Understanding Home CNG Stations

Think of a home CNG refueling station much like a garage EV charger—except you’re pumping compressed natural gas instead of electricity. It lives in your garage and delivers high-pressure fuel straight to your vehicle, meaning you skip weekly lines and lock in savings of up to 50% on fuel.

Electric vehicles top up overnight; residential CNG compressors follow suit. A 150 cubic foot per minute unit can refill a mid-size CNG car while you sleep, and a typical installation starts around $5,000 (installed).

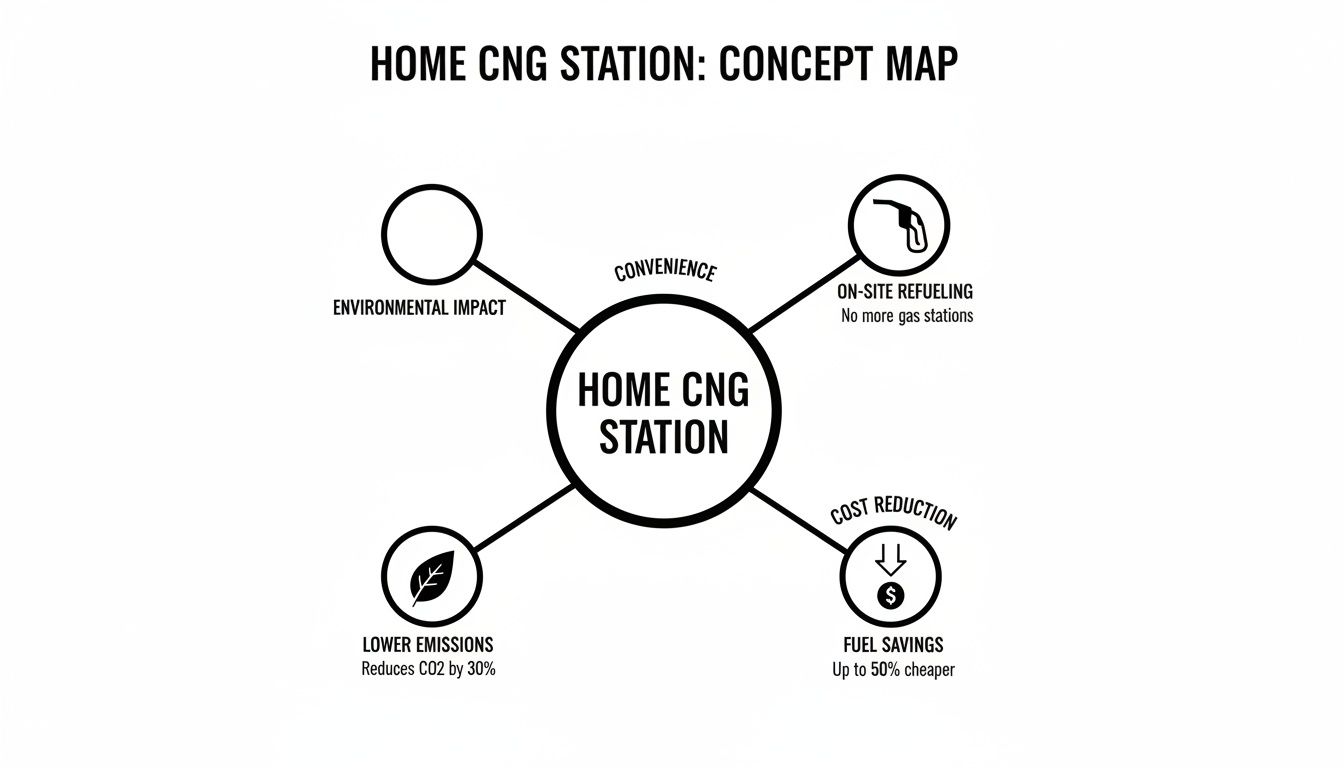

Key Benefits

- On-site refueling cuts travel time and pump lines.

- Save up to 50% per diesel gallon equivalent (DGE).

- Trim 20% off CO₂ emissions per mile.

- Build energy resilience with a backup fuel source.

Home Vs Public CNG Refueling Comparison

Here’s a quick glance at how a private setup compares with a public pump.

| Factor | Home Station | Public Station |

|---|---|---|

| Cost | $0.50–$0.80 per diesel gallon equivalent | $1.00–$1.60 per DGE |

| Convenience | 24/7 access in your garage | Fixed hours, weekend crowds |

| Safety | Controlled residential environment | Exposure to traffic and weather fluctuations |

Clearly, a home station delivers nonstop access, lower cost per unit, and a controlled fueling environment.

The diagram above shows the CNG molecule structure and multi-stage compression process—illustrating how high-pressure storage keeps tanks compact.

Imagine pulling into the driveway after work, but instead of plugging in for electricity, you pump clean-burning natural gas from your garage. In the U.S., there are over 700 public CNG stations, yet only half serve all drivers—leaving an opening for residential units.

On a global scale, nearly 10 million natural gas vehicles cruise city streets. The refueling station market, valued at USD 2.1 billion in 2024, is projected to reach USD 4.1 billion by 2034 at a 6.8% CAGR. Home refueling kits can cut costs by 40–50%, also curbing CO₂ by 20% per mile. You can explore these forecasts in the natural gas refueling stations market.

All told, home CNG stations blend savings, convenience, and cleaner operation. Next up, we’ll dive into system components, permitting steps, and ownership costs.

Home CNG stations cut fuel costs nearly in half.

Why Consider Home CNG

- Slash fuel costs by 50% with stable residential pricing

- Refuel on your schedule—no lines, no fixed pump hours

- Operate quietly indoors, away from loud outdoor stations

Exploring System Components and Station Footprint

A home CNG refueling station squeezes everything you’d find at a commercial pump into a footprint small enough for a garage or backyard shed. At its heart, you’ve got a high-pressure compressor, storage tanks, a dispenser module, and a set of safety controls—all arranged to blend into a residential setting.

That diagram lays out each compressor stage, cascade of storage tanks, dispenser, and control panel. You can trace how natural gas is compressed up to 3,600 psi, then held in modular tanks before being metered into your vehicle. The beauty is how it integrates with simple site features—floor drains, dedicated power outlets, even a small concrete pad.

Compressor Functions And Safety Valves

Think of the compressor like a home generator—except it boosts gas pressure instead of voltage. In a multi-stage setup, smaller pumps link together so heat never builds up too much. For example, a three-stage compressor can fill a mid-size CNG sedan overnight, quietly humming away in the corner of your garage.

Key Components

- Compressor Unit: Raises natural gas pressure through sequential stages

- Modular Storage Tanks: Securely store fuel at high psi

- Dispenser Unit: Precisely meters flow into your vehicle’s tank

- Safety Valves & Pressure Relief Devices: Prevent dangerous overpressure

- Control Panel & Sensors: Automate system monitoring and emergency shutdowns

Proper staging in a compressor can boost efficiency by up to 25% while easing thermal stress.

Space Requirements And Modular Arrangements

Depending on your needs, a residential kit can fit within 10×10 ft for a compact system or expand to 20×15 ft for larger capacity. You might tuck it into a garage bay, or place a small weatherproof enclosure beside your driveway. Modular rack designs even let you stack tanks vertically to save floor space.

Site Planning Tips

- Ensure adequate ventilation to disperse heat and any trace gas

- Run a dedicated 240V 30A circuit to support the compressor motor

- Keep gas lines straight—sharp bends increase pressure loss

- Set the station on a level concrete pad or compacted gravel base

Home stations are on the rise worldwide. In 2023, the Asia-Pacific market commanded 48.3% of global CNG sales, with China alone at 32.7%. Analysts forecast growth from USD 5 billion today to USD 9 billion by 2033 at an 8% CAGR. Learn more about these trends in this report.

Across both new builds and retrofit projects, modular CNG kits help owners cut fuel costs by 40–60% and shrink CO₂ emissions by around 20%.

Planning Electrical And Gas Connections

Most residential stations need a 240V 30A supply. You’ll likely install a dedicated breaker, consider a service panel upgrade, and add surge protection. On the gas side, a 2-inch steel or stainless-steel line from your meter to the compressor minimizes pressure drop.

Installation Steps

- Evaluate and upgrade electrical capacity as needed

- Lay out the gas supply line with proper slope and approved fittings

- Pour or position a reinforced pad or prefab base

- Secure all equipment with seismic straps in quake zones

- Tie the control panel into your building’s safety or local authority system

Don’t forget grounding rods and full compliance with local codes. With these preparations, your home CNG station integrates seamlessly, delivering quiet, reliable refueling whenever you need it.

Navigating Permits Codes And Safety Requirements

When you decide to install a CNG refueling station at home, permits and safety codes become your roadmap. Skipping a single rule can stall your project for months. That’s why understanding local fire, building, and environmental regulations from the get-go matters.

Cities and counties rely on an Authority Having Jurisdiction (AHJ) to keep everything in check. AHJs make sure your setup aligns with NFPA 52 for CNG, the IBC building code, and any local amendments. Find them early, introduce your plan, and you’ll dodge surprises later.

Authorities Having Jurisdiction

AHJs are your on-site referees. They:

- Review and approve your site plans

- Inspect equipment and electrical layouts

- Issue the occupancy permit for your new installation

They’ll also ask for operator training certificates and manufacturer approvals. A quick tip: meet your AHJ face-to-face before ordering gear. One Texas homeowner saved weeks by chatting with the fire marshal two months ahead.

Submitting Plans And Scheduling Reviews

A well-organized submittal package is your ticket to a swift review.

- Gather equipment cut sheets, load calculations, and grading plans

- Send everything over to the AHJ—digital or paper works

- Tackle inspector feedback promptly and resubmit if needed

Typical reviews take 4–6 weeks, though local demand can stretch that. A fast one-week turn on comments will keep your project rolling.

“Early coordination with AHJs shaved off almost a month from our approval timeline,” says a homeowner installer.

Real-World Approval Example

In Hillsborough County, Florida, a builder faced a 10-week wait for CNG permits. Rather than halt operations, they brought in mobile units from Blue Gas Express.

- No building permit for temporary skid units

- Deployment in under 24 hours

- No long-term inspections for non-permanent setups

This workaround kept a generator running through gas line delays. It also supplied a pressure relief test sheet that sped up the permanent install down the line.

Essential Safety Features

Building safety into your CNG station is non-negotiable. Think of it as installing airbags and seatbelts.

- Overfill Prevention System (OPS) stops filling at 95% tank capacity

- Automatic Shutoff Valves isolate the compressor during faults

- Pressure Relief Devices discharge gas safely when pressure spikes

- Gas Leak Detectors trigger emergency shutdowns

These safeguards protect your home and everyone in it.

Recommended Maintenance And Inspection Schedule

| Task | Frequency | Notes |

|---|---|---|

| Visual Equipment Check | Monthly | Inspect for wear and leaks |

| Safety Valve Function Test | Quarterly | Simulate fault conditions |

| Leak Detection Sensor Calibration | Semiannually | Follow manufacturer guidelines |

| Full System Pressure Test | Annually | Keep a 5-year record |

Sticking to this routine can cut downtime by over 30%. Frequent checks ensure your safety systems work when it counts.

Inspection And Final Sign-Off

After clearing AHJ reviews and safety tests, schedule that final walkthrough. Inspectors will:

- Verify grounding, signage, and shutdowns

- Check clearances around equipment

- Confirm permits are posted on-site

Once they hand over the signed certificate, your station is good to go. Keep all records—permits, test results, and maintenance logs—handy for future audits.

Homeowner Jane in Maryland notes her proactive communication cut approval time by 25%.

Best Practices For AHJ Engagement

- Engage AHJs during concept design—not after blueprints are set

- Share 3D renderings to clarify station layout

- Maintain open lines via email and site visits

Transparent dialogue often speeds permits and trims rework. After you’re up and running, revisit maintenance logs every quarter and update safety gear when the NFPA 52 standard changes. This keeps your CNG station on track and worry-free.

Estimating Costs And Maintenance Considerations

Balancing your initial investment with long-term savings is crucial when you’re setting up a home CNG refueling station. Breaking the project down into clear, bite-sized cost items gives you a realistic budget and helps you avoid unwelcome surprises. Let’s walk through what you can expect to pay up front, what it takes to keep the system running smoothly, and how to stretch your dollars over time.

Initial Capital Outlay

To get started, you’ll need a compressor, storage tanks, dispensers and installation work. Here’s how those pieces stack up:

| Component | Typical Range |

|---|---|

| Compressor Unit | $5,000–$10,000 |

| Storage Tanks | $2,000–$5,000 |

| Installation Labor | $1,500–$3,000 |

| Permitting Fees | $500–$1,200 |

| Site Prep | $1,000–$2,000 |

| Electrical Upgrade | $600–$1,200 |

| Gas Line Extensions | $800 |

A few notes:

- Site preparation may mean pouring a concrete pad or building a simple shelter, which usually runs $1,000–$2,000.

- Electrical upgrades for a dedicated 240V circuit can add another $600–$1,200, depending on your panel’s location.

- Don’t forget permitting fees—most jurisdictions charge between $500 and $1,200.

“Seeing the full cost breakdown helped us avoid surprises and stay on budget,” says a homeowner who recently added a station.

Ongoing Operational Costs

Once the station is live, you’ll see recurring expenses tied to energy use, routine filters and service checks. Here’s a quick overview:

- Electricity Usage: $200–$400 per year

- Filter Replacement: $50 every 6 months

- Annual Calibration: $300+

- Service Contracts: $500–$1,000 per year

In practice, a service contract covers preventive maintenance, sensor checks and emergency support. Locking in a multi-year agreement can shave up to 15% off your annual bill. If you’re weighing a mobile CNG delivery option—think Blue Gas Express—you’ll trade some fixed costs for per-fill charges priced similarly to public CNG stations.

Maintenance Strategies And Troubleshooting

A little prevention goes a long way. With a proactive maintenance plan, you can extend your equipment’s life by 20–30%. Start with these steps:

- Monthly Visual Inspections

- Check hoses and fittings for wear or leaks (a soapy-water test works wonders).

- Quarterly Safety Valve Tests

- Confirm emergency shut-off valves work instantly.

- Keep Detailed Logs

- Track replacements, repairs and unusual noises.

Simple Troubleshooting Steps

- Verify power supply and breaker status

- Check compressor oil level (if applicable)

- Inspect filters for clogging

- Test leak detectors and alarms

Maintenance Tips To Extend Equipment Life

- Keep everything clean and dry

- Replace consumables on schedule

- Lubricate bearings per manufacturer guidelines

- Store tanks within safe temperature ranges

Recording every service interaction not only prevents small issues from becoming big headaches, but it also strengthens your negotiating position when you renew service agreements.

Estimating Total Cost Of Ownership

Over a 5-year period, combining $1,000 per year in operating costs with an $8,000 initial investment, you can expect a payback window of about 4–5 years. That’s based on 30–50% fuel savings. Negotiating a 3-year service contract with a 10% discount, for example, cuts your annual fee to $450. Don’t forget to include performance guarantees and response-time clauses when you sign up. Bundling filter swaps and calibration checks can also save you administrative time and money.

By laying out every cost and implementing these maintenance strategies, you’ll maximize uptime, minimize unexpected repairs and lock in the fuel-cost benefits of home CNG refueling.

Comparing Permanent Installation And Mobile Delivery

Deciding whether to install a permanent CNG refueling station at home or rely on a mobile delivery service boils down to how often you’ll need fuel and how quickly you need access. A fixed station takes time: you’ll plan for site prep, permit applications, and utility inspections. On the other hand, a mobile unit can roll in within a day, skipping most of the upfront work.

Permanent setups lower your cost per Diesel Gallon Equivalent (DGE) over the long haul, but they demand an upfront capital outlay. Mobile delivery keeps you moving without major site work, though it comes with higher per-fill prices.

Installation Versus Delivery

A typical permanent CNG station runs between $8,000–$15,000, covering the compressor, storage tanks, and professional installation. You should budget 4–6 weeks for electrical upgrades, concrete pad pouring, and Authority Having Jurisdiction (AHJ) approvals.

In contrast, a mobile CNG unit from Blue Gas Express can arrive at your site in ≤24 hours. There’s no need for a concrete pad or dedicated power circuit—it’s all handled by the service provider.

Key Differences:

Lead Time

• Fixed Station: 4–6 weeks for permitting and setup

• Mobile Delivery: ≤24 hours from order to operationPer-Fill Pricing

• Fixed Station: $0.50–$0.80 per DGE

• Mobile Delivery: $1.00–$1.60 per DGESite Impact

• Fixed Station: Requires a garage bay or outdoor pad

• Mobile Delivery: No permanent footprint

Comparison Of Fixed Home Stations Versus Mobile Delivery

Below is a quick side-by-side look at the major factors that differentiate a permanent installation from mobile CNG delivery:

| Factor | Permanent Installation | Mobile Delivery Service |

|---|---|---|

| Installation Cost | $8,000–$15,000 | $0 initial, pay per fill |

| Deployment Time | 4–6 weeks | ≤24 hours |

| Space Requirement | Garage bay or outdoor pad needed | No on-site footprint |

| Regulatory Complexity | Multiple inspections, AHJ permits | Covered under utility service permits |

| Per-Fill Cost | $0.50–$0.80 per DGE | $1.00–$1.60 per DGE |

This table should help you weigh installation costs, timeline, space, permitting hurdles, and ongoing fuel pricing.

The chart below shows a side-by-side view of cost per fill and deployment timelines.

Case Studies

A regional delivery fleet averaged 100 miles of driving each day. Installing a home CNG station cut fueling costs by 30%, paying back its initial investment in under 18 months.

On a remote construction site, gas line hookups were delayed for weeks. Bringing in a mobile CNG unit from Blue Gas Express saved the project by supplying fuel within 48 hours, ensuring the backup generator ran without a hitch.

Steps To Decide:

- Assess annual mileage and total fuel volume

- Compare upfront capital with per-fill operating costs

- Match station lead times against project timelines

- Verify site readiness and local permit requirements

“Start by nailing down your fuel demand and schedule to avoid surprises later,” says a seasoned fleet manager.

Choosing Your Solution

Begin by plotting your daily or yearly mileage against the break-even point for a fixed station. Next, measure your available space for a compressor and tank bank. If you’re short on real estate or dealing with strict zoning, a mobile solution sidesteps those challenges.

Financially, compare the upfront capital of a permanent station against the variable per-fill charges of a delivery service. Generally,

- >12,000 miles/year often makes a fixed station worthwhile

- Short-term projects (<3 months) lean toward mobile delivery

- Limited space or strict codes favor a mobile unit

- Desire for the lowest per-DGE cost points to a home station

For a balanced approach, consider a small-scale compressor on-site with a mobile backup. You’ll capture cost savings while keeping an emergency fuel supply at the ready. Expert advice from Blue Gas Express can fine-tune your plan with accurate pricing and service terms.

Ultimately, your ideal choice aligns with your mileage, budget, and site constraints. Review these metrics, learn from the case studies, and select the option that fits your mission. The FAQ section below will answer common questions and outline the next steps.

Contact Blue Gas Express for a mobile CNG proposal or reach out to certified installers for a permanent station quote. Move forward with confidence.

Use Cases And Decision Checklist For Property Owners

When you’re weighing a home CNG refueling station, the smart move is to zero in on who benefits most right away.

- Daily commuters driving 80 to 120 miles per day enjoy big savings by filling up overnight.

- Small-fleet operators with 3 to 10 vehicles simplify routes and skip public pump queues.

- Contractors on remote sites swap out diesel deliveries for portable CNG skid units.

- Utilities hit by pipeline delays or outages keep systems running with fixed or mobile setups.

Daily Commuter Solutions

Imagine a driver covering 60 miles each way on a typical day. A compact 150 scfm compressor and two 120-gallon tanks slip neatly into a garage bay, delivering a full top-off in under two hours. That means no more weekend trips hunting for open pumps.

“Switching to home refueling boosted my weekends,” says a commuter in North Carolina.

- Dedicated pad or garage bay ensures a safe footprint

- 240 V 30 A circuit handles compressor power

- Licensed electrician and local permits get everything up to code

Small Fleet And Contractor Scenarios

A 5-vehicle delivery fleet putting in 250 miles daily can earn back installation costs in less than 2 years. Meanwhile, a contractor on a remote jobsite can deploy a mobile CNG skid in hours, sidestepping generator refuel delays altogether.

| User Type | Daily Miles | Ideal Setup |

|---|---|---|

| Delivery Fleet | 250 | 200 scfm compressor + 600 gal tanks |

| Contractor Site | 100 | Mobile skid + backup portable tank |

Decision Checklist Steps

Start by lining up your facts. These steps will steer you toward the right home CNG solution:

- Calculate your average daily mileage to size the compressor

- Measure available space in your garage or yard

- Set an upfront budget, including permit and installation fees

- Verify electrical capacity for a 240 V 30 A circuit

- Review local codes and prepare AHJ submittals early

- Choose between a permanent compressor or a mobile delivery service

- If annual miles > 12,000, a fixed station often pays off

- For short-term needs (< 3 months), mobile delivery cuts risk

Key Takeaway

Matching your driving patterns to the right setup keeps costs down over time.

Next Steps For Property Owners

Pull together a project timeline using the checklist above. Reach out to certified installers for quotes on permanent stations. Explore mobile options from Blue Gas Express for swift delivery and setup.

- Compare deployment lead times and per-fill costs

- Confirm permit timelines to avoid hold-ups

Once you settle on a design, submit your plans with clear site drawings. Store all approvals, test records and service logs in one digital folder for quick reference.

Property Owner Case Study

Homebuilder Sarah was logging 150 miles a day running community outreach events. She began with mobile CNG deliveries to skip permitting holdups. Four months later, she installed a 200 scfm compressor in her garage.

“The hybrid approach cut my fueling downtime by 70%.”

Within 14 months, Sarah hit her break-even point and now saves 45% on fuel. Phasing in a fixed station minimized her initial risk while locking in low per-DGE rates.

Best Practices For Home Stations

Think of your refueling setup like a household appliance—it needs regular care. Keep a digital log of each fill, inspection and service call. Look over hoses, valves and electrical connections every month for signs of wear.

- Schedule an annual pressure test and calibration with your installer

- Maintain clear access to all safety valves and controls

With these guidelines, you can compare options, map out budgets and move confidently toward cost-effective CNG fueling. Download the checklist and request a quote from Blue Gas Express today.

FAQ

Homeowners exploring a home CNG refueling station often have a pile of questions. This FAQ gathers real-world insights into clear, concise answers.

What Makes A Residential Compressor Different From A Public Pump?

A home unit taps directly into your gas meter, just as an EV charger plugs into your garage outlet. You control the environment—no open-air influences, no shifting fuel rates, and no waiting in line.

- Controlled environment cuts down on weather-related hiccups.

- Residential rates keep fuel costs predictable.

- Zero drive-through traffic or peak-hour queues.

By contrast, public stations juggle dozens of vehicles every hour and must meet high-speed throughput targets.

| Feature | Home Station | Public Pump |

|---|---|---|

| Cost per DGE | $0.50–$0.80 | $1.00–$1.60 |

| Availability | 24/7 At Your Location | Limited Hours |

| Site Control | Private And Enclosed | Open And Shared |

Installation costs for a typical home setup run $8,000–$15,000, covering permits, labor, and basic equipment. After that, expect $600–$1,200 a year for electricity and routine maintenance.

Common Certifications And Inspections

Most jurisdictions require NFPA 52 compliance plus approval from your local Authority Having Jurisdiction (AHJ). Routine checks generally include:

- Visual leak tests.

- Pressure relief device verifications.

- Control panel functionality.

Key Safety Certifications

Every station needs certified safety gear—automatic shutoff valves, overfill prevention systems, and more. Mandatory inspections typically occur at these stages:

- Pre-Commissioning: Final system walkthrough before first use.

- Quarterly: Safety valve performance tests.

- Annual: Full system pressure validation.

“Keeping your certifications up to date isn’t just red tape—it’s peace of mind,” says a certified installer.

Maintenance remains surprisingly straightforward. When something goes awry:

- Check the breaker and power connections.

- Inspect hoses and fittings for wear or leaks.

- Replace filters every six months.

- Test leak detectors monthly.

Logging each check helps you spot small issues before they become big problems. A few minutes of record-keeping extends your station’s lifespan and keeps downtime at bay.

Plan timelines in advance to smooth out permit approvals and equipment deliveries.

For reliable mobile CNG delivery or personalized guidance, contact Blue Gas Express today and keep your fuel supply on track.