At its heart, construction risk management is simply the process of figuring out what could go wrong on a project, analyzing how bad it could be, and then deciding what to do about it. It isn't about trying to build in a risk-free bubble—that's impossible. It's about taking control of the uncertainty that's baked into every single construction job.

Why Effective Risk Management Is Your Project's Foundation

Would you start building a high-rise without a thorough geotechnical report? Of course not. Kicking off a project without a real risk management plan is just as reckless; you're essentially gambling that nothing hidden will bring the whole thing down. This process is the bedrock of every successful build, turning potential disasters into manageable challenges.

Ignoring threats isn't just a bad habit—it has serious, real-world consequences that can cascade through a project. A single surprise, like a sudden 15% jump in steel prices or a critical subcontractor going bust, can set off a devastating domino effect. These aren't just headaches; they're direct threats to your business that lead to blown budgets, missed deadlines, safety incidents, and ugly legal disputes. Industry data consistently shows that a huge number of large projects run over budget, and poor risk management is almost always a key culprit.

When you get risk management right, you shift from constantly putting out fires to preventing them in the first place. It’s the difference between reactive chaos and proactive control. That strategic foresight is what protects your most important assets.

Here’s what that looks like in practice:

- Protecting Profits: When you anticipate financial risks, you can build in contingencies that shield your margin from unexpected hits.

- Maintaining Schedules: Spotting potential delays early lets you bake buffers into the timeline or line up backup plans before you're in a crisis.

- Ensuring Safety: A structured approach to identifying job site hazards drastically reduces incidents, which protects your crew and keeps OSHA off your back.

- Guarding Your Reputation: Nothing builds trust with clients like navigating hurdles smoothly and delivering a project as promised.

At its core, risk management is about making smarter, more informed decisions. It gives you the clarity to tell the difference between a calculated risk and a project-killing gamble, letting you lead with real confidence.

Think of this guide as your roadmap. We're going to walk through the essential pillars of this discipline, breaking down the jargon into simple, actionable steps. You'll learn how to systematically spot, evaluate, and neutralize the threats that are unique to our industry.

The table below lays out the fundamental framework we'll be exploring. It’s a high-level look at the journey from uncertainty to control.

Core Pillars of a Construction Risk Management Framework

| Pillar | Objective |

|---|---|

| Risk Identification | Uncovering and documenting potential threats across all project areas. |

| Risk Assessment | Analyzing the likelihood and potential impact of each identified risk. |

| Risk Mitigation | Developing and implementing strategies to reduce or eliminate threats. |

| Risk Monitoring | Continuously tracking risks and the effectiveness of mitigation plans. |

Each of these pillars builds on the last, creating a comprehensive system for protecting your projects, your people, and your profits. Let’s dive in.

Uncovering Common Risks on the Construction Site

To get a handle on risk, you first have to know what you’re looking for. Construction sites are complex, dynamic places where a thousand different things can go wrong. The trick is to stop thinking about it as an endless list of potential disasters and start seeing risk identification as a strategic advantage—like creating a field guide for your specific project.

Instead of just winging it with a random checklist, the pros organize potential threats into clear categories. This structured approach helps ensure nothing slips through the cracks, from the numbers on a spreadsheet to the mud on the ground. A solid construction project risk management plan starts by sorting these dangers into logical buckets.

Financial and Economic Risks

Let's start with the most obvious one: money. Financial risks are all the things tied directly to your project’s budget, profitability, and basic economic survival. These aren't just about spending too much on materials; they also include those big, external economic shifts that can turn a profitable job into a loser overnight.

Think about a sudden spike in material costs. If the price of steel or lumber jumps 20% after you've already locked in a fixed-price contract, that difference comes straight out of your pocket. That’s a classic financial risk. Smart contractors plan for this by locking in prices with suppliers early or writing cost escalation clauses into their contracts.

Another big one is getting paid. A client who pays late or constantly disputes invoices can trigger a major cash flow crisis. Suddenly, you can't pay your subs or suppliers on time. It's a single issue that can grind a whole project to a halt and burn important relationships.

Understanding the financial landscape is non-negotiable. A project can be perfectly designed and executed, but if the numbers don't work, it's a failure before the first shovel hits the ground.

Operational and Labor Risks

Operational risks are the tangible, on-the-ground problems that mess with the actual process of building. These are the daily headaches that throw schedules off, hurt quality, and kill productivity. Usually, they come down to people, processes, or equipment.

A perfect example is when a critical piece of equipment, like a tower crane, breaks down. That’s a massive operational risk. It’s a single point of failure that can create a domino effect of delays, leaving entire crews with nothing to do while you scramble for a fix. This is why rigorous maintenance schedules and backup plans for essential gear are so important.

Right now, one of the biggest operational challenges is the skilled labor shortage. In North America alone, the industry needs an estimated 500,000 more workers to keep up with demand. This forces companies to hire less experienced people, which can lead to quality issues and more safety incidents. In response, many are adjusting contract terms and padding their contingency budgets to deal with the uncertainty. You can get a deeper look into the workforce challenges in the construction industry in this analysis.

Safety and Environmental Risks

On any job site, safety is priority number one. The risks here have a real human cost, not to mention massive legal and financial fallout. These are the threats that can lead to injuries, accidents, or worse. Environmental risks run a close second, dealing with your project's footprint and the maze of regulations you have to follow.

The most common safety risks are, unfortunately, the ones we've known about for decades:

- Falls from height: Still a leading cause of fatalities in the industry.

- Electrical hazards: Often from bad grounding or accidental contact with live power.

- Struck-by incidents: Workers getting hit by moving equipment or falling materials.

Environmental risks can be just as damaging to the bottom line. Imagine digging into a site and discovering contaminated soil. That discovery can trigger enormous cleanup costs and bring the project to a dead stop while you navigate a web of environmental regulations. Good due diligence and site investigation before you start work are the best ways to avoid these surprises.

Legal and Contractual Risks

Finally, we have the risks buried in paperwork. Legal and contractual risks are born from the agreements that define the entire project. They often hide in the fine print and can erupt into expensive disputes, lawsuits, and liability claims down the road.

A poorly defined scope of work is probably the biggest offender. If the contract isn't crystal clear about what's included in the price, you're just asking for arguments over change orders and what constitutes "extra" work. It's a surefire way to ruin a client relationship.

Another major risk is when a subcontractor defaults. If a key sub fails to perform or just goes out of business, it can blow a massive hole in your schedule and budget. That’s why thorough subcontractor prequalification and requiring performance bonds aren't just red tape—they're essential shields protecting your project from someone else's failure.

How to Assess and Prioritize Project Threats

Once you’ve brainstormed a long list of everything that could possibly go wrong on a project, it's easy to feel a bit overwhelmed. Trying to tackle every single risk with the same urgency is a surefire way to burn out your team and misallocate your budget.

The real skill in construction project risk management isn’t just identifying the dangers—it’s knowing which ones need your full attention right now and which can be put on a watchlist.

This is where risk assessment comes into play. Think of it as a triage system for your project. An ER doctor doesn't treat a sprained ankle before a heart attack, and you shouldn't waste time on a minor vendor delay when a major safety hazard is looming. You have to figure out what's most severe.

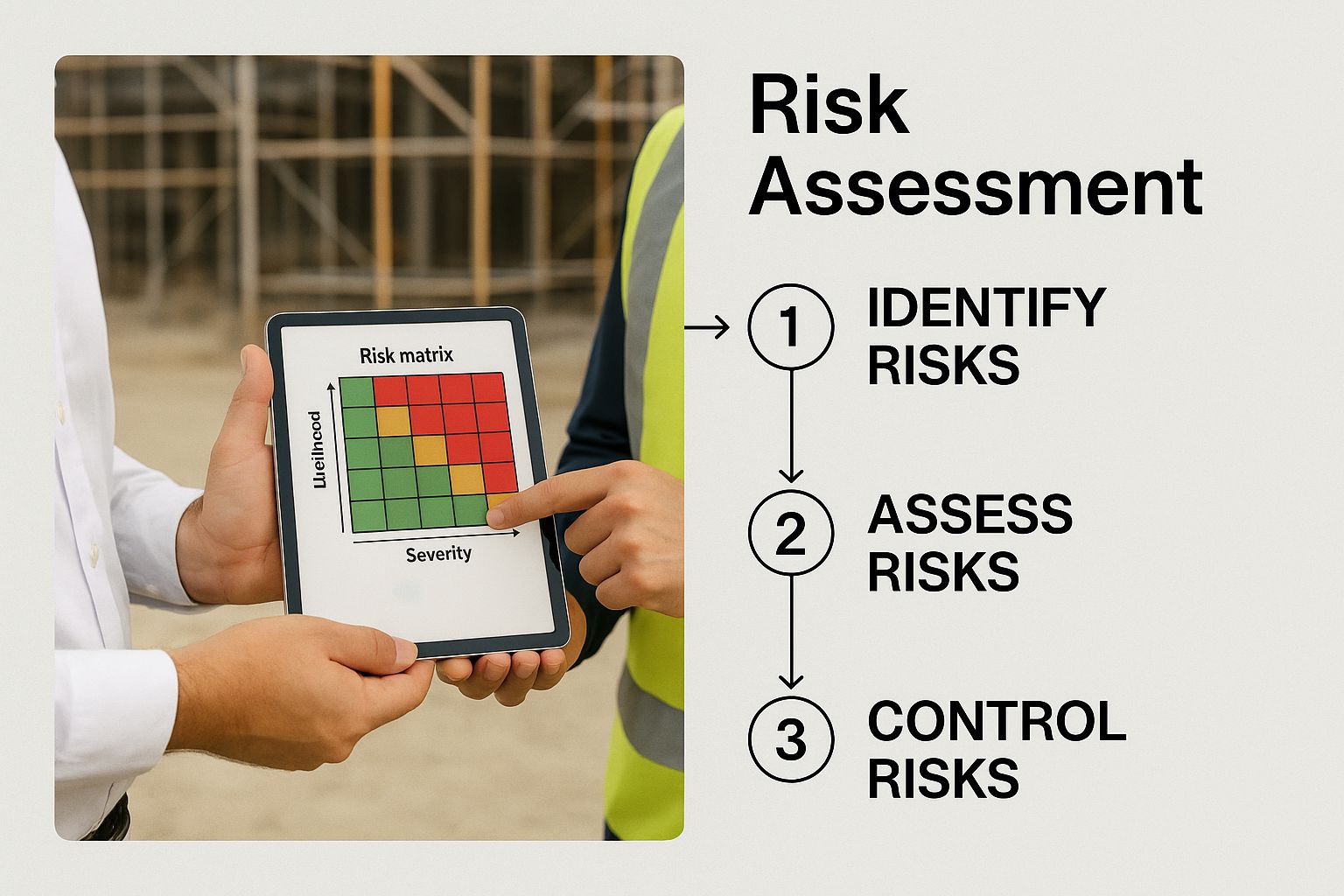

To do that, we need a simple but incredibly effective tool for sorting through the noise. This infographic shows how project managers turn a chaotic list of worries into a clear, visual action plan.

As you can see, the process boils down to plotting risks based on two simple questions. This focus helps teams zero in on the most critical vulnerabilities first.

Understanding the Risk Matrix

The most common way to prioritize threats is with a risk matrix. It’s a simple grid that organizes risks based on two critical factors:

- Likelihood: How likely is this to actually happen?

- Impact: If it does happen, how bad will the damage be?

By plotting each risk on the chart, you get an instant visual of your threat landscape. Most matrices are color-coded—like a traffic light—to make prioritization intuitive. Risks in the red zone (high likelihood, high impact) are your top priority. Those in the green zone (low likelihood, low impact) can be monitored but don't require an immediate, all-hands-on-deck response.

Let's walk through a real-world example. Say you've identified a risk: "A severe, multi-day storm could hit the site during the first month of excavation."

Now, you have to place it on the matrix.

- Likelihood Assessment: You check historical weather data for that time of year in that specific region. You find that a storm of that magnitude is "Likely." On a 5-point scale, that's a solid 4.

- Impact Assessment: If that storm hits, all excavation stops. You're looking at a week of schedule delays, thousands in dewatering costs, and potential soil erosion that needs remediation. The fallout is severe, so you rate the impact as "Major"—a 5 on the scale.

When you plot this on your matrix, the storm risk lands squarely in the red zone. This is a threat you absolutely cannot afford to ignore.

A risk matrix turns a list of abstract worries into a visual roadmap. It forces you to think critically about each threat, ensuring your time and money go where they'll have the biggest effect.

From Assessment to Action Plan

This isn't just a paper-pushing exercise; it directly dictates what you do next. Once your risks are mapped out, your priorities become crystal clear.

Here’s how the matrix guides your next moves:

- High-Priority (Red Zone): These are the potential project-killers. For our storm risk, this means developing a robust mitigation plan right now. You might pre-order dewatering pumps, build buffer days into the excavation schedule, or have erosion control materials on standby.

- Medium-Priority (Yellow Zone): These risks need a plan, but it might not need to be as intensive. Think of a potential delay from a secondary materials supplier. Your plan could be as simple as identifying two backup suppliers without putting any money down yet.

- Low-Priority (Green Zone): These are the risks you typically accept and monitor. For instance, a one-day delay caused by a local parade route closing a street. You know it could happen, but you don't spend significant resources planning for it.

By working through the risk matrix, you systematically transform that overwhelming list of problems into a prioritized, actionable plan. This becomes the foundation for the next crucial step: deciding how to mitigate these threats.

4 Proven Strategies for Handling Construction Risks

Once you’ve identified and sized up the threats to your project, it’s time to decide what to do about them. This is where your careful planning shifts into a concrete action plan. In construction project risk management, every response you can take boils down to one of four core strategies.

Think of it like a toolkit. You wouldn’t grab a sledgehammer to drive a finishing nail. The trick is picking the right tool—the right strategy—for each specific risk. This ensures your response is not just effective, but also efficient.

1. Avoid the Risk Entirely

The most direct approach is risk avoidance. This isn't about ignoring a problem; it's about fundamentally changing your plan to eliminate the threat before it can even materialize. You make a strategic move that prevents the risk from ever becoming a reality.

Let's say a project design specifies a unique cladding material that comes from a single supplier overseas. That's a huge supply chain risk waiting to happen. To avoid it, the team could redesign the building's exterior to use a high-quality, locally sourced material instead. Just like that, the risk of an international shipping nightmare is completely off the table.

Risk Avoidance: A proactive decision to sidestep a threat altogether. This is often the best choice for high-impact, high-likelihood risks that are too big to wrestle with.

Of course, avoidance isn't always an option. It can sometimes mean turning down a lucrative project or drastically changing its scope, which isn’t always a practical business decision.

2. Transfer the Burden of Risk

When you can't sidestep a risk, your next best move might be to transfer it. This strategy doesn't make the risk vanish, but it shifts the financial responsibility for the consequences onto another party who is better equipped to handle it.

Insurance is the classic example of risk transfer. You pay a premium, and in exchange, the insurance company agrees to cover specific financial losses, like a major fire or equipment theft.

In construction, this happens all the time through contracts and legal agreements:

- Subcontractor Bonding: Requiring your subs to get performance bonds transfers the risk of them failing to complete their work. If they default, the surety company has to step in and either finish the job or pay for it.

- Indemnification Clauses: These are powerful clauses in a contract that require one party (like a subcontractor) to cover the losses of another (the general contractor) for specific incidents.

This approach is absolutely essential for managing the financial and legal exposures that are baked into every construction project.

3. Mitigate the Risk's Impact

By far the most common strategy is risk mitigation. The goal here is to reduce either the likelihood of a threat happening or the impact it will have if it does. You’re not getting rid of the risk, but you're taking deliberate steps to make it far less damaging.

Think about safety risks. The danger of someone falling from a height is always present on a multi-story job site. You mitigate this risk by putting a robust safety program in place:

- Mandating fall protection harnesses and other personal protective equipment (PPE).

- Installing guardrails around every open edge.

- Holding daily safety talks and ongoing training.

None of these actions eliminate gravity or heights, but together they drastically reduce the probability of a fall and the severity of an injury. In the same way, you mitigate schedule risks by building buffer time into your timeline or tackle quality risks with a strict inspection process.

4. Accept the Remaining Risk

Finally, there’s risk acceptance. This is a conscious, informed decision to do nothing about a risk and simply absorb the consequences if it happens. It might sound passive, but it’s a perfectly valid strategy for small risks where the cure would be worse than the disease.

For instance, a project manager might identify a risk of a half-day delay because a minor piece of equipment could malfunction. The impact is minimal, and the likelihood is low. Spending time and money to create a complex mitigation plan for that just doesn't make sense. Instead, the team accepts it, knowing they can likely make up a few hours without derailing the whole schedule.

Acceptance is often paired with a contingency plan. This means you accept the risk but have a backup plan ready, often by setting aside a specific amount of money or time in a contingency fund just in case that risk becomes a reality.

Using Technology for Smarter Risk Management

In today's complex construction world, relying on manual spreadsheets and gut feelings just doesn't cut it anymore. The game has changed. The most effective construction project risk management is now driven by technology, helping teams shift from putting out fires to preventing them in the first place. These tools give us a kind of foresight that was pure science fiction just a decade ago.

Instead of waiting for a problem to pop up on-site, we can now see it coming. Think of Building Information Modeling (BIM) as more than just a 3D model; it's a risk-detection engine. Before anyone even steps on the job site, BIM can run "clash detection" simulations. It digitally flags where a plumber's pipe is about to run straight through a structural beam or where HVAC ducts are on a collision course with electrical conduits. Every clash you catch in the model is a massive, costly rework order you just avoided in the real world.

Real-Time Eyes on the Job Site

The job site itself has become a goldmine of data. Drones aren’t just cool toys anymore; they're essential monitoring tools. A quick daily drone flight gives project managers a bird's-eye view of the entire site in stunning detail. You can spot safety hazards from your office, keep an eye on material stockpiles, and check progress against the schedule with pinpoint accuracy. This real-time visual proof is a lifesaver for settling disputes and making smart decisions on the fly.

At the same time, the Internet of Things (IoT) is embedding intelligence right into the work itself.

- Equipment Sensors: Tiny sensors on heavy machinery like cranes and excavators track everything from engine hours to vibration patterns. This data tells you when a machine needs maintenance before it breaks down and brings work to a screeching halt.

- Environmental Monitoring: Sensors placed around the site can monitor temperature, humidity, and air quality. You get instant alerts for conditions that could ruin materials or put your crew's safety at risk.

All this tech works in concert to paint a live, data-rich picture of the project, taking the guesswork out of daily operations.

Technology transforms risk management from a periodic review into a continuous, automated process. It’s like upgrading from a rearview mirror to a full suite of forward-looking radar and predictive alerts.

The Predictive Power of AI

The next big leap is happening right now with Artificial Intelligence (AI). By 2025, advanced tech is becoming a core part of how we manage risk. AI algorithms are brilliant at sifting through enormous amounts of data to find patterns a person would never spot.

Feed an AI model your historical project data, current progress reports, and even outside info like weather forecasts, and it can start making incredibly accurate predictions. For example, AI can warn you about likely schedule delays due to an upcoming storm system or flag a piece of equipment for showing unusual usage patterns. This lets you schedule preventive maintenance and sidestep an expensive breakdown. Learn more about how construction firms are proactively mitigating risk in 2025 by integrating these kinds of tools.

This data-driven mindset lets managers get ahead of problems, neutralizing them before they can ever touch the budget or timeline. It’s a fundamental change that leads to safer, more efficient, and far more predictable outcomes.

Comparing Traditional vs. Tech-Enabled Risk Management

The shift from old-school methods to new technological tools isn't just an upgrade—it's a complete change in philosophy. The table below breaks down the key differences between the reactive, manual approaches of the past and the proactive, data-driven strategies of today.

| Aspect | Traditional Approach | Tech-Enabled Approach |

|---|---|---|

| Data Collection | Manual entry, paper forms, and verbal reports. Often delayed and prone to human error. | Automated data capture via drones, sensors (IoT), and mobile apps. Real-time and highly accurate. |

| Risk Identification | Relies on past experience and "gut feeling." Risks are often identified after they've occurred. | Proactive and predictive. BIM clash detection and AI pattern analysis identify risks before they materialize. |

| Monitoring | Periodic site walk-throughs and weekly meetings. Provides a snapshot in time. | Continuous, 24/7 monitoring through live data feeds and automated alerts. A complete, ongoing picture. |

| Decision-Making | Based on lagging indicators and anecdotal evidence. Often reactive and slow. | Based on leading indicators and verifiable data. Enables quick, informed, and proactive decisions. |

| Communication | Siloed information shared through emails and phone calls. Can lead to miscommunication and delays. | Centralized data on a common platform. All stakeholders have access to the same single source of truth. |

As you can see, the tech-enabled approach provides a level of control and foresight that was simply impossible with traditional methods. It empowers teams to be strategic and preventive rather than just responsive.

We're All Risk Managers: Building a Culture of Proactive Awareness

Let's be clear: the most sophisticated software and the most detailed risk registers are just tools. They’re incredibly useful, but they don't manage risk. People do. At its core, real construction project risk management isn't just another process to follow—it's a mindset that needs to be woven into the very fabric of your company culture.

This is about creating an environment where everyone, from the apprentice on their first day to the seasoned project executive, feels a sense of ownership. It's a shift from a reactive, top-down model where problems are ignored until they land on a manager's desk with a thud. Instead, you're building a system where flagging a potential issue is just a normal, expected part of the job.

But a culture like this doesn't just spring up on its own. It has to be intentionally built and consistently reinforced by leadership.

Keep the Lines of Communication Wide Open

The bedrock of a risk-aware culture is psychological safety. Your team on the ground—the ones pouring the concrete and framing the walls—are your best eyes and ears. They’re the ones who will notice the small detail that’s slightly off long before it shows up on a formal report.

They need to know, without a doubt, that they can point out a concern without fear of being blamed or brushed aside.

To get there, you need clear, easy-to-use channels for reporting potential risks. This could be as simple as a dedicated moment during the daily toolbox talk, a specific function in your project management app, or a genuine open-door policy with site supers. The specific method isn't what's important; the message is. And that message must be: we want to hear about problems early.

Of course, this dialogue is a two-way street. When a crew member flags a potential issue, leadership has to acknowledge it, explain the plan to deal with it, and follow up. This simple act of closing the loop shows their input matters and that their vigilance makes a tangible difference.

A strong risk culture turns every team member into a risk sensor. It multiplies your ability to see around corners by creating a network of proactive problem-solvers who are invested in the project's success.

Make Your Risk Reviews Matter

Finally, risk management can't be a "set it and forget it" task you check off a list. It has to be part of the project's natural rhythm. These discussions shouldn't feel like a bureaucratic chore but like a dynamic, forward-looking huddle that actually drives decisions.

Hold quick, regular risk review meetings with the key players. The agenda doesn't need to be complicated:

- Top Risks Check-In: What are the biggest things that could bite us right now?

- Mitigation Reality Check: Are the plans we put in place actually working?

- What's New?: What fresh challenges have popped up since we last talked?

By embedding this kind of awareness into your company’s DNA, you build an organization that doesn’t just get knocked around by challenges—it anticipates them, adapts, and overcomes them. This proactive culture is the ultimate competitive advantage for delivering great projects, every single time.

Got Questions? Here Are Some Real-World Answers

Even the best-laid plans hit a snag when they meet the reality of a busy job site. It’s one thing to talk about a construction project risk management framework in an office, but it's another to put it into practice. Let’s tackle some of the most common questions that come up in the field.

How Often Should We Actually Be Reviewing Risks?

Think of risk management as a conversation, not a one-time announcement. It’s not something you can just check off the list during pre-construction and then forget about. The ground is constantly shifting on a project—new subs arrive, weather patterns change, a supplier suddenly has a backlog.

A good rule of thumb? Hold a dedicated risk review meeting at least every two weeks. If you're running a massive, complex job, you should probably be doing it weekly. The whole point is to keep the dialogue active, so you can catch new problems before they grow and make sure your old solutions are still holding up.

The most dangerous risk isn't the one you don't know about—it's the one you identified three months ago and then let fall off the radar. Regular check-ins turn your risk register from a dusty document into a living tool that actively defends the project.

This consistent rhythm keeps everyone on the team switched on, encouraging them to think ahead instead of just reacting to fires.

So, Whose Job Is It to Manage All This Risk?

While every single person on site has a part to play in spotting trouble, the buck ultimately stops with the project manager. The PM is the nerve center, pulling in information from all sides, leading the assessment, and making sure the response plans are actually being carried out.

But a good PM knows they can't be everywhere at once. They act more like the conductor of an orchestra, empowering specific people to "own" certain risks.

Here's how that might look:

- The site superintendent owns the day-to-day safety and operational hazards.

- The procurement manager is on top of any supply chain hiccups.

- The financial controller keeps a close eye on the budget and cash flow risks.

This strategy creates clear accountability. Everyone knows what they're responsible for, and they're empowered to lead the charge if something goes wrong in their area. The PM provides the oversight, but risk management becomes a shared mission, not just one more thing on the project manager's plate.