So, what exactly is a Compressed Natural Gas (CNG) fueling system? Think of it as your own private gas station, but for natural gas. These specialized systems tap into a standard utility pipeline, take that low-pressure gas, compress it way up, and store it so your vehicles can fuel up on-site.

It’s all about creating a cleaner, more affordable alternative to gasoline and diesel, especially for commercial fleets.

How CNG Fueling Systems Actually Work

The fundamental job of a CNG fueling system is pretty straightforward: it turns the natural gas flowing through a utility pipe into a high-pressure fuel that can power a vehicle. This step is non-negotiable. In its natural state, the gas isn't dense enough to give a vehicle any practical driving range. Compression is what makes it a viable transportation fuel.

A good analogy is filling a scuba tank. A compressor sucks in a huge volume of air and squeezes it into a small, incredibly strong tank. A CNG system does the same thing with natural gas. It pulls gas from the pipeline and uses a powerful compressor to crank the pressure up to between 3,600 and 4,500 psi (pounds per square inch).

The Basic Fueling Process

After being compressed, the gas is channeled into a series of high-pressure storage vessels, often called a "cascade" system. This cascade acts as a reservoir, holding the CNG until a vehicle is ready to fuel. When a driver hooks up the dispenser nozzle, the high-pressure gas flows from the storage tanks directly into the vehicle's onboard cylinders until they're full.

The entire setup is engineered to solve a core problem for fleets trying to cut costs and shrink their carbon footprint. By taking readily available natural gas and turning it into a clean, usable vehicle fuel, cng fueling systems open the door to some serious operational advantages.

The real goal here is to build a reliable, on-site fueling infrastructure. This makes CNG a practical, everyday replacement for diesel and gasoline, particularly for "return-to-base" fleets like buses, garbage trucks, and delivery vans.

Why It Matters For Your Fleet

Getting a handle on this basic process is the first step toward seeing the strategic value of CNG. Drawing your fuel directly from a utility line can lead to massive cost savings and price stability, which is a world away from the rollercoaster of the petroleum market. Plus, since natural gas is a domestic resource, it improves your energy independence.

On top of that, burning CNG produces far fewer harmful emissions—a huge win for companies working to hit sustainability targets and stay ahead of regulations. This guide will walk you through the nitty-gritty: the components, the different types of stations, and what you need to think about when deciding if CNG is the right move for your operations.

Understanding the Core Components of a CNG System

At first glance, a CNG fueling system can look like a complex jumble of pipes, tanks, and machinery. But if you break it down, it’s really just a well-organized assembly line where each part has a specific, vital job.

Think of it like a relay race. The natural gas gets handed off from one component to the next, with each one doing its part before passing it along. Understanding this five-step journey is the key to seeing how natural gas travels from a utility pipeline right into a vehicle's fuel tank.

The Gas Dryer: Protecting the System

The very first stop for the gas coming in from the utility line is the gas dryer. You can think of this as a powerful, industrial-strength dehumidifier. The natural gas flowing through pipelines contains a surprising amount of water vapor, which can wreak havoc on the high-pressure equipment down the line.

If that moisture isn’t removed, it can condense into liquid, causing corrosion, freezing up in cold weather, and seriously damaging sensitive parts in both the compressor and the vehicle’s fuel system. The gas dryer ensures the gas is bone-dry, protecting the entire investment from costly wear and tear.

The Compressor: The Heart of the Station

Once the gas is perfectly dry, it heads to the compressor—the true workhorse of any CNG station. Its job is to take low-pressure gas from the utility line (typically under 100 psi) and squeeze it down to an incredibly high pressure, usually somewhere between 3,600 and 4,500 psi.

This is the "compressed" part of Compressed Natural Gas. Without this step, you couldn't pack enough energy into a vehicle's tank to give it a practical driving range. The compressor’s size and horsepower directly dictate how many vehicles a station can refuel and how quickly it can do it.

The Storage Cascade: The Energy Reservoir

After being pressurized, the gas needs a place to wait until a vehicle pulls up. That’s the job of the storage cascade—a series of massive, high-pressure cylinders all linked together. Imagine a bank of giant scuba tanks, all holding a ready reserve of compressed gas.

This cascade is what makes fast fueling possible. Instead of forcing a driver to wait for the compressor to pressurize gas on demand, the vehicle can pull directly from this pre-filled, high-pressure reservoir.

The cascade is cleverly designed with multiple banks set at different pressure levels (high, medium, and low). This strategy uses pressure differences to achieve faster, more complete vehicle fills.

The Priority Panel: The Traffic Controller

Directing the flow of all this high-pressure gas is the priority panel, sometimes called a sequencing panel. It’s the brain of the whole operation, acting like an air traffic controller for natural gas. Using a series of valves, it tells the gas where to go and when.

Its main jobs include:

- Directing Gas: It sends gas from the compressor to the right storage bank, always topping off the high-pressure bank first.

- Managing Dispensing: When you fuel up, the panel intelligently pulls gas from the lowest-pressure bank first, then the medium, and finally the high-pressure bank.

- Optimizing Fills: This sequencing ensures every vehicle gets the fullest tank possible while minimizing strain on the compressor.

By managing the flow so precisely, the priority panel makes the entire system run smoothly and efficiently.

The Dispenser: The Final Connection

The final piece of the puzzle is the dispenser. This is the part everyone sees and uses, looking a lot like a traditional gasoline pump. It holds the hose, nozzle, and metering gear that safely transfer the high-pressure CNG from the storage cascade into the vehicle.

CNG dispensers are packed with safety features, like breakaway hoses and specialized nozzles that form a perfect seal with the vehicle’s fuel port. The dispenser measures the gas in Gasoline Gallon Equivalents (GGEs) and shows the final price, completing the journey from pipeline to power.

To help visualize how these parts work together, here’s a quick breakdown of their roles.

Key Components and Their Functions in a CNG System

| Component | Primary Function | Analogy |

|---|---|---|

| Gas Dryer | Removes moisture from incoming natural gas. | A dehumidifier |

| Compressor | Increases gas pressure from low to very high (e.g., 4,500 psi). | The heart of the station |

| Storage Cascade | A series of tanks that store the high-pressure gas. | An energy reservoir or battery |

| Priority Panel | Directs the flow of gas between the compressor, storage, and dispenser. | A traffic controller |

| Dispenser | Transfers the gas to the vehicle and measures the amount. | The fuel pump |

Each component is a critical link in the chain, working in concert to provide safe, fast, and efficient fueling.

Time-Fill vs. Fast-Fill CNG Fueling Stations

When you're looking to switch your fleet to compressed natural gas, one of the first and most important decisions you'll make is what kind of fueling station to build. Not all CNG fueling systems are built the same. They generally fall into two buckets based on how they get the fuel into your vehicles: time-fill and fast-fill. The right choice isn't about which one is "better" but which one fits the natural rhythm of your fleet's daily operations.

Think of it like charging your phone. A time-fill station is like plugging it in overnight—a slow, patient process that takes hours but guarantees a full battery by morning. On the other hand, a fast-fill station is like using a public supercharger to get a massive boost in just a few minutes so you can get back on your way.

Both methods get high-pressure CNG into your tanks, but the equipment, cost, and best-use scenarios couldn't be more different. Getting a handle on these operational differences is key to designing a system that works with your daily workflow, not against it.

The Slow and Steady Approach of Time-Fill Stations

Time-fill stations are all about simplicity and keeping costs down. The principle is simple: refuel vehicles slowly over a long period, usually overnight. In a time-fill setup, vehicles connect directly to a compressor that gradually fills their tanks over several hours.

This approach completely sidesteps the need for a large, expensive storage cascade. Because the fueling happens at a snail's pace, a smaller, less powerful compressor can easily service an entire fleet. This dramatically lowers the initial investment and the amount of space the station takes up.

- Ideal Use Case: Time-fill systems are a perfect match for any "return-to-base" fleet. Think of municipal bus depots, school districts, garbage truck fleets, and local delivery companies. Their vehicles park in the same spot every night for predictable, extended periods.

- Operational Flow: At the end of a shift, drivers park, hook up the fueling hose, and head home. The system takes it from there, making sure every vehicle has a full tank and is ready to roll by the next morning.

A huge plus for time-fill is that vehicles get a truly full tank. The slow, gradual pressurization allows the gas to stay cool as it enters the tank, which means you get a denser, more complete fill compared to the heat that builds up during a fast-fill.

The Need for Speed with Fast-Fill Stations

Fast-fill stations are built to mimic the experience you'd get at a regular gas station. Speed is the name of the game. These systems can get a heavy-duty truck back on the road with a full tank in just 5-10 minutes, making them a must-have for fleets where downtime is a dealbreaker.

To hit those speeds, fast-fill stations depend on a large storage cascade—that bank of high-pressure tanks we talked about earlier. The compressor works around the clock to keep this cascade packed with CNG, creating a ready-to-go reservoir of fuel. When a vehicle shows up, the gas is blasted in from the cascade, not trickled in from the compressor.

This kind of setup is naturally more complex and expensive. It needs a bigger compressor, a lot of high-pressure storage tanks, and a sophisticated priority panel to direct the flow of gas, all of which adds up to a much bigger upfront investment.

- Ideal Use Case: Fast-fill is the only way to go for public retail stations, highway truck stops, and high-turnover fleets running 24/7. Taxi services, regional haulers, and any fleet that needs to top off mid-shift relies on this model.

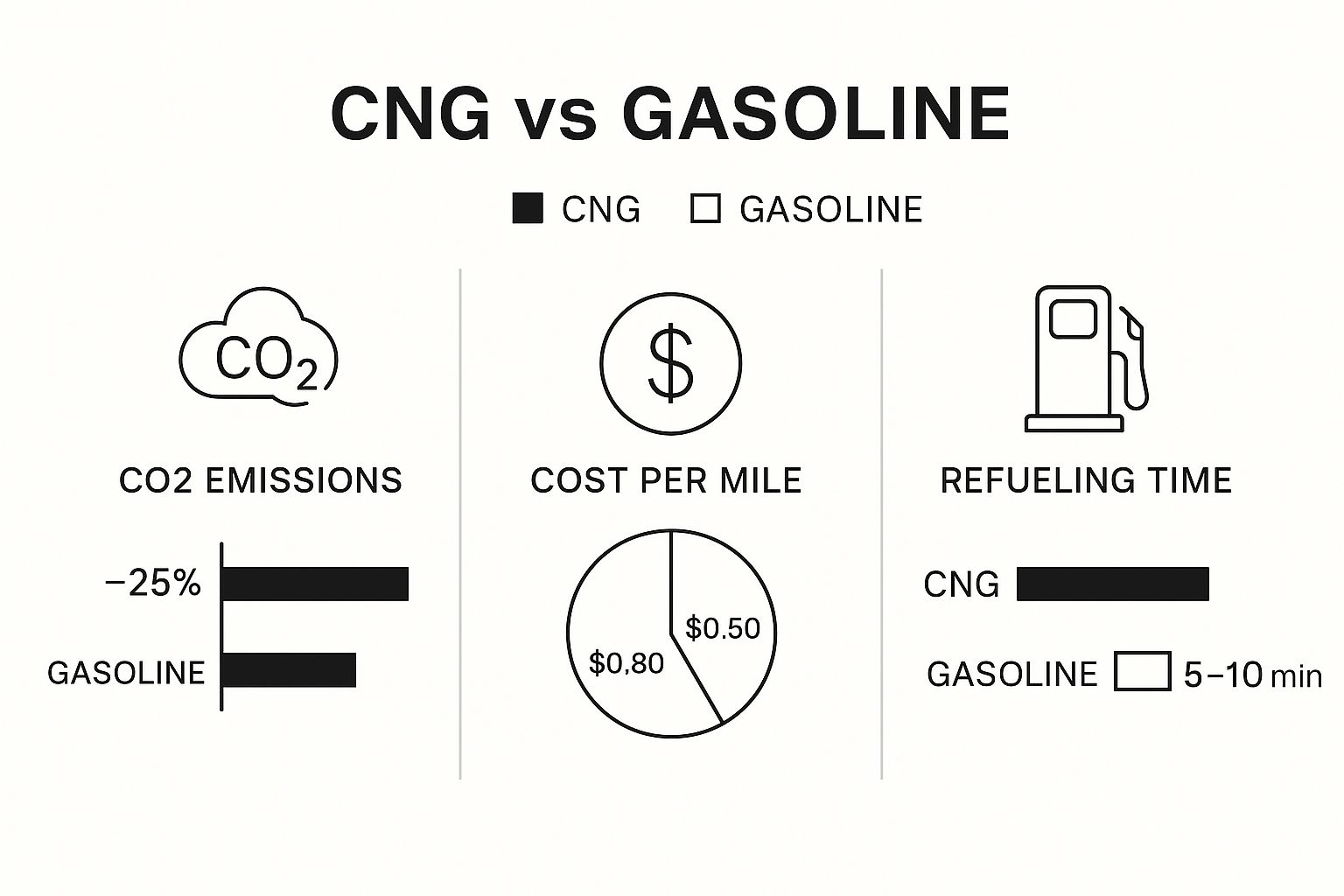

The infographic below puts CNG in context with gasoline, comparing emissions, costs, and refueling times, which helps frame why these station choices are so important.

As the data shows, even though CNG might take a few more minutes to refuel than gasoline, its major advantages in cost and emissions make it a very attractive option for fleet managers.

Demand for cleaner, cheaper fuel is pushing the market forward in a big way. The global market for natural gas refueling stations is set to grow at a compound annual growth rate of about 15% from 2025 through 2033. This growth is being driven by the auto industry's shift toward greener vehicles and helpful government incentives. You can read more on this market expansion and its underlying causes.

To make the differences crystal clear, let's break them down side-by-side.

Time-Fill vs. Fast-Fill CNG Systems Comparison

| Feature | Time-Fill System | Fast-Fill System |

|---|---|---|

| Refueling Time | 4-8+ hours (overnight) | 5-10 minutes (similar to diesel) |

| Ideal Fleet Type | Return-to-base (e.g., buses, refuse trucks) | High-turnover fleets, public retail |

| Key Infrastructure | Smaller compressor, no storage cascade | Large compressor, high-pressure storage |

| Upfront Cost | Lower | Significantly higher |

| Operational Cost | Lower (less energy demand, simpler) | Higher (more complex, higher energy use) |

| Footprint | Smaller, more compact | Larger, requires more space |

| Fill Quality | Denser, more complete "full" fill | Slightly less dense due to heat buildup |

Choosing between these two comes down to a clear understanding of your fleet's daily life. One is not inherently superior; they are simply different tools for different jobs.

Making the Right Choice for Your Operations

So, which one is for you? The answer is written in your fleet's daily schedule. A city waste management company with 50 trucks that all come back to the yard by 6 PM and don't leave until 6 AM is a textbook case for a time-fill system. The lower initial cost and dead-simple operation make it a no-brainer.

On the flip side, a logistics company running long-haul routes needs its trucks fueled and gone in minutes. For them, a fast-fill station at their main hub is a non-negotiable part of doing business. The higher cost is easily paid for by keeping trucks on the road and meeting tight delivery windows.

At the end of the day, the best CNG fueling systems are the ones that blend seamlessly into your workflow, giving you reliable, affordable fuel without ever disrupting the rhythm of your business.

Why Mobile and Containerized CNG Solutions Are Gaining Ground

Beyond the traditional, permanent station, a whole new breed of flexible CNG fueling systems is really starting to shake things up. These aren't your typical brick-and-mortar setups; we're talking about agile mobile and containerized units that are making CNG accessible to more operators than ever before.

Why the sudden popularity? It's simple. They sidestep the biggest hurdles of traditional stations: massive upfront costs and long construction lead times. Think of them as "plug-and-play" fueling. You get the fuel you need, right where you need it, without committing to a huge infrastructure project. This kind of flexibility is a game-changer for fleets and industrial sites.

The Rise of Mobile CNG Fuelers

A mobile fueler is exactly what it sounds like: a complete CNG station on wheels. It’s a self-contained unit, usually mounted on a trailer, that packs everything you need—a compressor, storage tanks, and a dispenser. This setup offers incredible adaptability, especially for temporary or transitional fueling needs.

Picture a large construction crew building a new highway in a remote area. Instead of constantly trucking in expensive diesel, they can bring a mobile CNG fueler right to the job site. It powers their equipment and vehicles for the entire project, and when the job's done, it simply moves on to the next one.

This on-demand approach is also a perfect fit for:

- Disaster Relief: When normal infrastructure is down, these units can provide crucial fuel for first responder vehicles and generators.

- Pilot Programs: A fleet can test-drive a few CNG vehicles and see how they perform in the real world before committing to a permanent station.

- Market Testing: You can set up a temporary public fueling spot to gauge local demand without digging a single hole.

Containerized Systems for Rapid Deployment

Containerized CNG systems offer a different flavor of flexibility. Imagine a complete, pre-packaged station built inside a standard shipping container. All the core components—the compressor, dryer, storage, and controls—are assembled and factory-tested, then delivered as a single, ready-to-go unit.

It’s essentially a semi-permanent station you can drop into place with minimal site prep. This "station-in-a-box" approach slashes deployment time from many months down to just a few weeks. Once it's on-site, you just need to hook it up to a power source and a natural gas line, and you're in business.

The real magic of both mobile and containerized solutions is agility. They give companies the power to react quickly to changing needs, avoiding the financial headaches and logistical nightmares of building permanent infrastructure from the ground up.

Key Advantages of Agile CNG Solutions

These flexible systems are gaining traction because they solve real-world business problems. By lowering the barrier to entry, they open the door for more organizations to tap into the economic and environmental perks of compressed natural gas.

Here’s a quick rundown of the main benefits:

- Lower Capital Costs: You get to skip the extensive civil engineering, architectural plans, and long construction phases, which cuts the initial investment dramatically.

- Faster Deployment: A containerized system can be up and running in a fraction of the time it takes to build a traditional station.

- Scalability: Fleets can start small with one unit and simply add more modules as their number of CNG vehicles grows.

- Relocatability: If your operational needs change or a facility closes, the entire fueling station can be packed up and moved to a new location. Your investment is protected.

These innovative approaches are leveling the playing field and making cleaner fuel more accessible. For any business that needs a temporary fix, operates in a remote location, or just isn't ready for a permanent build-out, mobile and containerized CNG fueling systems offer a smart, cost-effective way forward.

The Real-World Payoff: Why Fleets are Moving to CNG

Making the switch to compressed natural gas isn't just about changing what you pump into the tank. It's a fundamental business decision with powerful, real-world returns. While the engineering behind CNG fueling systems is impressive, the real story is why so many fleet managers are making the move. The reasons boil down to three big wins: serious cost savings, major environmental benefits, and some surprising operational perks.

Seeing how these advantages stack up makes it clear why investing in CNG infrastructure isn't just an expense—it's a direct path to a more resilient, sustainable, and profitable business.

Get a Handle on Your Fuel Budget

For most fleets, the most compelling reason to adopt CNG is the immediate impact on the bottom line. Historically, natural gas has been consistently cheaper than diesel and gasoline. But the real game-changer is its price stability. Petroleum prices are notorious for wild swings tied to global politics, but natural gas prices are mostly driven by domestic factors. This shields your budget from the gut-wrenching volatility of the oil market.

That stability is more than just a nice-to-have. It turns fuel—one of your biggest and most unpredictable expenses—into a predictable, manageable cost. For fleets that rack up serious miles, this can mean saving hundreds of thousands, or even millions, of dollars every single year.

When you unchain your fuel budget from the volatile global oil market, you gain a massive competitive edge. Suddenly, you can forecast your expenses with confidence and protect your profit margins from the next unpredictable price spike.

This shift is backed by a booming market. The global demand for CNG is expected to grow from around USD 12.46 billion in 2024 to USD 22.48 billion by 2032, largely because of these economic and green advantages. This growth is also fueled by government incentives that can help take the sting out of initial conversion costs and support the build-out of new fueling stations. You can get a closer look at these market trends and their drivers.

A Clear Win for the Environment

Beyond the dollars and cents, switching to CNG is a huge step forward for corporate sustainability. If your company is serious about hitting its green targets and shrinking its carbon footprint, CNG provides a proven and effective way to do it.

Natural gas is simply a cleaner fuel than diesel or gasoline. When it burns, it produces far fewer of the harmful emissions that cause smog, acid rain, and contribute to climate change.

Here’s what that looks like in practice:

- Less CO2: CNG vehicles can cut carbon dioxide emissions by up to 25% compared to their gasoline or diesel counterparts.

- Almost No Soot: It produces virtually zero particulate matter. That’s the fine, black soot from diesel exhaust that’s a known cause of respiratory problems.

- Cleaner Air: Emissions of nitrogen oxides (NOx), a primary ingredient in city smog, are also cut dramatically.

These reductions help companies do more than just comply with regulations—they allow them to get ahead of the curve, bolster their public image, and show a real commitment to being a good corporate citizen.

Smarter, Quieter Operations

The benefits of CNG don't stop at the budget or the environment; they make a real difference in the daily grind of running a fleet. These practical improvements can make for happier drivers, simpler maintenance routines, and a better overall work environment.

One of the first things you'll notice is how much quieter the trucks are. CNG engines run with a lot less clatter than diesel engines, which is a massive plus for vehicles that work in residential areas, like garbage trucks and delivery vans. The reduced noise means fewer community complaints and less driver fatigue on long shifts.

On top of that, CNG burns so cleanly that it leaves less carbon gunk on engine parts like spark plugs and valves. Over time, this can lead to longer service intervals and even extend the life of the engine, meaning less downtime and a lower total cost of ownership for every vehicle on the road.

How to Choose the Right CNG Fueling System for Your Fleet

Picking the right CNG fueling system for your fleet can seem daunting, but it really boils down to answering a few key questions about how you operate. The best system isn't just a piece of hardware; it’s a solution that fits your fleet's unique rhythm like a glove. Think of it less like buying equipment and more like designing a custom fueling strategy from the ground up.

The first step is always a deep dive into your fleet’s day-to-day life. This groundwork will inform every decision that follows, making sure the system you choose helps your workflow, not hinders it. When you start with a crystal-clear picture of your needs, you can navigate the options with confidence and make an investment that will pay off for years.

Analyze Your Fleet's Operational Profile

Before you even start looking at compressors or dispensers, you need to know your vehicles inside and out. The idea is to build a detailed snapshot of your daily fuel demand and how your vehicles move.

Start by asking these questions:

- What’s in your fleet? A lineup of light-duty vans has completely different needs than a fleet of heavy-duty garbage trucks. Get a handle on the tank capacity (in GGEs) for each type of vehicle you run.

- What do their routes look like? Do your vehicles follow the same path every day and return to a central yard each night? Most importantly, how long do they sit idle—their "dwell time"—once they're parked? A city bus fleet that parks for eight hours overnight is a perfect candidate for one type of system, while a taxi fleet that’s always on the move is a totally different story.

- How much fuel do they use daily? You’ll need to know how much fuel each vehicle burns on an average day. This number is critical for figuring out the total daily volume your station needs to supply. Getting this right prevents you from building too small or overspending on capacity you don't need.

The answers here will quickly point you toward either a time-fill or fast-fill solution. If you have long, predictable dwell times, a time-fill system is almost certainly your most cost-effective bet. If your vehicles need to gas up and get back on the road in a hurry, a fast-fill setup is the only way to go.

Evaluate Your Site Logistics and Infrastructure

Once you have a firm grasp on your fleet's needs, it's time to look at your physical property. The specifics of your site can have a huge impact on your choice of CNG fueling systems, sometimes making one option far more practical than another.

The single most important factor is your access to a natural gas utility line. Is there already a pipeline on or near your property? The pressure and volume it can deliver are everything. A high-volume, high-pressure line can support a bigger station with less work from your compressors, whereas a smaller, low-pressure line might limit the size of the system you can realistically install.

Space is the other big piece of the puzzle. A compact, time-fill station might only take up the area of a few parking spots. A public fast-fill station, on the other hand, needs a significant amount of real estate to accommodate a large storage cascade, multiple dispensers, and room for trucks to maneuver safely. You have to be sure your site can handle the equipment and meet all the necessary safety clearances.

Calculate the Total Cost of Ownership

It’s a classic mistake to only look at the sticker price of a fueling station. A much better approach is to calculate the Total Cost of Ownership (TCO), which gives you the full financial picture over the system's entire life. This means looking beyond the initial check you write to include all the ongoing operational costs.

Your TCO analysis should go far beyond the purchase price. Factor in installation, site prep, utility upgrades, and long-term maintenance. This complete view uncovers the true financial impact and helps you calculate a much more accurate return on investment.

This kind of forward-thinking math helps you compare different CNG fueling systems on a true apples-to-apples basis. For instance, a time-fill system might have a lower upfront cost, but it could become a headache if your fleet’s needs change down the road. In contrast, a more expensive fast-fill system might actually deliver a quicker ROI by keeping your vehicles on the road and productive.

The move toward natural gas vehicles is sparking major market growth, with projections showing the global natural gas fueling station market jumping from $47.78 billion in 2025 to nearly $85 billion by 2033. This trend underscores the long-term financial sense and growing sophistication of CNG infrastructure. You can explore more on these market projections.

By carefully weighing these factors—fleet profile, site logistics, and TCO—you can confidently choose the right CNG fueling system that perfectly matches both your operational demands and your financial goals.

Your Top Questions About CNG Fueling Systems, Answered

Making a big operational change, like switching your fleet to compressed natural gas, naturally brings up a lot of questions. When you're looking at a whole new fueling setup, you're going to be thinking about safety, cost, and whether it's actually practical for your team.

We get it. These are the details that matter. So, let's walk through some of the most common questions fleet managers ask when they're considering the move to CNG.

Are CNG Fueling Systems Safe?

Absolutely. Safety isn't just a feature; it's at the core of how these systems are built. Modern CNG fueling stations come with layers of protection built right in. Think incredibly tough high-pressure tanks, breakaway hoses that instantly shut off the gas if they get pulled away, and sensitive detectors that can sniff out methane long before it becomes an issue.

It also helps that natural gas behaves differently than gasoline or diesel. If you have a liquid fuel spill, it pools on the ground, creating a lingering fire hazard. Natural gas, on the other hand, is lighter than air. In the unlikely event of a leak, it just rises and dissipates into the atmosphere, which dramatically lowers the risk of it finding an ignition source.

How Much Space Do I Need for a CNG Station?

This really depends on what you're trying to do. The physical footprint for a CNG station can be surprisingly small or quite large, depending on the type and how many vehicles you need to fuel.

- A small, private time-fill system for a return-to-base fleet might only need the space of a couple of parking spots. It's a compact setup designed to refuel a handful of vehicles overnight.

- On the other end of the spectrum, a large public fast-fill station needs a lot more real estate. You have to account for the large storage cascade, several dispensers, and enough room for big trucks to get in and out safely.

Containerized or "station-in-a-box" solutions are a great middle ground, packing everything into a single, compact unit that works well for sites where space is tight.

Wondering about the return on investment? The ROI on a CNG station is tied directly to your fleet's size, daily fuel use, and the local price difference between natural gas and diesel. Fleets that put on a lot of miles often see a payback in just 2-4 years from fuel savings alone.

What if I Don’t Have Access to a Gas Pipeline?

That's a common problem with a clever solution. If your property isn't near a major gas pipeline, you can set up what’s called a "virtual pipeline." It sounds complex, but it's pretty straightforward: we truck in CNG using special mobile trailers and deliver it to a receiving station at your site.

This "daughter station" model means fleets in more remote areas can still get all the cost and environmental benefits of CNG. It essentially breaks the link between your fueling operation and a physical utility connection, opening the door for many more businesses to make the switch.

Facing natural gas pipeline delays or maintenance outages? Blue Gas Express provides temporary mobile CNG and LNG solutions to keep your projects on track across North Carolina, South Carolina, Tennessee, and Virginia. Ensure your operations continue without interruption by visiting our Blue Gas Express website.