So, what exactly is a home filling station for CNG? Think of it as your own private, automated fuel pump, installed right at your business or depot. It taps directly into the natural gas line from your utility company, letting your fleet vehicles refuel overnight, right where they’re parked.

This simple shift completely changes the game, turning unproductive downtime into valuable refueling time.

How a Home CNG Filling Station Transforms Fleet Fueling

Picture this: your entire fleet starts every single day with a full tank. No more burning daylight sending drivers to public stations. No more wrestling with fuel card reconciliation. And no more being at the mercy of wildly fluctuating gasoline and diesel prices.

That’s the operational reality a home filling station for CNG delivers. It's a lot like plugging in an electric car to charge overnight, but for your natural gas trucks.

Here's how it works. The system pulls low-pressure natural gas from your existing utility line and feeds it into a specialized, compact compressor. This unit runs quietly and steadily through the night, pressurizing the gas up to the 3,600 psi needed to power a vehicle.

At the end of the day, your drivers just park, connect a hose, and walk away. The next morning, they come back to a truck that’s 100% ready to hit the road.

The Core Value Proposition for Fleet Managers

This setup is a perfect match for any "return-to-base" operation, like construction companies, utility providers, or local service fleets where vehicles come back to a central yard each night. The benefits stack up quickly and fall into three main categories:

- Significant Fuel Cost Reduction: On a gallon-equivalent basis, natural gas is consistently cheaper than gasoline or diesel—often by as much as 40-50%. Those savings go straight to your bottom line.

- Enhanced Operational Efficiency: Think about all the time you'll get back by cutting out daily or weekly trips to a public pump. We’re talking hundreds of hours a year in labor and vehicle time that can be spent on actual, revenue-generating work.

- Improved Environmental Footprint: CNG just burns cleaner. Compared to traditional fuels, it can cut greenhouse gas emissions by up to 20-30% and slash particulate matter by over 90%.

This isn't just some niche idea. The move to on-site fueling is gaining serious traction, and the global demand for natural gas filling stations proves it.

The numbers back this up. The global market for these stations was valued at USD 2.22 billion in 2024 and is on track to hit USD 3.13 billion by 2033. This trend is part of the larger boom in the CNG sector, which is projected to jump from USD 91.11 billion in 2024 to USD 132.32 billion by 2035 as more operators look for cleaner, more affordable fuel. Learn more about these market trends and their impact.

Of course, before you jump in, it’s crucial to do your homework. You'll need to carefully look at factors like your utility access, site layout, and fleet needs to build a solid business case.

Does On-Site CNG Fueling Make Sense for Your Business?

Deciding to install an on-site compressed natural gas (CNG) system is a major move. Before you start getting quotes and blocking out time on the calendar, you need to take a hard, honest look at your current operations. Is a home filling station for CNG the strategic key you've been looking for, or is it an expensive solution to a problem you don't really have?

The first thing to understand is that the whole system hinges on your connection to the local natural gas utility. This isn't just about having a gas line running to your property; it’s about having the right kind of gas line.

You need a reliable, steady supply with enough pressure and volume to feed the compressor. Think of it like the water pressure in your house—you can't expect a powerful shower if you're working with a trickle from the main pipe. In the same way, a standard residential gas line might not have the oomph to power a compressor fueling a fleet of commercial vehicles.

The Make-or-Break Site Requirements

Before you get too far down the road, there are a few non-negotiables you have to tick off the list. These are the foundational pieces of the puzzle; without them, the business case falls apart.

- Sufficient Gas Supply: Your very first call should be to your local gas utility. They can send someone out to assess your current service and tell you definitively if it can handle the extra demand from a CNG compressor.

- Adequate Electrical Service: These compressors are serious machines. They typically need a dedicated 240V circuit—the same kind you'd use for an electric stove or a heavy-duty clothes dryer. A standard 120V wall outlet just won't cut it.

- Physical Space: The compressor unit itself is about the size of a large water heater or a small commercial freezer. You'll need a designated spot for it in a well-ventilated area, like a garage, a purpose-built shed, or a secure outdoor enclosure with enough clearance for maintenance and safety.

Pinpointing the Perfect Fleet Profile

While lots of businesses can find value here, the technology really shines for a specific type of operation: the return-to-base fleet. This is any fleet where vehicles come back to a central location at the end of every workday.

This setup is tailor-made for slow-fill, overnight refueling. The vehicles sit idle anyway, so why not use that time to fill them up? Fleets that fit this model perfectly include:

- Plumbing and HVAC contractors

- Local delivery and last-mile logistics companies

- Municipal and public utility crews

- Construction and specialty trade businesses

For these kinds of operations, you can completely sidestep the hassle of mid-day refueling stops. Every vehicle starts the day with a full tank, ready to hit the road without wasting a minute of billable time at a public gas station.

The push for CNG is a global trend, and smaller, on-site fueling stations are a huge part of it. The market is booming, especially in the Asia Pacific region, which was responsible for 48.3% of global CNG revenue in 2023. Systems from companies like Blue Gas Express typically run $4,000-$6,000 installed. They work by compressing gas from your standard utility line to 3,600 psi overnight, giving a vehicle a range of 200-300 miles. In states like California, this can translate into fuel savings of up to $1,500 per vehicle, per year. You can explore the full analysis of the global CNG market here.

Your Feasibility Decision Checklist

To really see if this makes financial sense, you need to dig into your own data. This checklist is designed to help you quickly determine if a home CNG station is a smart investment for your specific fleet.

Here's a straightforward way to size up the opportunity.

Home CNG Station Feasibility Checklist

| Feasibility Check | Requirement/Consideration | Ideal Scenario for Investment |

|---|---|---|

| Fleet Size | How many vehicles will use the station? | A fleet of 5 or more vehicles that can refuel sequentially or simultaneously, maximizing the compressor's usage. |

| Daily Mileage | What is the average daily distance traveled per vehicle? | High daily mileage (100+ miles) accelerates fuel cost savings and shortens the ROI period significantly. |

| Local Energy Costs | What is the price difference between natural gas and gasoline/diesel in your area? | A large price gap (e.g., CNG at $2.50/GGE vs. gasoline at $5.00/gallon) creates a powerful financial incentive. |

| Vehicle Type & Age | Are your vehicles bi-fuel compatible or due for an upgrade? | Fleets with long-lasting trucks and vans are better candidates, as the conversion cost is spread over a longer vehicle lifespan. |

If you check off most of the boxes in the "Ideal Scenario" column, you have a strong preliminary case for moving forward.

What Goes Into the Setup? A Look at Equipment and Site Prep

Bringing CNG fueling to your own yard means getting the right hardware and planning the installation site carefully. It might sound daunting, but think of it less like a massive industrial build-out and more like installing a powerful piece of commercial equipment. With the right expertise, it's a very manageable process.

The workhorse of any home filling station for CNG is the compressor unit. This machine does one job and does it well: it takes the low-pressure natural gas from your standard utility line, cranks it up to 3,600 psi, and sends it through a specialized hose right into your vehicle's tank.

It's important to know we're talking about "slow-fill" stations. These are designed to refuel vehicles over several hours, which is perfect for fleets that park overnight. They are a different beast entirely from the giant "fast-fill" setups you see at public stations, which fill up a truck in minutes but come with a much bigger price tag and a more complex footprint.

Your Core Equipment Checklist

The compressor gets all the attention, but a safe and effective system relies on a few other key players working together.

- The Compressor: This is the main unit that does the heavy lifting of pressurizing the gas.

- Dryer/Filter System: Before the gas ever gets to the compressor, this system strips out any moisture or impurities. This is non-negotiable for protecting the compressor and your vehicle's fuel system from long-term damage.

- Dispensing Hose and Nozzle: You'll have a high-pressure hose and a purpose-built nozzle that creates a secure, leak-proof seal with the vehicle every time you connect.

- Safety Shut-Offs and Monitors: Every modern system is loaded with safety features, from automatic shut-off valves to methane detectors that will instantly kill the power if they sense a problem.

This all-in-one package guarantees the fuel going into your trucks is clean, dry, and at the right pressure, night after night.

A Project Manager's Guide to Site Prep

A solid installation starts with the groundwork. Getting the site prepped correctly is crucial for both safety and reliability, and this is where you bring in the licensed pros for gas and electrical work. This is not a DIY weekend project.

First up is the power. The compressor needs its own dedicated 240V circuit, much like you'd run for a commercial-grade oven or heavy-duty shop welder. An electrician will need to pull this line directly from your panel to the spot where the unit will live, ensuring it gets the clean, consistent power it needs to operate safely.

Next, you have to pick the right spot. The compressor must be in a well-ventilated area to prevent any possibility of gas buildup. Good options include a spacious corner of a well-aired workshop, a purpose-built shed with proper venting, or even an outdoor concrete pad in a secure, designated area.

A successful installation is all about laying the proper groundwork. This means addressing utility connections, electrical capacity, and physical placement before the first piece of equipment is even unboxed. Getting these details right from the start prevents costly and time-consuming rework later.

For the underground work, you’ll need a specialized contractor. Tapping into the main gas line requires a PG&E OQ certified gas line trenching company to ensure everything is done to code. They handle the critical task of installing a new line that can supply the right volume and pressure to the compressor without disrupting your existing service. This is a vital step for both safety and performance, making sure your entire system is built on a solid, compliant foundation.

Calculating Your ROI and Project Timeline

Putting in a home CNG filling station is a serious investment, no doubt about it. But it's one of those decisions that can start paying you back faster than you might think. Before you sign any checks, you need a firm grasp on the total cost of ownership and, more importantly, your potential return on investment (ROI). This isn't just about the price of the compressor; it's about seeing the long-term financial win.

At the same time, you need a realistic project timeline. Knowing what to expect from day one helps you manage everything from contractor schedules to your own team's expectations. A well-planned installation, from the initial site visit to the moment you fuel up the first time, makes the whole transition a lot smoother.

Deconstructing the Total Cost of Ownership

So, what’s the real number? The final price tag for your on-site fueling setup will definitely shift based on your specific needs and what your property looks like. But we can break it down into a few key buckets to get a clear picture of where the money goes.

- The Compressor Unit: This is the heart of the operation and easily the biggest line item. Prices can vary a lot depending on how powerful the unit is and what features it comes with.

- Professional Installation: You can't just plug this thing in. This cost covers the specialized electrical work for a dedicated 240V circuit and the crucial gas line plumbing, which absolutely must be done by certified pros.

- Utility Upgrades: Sometimes, your existing natural gas line isn't quite up to the task. If you need more volume or pressure, you might have to pay your utility company for an upgrade.

- Permitting Fees: Your local city or county will want to sign off on this. They'll require permits to make sure everything is installed safely and up to code, and those permits come with fees.

It's easy to get fixated on the upfront cost, but the real story here is the long-term savings. The goal is to hit a breakeven point where your fuel savings have completely paid for the initial investment. After that, every single fill-up is pure profit for your bottom line.

Mapping Your Project from Start to Finish

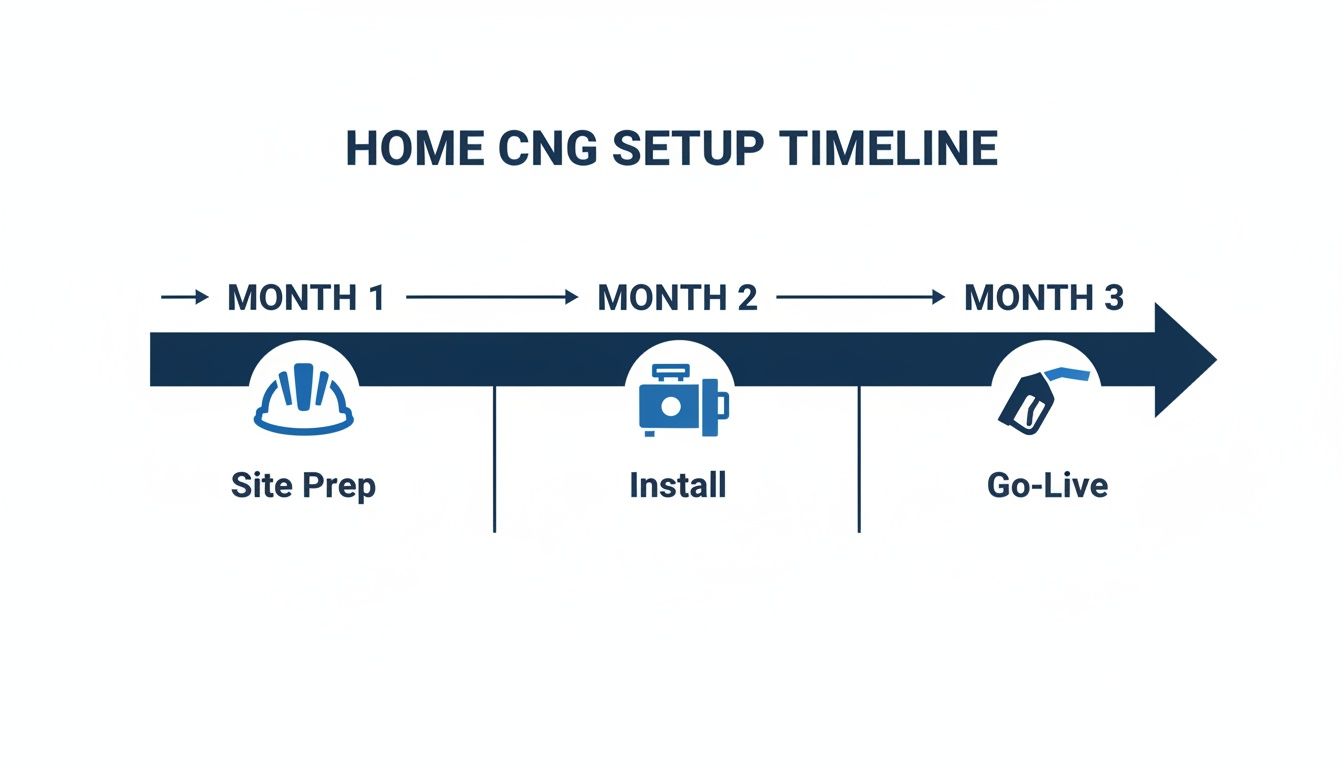

A typical installation isn't a one-day job; it's a structured process with a few distinct phases. While the exact timeline can change based on how busy your contractors are or how quickly the city moves on permits, most projects follow a pretty predictable path.

This visual gives you a good sense of the journey. It’s a methodical process that moves from preparation to installation and finally to commissioning, all designed to ensure the system is safe, reliable, and ready to go.

A Step-by-Step Guide to Calculating Your ROI

Figuring out your potential ROI doesn't require an MBA. With a straightforward formula and some real numbers from your own fleet, you can get a powerful estimate of how long it will take to get your money back.

The formula is simple:

Total Investment Cost / Annual Fuel Savings = Payback Period (in years)

Let's run the numbers for a small commercial fleet to see how this plays out in the real world.

Cost Breakdown and ROI Calculation Example

Here's a sample breakdown of what the costs could look like and how you'd calculate the payback period for a small commercial fleet.

| Cost Component | Estimated Range | ROI Calculation Step | Example Value |

|---|---|---|---|

| Compressor Unit | $4,500 – $7,500 | 1. Total Investment (Compressor + Install + Permits) | $12,000 |

| Installation | $2,000 – $5,000 | 2. Annual Mileage / Vehicle | 30,000 miles |

| Permits & Upgrades | $500 – $2,500 | 3. Vehicle Fuel Efficiency (Gas Gallon Equivalent) | 15 MPG |

| – | – | 4. Annual Fuel Use / Vehicle (30k mi / 15 MPG) | 2,000 GGE |

| – | – | 5. Total Fleet Fuel Use (5 vehicles) | 10,000 GGE |

| – | – | 6. Local Gasoline Price | $3.75 / gallon |

| – | – | 7. Local CNG Price | $2.25 / GGE |

| – | – | 8. Savings per GGE | $1.50 |

| – | – | 9. Total Annual Fuel Savings (10,000 GGE x $1.50) | $15,000 |

| – | – | 10. Payback Period ($12,000 / $15,000) | 0.8 years (≈ 10 months) |

As you can see, the payback period can be incredibly short once your fuel savings start kicking in.

The bigger picture for CNG is just as strong. The global market is expected to grow by a massive USD 32.28 billion between 2025-2029. Home units give you crucial 24/7 fuel access—a huge advantage when you realize there are only about 1,500 public CNG stations in the entire U.S., compared to 168,000 regular gas stations.

With average installation costs often falling around $3,500 and savings between $0.80-$1.20 per GGE, many fleet operators see a full ROI in just 18-24 months. It just makes good financial sense. You can discover more insights about the growing CNG market to see the trend for yourself.

Keeping Your Station Safe and Running for the Long Haul

When you're working with high-pressure gas, safety is everything. It's the bedrock of the entire system. A professionally installed home filling station for CNG is built from the ground up with multiple layers of protection, making every fill-up both safe and straightforward. It’s a lot like the safety features in a modern car—they operate silently in the background, heading off trouble before it ever starts.

Built-In Safety and Navigating Permits

The compressors themselves are packed with safety tech. These aren't just bells and whistles; they're core to the design. For example, automatic shut-off systems keep a constant eye on pressure and flow. If they sense anything unusual—say, a hose gets disconnected or there's a sudden pressure drop—the whole operation stops on a dime.

Pressure relief valves are another critical failsafe, making sure the system never gets pushed past its operational limits. Many units even have methane detectors that can pick up the tiniest gas leak, instantly cutting both power and gas flow to the compressor. It’s an essential security blanket.

Of course, before a single wrench is turned, you’ll need to navigate the local permitting process. This isn't just red tape; it's how we ensure your setup meets all the right safety codes. It's a team effort with a few key players:

- Local Building Authorities: They'll check your installation plans against structural and electrical codes to make sure the spot you picked is suitable and the power source is correctly wired.

- Fire Departments: Their job is to focus on fire safety. They’ll look at ventilation, make sure there’s enough clearance around the equipment, and confirm the emergency shut-offs are placed correctly.

- Gas Utilities: Your gas company has to sign off on the connection to their main line. They need to be sure your system is compatible and won't cause any issues for their grid.

The good news is that your certified installer usually takes the lead here, handling the paperwork and lining up inspections. Their expertise makes for a smooth, compliant installation from the get-go.

"A proactive maintenance schedule is the single most effective way to guarantee the long-term safety, reliability, and efficiency of your CNG fueling equipment. It transforms upkeep from a reaction to a strategy."

A Practical Maintenance Routine

Once you're up and running, consistent maintenance is what will keep your station performing well for years. Think of it in two parts: simple checks you can do yourself and deeper inspections best left to the pros.

A simple routine handled by a facility manager or trained employee can catch most potential problems early.

Routine Owner Checks (Monthly):

- Visual Inspection: Just do a quick walk-around. Look for any wear and tear on the hoses, make sure all the fittings are snug, and keep the area around the compressor clean.

- Listen for Odd Noises: You'll get used to the normal hum of your compressor. If you hear anything new—a clank, a hiss, a rattle—make a note of it and call your service provider.

- Check Filter Indicators: Most systems have a little gauge or light that tells you when the filters are getting dirty. A quick glance is all it takes to know if it's time for a swap.

These monthly checks are vital, but they don't take the place of a professional service call. An annual inspection by a certified technician is absolutely crucial. They'll go much deeper, testing safety sensors, calibrating pressure gauges, and running diagnostics that a simple visual check can't cover.

To keep everything organized, it’s a great idea to use an equipment preventative maintenance checklist. This gives you a clear roadmap for both your own checks and the scheduled professional service, so nothing ever falls through the cracks.

Your Action Plan for On-Site CNG Fueling

So, you're thinking about bringing CNG fueling in-house? Great idea. But moving from a concept to a working fueling station isn't something you do on a whim. It’s a process, a series of deliberate steps where each one sets you up for the next.

Think of it like building a house. You don't just start hammering boards together. You need a blueprint, a solid foundation, and a clear plan. This action plan is your blueprint for turning that idea of a home filling station for CNG into a real-world asset that saves your fleet time and money.

Step 1: Start with an Internal Fleet Feasibility Study

Before you even think about picking up the phone to call a vendor, you need to look in the mirror. A thorough internal check-up is the only way to know if this switch makes sense for your specific operation. This is about more than just fuel savings; it’s about your fleet's daily grind.

Get your hands on some real data. Your study should zero in on these key metrics:

- Your Vehicle Roster: Make a list of every vehicle, its age, and what it runs on. Are they already set up for CNG or bi-fuel? If not, you'll need to pencil in the cost of conversion, which can run about $11,000 for a heavy-duty truck.

- Daily Mileage Logs: How far does each truck actually go every day? The vehicles that rack up the most miles are the ones that will give you the fastest payback.

- Fuel Consumption Records: Get a hard number for how much gasoline or diesel you're burning through each month. This figure is the foundation for your entire return-on-investment calculation.

- Refueling Downtime: How much time are your drivers wasting at public fueling stations? Add up the labor hours and vehicle downtime—it's a hidden cost that an on-site station makes disappear.

Step 2: Talk to Your Local Gas Utility

This is a big one. In fact, it's probably the most critical hurdle to clear. Your project is dead in the water if your local gas utility can't confirm that your existing service can handle the demand of a compressor.

When you make that call, be ready to talk specifics about the kind of compressor you're looking at. The utility needs to know if your current gas line has enough pressure and volume to feed it. If it doesn't, they'll give you a quote for the necessary upgrades, which you have to bake into your total project budget. Having this conversation early saves a world of headaches and surprise costs later on.

Securing budget approval and coordinating the final installation are the last pieces of the puzzle. But the entire project stands or falls on the foundational steps of internal assessment and utility confirmation. Get these right, and the rest of the process flows smoothly.

Step 3: Find the Right Equipment Suppliers

Once you have your fleet data and the green light from the utility, it's time to talk to the pros. You can now have a meaningful conversation with equipment suppliers, giving them the details they need to provide an accurate quote for a system that fits your operation like a glove.

When you're checking out potential installers, look for experience and certification above all else. Don't be shy—ask for case studies, talk to their past clients, and see their credentials for working with high-pressure gas systems. A top-notch installer won't just set up the gear; they'll also steer you through the maze of permitting.

Step 4: Lock Down the Budget and Schedule the Install

With solid quotes in hand for equipment, installation, and any utility work, you can finally put together a complete financial proposal to get budget approval. And be sure to look around for government incentives or financing options for clean energy projects—you might be surprised what's out there.

Once the budget is approved, it’s all about coordination. You'll need to work hand-in-hand with your installer to line up the site prep, electrical work, gas line hookup, and the final commissioning of the equipment. A well-managed installation means less disruption for your team and a safe, efficient start to your new on-site fueling operation.

Got Questions? We've Got Answers

Even after seeing the benefits, you probably have some practical questions about what it’s like to have a CNG filling station on your property. Let's tackle some of the most common things fleet managers ask when they're thinking about making the switch.

How Long Does It Take to Fill Up a Vehicle?

This is where you need to shift your thinking from a gas station pump. Home CNG systems are "slow-fill" by design, meaning a complete fill-up can take anywhere from 4 to 10 hours. The exact time depends on your vehicle’s tank size and the compressor's power.

But this isn't a bug; it's a feature. The whole idea is built for fleets that come back to a central location at the end of the day. Vehicles plug in and refuel overnight during their natural downtime, ensuring they're topped off and ready to roll every morning without anyone having to wait around.

Can I Just Install This Thing Myself?

Let me be crystal clear: absolutely not. Installing a home CNG station is a job strictly for certified professionals, and for good reason. You're dealing with high-pressure natural gas lines and high-voltage electrical connections—a combination that's incredibly dangerous in untrained hands.

Hiring a pro isn't just about safety. It's about ensuring your system complies with every local building and fire code, and it's the only way to keep your manufacturer's warranty valid. Trying to DIY this is not only hazardous and likely illegal, but it will also instantly void any guarantee on your expensive equipment.

What If My Natural Gas Service Goes Out?

It's a valid concern. If your utility's natural gas supply is interrupted, your station won't be able to operate. This is precisely why the vast majority of commercial CNG fleets run on "bi-fuel" vehicles.

Think of it as a built-in insurance policy. These vehicles can run on gasoline just as easily as they run on natural gas. If the gas supply ever goes down, your drivers can simply flip a switch, head to a regular gas station, and keep the fleet moving without missing a beat.

The physical footprint of a home CNG compressor is often surprisingly small, comparable to that of a large home appliance like a water heater or an HVAC unit. This makes finding a suitable, safe location more straightforward than many people assume.

As part of the process, your installer will conduct a thorough site survey. They'll pinpoint the safest and most efficient spot that meets all the necessary clearance and ventilation rules, whether that's inside a well-ventilated garage, a purpose-built shed, or a secure outdoor housing.

For fleets that need immediate or temporary natural gas solutions without the commitment of a permanent installation, Blue Gas Express offers mobile CNG and LNG delivery to keep your projects on track. Discover our flexible mobile gas solutions.