Getting fossil fuels from the ground to the end-user is a massive global undertaking. It's a complex dance of pipelines, supertankers, railways, and trucks that acts as the circulatory system for the modern economy, moving oil, natural gas, and coal to the power plants, factories, and homes that depend on them. This entire process relies on incredible infrastructure and ironclad safety protocols to manage the risks that come with the territory.

The Unseen Network Powering Our World

It helps to think of the global energy grid like a circulatory system. The fossil fuels are the lifeblood, and the methods for transporting fossil fuels are the arteries that keep our industrial world pumping. While we hear a lot about the growth of renewables, the reality is that these traditional fuels are still the bedrock of daily operations for countless businesses.

Whether it’s firing up heavy machinery on a remote construction site or keeping a commercial building warm in the winter, the need for a steady, reliable energy supply is non-negotiable. But getting that energy from its source to where it's needed is a logistical puzzle of epic proportions. We're talking about moving staggering volumes across continents and oceans, often through some of the world's most challenging environments.

The Scale of the Challenge

Moving energy isn't as simple as just filling up a tank and hitting the road. The entire operation is wrapped in a thick layer of regulations, safety standards, and geopolitical tensions that can change at a moment's notice. A single disruption in one corner of the globe can send shockwaves through the entire supply chain, affecting prices and availability thousands of miles away.

Just look at the core challenges involved:

- Vast Distances: Energy sources are rarely next door to the cities and industries that need them. This means thousands of miles of pipelines have to be laid, or tankers must embark on multi-week voyages.

- Regulatory Hurdles: Every country, state, and even municipality has its own rulebook for environmental and safety compliance. Navigating this maze without a misstep is critical to avoiding serious legal and financial trouble.

- Safety and Security: The materials themselves are often volatile. Transporting them safely requires specialized containment, meticulously maintained equipment, and highly skilled crews who know exactly what they're doing.

This intricate network is a marvel of modern engineering and planning, but its complexity is also its weakness. When just one link in that long chain fails—whether it’s a pipeline rupture, a bad storm at sea, or scheduled maintenance—the impact on the end-user can be sudden and severe.

Why Flexible Solutions Are Essential

This dependence on a rigid, large-scale system creates some obvious gaps. For instance, what do you do when a new factory is ready to open but the permanent gas line is still six months from completion? Or when a utility company has to take a primary pipeline offline for critical repairs, threatening service to thousands?

In these all-too-common scenarios, the traditional ways of transporting fossil fuels just don't cut it. They're too slow and inflexible, leading to expensive downtime and project delays.

This is exactly where more agile, modern solutions come into play. Mobile energy delivery acts as a vital stopgap, a "bridge" that ensures businesses can keep running when permanent infrastructure is either not ready or temporarily out of commission. By understanding the basics of this global energy network, it becomes much clearer why having adaptable, on-demand delivery options is so important for keeping the lights on.

How Are Fossil Fuels Transported?

Getting fossil fuels from a well deep in the ground to the places where we actually use them is a massive logistical puzzle. The way we move this energy depends entirely on what kind of fuel it is, how far it needs to go, and the terrain it has to cross. It’s not a one-size-fits-all operation; it’s a complex network with a few key players.

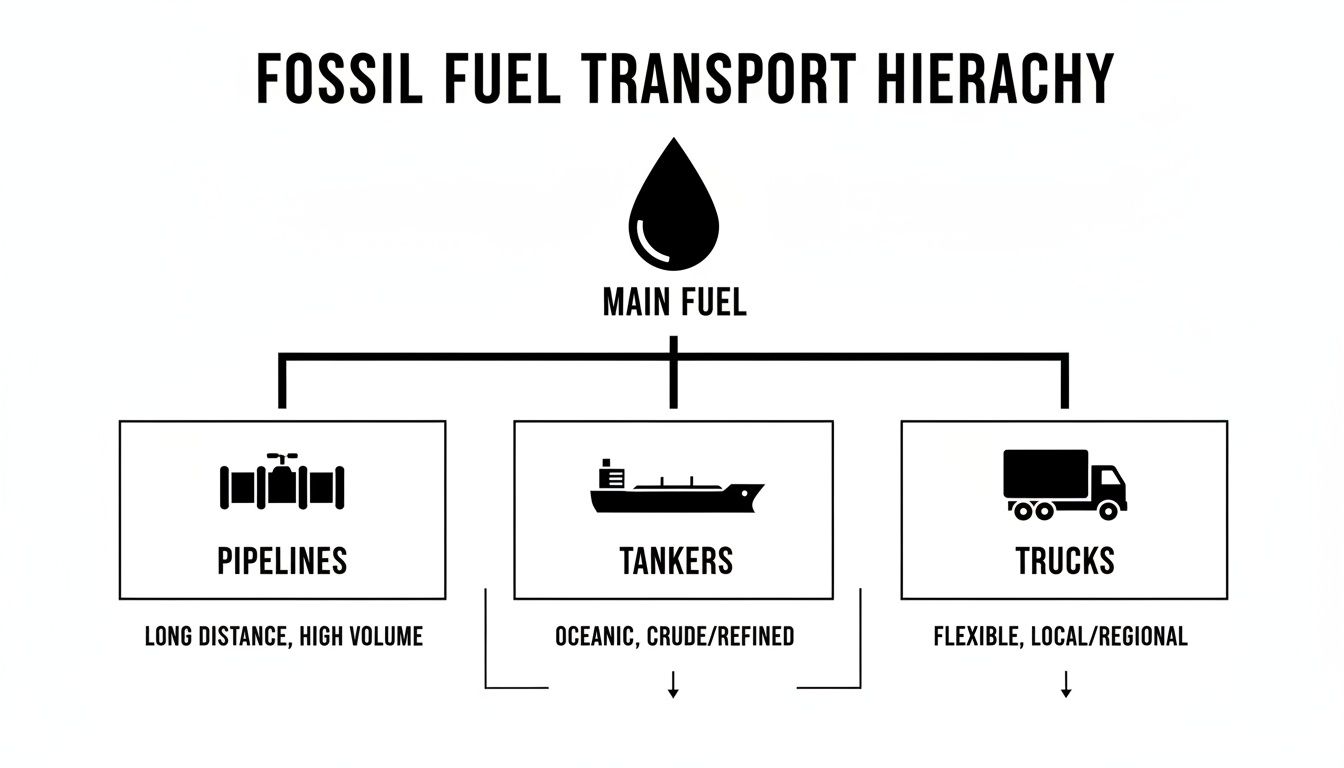

At its core, this network boils down to three main transportation modes: pipelines, massive ocean-going tankers, and the ground crew of trains and trucks. Each one has its own job, its own strengths, and its own set of challenges, from shipping enormous volumes across continents to making pinpoint deliveries to a single job site.

Pipelines: The Interstate Highways of Energy

Pipelines are the real workhorses of the energy world. They are the arteries that carry incredible volumes of crude oil and natural gas across vast stretches of land. For sheer efficiency and cost-effectiveness over long distances, nothing beats a pipeline. A single large-diameter pipeline, for instance, can move well over a million barrels of oil every single day.

Think of the pipeline network as the interstate highway system for fuel. It provides a direct, non-stop route from the major production fields to refineries and big distribution centers. Just like our highways support a constant flow of trucks, pipelines support a constant flow of energy for high-demand areas.

But their biggest advantage—being a fixed, permanent structure—is also their biggest weakness. Once a pipeline is in the ground, that's it. The route is set. The upfront cost to build one is staggering, and the planning can take years. This makes them completely impractical for getting fuel to a remote community or powering a temporary construction project.

Maritime Tankers: The Global Cargo Ships

When fuel needs to cross an ocean, we turn to maritime tankers. These are the colossal cargo ships of the energy industry, connecting the world’s supply and demand. Tankers are absolutely essential for moving crude oil from production powerhouses like the Middle East to energy-hungry markets in Europe, Asia, and North America.

They're also the only way to move liquefied natural gas (LNG) on a global scale. To do this, natural gas is chilled to a mind-boggling -260°F (-162°C). This process turns it into a liquid that takes up 600 times less space than its gaseous form, allowing an incredible amount of energy to be shipped safely on a single vessel.

The scale of these operations is hard to wrap your head around. The world's largest supertankers can haul over 2 million barrels of crude oil in a single trip. They are floating giants that play a critical role in keeping the global economy running.

Of course, tankers can't do the job alone. They're just one link in a much longer chain. They need specialized ports to load and unload their cargo and rely on pipelines, trains, and trucks to get the fuel inland to its final destination.

Rail and Trucking: The Last-Mile Delivery Network

This is where trains and trucks come in. They’re the final, most nimble piece of the transportation puzzle. If pipelines are the highways and tankers are the ocean freighters, then rail and trucking are the local delivery fleet. They are what make it possible to get fuel to the specific places that need it, especially those far from a pipeline.

Rail is a great middle-ground option. It’s often used to haul coal and large amounts of crude oil through areas where there are no pipelines, offering a good mix of high capacity and route flexibility.

Trucking, though, is the ultimate "last-mile" solution. Tanker trucks deliver gasoline, diesel, and natural gas right to the pump, to an industrial plant, or to a remote construction site. Their agility is what makes our energy supply chain so resilient, allowing them to bring fuel to temporary operations or hard-to-reach locations where building permanent infrastructure just doesn't make sense.

Here’s a quick breakdown of how these methods stack up against each other.

Comparing Fossil Fuel Transportation Methods

This table offers a quick comparison of the primary methods for transporting fossil fuels, highlighting their key characteristics.

| Method | Primary Fuel Type | Best For | Capacity | Relative Cost | Flexibility |

|---|---|---|---|---|---|

| Pipelines | Crude Oil, Natural Gas | Long-distance, high-volume overland transport | Very High | Low (per unit) | Low |

| Maritime Tankers | Crude Oil, LNG | Intercontinental, cross-ocean transport | Highest | Moderate | Moderate |

| Rail & Trucking | Coal, Crude Oil, Refined Products, CNG/LNG | Last-mile delivery, remote locations | Varies (Low-High) | High (per unit) | Very High |

As you can see, each mode has a distinct role. While pipelines and tankers are built for massive scale, it's the flexibility of rail and trucking that ensures energy can be delivered precisely where and when it's needed.

Navigating Environmental and Operational Risks

The global network that moves fossil fuels is an engineering marvel, but it’s also riddled with serious challenges. When you're transporting volatile materials across entire continents and oceans, the environmental and operational risks are immense. These aren't just theoretical problems on a spreadsheet; they are real-world threats that demand constant vigilance and ironclad safety protocols from everyone in the supply chain.

Think about the journey from a wellhead to a power plant. It's a long and perilous one, fraught with potential spills, aging infrastructure, and countless other hurdles. Getting a handle on these risks is the first step to truly appreciating the monumental effort required to keep our energy supply safe and reliable.

This diagram breaks down the main ways we move fossil fuels, from the massive pipelines and tankers down to the trucks that make the final delivery.

Each of these methods comes with its own unique set of risks, and managing them is crucial to preventing environmental disasters and operational chaos.

The Environmental Stakes

The risk everyone thinks of first is an oil spill. It’s the most visible and often the most devastating. A tanker accident at sea or a pipeline rupture on land can unleash a torrent of crude oil that poisons ecosystems, kills wildlife, and pollutes water sources for decades. The cleanup is a gargantuan task—expensive, difficult, and rarely 100% effective.

But there are quieter, less visible threats that are just as serious. Methane leaks from natural gas infrastructure are a perfect example. Methane is a brutally potent greenhouse gas, with over 80 times the warming power of carbon dioxide over a 20-year window. These "fugitive emissions" seep out from tiny cracks in pipelines, faulty valves, and during transfer operations, silently contributing to climate change.

Beyond spills and leaks, the simple act of transportation has its own carbon footprint. The ships, trains, and trucks that haul these fuels are burning fuel themselves. This adds another layer of emissions and complicates the total energy lifecycle.

Transportation emissions are a massive piece of the global puzzle. In March 2025 alone, the sector was responsible for 761.64 million tonnes of CO2 equivalent. On an annual basis, transportation accounts for nearly a quarter of all energy-related CO2 emissions, a stark reminder of its significant environmental toll.

Operational and Logistical Hurdles

Beyond the direct environmental impact, there's a whole other category of operational headaches that can bring the entire supply chain to a grinding halt. These risks are less about spills and more about the tough, practical realities of keeping a massive, aging, and geographically sprawling infrastructure network running.

Here are a few of the big ones:

- Infrastructure Maintenance: Pipelines corrode. Pumping stations fail. Tankers need constant, expensive upkeep. The sheer scale of this system means that just keeping it from falling apart is a relentless battle against time and the elements. If maintenance is neglected, the results can be catastrophic.

- Geopolitical Instability: A huge portion of the world's fossil fuels passes through politically volatile regions. A regional conflict, a sudden trade embargo, or an act of sabotage can instantly sever a critical supply line, causing price shocks and energy shortages thousands of miles away.

- Regulatory Compliance: The rulebook for transporting hazardous materials is a labyrinth. It’s dense, complex, and always changing. Companies have to navigate a maze of local, national, and international laws. One mistake—one missed compliance check—can lead to crippling fines, legal battles, and a complete shutdown of operations.

A key part of navigating this is having a solid plan for effective Hazmat waste management. This isn't just about the fuel itself, but also about ensuring any hazardous byproducts are handled with the utmost care.

Ultimately, staying on top of these operational risks requires a proactive mindset, not a reactive one. It means pouring money into pipeline inspection tech, investing in crew training, and building robust security to protect these vital energy arteries. By tackling these challenges head-on, the industry strives to make the process of transporting fossil fuels as safe and reliable as humanly possible.

Why Natural Gas Logistics Are Unique

While moving crude oil or coal has its own set of challenges, getting natural gas from point A to point B is a completely different kind of puzzle. In its natural state, it’s a gas. That means it wants to expand and fill whatever space it’s in, which makes it wildly inefficient to transport. It’s like trying to ship a massive, fluffy cloud—it just isn't practical.

To make moving this critical fuel source even remotely feasible, we have to shrink its volume. A lot. This is where the industry gets clever, using two primary techniques: compression and liquefaction. Each one solves the volume problem in a different way, turning what would be a logistical nightmare into a well-oiled operation.

Think of it like making juice from concentrate. You don’t ship truckloads of water with a little bit of flavor; you take the water out first. That leaves you with a much smaller, denser product that’s easy to handle. Natural gas logistics work on a similar principle.

The Power of Compression and Liquefaction

First up is Compressed Natural Gas (CNG). By pressurizing natural gas to a whopping 3,600 psi, its volume shrinks to less than 1% of what it would be at normal atmospheric pressure. This makes it dense enough to be safely stored in specialized high-pressure tanks and moved around on trucks.

The second method is more intense but also more effective: creating Liquefied Natural Gas (LNG). This involves chilling the gas down to a mind-bogglingly cold -260°F (-162°C). At that temperature, it becomes a clear, colorless liquid that takes up 600 times less space than it does as a gas. This incredible density is what makes LNG the only practical way to ship natural gas across oceans in massive tankers.

Both CNG and LNG are the same core product—natural gas—just in different physical states. The choice between them really boils down to how far the gas needs to go and how much of it is needed. CNG is perfect for shorter, regional trips, while LNG is the global standard for long-haul shipping.

Of course, neither of these processes is simple. They both demand a serious investment in highly specialized infrastructure.

- LNG Facilities: To produce and use LNG, you need a liquefaction plant at the source to super-cool the gas and a regasification terminal at the destination to warm it back into a usable state.

- CNG Stations: For CNG, you need a whole network of compression stations to pressurize the gas before it can be transported and distributed.

This specialized equipment really underscores the unique challenges that come with moving this particular fossil fuel.

Bridging the Infrastructure Gap

Demand for natural gas is booming everywhere—from construction sites and industrial plants to utility providers. The problem is, building permanent pipelines to meet that demand is a monumental task. It's incredibly expensive, often running into millions of dollars per mile, and projects can get bogged down for years in permitting and construction.

This creates a huge logistical gap. A new housing development might be completely finished, but the permanent gas line is still months away from being connected. A factory might want to switch to cleaner-burning natural gas, but it’s located miles from the nearest pipeline.

This is where the unique properties of CNG and LNG become so valuable. The global transport sector is still heavily reliant on fossil fuels, with trucks and buses being 96% dependent on them. That breaks down to 81% diesel, 11% gasoline, and 3% natural gas. While small, that 3% shows the important role natural gas plays as a cleaner alternative, and mobile solutions are key to making it more accessible. For a closer look, you can find more information about energy use in transportation.

By loading CNG or LNG onto trucks, energy providers can create a "mobile pipeline." It’s a flexible, immediate solution that brings the fuel directly to where it’s needed, completely bypassing the long waits and high costs of permanent infrastructure.

Solving Logistical Gaps with Mobile Natural Gas

Permanent infrastructure for transporting fossil fuels, like pipelines, is a massive undertaking—a huge investment of both time and money. But what happens when that infrastructure just isn't there? What if a pipeline is down for maintenance, or a new construction site is miles from the nearest gas main?

This is a more common—and costly—problem than you might think. A construction manager could be facing thousands in daily penalties because a new building can’t get its certificate of occupancy without a live gas connection. An industrial plant manager might be staring down a complete shutdown during a scheduled pipeline repair, grinding production to a halt.

In these situations, just waiting around isn't an option. This is exactly where mobile natural gas delivery systems—often called a "pipeline on wheels"—come in to save the day. Think of them as large-scale mobile power banks, delivering a reliable, temporary supply of CNG or LNG precisely when and where it's needed most.

A Practical Solution for Project Continuity

Let's walk through a real-world scenario. Imagine you're managing a large commercial building project. Everything is on schedule, but then you get the call: the local utility says connecting the permanent gas line will be delayed by three months.

Without gas, you can't commission the HVAC systems, test the backup generators, or even provide temporary heat for the crews working on interior finishes during the cold season. Every single day of delay means paying for idle workers and equipment, pushing you closer to missing critical deadlines.

Mobile natural gas delivery completely changes this equation. A specialized truck carrying CNG or LNG can be sent directly to your site, often within hours. This temporary supply connects right into your project’s existing gas plumbing, and just like that, your project is back on track.

This is what makes mobile natural gas a strategic tool for anyone managing a project or facility. It’s not just about getting energy; it’s about maintaining momentum and avoiding the catastrophic financial losses that come with downtime.

A "pipeline on wheels" is more than just a temporary fix. It's a logistical bridge that ensures operational continuity when permanent infrastructure is delayed, disrupted, or simply doesn't exist yet.

Key Applications and Benefits

Mobile natural gas delivery is incredibly versatile, stepping in to solve a whole range of logistical headaches across different industries. The ability to provide an immediate, reliable energy source makes it a game-changer in several key situations.

Here are some of the most common applications:

- Construction and Development: It provides temporary heat for curing concrete, drying out materials, and letting interior work continue through the winter. It’s also crucial for commissioning gas-powered equipment and, most importantly, securing final occupancy permits before the permanent utility hookup is ready.

- Utility Pipeline Maintenance: When a section of pipeline needs to be taken offline for repairs, mobile units can "bypass" the outage. This ensures homes and businesses never lose service, preventing widespread disruption.

- Industrial Plant Operations: For factories that depend on a constant supply of natural gas, any interruption is a disaster. Mobile delivery can act as a primary or backup fuel source during planned maintenance or unexpected emergencies, keeping the production lines humming.

- Emergency Response: After natural disasters damage pipelines, mobile gas units can be deployed quickly to power critical facilities like hospitals, shelters, and emergency command centers.

The biggest benefit across the board is the avoidance of costly downtime. The expense of a temporary gas supply is almost always a fraction of what a single day of a full-scale shutdown would cost. By bridging the gap, mobile natural gas keeps projects on schedule, maintains factory output, and ensures communities have the energy they need when it matters most.

When we look at the future of energy logistics, it's clear things are changing. While the world is rightly talking more and more about renewables, the vast, complex system for transporting fossil fuels is still what powers our daily lives. The future isn't about an overnight switch; it’s about making our energy grid smarter and more resilient—a true hybrid system.

This new approach will need to blend the old with the new. We’ll still rely on massive, permanent infrastructure like pipelines and LNG terminals to move the bulk of the world's energy for years to come. But these systems are rigid, and that rigidity creates gaps—gaps that demand faster, more tactical solutions.

Embracing a Hybrid Energy Model

A truly reliable energy future hinges on combining the raw power of large-scale infrastructure with the agility of mobile delivery. This strategy gives us the stability we count on while also providing the flexibility to handle short-term hiccups and changing demands. It’s a practical way to support what we need today while preparing for what comes next.

You can already see this playing out in global investment trends. In 2024, a mind-boggling USD 757.4 billion was invested in electrified transport, a clear sign of the push to modernize. Even with that massive investment, fossil fuels are still the main energy source for the transportation sector, which just goes to show how critical safe and effective logistics remain. You can dive deeper into these global trends in transport energy investment.

The future of energy transportation isn't a choice between fossil fuels and renewables, but an integration of both. Success will depend on creating a system that is robust enough for today and flexible enough for tomorrow.

Preparing for Evolving Demands

At the end of the day, the goal is an energy network that’s both powerful and adaptable. For anyone managing a construction site, running a utility, or leading an industrial operation, this means looking at modern solutions that can fill those logistical gaps. In a world full of unexpected delays and dynamic project needs, relying only on permanent infrastructure just isn't going to cut it anymore.

By bringing in flexible options like mobile natural gas, companies can protect their operations from disruption, keep projects on track, and stay competitive. This isn't just about putting out today's fires—it's about building the kind of resilience needed to meet the energy challenges of the future head-on.

Your Questions About Fossil Fuel Transport, Answered

When you're dealing with fossil fuel logistics, a lot of questions pop up, especially when you need a temporary fix for a project. Let's walk through some of the common things people ask about the safety, speed, and cost of moving these fuels, particularly when it comes to mobile natural gas services.

What Kind of Safety Rules Govern Natural Gas Transport?

Moving natural gas, whether as Compressed Natural Gas (CNG) or Liquefied Natural Gas (LNG), isn't a free-for-all. It’s a tightly regulated field, with agencies like the Department of Transportation (DOT) setting the rules. These aren't just guidelines; they're strict requirements covering everything from the design of the trucks and tanks to specialized driver training and what to do in an emergency.

For any mobile delivery, the vehicles themselves have to meet some pretty tough safety standards for their pressurized containers. On top of that, every single operator and technician handling the gas must be certified for hazardous materials. Any provider worth their salt will follow all federal and state regulations to the letter, ensuring safety from the moment they leave their facility to the time they're set up on your site.

Safety isn't just a priority in mobile gas delivery; it's the entire foundation. The whole system is built on solid engineering, strict regulatory compliance, and intensive training. This ensures that a temporary energy solution is also a profoundly safe one.

How Fast Can You Get a Mobile Gas Unit on Site?

This is where mobile solutions really shine. In many situations, a temporary CNG or LNG unit can be on your project site within hours of the call. That kind of rapid response is a game-changer during emergencies, like an unexpected pipeline shutdown, or for projects where every minute of delay costs a fortune.

The whole deployment process is built for speed without sacrificing safety. It starts with a quick site assessment to find the best and safest spot for the equipment. Once that's sorted, certified technicians bring in the mobile unit, get it connected, and get your gas flowing again, helping you sidestep those costly work stoppages.

Is Mobile Natural Gas Actually a Cost-Effective Choice?

It's true there's a cost for the service, but you have to weigh it against the alternative: shutting down the entire project. The financial hit from a construction or industrial delay can be massive. Think about the daily costs piling up from crew wages, idle equipment rentals, and the penalties for blowing past a deadline.

A temporary gas supply keeps the essential work moving forward. This is crucial for things like:

- Firing up generators and other big pieces of equipment for the first time.

- Running temporary heaters to protect materials or keep crews productive in the cold.

- Getting that final certificate of occupancy so a building can open for business on time.

When you look at the huge financial drain a work stoppage causes, bringing in a mobile natural gas solution is a smart, strategic move to protect your schedule and your bottom line. It's a practical way to keep things on track.

When pipeline delays or outages threaten to bring your project to a standstill, don't let it happen. Blue Gas Express delivers fast, reliable, and safe mobile natural gas solutions to keep your operations running. You can learn more and get a quote on their website.