Imagine having your own private gas pump right in your garage. That's essentially what a home CNG filling station is. It’s a compact appliance that hooks up to your home's natural gas line, letting you refuel your Natural Gas Vehicle (NGV) while you sleep. You're using the same low-cost energy that runs your furnace and water heater to power your car.

How a Home CNG Filling Station Works

The best way to think about a home CNG station is like a supercharged air compressor, but designed specifically for natural gas. It takes the low-pressure gas from your utility line and, over several hours, concentrates it into high-pressure fuel ready for your vehicle. It’s a process that makes refueling at home surprisingly simple.

The unit connects directly to your existing natural gas plumbing, sipping a small, steady amount of gas. This is the same gas that fuels your stove, but it’s at a pressure that’s way too low to do anything for a car on its own.

The Compression Cycle

At the heart of the system is a multi-stage compressor. This is the workhorse that methodically boosts the gas pressure from the 0.25 PSI (pounds per square inch) in your home's pipes all the way up to 3,000 to 3,600 PSI—the pressure your vehicle's tank needs. This slow-and-steady compression, usually done overnight, is what makes the system so efficient and prevents it from putting any real strain on your utility service.

But before the gas is fully compressed, it goes through a crucial dehydration step. A dryer unit inside the station strips out any water vapor from the natural gas. This might seem like a small detail, but it’s critical for a couple of reasons:

- It Prevents Corrosion: Keeping moisture out protects your vehicle's fuel tank and engine parts from rusting from the inside out.

- It Avoids Freezing: In colder climates, any trapped moisture in high-pressure lines or fittings could freeze solid, causing a blockage or damage.

After being compressed and dried, the CNG is ready. It flows through a specialized dispensing hose and into your vehicle’s fuel tank, with the whole operation being fully automated and built around safety.

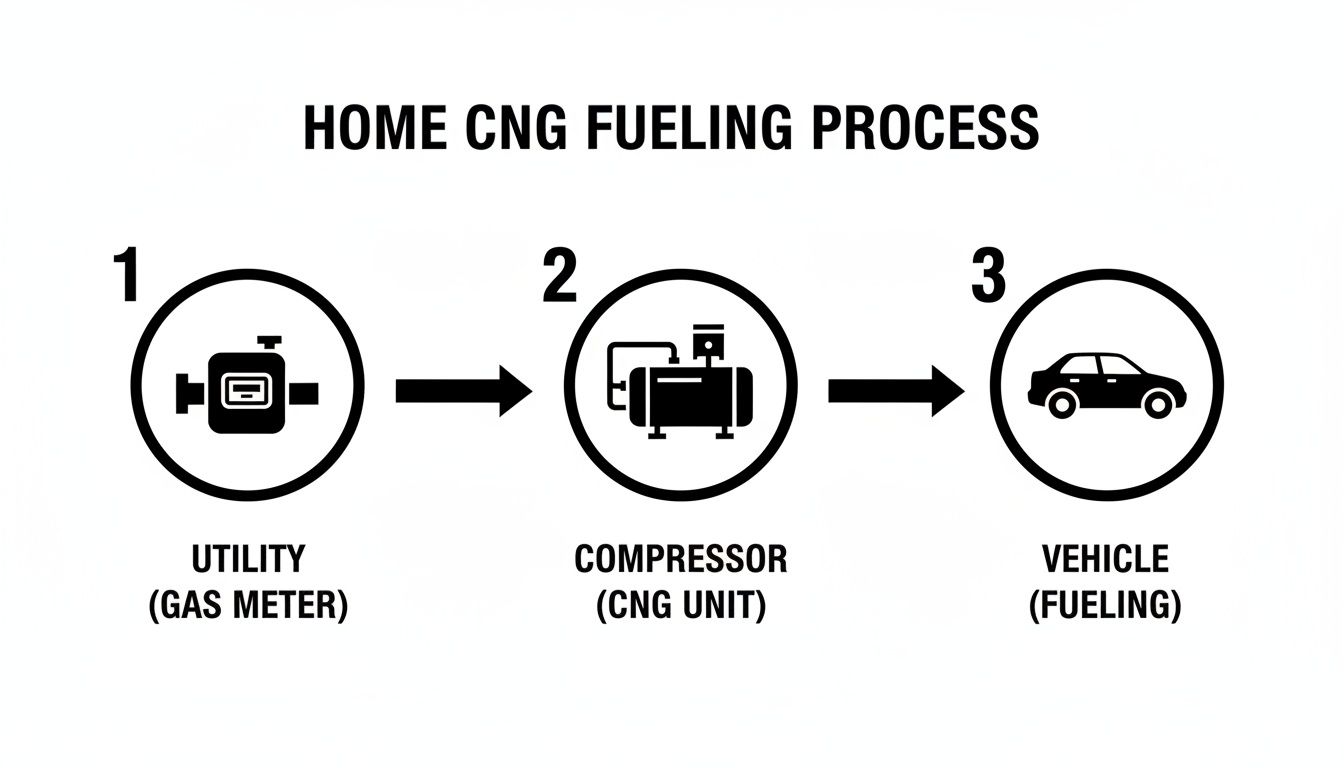

This simple diagram shows how the gas gets from your house to your car.

As you can see, the station is really just a bridge, converting the everyday utility gas in your home into powerful, high-pressure fuel for the road.

The Final Step: Transferring Fuel

The last piece of the puzzle is getting that compressed gas into your vehicle. You just connect the dispenser's nozzle to your NGV's fueling port—it's a lot like plugging in an electric car. From there, the station takes over. It has safety interlocks that ensure the connection is solid before starting the flow, and it automatically shuts off once your tank is full.

The real beauty of this setup is how effortless it is for the driver. You come home, plug in your car like you would your smartphone, and wake up every morning with a full tank. No more extra trips to the filling station.

Why Home Natural Gas Fueling Is Gaining Momentum

The idea of having your own private fuel station might sound like something from the future, but it's quickly becoming a reality for a growing number of people. Two powerful forces are driving this trend: the constant rollercoaster of gasoline prices and a real, collective push for cleaner ways to get around. A compressed natural gas home filling station sits right at the intersection of these two issues.

For most folks, the initial draw is purely economic. Think about it. Natural gas is a domestic resource, so its price isn't jerked around by global events nearly as much as gasoline. This stability means you can fuel up your car for a lot less, turning a huge, unpredictable household expense into just another manageable utility bill.

Let's look at the numbers. While gas prices can spike overnight, the natural gas piped to your home is remarkably consistent and cheap. As an example, some city fleets have reported paying as little as $1.10 per gasoline gallon equivalent (GGE) for CNG. During that same time, regular gasoline was $1.91 per gallon—and that's before any bulk discounts. That kind of predictability makes budgeting a whole lot easier and adds up to serious savings over the years.

The Environmental Advantage

Money isn't the whole story, though. A growing sense of environmental responsibility is a massive motivator. As we all look for ways to shrink our carbon footprint, CNG emerges as a much cleaner-burning fuel than gasoline or diesel. It pumps out far fewer harmful emissions, which is a big win for anyone who cares about air quality.

When you burn natural gas, you get:

- Up to 30% less carbon dioxide (CO2), the main culprit behind climate change.

- Significantly fewer nitrogen oxides (NOx), which are a key ingredient in smog.

- Almost no particulate matter, that nasty soot that’s terrible for our lungs.

This cleaner burn means every trip to the grocery store or commute to work is a little bit better for the air in your neighborhood. It’s a simple way to align your daily routine with bigger environmental goals, turning your drive into a positive act.

For many, installing a home CNG system is about taking control. It’s a declaration of independence from volatile fuel markets and a personal commitment to a healthier planet, all from the convenience of their own garage.

Market Growth and Future Outlook

This powerful one-two punch of economic and environmental benefits isn't just a niche interest; it's driving a major global shift. The market for compressed natural gas is growing fast as more industries and everyday drivers catch on. This growth creates a virtuous cycle: more demand leads to more vehicle options, better technology, and stronger infrastructure to support it all.

The global Compressed Natural Gas (CNG) market has seen impressive growth, hitting a market size of USD 91.11 billion in 2024. And it’s not slowing down. Projections show the market expanding to USD 132.32 billion by 2035, which is a steady compound annual growth rate of 3.45%. This proves CNG is here to stay. Discover more about this impressive market expansion and its key players-market).

This momentum makes it clear that a compressed natural gas home filling station isn't just a smart buy for today. It’s a forward-thinking decision that lines up perfectly with where energy and transportation are headed. It puts you at the forefront of a movement that values efficiency, savings, and environmental stewardship, making it an incredibly compelling choice.

Getting to Know the Core Components and Site Requirements

A home CNG filling station might sound like something out of a sci-fi movie, but it's really just a clever assembly of heavy-duty parts working in concert. Before you can even think about installation, it helps to understand what makes these systems tick and what your property needs to support them. Think of it as peeking under the hood to see how the engine works.

This isn't just one big machine—it's a team of specialized components, each with a crucial role. From pulling gas from your utility line to safely pumping it into your vehicle, every piece has a purpose. Let's break down the essential hardware.

The Heart of the System: The Compressor

At the center of it all is the compressor. This is the workhorse of your home fueling station. Its job is to take the low-pressure natural gas from your utility line—usually sitting at a gentle 0.25 to 2 PSI—and squeeze it down until it reaches the 3,600 PSI needed to fuel a car.

This isn't a race. The process is designed to be slow and steady, filling your vehicle over several hours, typically overnight. This "time-fill" approach is much easier on the equipment and your home's gas line, preventing the kind of sudden demand spikes that could cause problems. It’s what makes a powerful industrial process safe and practical for your garage.

To better understand how each part contributes, here’s a quick look at the main components and their functions.

Home CNG System Component Functions

| Component | Primary Function | Key Consideration |

|---|---|---|

| Compressor | Increases gas pressure from utility levels (0.25-2 PSI) to vehicle-ready levels (3,600 PSI). | Requires a dedicated 240-volt electrical circuit. |

| Gas Dryer | Removes moisture and water vapor from the natural gas using a desiccant. | Prevents internal corrosion of the system and vehicle fuel tank. |

| Coalescing Filters | Captures oil aerosols and fine particulates to purify the gas. | Ensures only clean, dry gas reaches the vehicle's engine. |

| Dispenser Hose & Nozzle | Safely transfers high-pressure gas from the system to the vehicle. | Equipped with safety features like check valves and breakaway couplings. |

Each of these parts is a critical link in the chain, ensuring a safe and reliable refueling process every time.

Keeping It Clean: The Dryer and Filters

Before the gas can be compressed, it needs to be cleaned up. The natural gas flowing through your pipes contains tiny amounts of water vapor and lubricant oils, which can become corrosive and damaging under extreme pressure. That’s where the filtration system steps in.

- Gas Dryer: This component is like a super-powered dehumidifier. It uses a special material called a desiccant to pull all the moisture out of the gas stream. Getting the water out is non-negotiable for preventing rust inside the filling station and your car’s fuel tank.

- Coalescing Filters: Next, these filters work to trap tiny oil droplets and other particles, making sure only pure, dry gas moves on to the compressor. This step is vital for protecting sensitive engine components from gunk and buildup.

Think of it this way: clean, dry gas is the lifeblood of a healthy CNG system. Proper filtration is the unsung hero that protects your entire investment, from the compressor in your garage to the engine in your car.

The Final Step: Dispenser Hose and Nozzle

Once the gas is compressed and purified, you need a safe way to get it into your vehicle. That’s the job of the dispenser assembly, which includes a tough, high-pressure hose and a specialized nozzle.

These aren't your average gas station parts. They are engineered with multiple safety features, like breakaway couplings that stop the flow in an emergency and check valves that prevent gas from escaping. The nozzle itself creates a perfect, airtight seal with your car’s fuel port before any gas can flow, and the whole system shuts off automatically once the tank is full. It makes the entire process incredibly safe and straightforward.

While these components are purpose-built for CNG, having a basic knowledge of general fuel tank services can give you a broader perspective on maintaining fuel systems of all types.

Preparing Your Property: Site Requirements

Beyond the hardware, your home itself has to be ready to host a CNG filling station. Before an installer even steps on your property, you’ll need to make sure you have the right infrastructure in place.

Here’s what you’ll need to check off the list:

- Natural Gas Supply: The system taps directly into your home's natural gas line. An installer will coordinate with your local utility to confirm your service can handle the load. For most homes, a standard residential supply is perfectly fine.

- Sufficient Electrical Service: These compressors need a good bit of juice. They typically require a dedicated 240-volt electrical circuit—the same kind used for an electric stove or clothes dryer. You'll need an electrician to install the right outlet near where you plan to put the unit.

- Proper Location and Ventilation: Safety codes are strict about where these units can be placed. It must be in a well-ventilated area, like a garage, with mandatory clearances from windows, doors, and any potential sources of ignition. This ensures that if a leak ever occurred, the gas would dissipate harmlessly. A certified installer is your best guide for navigating these critical placement rules.

Navigating Safety Codes and Permitting

Putting a compressed natural gas home filling station on your property isn't just about picking the right equipment. You've also got to navigate a complex web of safety regulations, building codes, and permits. Think of it as the official rulebook for a safe installation—one that protects your family, your property, and your neighbors.

To get this done right, you'll be working with a few key players. Your local building or planning department, your natural gas utility, and maybe even the local fire department will all have a say. Each one plays a part in signing off on the project and making sure every single component meets their strict safety standards.

Understanding the Key Regulations

The world of CNG safety revolves around standards set by national organizations. For home fueling, the most important document you'll hear about is the National Fire Protection Association's NFPA 52 Vehicular Gaseous Fuel Systems Code. This is the bible for CNG installations across North America.

NFPA 52 lays out very specific, non-negotiable rules for everything from where you can place the unit to the kinds of materials you have to use. The whole point is to eliminate risk by making sure the system is tough, reliable, and installed perfectly. A certified installer knows these codes by heart, which is why their expertise is so critical.

A few key things NFPA 52 covers are:

- Location and Clearances: The code is very precise about where a fueling appliance can go. It spells out required distances from doors, windows, air intakes, and any potential ignition source, like the pilot light on a water heater.

- Ventilation Requirements: Good airflow is a must. The standards make sure that if a leak ever did happen, the natural gas (which is lighter than air) could easily float up and away instead of building up.

- Electrical Safety: Every electrical part has to be rated for the environment to prevent any chance of a spark. This usually means using specific types of wiring and protective conduit.

These aren't just friendly suggestions—they are mandatory rules that form the backbone of a safe, legal installation.

The Permitting Process Step by Step

Getting the right permits is the formal process that confirms your installation plan is safe and compliant before a single wrench is turned. The exact steps can change a bit from town to town, but the overall flow is pretty consistent.

- Initial Consultation: It all starts with a certified installer visiting your property. They'll assess the site, check that your gas service is up to the task, and help you choose a system that meets all the code requirements.

- Plan Submission: Next, your installer will draw up detailed plans and schematics showing exactly how the system will be installed. These documents get submitted to your local building department for review.

- Plan Review: City officials will go over the plans with a fine-toothed comb, checking them against local building codes, electrical codes, and the fire safety rules in NFPA 52.

- Permit Issuance: Once your plans get the stamp of approval, the building department issues the permits. This is the official green light to start the installation.

- Installation and Inspection: After a certified pro installs the system, a city inspector comes out. They’ll do a thorough check to make sure the work matches the approved plans and that all the safety features are working as they should.

Your system is only cleared for operation after it passes this final inspection.

Here's the bottom line: this is absolutely not a DIY project. The high pressures and strict safety rules for a compressed natural gas home filling station demand an expert who knows the codes inside and out.

Mandatory Safety Features and Best Practices

Today's home CNG systems are built with multiple layers of safety. The codes mandate several built-in features designed to prevent accidents and shut the system down if anything goes wrong. These include things like automatic gas shut-off valves, pressure relief devices that can vent excess pressure safely, and even leak detection sensors.

Beyond the CNG-specific rules, it's always a good idea to brush up on general gas safety tips that apply to any gas appliance in your house. Knowing the basics gives you an extra layer of confidence. By sticking to the established codes and working with qualified professionals, you can rest easy knowing your home fueling station is as safe as it gets.

Is It Worth It? Crunching the Numbers on Your ROI

Putting a compressed natural gas filling station at your home is a serious investment, no doubt about it. But it's an investment that can pay you back big time. The key is to look past the sticker price and figure out your real-world return on investment (ROI). It all boils down to a simple calculation: weigh the upfront costs against how much you'll save on fuel month after month.

The total cost isn't just the price of the compressor. To get the full picture, you have to account for everything it takes to get the system installed safely and up to code. These numbers can swing quite a bit depending on where you live, the layout of your property, and who you hire to do the work.

Your Upfront Investment: A Realistic Breakdown

Before you can enjoy filling up in your PJs, you need a clear budget. Knowing all the costs ahead of time helps you avoid any nasty surprises.

Here’s what you should plan for:

- The Compressor: This is the heart of the system and your biggest line item. Residential models typically run between $4,500 and $10,000, depending on how powerful and feature-rich you want to go.

- Professional Installation: This is absolutely not a weekend DIY project. You need a certified pro to handle the installation to ensure it's safe and meets local codes. Labor can easily add another $2,000 to $5,000 (or more) to your bill.

- Getting Your House Ready: Your home might need a few tweaks. You'll almost certainly need a dedicated 240-volt electrical circuit, and you may need to upgrade your gas lines. These upgrades can range from a few hundred to a couple of thousand dollars.

The Payoff: Fuel Savings and Your Break-Even Point

Once you're up and running, the savings start immediately. The magic happens when you compare the cost of CNG to gasoline. Natural gas is sold in cubic feet, but to make a fair comparison, we convert it to a gasoline gallon equivalent (GGE). Think of a GGE as having the same punch as one gallon of regular gasoline.

To figure out your cost per GGE, you just look at your utility bill for the price of natural gas and add a little extra for the electricity the compressor uses. Even with that added cost, CNG is almost always a world cheaper than gasoline.

Let's run through a quick example to see how this works in the real world.

ROI Calculation Example

| Metric | Value | Notes |

|---|---|---|

| Annual Mileage | 15,000 miles | A pretty standard amount of driving for a year. |

| Vehicle Efficiency | 25 miles/GGE | Assuming your car gets 25 miles per gallon. |

| Annual Fuel Needed | 600 GGE | (15,000 miles / 25 miles per GGE) |

| Average Gasoline Price | $3.50/gallon | A conservative guess for gas prices. |

| Your CNG Cost per GGE | $1.25/GGE | This includes both the gas and electricity. |

With these numbers, you'd spend $2,100 a year on gasoline (600 gallons x $3.50). But with your own CNG station, that drops to just $750 (600 GGE x $1.25). That's a cool $1,350 back in your pocket every single year.

So, how long until you break even? If your total installation cost was $10,000, it would take you about 7.4 years to make your money back ($10,000 / $1,350 per year). And if gas prices in your area are higher than our example, you'll hit that break-even point even sooner.

This isn't just a niche idea; the market is catching on. The entire natural gas refueling station market—including home and commercial setups—was valued at USD 5 billion in 2025 and is expected to grow by a massive 15% each year through 2033. You can dig deeper into this trend over at archivemarketresearch.com. This kind of growth shows that more and more people are realizing that making the switch just makes good financial sense.

Your Step-by-Step Home CNG Installation Checklist

So, you're ready to turn your garage into a personal refueling hub? It's a big project, but breaking it down into a clear, step-by-step process makes it manageable. Think of this as your roadmap for installing a compressed natural gas home filling station, guiding you from initial research to that first satisfying overnight fill-up.

Each phase builds on the one before it. Follow these steps in order, and you’ll sidestep common pitfalls and ensure your installation is safe, compliant, and ready to go without any expensive surprises.

Phase 1: Initial Feasibility and Planning

This is the homework phase. Before you spend a dime, you need to make sure a home CNG system is actually a good fit for your property and vehicle. Getting these details right from the start will save you a world of headaches down the line.

- Confirm NGV Availability: This might sound obvious, but it's the most important first step. You either need to own a Natural Gas Vehicle (NGV) or have a solid plan to buy one. These refueling systems are built specifically for NGVs and are not compatible with standard gasoline or diesel cars.

- Consult Your Gas Utility: Get on the phone with your local natural gas provider. You need to ask them if your home’s existing gas line has enough pressure and volume to support a home fueling appliance. The last thing you want is to find out you need a major, costly service upgrade halfway through the project.

- Research Certified Installers: This is not a job for a general plumber or electrician. You need a technician who is specifically certified to install CNG fueling stations. Don't be shy—ask for their credentials, references, and photos of past residential projects.

Phase 2: Permitting and Site Preparation

Once you’ve confirmed the project is a go, it's time to handle the official requirements and get your property prepped. This stage is all about making sure your system is 100% legal and safe.

The permitting process isn't just red tape; it's a crucial safety check. It ensures that a qualified third party has reviewed your plans and confirmed they meet the stringent national and local codes designed to protect you and your community.

The global boom in CNG vehicle use, particularly in the Asia-Pacific region, has helped create a solid foundation of best practices. Countries like China and India have poured resources into CNG infrastructure, and that worldwide experience has helped standardize the safety protocols that shape our local regulations. You can discover more insights about regional CNG infrastructure growth on marketreportanalytics.com.

Phase 3: Installation and Commissioning

This is where the magic happens. The final, hands-on stage brings your plans to life.

- Schedule the Installation: Coordinate with your certified installer to book the work. They will physically mount the compressor, run the necessary connections to your gas and electrical lines, and set up the dispensing hose.

- Final Inspections: After the installation is finished, your local building inspector will need to come out for a final sign-off. They’ll check the work against the approved plans and verify that every component meets all safety codes.

- System Walkthrough: Before the installer leaves, they should give you a complete tour of your new system. This isn't just a quick handshake—they need to show you how to safely connect and disconnect the nozzle, explain the maintenance schedule, and point out all the emergency shut-off features.

Your Top Questions About Home CNG Fueling Answered

Thinking about adding a compressed natural gas home filling station to your property? It's a big step, so it's natural to have a few questions. This isn't just another appliance; it's a whole new way to fuel your vehicle.

Let's walk through some of the most common things people wonder about. We'll cover everything from how long it takes to fill up to what you need to do to keep it running smoothly.

How Long Does a Home CNG Fill-Up Take?

The first thing to understand is that a home system isn't like the pump at a public station. Public stations use a "fast-fill" method that gets you in and out in minutes. Home units, on the other hand, are designed for what’s called a "time-fill" or slow-fill. This approach is much easier on your home's natural gas line and the fueling equipment itself.

- Typical Refueling Time: For a standard passenger vehicle starting from empty, you can expect a full tank in about 6 to 10 hours.

- Overnight Convenience: This is where the magic happens. You pull into your garage, connect the nozzle, and go about your evening. By morning, you have a completely full tank, ready for the day's drive.

It completely changes your routine. Instead of scheduling weekly trips to a fueling station, refueling just becomes part of your end-of-day habit, like plugging in your phone.

What Kind of Maintenance Is Required?

If you can take care of a high-end air compressor, you can handle the upkeep on a home CNG station. It's surprisingly simple. The main goal is just to keep the system running efficiently and ensure the gas going into your vehicle is clean and dry.

Your routine tasks will mostly involve:

- Checking the compressor's oil levels from time to time.

- Swapping out key filters—like the gas dryer and coalescing filters—on a regular schedule. This is crucial for stopping moisture and other gunk from getting into your vehicle's fuel system.

Most manufacturers also recommend having a certified technician come out once a year to give everything a professional once-over. This ensures the unit is operating safely and performing at its best.

The core safety principle is simple: a properly installed and maintained home CNG fueling system is just as safe as any other major gas appliance in your home, like a furnace or water heater.

Is It Safe to Have in My Garage?

Yes, absolutely. But there’s a critical condition: it must be installed by a certified professional who follows all safety codes to the letter. These systems aren't just thrown together; they're engineered with multiple safety layers built right in. National standards like NFPA 52 lay out strict requirements for them.

Some of the built-in safety features include:

- Automatic Shut-Off Valves: If the system detects any kind of problem, these valves instantly cut the flow of gas.

- Pressure Relief Devices: In the rare event that pressure builds up too high, these devices safely vent it.

- Leak Detectors: Many setups come with sensors that can sniff out even a small gas leak and trigger an immediate shutdown.

When a professional handles the installation and you follow the maintenance schedule, a compressed natural gas home filling station is a perfectly secure and reliable part of your home.

For commercial or industrial projects facing delays, Blue Gas Express provides mobile CNG and LNG solutions to keep your operations running without interruption. Learn more about our temporary natural gas services.