A successful build isn't luck—it's the direct result of a meticulously crafted plan. You have to think of residential construction project scheduling less as a rigid document and more as a living roadmap that guides every single decision, from the first shovel in the ground to the final client walkthrough. A great schedule is what separates a profitable, smooth-running job from a chaotic money pit.

Why Your Project Schedule Is Your Most Critical Tool

Your construction schedule is the central nervous system of any home build. It dictates the flow of materials, labor, and cash, making sure every piece of the puzzle slots into place at exactly the right time. Without a strategic timeline, even the most experienced builders end up fighting fires, which inevitably leads to blown budgets and unhappy clients.

This plan is so much more than a simple list of dates. It’s an operational strategy that anticipates roadblocks and coordinates dozens of moving parts. To really grasp its power, it’s worth digging into the details of a comprehensive building construction schedule to see how that level of planning translates directly into on-site efficiency.

The True Cost of Poor Scheduling

When a schedule goes off the rails, the consequences cascade through the entire project. We’ve all seen it happen: the drywall crew shows up on Monday morning, ready to go, but the plumbing and electrical rough-in inspections failed. Now what? That crew is standing around, you're paying for their downtime, and the painters you booked for next week are completely thrown off.

This one hiccup creates a domino effect of expensive rescheduling, finger-pointing, and trade stacking.

A project schedule is the ultimate communication tool. It tells everyone involved—from the excavator to the electrician—what is expected of them and when, transforming a complex process into a coordinated effort.

Turning Chaos Into Control

On the flip side, a well-managed schedule provides total clarity and accountability. It becomes the single source of truth that gets the homeowner, your subs, and your suppliers all on the same page. By mapping out dependencies and building in a little buffer, you can navigate the immense pressures modern builders face every day.

This is especially critical when you're up against factors you can't control, like:

- Supply Chain Disruptions: A sudden backorder on windows or appliances can bring the whole job to a grinding halt for weeks.

- Utility Backlogs: Waiting on the utility company to set a meter or hook up a gas line is a notorious bottleneck that can hold up your final inspections and occupancy permit.

- Labor Shortages: A key subcontractor gets sick or overbooks themselves, and suddenly a critical phase of your project is dead in the water.

A solid schedule anticipates these risks. It uses a combination of smart digital tracking and agile, on-the-ground problem-solving to keep things moving forward, no matter what gets thrown at you. It’s how you stay in control.

Translating Blueprints Into An Actionable Timeline

Before a single nail is hammered, the most important work happens on paper, not on the job site. Architectural drawings are the dream, but they aren't a schedule. The real first step in building a house is meticulously translating those plans and the client contract into a detailed, sequential scope of work.

This is where you essentially deconstruct the entire build in reverse. Think of it like taking apart a complex machine to understand how every gear and wire connects. You'll break the project down from broad phases into the nitty-gritty, actionable tasks that can be assigned, tracked, and measured.

From Major Phases to Granular Tasks

You have to start big before you can go small. Outlining the major construction phases is the skeleton of your schedule. Every builder knows this rhythm by heart, but formally documenting it is what stops scope creep in its tracks and ensures nothing gets overlooked.

- Foundation and Sitework: This covers everything from digging the hole and pouring the concrete to getting the underground plumbing in place.

- Framing and Dry-In: This is where the house takes shape—floor systems, walls, roof trusses, sheathing, and finally, the windows and exterior doors that make it weathertight.

- Rough-Ins and Insulation: A make-or-break stage. This is when all the "guts" of the house—plumbing, HVAC ductwork, and electrical wiring—are run through the open walls before they're closed up forever.

- Interior Finishes: Now it starts to look like a home. Drywall goes up, paint goes on, and flooring, cabinets, and trim get installed.

- Final Finishes and Punch List: The home stretch involves installing light fixtures and appliances, passing all final inspections, and walking the client through to create the final to-do list.

Within each of these phases, you then have to list every single task. Under "Framing and Dry-In," you’re not just listing "frame the house." You’re listing "Install first-floor joists," "Frame exterior walls," "Set roof trusses," and "Install house wrap." This level of detail isn't optional; it's the only way to build a timeline that has a fighting chance of being accurate.

Mapping Dependencies: The Key to a Realistic Schedule

The single most common mistake I see in scheduling is failing to properly map dependencies—the relationships that dictate what has to happen before something else can start. You can't start drywall until your plumbing, electrical, and mechanical rough-in inspections have all passed. This isn't just a suggestion; it's a hard stop enforced by the building inspector.

Imagine your electrical contractor gets delayed by a week. This doesn't just push back the electrical final. It creates a domino effect that can cripple your timeline. The insulation crew can't start, which means the drywall team is sitting on their hands, which pushes back the painters, and so on down the line. A single missed dependency can easily add weeks and thousands of dollars in wasted labor costs to a project.

Building a schedule isn't about just listing tasks in order. It's about understanding how each task enables or blocks the next, creating a chain of events where a delay in one link can fracture the entire project.

This process has become more critical than ever. The construction landscape is incredibly volatile, a lesson driven home during the pandemic when residential construction activity in the U.S. exploded by 275% between March and July 2020. That boom exposed just how fragile our supply chains and labor pools really are, forcing builders to get good at adapting on the fly. These disruptions are still with us, with things as simple as a natural gas line delay halting occupancy permits for weeks—a massive headache for any builder. Smart project managers now plan for these external risks from day one. You can get more insight into these construction industry trends and what they mean for scheduling on toolsense.io.

Identifying And Tracking Critical Milestones

Once you start mapping out your tasks and their dependencies, your project's critical milestones will naturally emerge. These aren't just tasks; they're major checkpoints. They signify the completion of a huge chunk of work and often trigger a bank draw or a crucial city inspection.

Understanding these milestones is key to managing project flow. Below is a simple table that shows how key milestones are tied directly to the work that comes before them.

Key Project Milestones And Their Dependencies

| Milestone | Key Dependencies (Tasks to complete before) | Typical Impact of Delay |

|---|---|---|

| Foundation Inspection Passed | Footings poured, foundation walls formed and poured, anchor bolts set, drainage installed. | Delays the start of all vertical construction (framing). |

| Achieved "Dry-In" | Framing complete, roof installed, windows and exterior doors set, house wrap on. | Prevents all interior work (MEP, insulation) from starting, exposing materials to weather. |

| Rough-In Inspections Passed | All electrical, plumbing, and HVAC lines run, inspected, and approved by the city. | A hard stop. Drywall cannot be hung until all three inspections are cleared. |

| Certificate of Occupancy | All final inspections passed, utility meters set, all life-safety systems functional. | Prevents client move-in and final payment release. |

By translating your blueprints into this detailed, dependency-aware framework, you’re no longer just looking at a plan—you’re looking at a realistic, actionable timeline. This initial work is the true foundation upon which your entire project's success is built.

Orchestrating Your Trades For A Seamless Workflow

The real magic in residential construction scheduling isn't just making a list—it's mastering the intricate dance of subcontractors. Sequencing your trades is all about creating a logical flow where each crew perfectly sets the stage for the next. This carefully planned sequence is what we call the project's critical path, the series of dependent tasks that ultimately determines how long the build will take.

Getting this right is the difference between a job site that hums with activity and one bogged down by delays, rework, and frustration. A botched sequence means subs are tripping over each other, damaging finished work, and starting a domino effect of delays that can wreck your budget and timeline.

Expertly coordinating general trades is about thinking three steps ahead, always anticipating what the next crew needs before they even pull up to the site.

The Standard Sequence of Trades

While every custom home has its quirks, the basic order of operations follows a logic that’s been proven over decades. You build from the ground up and from the guts out, always making sure the structure is sealed from the weather before sensitive interior work can begin.

Here’s how it typically unfolds:

- Sitework and Foundation: It all starts with the dirt. This phase covers excavation, pouring the footings and foundation walls, and getting the underground plumbing (the "ground rough") in place before the slab is poured.

- Framing: Once the concrete cures, the framers show up and the house explodes into existence. This is where the skeleton—walls, floors, and roof system—takes shape with surprising speed.

- Dry-In: This is a huge milestone. We hit the dry-in stage when the framing is done and the exterior is sealed up tight with roof sheathing and covering, windows, exterior doors, and house wrap. The goal is to make the building weathertight so we can get to work inside.

- MEP Rough-In: With the interior protected, it’s time to install the home’s guts. This is a flurry of activity where plumbers, HVAC techs, and electricians run pipes, ductwork, and wires through all the open walls and ceilings. Close coordination here is non-negotiable.

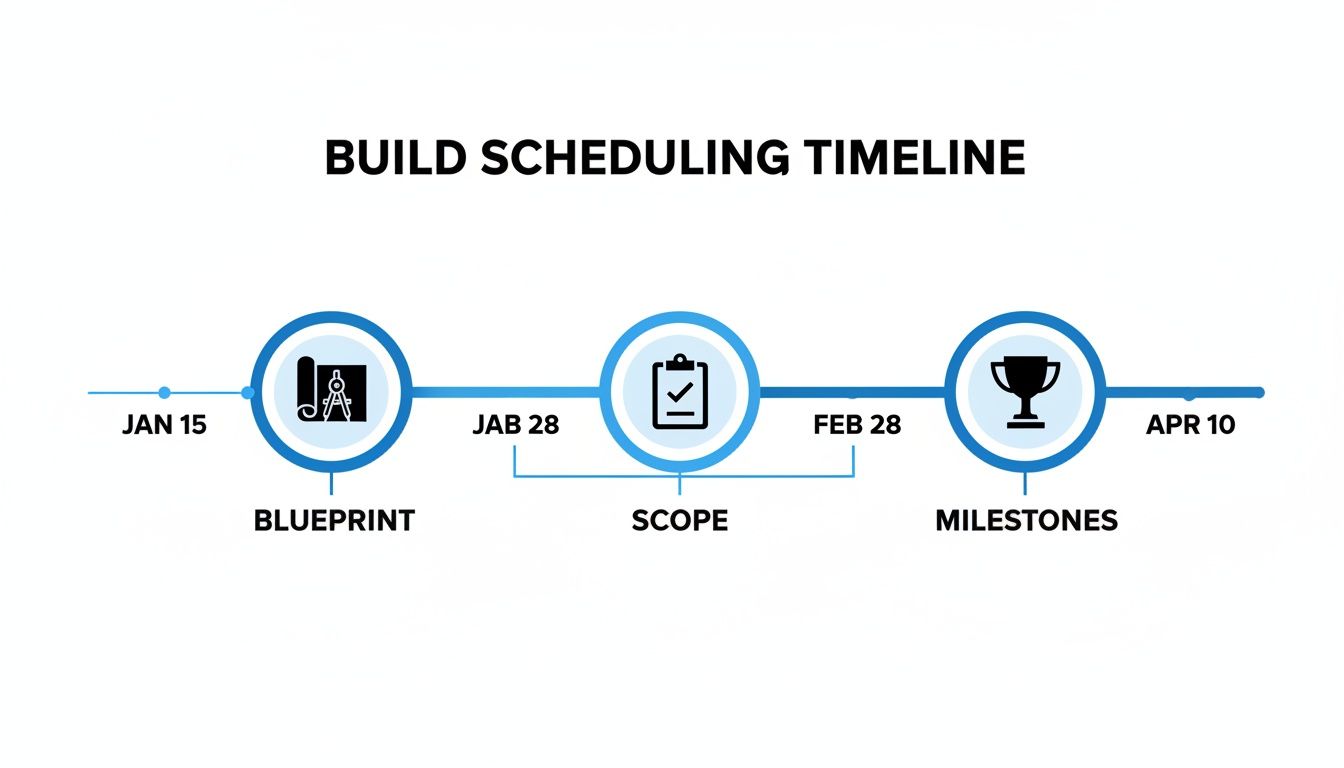

The timeline below shows how the initial planning stages—blueprinting, scoping, and setting milestones—are the foundation for the entire construction sequence.

As you can see, this early-stage strategy directly feeds into the on-site workflow, establishing clear checkpoints before the first nail is even hammered.

Optimizing The Workflow and Managing Overlap

Just listing trades in order is scheduling 101. Real pros find efficiency by strategically overlapping tasks without causing chaos. For instance, once the roof is on and the windows are in, you don't need to wait for the electrician to finish the entire house before the plumber can even start.

You can have the electrician wiring the second floor while the plumber is running PEX on the first. This is where a detailed schedule proves its worth, allowing you to run multiple rough-in trades at the same time by assigning them to different zones of the house. Done right, this can shave weeks off the timeline.

This kind of overlap, however, demands constant and clear communication. A quick daily huddle or a weekly scheduling meeting ensures everyone knows the plan and prevents crews from battling for space.

Pro Tip from the Field: Never, ever have drywall delivered until you have the signed-off inspection cards for plumbing, electrical, and mechanical in your hand. A failed inspection with a garage full of sheetrock is a logistical nightmare that stops all forward momentum.

Building In Buffer Time For The Unexpected

Let’s be honest: no construction schedule survives first contact with reality. Bad weather, a sick subcontractor, or a backordered appliance aren't just possibilities—they're eventualities. This is why building buffer time, or "float," into your schedule is absolutely critical.

But don't just tack two weeks onto the end of the project. A smarter approach is to sprinkle buffer days after high-risk milestones. Add a few days of float after the foundation is supposed to be done, since that’s a phase that’s notoriously at the mercy of the weather. Similarly, build in a cushion before your drywall hangers are scheduled to start, just in case an inspector throws you a curveball.

This gives you flexibility right where you're most likely to need it. It allows your schedule to absorb a minor delay without forcing you to re-sequence every single trade that follows, protecting both your timeline and your sanity.

Navigating Inspections And Utility Delays

Let's be honest: even the most carefully crafted schedule lives in the real world, not in a perfect bubble. A timeline that looks flawless on your laptop can get blown up in an instant by third parties who are definitely not on your clock. This is where the rubber really meets the road—weaving the unpredictable schedules of city inspectors and utility companies into your own.

Failing to build in buffers for these outside groups is one of the quickest ways to watch a project go off the rails. You can have the best crew in the state, but their work doesn't mean a thing until an inspector gives it the green light. You don't just finish a phase; you have to plan for the approval of that phase.

This means you absolutely must treat inspections as their own critical tasks with real time allotted to them. The minute you know the target completion date for a phase, someone should be on the phone with the building department.

Proactively Scheduling Key Inspections

In home building, you’ll face a series of mandatory inspections that basically act as gates. You can't move to the next stage until you pass. Just "getting the work done" and then calling for an inspection is a rookie move that can leave your crew sitting idle for days, sometimes even weeks.

You need to anticipate these major checkpoints and build them right into your schedule:

- Footing and Foundation: This is one of the first. It happens after you’ve dug the trenches and laid the rebar, but before a single drop of concrete is poured.

- Framing Inspection: This is a big one. The inspector walks the site to ensure the structural frame, sheathing, and bracing all match the approved plans before you can even think about insulation or drywall.

- Rough-In MEP Inspections: Before you close up the walls, separate inspectors for electrical, plumbing, and mechanical systems have to sign off on all the guts of the house—the wiring, pipes, and ductwork.

- Final Inspections: This is the last hurdle to clear before getting your Certificate of Occupancy. It's a comprehensive look to make sure the home is safe, complete, and built to code.

The trick is to get these inspections on the books well in advance by giving the city a target date. This gets you in their queue and cuts down the dead time between finishing the work and getting the official sign-off.

The Ultimate Schedule Killer: Utility Company Delays

While you can usually manage inspections with good planning, the notoriously slow timeline of utility hookups is often the final boss of project scheduling. It's a scenario every builder knows and dreads: the house is finished, cleaned, and ready for the homeowner, but you're stuck waiting weeks or even months for the local gas company to set a meter.

This isn't just a small snag; it’s a complete stop. Without that permanent gas line, you can't fire up the HVAC system, you can't test the kitchen appliances, and you can't heat the home for final finish work in the winter. Most importantly, you can't pass your final inspections and get the Certificate of Occupancy. That means the client can’t move in, and you can’t get paid.

A project that is 99% complete is 0% sellable. Waiting on a utility company can turn a profitable, on-time project into a cash-flow nightmare, with your capital tied up in a finished but unusable asset.

This is where being able to pivot and adapt your schedule becomes a massive competitive advantage.

Using Temporary Energy to Bypass Delays

Instead of letting your project grind to a halt while you wait for the utility company, you can take back control of your timeline. This is where a temporary energy solution, like mobile compressed natural gas (CNG), becomes an incredibly valuable tool in your arsenal.

Imagine the gas utility gives you the bad news: it'll be another six weeks before they can connect the permanent line. Your schedule is about to be completely torched. Instead of just accepting that crushing delay, you can bring a temporary gas source right to the job site.

Taking this proactive approach lets you:

- Commission the HVAC System: You can fire up the furnace and AC to prove they work, which is exactly what the mechanical inspector needs to see.

- Test All Gas Appliances: Get that stove, water heater, and fireplace running to ensure they’re operational for the final walkthrough.

- Secure Your Certificate of Occupancy: By showing that all systems are fully functional, you can pass your final inspections, get that C of O, and close out the project.

By strategically using a temporary solution from a provider like Blue Gas Express, you essentially pull the utility company's timeline right off your critical path. This agile move turns a potentially disastrous, multi-week delay into a manageable, one-day problem. You get to hand over the keys, get your final payment, and move on to the next job.

Building a Schedule That Bends, Not Breaks

Let's be honest: a perfect construction schedule is a unicorn. The minute you hit "print," the real world starts throwing curveballs. The real art of scheduling isn’t about creating a flawless plan from the get-go; it's about building an agile one that can take a punch from material shortages, labor no-shows, and crazy weather without falling apart.

This requires a mental shift. Don't think of your schedule as a fragile document set in stone. Treat it as a living, breathing framework for navigating the chaos. A truly resilient schedule anticipates problems and has contingency plans already worked into its DNA. This way, you're adapting and overcoming, not just reacting and getting derailed.

Spotting Trouble Before It Starts

The best way to handle a problem is to see it coming a mile away. This means actively looking down the road at every phase and asking, "What's the most likely thing to go wrong here?"

This isn’t about vague worrying. It's about a specific, brutally honest assessment of your project's weak spots.

- Materials: What items have notoriously long lead times or are subject to supply chain drama? Think windows, custom cabinets, and certain high-end appliances. Those are your usual suspects.

- Labor: Is your go-to plumbing sub stretched thin across three other jobs? What's the backup plan if half your framing crew calls in sick during a critical push?

- The Uncontrollables: Are you building during hurricane season? Is there a huge local festival that's going to snarl traffic and delay deliveries for a week? And the big one: are the local utility companies famous for taking their sweet time?

Once you've identified a risk, you have to weigh its impact. A single rain day is an annoyance. But a six-week delay on the natural gas hookup? That's a potential project-killer that can stop you from getting your Certificate of Occupancy and your final payment.

A resilient schedule is built around what's probable, not just what's planned. It's about turning those "what if" scenarios into practical "if this, then that" strategies that keep the job moving forward.

Weaving In "Float" for High-Risk Tasks

This is where you bake flexibility right into your timeline. "Float" or "buffer" time is just a strategic cushion you add to the tasks most likely to get delayed. But don't just tack a few weeks onto the end of the project and call it a day. Embed that buffer time right where you anticipate needing it most.

Here’s a classic example: MEP rough-in is done, and inspections are next. You're now at the mercy of an outside party—the inspector. A smart schedule builds in three to five days of float right after the rough-in is supposed to be finished. That buffer can absorb a failed inspection or a backed-up city official's calendar without immediately torching your drywall, taping, and painting schedule.

How to React When Delays Hit Anyway

Even with the best-laid plans, things go sideways. How you respond is what separates the pros from the amateurs. It’s all about quick assessment and decisive action. Let’s go back to that all-too-common natural gas delay scenario:

- Identify the Risk: The utility company just told you the gas line connection is now six weeks out.

- Assess the Impact: You know this means no HVAC commissioning, no appliance testing, and no final inspections. In short, no Certificate of Occupancy.

- Implement the Solution: Instead of just waiting and bleeding money, you pivot. You bring in a temporary CNG service. In as little as 24-48 hours, you have a gas source on-site, which means you can finish all your tests and pass your inspections.

That kind of agile response turns a catastrophic delay into a manageable logistical hurdle. This is where having the right tools and services in your back pocket is a game-changer. The global market for construction scheduling software was valued at $2.5 billion in 2023 for a reason—it gives you the visibility to manage these moving parts. When you pair good software with on-the-ground solutions like temporary energy, you create a powerful system for keeping momentum. You can dive deeper into the construction scheduling software market on dataintelo.com to see how these tools are evolving.

Questions We Hear All the Time About Construction Schedules

Even with a perfect plan on paper, the real world of residential construction always throws a few curveballs. On just about every job site, I see builders and project managers wrestling with the same handful of scheduling headaches that can stall a project and blow up a budget.

Getting straight, practical answers to these questions is what separates a smooth, profitable build from one that’s stuck in a cycle of delays. Let's dig into the big ones.

What's the Single Biggest Scheduling Mistake?

Hands down, the most destructive mistake I see is failing to account for things you can't control. This isn't about underestimating how long it takes to frame a house; it's about being wildly optimistic about timelines for outside groups.

There are two usual suspects here:

- Permitting and Inspections: You might wrap up your electrical rough-in on Tuesday, but that doesn't guarantee the city inspector shows up on Wednesday. Assuming a next-day sign-off is a classic rookie mistake. A backlog at the permit office can leave your crew sitting around for days, which means the insulation and drywall guys get pushed back, and so on down the line.

- Utility Companies: This one is the real project-killer. It’s shockingly common for a house to be 100% finished—I'm talking final paint touch-ups, floors sparkling, ready for the homeowner—but it's stuck in limbo for weeks waiting for the gas company to set a meter. This one dependency can hold your Certificate of Occupancy hostage, which freezes your final payment and leaves you with a furious client.

The only way to handle this is to treat these outside approvals as major milestones in your schedule. You have to build in realistic buffers and always have a Plan B, especially for that final utility hookup.

How Much Buffer Time Is Enough?

Adding a buffer, or "float," to your schedule is non-negotiable, but there's a right way and a wrong way to do it. The common approach is to just tack on a couple of weeks to the end of the project. It feels safe, but it's lazy scheduling because it doesn't protect you from the specific delays that are most likely to happen.

A much sharper strategy is to add your buffer right after the high-risk phases. Don't just pad the finish date; analyze your schedule and identify the spots where a delay would cause the most chaos.

Instead of one big buffer at the very end, think about sprinkling smaller, targeted buffers throughout the schedule. For example, adding three to five days of float after your MEP (mechanical, electrical, plumbing) rough-ins are scheduled to be done gives you a critical cushion before drywall starts. That small buffer can absorb an inspection delay without derailing the entire back half of the project.

You could also try a percentage-based approach. If you're pouring a foundation during a rainy spring, maybe add a 10-15% time buffer just for that phase. For interior trim work, where things are more predictable, a smaller 5% buffer might be all you need. This way, you’re putting flexibility exactly where you need it most.

Is Scheduling Software Overkill for a Small Builder?

I get this question a lot. If you're a small builder juggling just a couple of projects, paying for fancy scheduling software can feel like buying a sledgehammer to crack a nut. A whiteboard or an Excel sheet seems good enough, right? Maybe, but you'd be missing out on three huge advantages that directly protect your profit margins.

First, you get crystal-clear visibility. With good software, everyone from your excavator to your painter is looking at the exact same plan, updated in real time. This single source of truth kills the endless "Are we still on for Tuesday?" phone calls and stops expensive miscommunications before they happen.

Second, it drives communication and accountability. A sub is running behind? You can adjust the schedule in seconds, and every trade contractor affected by that change gets notified automatically. It creates a clear record of who was supposed to do what and when, which really cuts down on the finger-pointing.

Finally, it makes you look like a true professional. When you sit down with a client or a lender and show them a clean, professional Gantt chart instead of a crumpled, handwritten list, it builds instant confidence. It tells them you're organized and in control. For a smaller company, that professional image is a massive competitive edge.

Don't let utility hookup delays kill your project momentum and your bottom line. When you're told the permanent gas line is weeks out, Blue Gas Express can have a temporary solution on-site within hours, keeping your schedule moving. Find out how we help you pass inspections and secure your Certificate of Occupancy without the wait at https://bluegasexpress.com.