides (NOx): This is a big one. You’ll slash NOx emissions—the pollutants behind smog and acid rain—by up to 90%.

- Particulate Matter (PM): CNG virtually eliminates the fine soot that comes from diesel exhaust, which is a known health hazard.

These aren't just abstract numbers. They mean cleaner air for your team, your equipment, and the communities you work in. Adopting CNG is a concrete, practical step toward a more sustainable way of doing business.

Enhancing Operations With Unmatched Flexibility

This might be the most powerful benefit of all: the sheer operational agility you gain with on-demand CNG. A virtual pipeline from a provider like Blue Gas Express completely untethers you from fixed infrastructure. Suddenly, you have the freedom to power your operations anywhere, at any time.

Think about what that means. You can set up on a remote job site, keep production humming during a utility pipeline outage, or scale your energy supply up or down on the fly. All of this is possible without pouring money and time into new construction. The "plug-and-play" nature of mobile CNG fuel delivery ensures you have a reliable, uninterrupted flow of energy precisely when you need it, guaranteeing 100% operational uptime. It’s this logistical freedom that lets you take on projects and expand into areas that would have been impossible before.

CNG vs Traditional Fuels A Comparison

When you put CNG head-to-head with traditional fuels like diesel and propane, the advantages become crystal clear. The table below breaks down the key differences in cost and environmental impact.

| Fuel Type | Average Cost per MMBtu | CO2 Emissions Reduction vs Diesel | NOx Emissions Reduction vs Diesel |

|---|---|---|---|

| CNG | Lower & More Stable | ~25% | Up to 90% |

| Diesel | Higher & Volatile | N/A | N/A |

| Propane | Higher & Volatile | ~13% | Lower than diesel |

As you can see, from cost stability to significant emissions reductions, CNG consistently outperforms its more conventional counterparts, making it a smarter choice for forward-thinking operations.

Is CNG Safe? A Look at the Layers of Protection

When you’re thinking about bringing a new fuel source to your site, safety is always the first question. Let's be honest, the idea of high-pressure natural gas might sound a little intense. But the reality is, the entire CNG fuel delivery system is built from the ground up with multiple, overlapping layers of safety. Every piece of equipment, every step in the process, and every person involved is laser-focused on one goal: delivering clean energy safely and reliably.

One of the biggest safety features is actually built right into the fuel itself. Natural gas is lighter than air. Unlike propane or diesel, which are heavier and can pool dangerously on the ground if they leak, natural gas just rises and dissipates into the atmosphere. This simple fact dramatically lowers the risk of any ground-level fire.

It’s this inherent quality that serves as the starting point for a comprehensive, safety-first approach.

Built-In Safety from the Ground Up

The safety measures for mobile CNG aren't just a checklist; they're woven into the very fabric of the technology and our day-to-day operations. Everything from the design of the transport trailers to the extensive training our technicians receive is governed by strict federal and industry regulations. It's all about ensuring predictable, safe performance every single time.

Take the transport cylinders, for example. These aren't just standard tanks. They’re constructed from high-strength steel or advanced composite materials, specifically engineered to handle immense pressure and withstand serious physical impacts.

To get certified, these cylinders are put through the wringer. They undergo brutal tests that go far beyond anything they'd experience in the real world—think extreme pressure tests, impact simulations, and even bonfire tests. This process guarantees they can hold up under the toughest conditions imaginable.

This robust construction is your first line of defense, making sure the CNG is securely contained all the way from our facility to your doorstep.

Intelligent Monitoring and Failsafe Systems

Technology adds another critical layer of security. Every mobile CNG fuel delivery trailer is a smart system, equipped with sophisticated sensors that act as a 24/7 watchdog. These systems keep a close eye on all the vital signs to make sure everything is operating exactly as it should.

Here's what they're constantly tracking:

- Cylinder Pressure: Sensors continuously measure the internal pressure, ensuring it stays well within the designated safe range during transport and delivery.

- Gas Temperature: Temperature and pressure are directly related, so monitoring the gas temperature gives us another way to confirm everything is stable.

- Flow Rates: As the gas is delivered to your site, the flow rate is precisely controlled to prevent any sudden changes that could affect your equipment.

All this data is streamed back to our central operations team, giving us real-time oversight. If any reading even hints at a problem, automated failsafe systems kick in instantly. Emergency shut-off valves can cut off the gas supply in a fraction of a second, neutralizing a potential issue before it has a chance to develop. It’s a proactive system designed for total peace of mind.

The Human Element: Highly Trained Technicians

The final, and perhaps most important, piece of the safety puzzle is our people. The technicians who manage your on-site CNG fuel delivery are more than just drivers; they are highly skilled energy professionals. At a trusted provider like Blue Gas Express, every team member goes through rigorous training that covers every possible scenario related to CNG handling and emergency response.

This training dives deep into:

- Safe Connection and Disconnection: Our technicians follow a meticulous, multi-step checklist every single time they connect to your equipment, ensuring a secure, leak-free seal.

- Emergency Response Protocols: They know exactly how to identify and react to any issue, from a minor equipment hiccup to a full emergency shutdown, ensuring a fast and safe resolution.

- Regulatory Compliance: We stay on top of all Department of Transportation (DOT) and industry safety standards, so you can be confident every delivery meets the highest requirements.

When you combine the natural safety of the fuel with incredibly tough equipment, smart monitoring, and expert technicians, you get a mobile energy solution that is as reliable as it is secure.

Common Questions About CNG Fuel Delivery

When you're thinking about using a virtual pipeline, a lot of practical questions pop up. It's only natural. Getting a handle on the specifics helps you see exactly how mobile CNG fuel delivery can fit into your operation and solve some very real energy headaches. Let's tackle some of the most common questions head-on so you can make a smart decision.

We'll clear up the confusion between different gas fuels, walk through the surprisingly simple on-site requirements, and show you why this modern energy solution is trusted for even the most demanding, 24/7 jobs.

How Is CNG Different From LNG or LPG?

It’s easy to get the acronyms mixed up, but CNG, LNG, and LPG are completely different products with their own unique jobs. They're all good fuels, but knowing what sets them apart makes it clear why CNG is so often the right call for temporary power on industrial sites.

The main differences really come down to temperature, pressure, and whether it's a gas or a liquid.

CNG (Compressed Natural Gas): This is just natural gas, the same stuff that comes through a pipeline, but squeezed under high pressure (around 3,600 psi) at normal, everyday temperatures. The best analogy is the air in a scuba tank—it’s a gas compressed to fit into a smaller space. That simplicity is what makes it perfect for mobile delivery where you need to get set up fast with straightforward equipment.

LNG (Liquefied Natural Gas): This is natural gas that's been flash-frozen to an incredibly cold -260°F, which turns it into a liquid. Chilling it like this shrinks its volume by a huge amount, making it a great way to ship massive quantities of gas across oceans. The trade-off? You need highly specialized cryogenic tanks and equipment to warm it back into a gas, which adds a lot of cost and complexity for on-site use.

LPG (Liquefied Petroleum Gas): You probably know this one as propane. It's a totally different substance, a byproduct of oil refining. It turns into a liquid under just a bit of pressure and is stored in those familiar white tanks. While useful, it has different burning characteristics and a completely different cost structure than natural gas.

For most jobs needing temporary heat and power, the "plug-and-play" nature of cng fuel delivery just makes sense. It offers the best mix of energy punch, safety, and operational ease.

What On-Site Equipment Is Required?

Honestly, this is one of the best parts of using a virtual pipeline: the tiny footprint and hassle-free setup. Forget the major construction and site disruptions that come with permanent infrastructure. Mobile CNG is designed to plug right into your existing setup without getting in the way. You don’t have to buy a thing.

The entire system is self-contained. Our team brings everything needed to connect the virtual pipeline to your machinery, requiring only a small, level area to park the trailer and pressure reduction unit. It’s a true turnkey solution.

So, what do we need from you? It's a short list.

- A Stable, Accessible Location: All we need is a firm, level spot big enough for a standard tractor-trailer.

- A Connection Point: Just show us where to tie into your equipment’s fuel line.

That’s it. Your provider handles everything else. A trained technician arrives with the tube trailer and a Pressure Reduction Unit (PRU). They'll securely connect the system, dial in the pressure to your exact needs, and make sure you have a steady, reliable flow of gas before they leave.

Can Mobile CNG Support Continuous 24/7 Operations?

Without a doubt. The virtual pipeline was built for reliability. It's the go-to solution for industries like manufacturing and gas utilities where downtime simply isn't an option. We keep you running 24/7 through meticulous planning and a rock-solid supply chain.

Here’s how our system guarantees you never skip a beat:

- Constant Monitoring: We keep a close eye on the gas volume in your on-site trailer remotely, in real time.

- Proactive Swaps: Long before a trailer gets low, we dispatch a fresh, full one to your site for a quick and seamless swap.

- Redundant Supply: For those absolutely mission-critical jobs, we can bring in multiple trailers to create an on-site reserve. You will not run out of fuel.

This hands-on management means your operation gets a constant, uninterrupted stream of energy. You can run your processes around the clock with total confidence in your fuel supply.

Ready to ensure your project has the reliable, clean, and cost-effective energy it needs? Blue Gas Express delivers on-demand CNG solutions that keep your operations running without interruption.

Learn more about our mobile CNG fuel delivery services and get a quote today.